30 ton overhead crane Safety Certifications

Safety certifications for a 30 ton overhead crane are crucial to ensure compliance with industry standards and regulations, guaranteeing the safe operation of the equipment. Key certifications include:

1. OSHA Regulations (Occupational Safety and Health Administration): Adherence to OSHA standards is mandatory in the United States, focusing on structural integrity, proper installation, and regular maintenance of overhead cranes.

2. ASME B30 Standards (American Society of Mechanical Engineers): The ASME B30.2 standard specifically addresses overhead and gantry cranes, providing guidelines on design, inspection, testing, maintenance, and operation.

3. ISO 9001 (International Organization for Standardization): This quality management certification ensures that the manufacturer adheres to rigorous production standards, enhancing the reliability and safety of the crane.

4. CE Marking (Conformité Européenne): Required for cranes operating in Europe, the CE marking certifies that the equipment meets EU safety, health, and environmental protection requirements.

5. CMAA (Crane Manufacturers Association of America) Standards: CMAA Specification No. 70 is particularly relevant for overhead cranes and covers design, service, and installation.

6. Maintenance and Inspection Certifications: Regular inspections by certified professionals are mandatory. Certifying bodies such as the Crane Institute of America (CIC), National Commission for the Certification of Crane Operators (NCCCO), and others provide credentials for inspectors and maintenance personnel.

7. Load Testing Certification: Before operational use, cranes must undergo rigorous load testing to ensure they can handle their rated capacity safely.

Each of these certifications plays a vital role in maintaining operational safety, minimizing risks of accidents, and ensuring the durability and efficiency of the overhead crane. Regular training for operators and adherence to certification requirements are essential for optimal safety and performance.

List Reference Technical Parameters of “30 ton overhead crane”

When specifying a 30-ton overhead crane, it is crucial to consider several technical parameters to ensure it meets the intended application requirements. Here are the key parameters:

1. Load Capacity: The crane can lift a maximum load of 30 tons (30,000 kg).

2. Span: The distance between the crane runways, typically ranging from 10 to 40 meters, depending on the application and building specifications.

3. Lift Height: The maximum vertical distance the hook can move, generally between 6 to 30 meters, tailored to the operational needs.

4. Duty Class/Rating: Indicates the crane’s intended frequency of use and load capacity over time, with classifications ranging from A1 (light duty) to A8 (heavy duty), based on standards like those from FEM, CMAA, or ISO.

5. Hoist Speed: The speed at which the crane can lift or lower the load, usually specified in meters per minute (m/min). It can have single-speed, dual-speed, or variable speed (using VFDs) options.

6. Trolley Speed: The speed at which the trolley (which carries the hoist) travels along the bridge, generally in the range of 20 to 40 m/min.

7. Bridge Travel Speed: The movement speed of the entire crane along the runways, typically from 40 to 100 m/min.

8. Control Type: Options include pendant controls, remote controls, or cab controls, depending on the operational environment and safety requirements.

9. Power Supply: Voltage and phase specifications, usually 380V/400V/415V 3-phase 50/60Hz to match local electrical standards.

10. Bridge Type: Single girder or double girder, affecting the structural design and load distribution.

11. Structural Design: Materials and build quality, such as steel grades, corrosion resistance, and climate considerations (e.g., for outdoor or hazardous environments).

12. Safety Features: Overload limiters, anti-collision devices, emergency stop systems, and load sway reduction.

13. Standards Compliance: Ensures adherence to local and international standards like ISO, ASME, ANSI, and DIN.

These parameters ensure the 30-ton overhead crane is suitable for its intended industrial, manufacturing, or warehousing operations, providing safe and efficient material handling.

List Product features of “30 ton overhead crane”

The 30-ton overhead crane is a robust and versatile lifting solution commonly used in industrial settings. Here are its key product features:

1. High Load Capacity: Capable of lifting up to 30 tons, making it suitable for heavy-duty applications.

2. Durable Construction: Built with high-strength steel and components designed for longevity and reliability under heavy use.

3. Precise Control: Equipped with advanced control systems, including variable speed drives and precision positioning, ensuring accurate and safe load handling.

4. Safety Features: Includes overload protection, emergency stop buttons, and safety interlocks to ensure the safety of operations.

5. Customizable Options: Can be tailored with various configurations such as single girder, double girder, top running, or under running to fit specific operational needs.

6. Advanced Hoisting Mechanism: Features a high-performance hoist with smooth operation, minimizing load swing and enhancing stability.

7. Wide Span Coverage: Designed to cover large areas with spans typically ranging from 10 to 35 meters, suitable for various industrial environments.

8. Efficient Power Usage: Incorporates energy-efficient motors and regenerative braking systems to reduce energy consumption and operational costs.

9. Easy Maintenance: Designed for ease of maintenance with accessible components, reducing downtime and maintenance costs.

10. Integration Capabilities: Can be integrated with other industrial systems such as automated production lines or warehouse management systems for enhanced efficiency.

11. Operator Comfort: Ergonomic operator controls, including remote control options, ensure ease of use and reduce operator fatigue.

12. Compliance and Standards: Adheres to international standards and regulations, ensuring compliance and safety in different regions.

13. Environment Adaptability: Suitable for various environments, including outdoor applications, with options for weatherproofing and corrosion resistance.

This combination of features makes the 30-ton overhead crane an essential tool for heavy lifting in industries such as manufacturing, construction, shipping, and more.

List Various Types of “30 ton overhead crane”

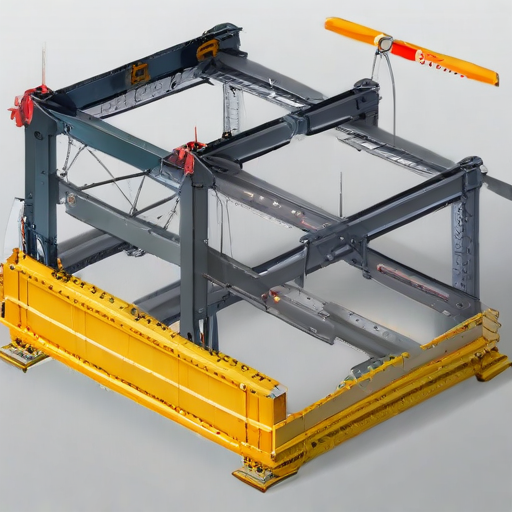

A 30-ton overhead crane is a robust piece of material handling equipment used in various industries for lifting and moving loads up to 30 tons. Here are different types of 30-ton overhead cranes:

1. Single Girder Overhead Crane:

– Typically features a single bridge beam with a trolley and hoist running on the lower flange.

– Suitable for lighter duty and environments with space constraints.

2. Double Girder Overhead Crane:

– Comprises two bridge beams for added strength and rigidity.

– Ideal for heavy-duty applications, allowing higher lifting heights and higher performance.

3. Top Running Overhead Crane:

– The crane runs on rails mounted on the top of the runway beams.

– Provides maximum lifting height and is suitable for heavy load lifting.

4. Under Running (Underslung) Overhead Crane:

– The crane runs on the bottom flange of the runway beams.

– Suitable for lighter loads and environments with limited headroom.

5. Gantry Crane:

– Uses legs to support the bridge, which runs along a track at ground level.

– Ideal for outdoor applications or locations where overhead crane installation isn’t feasible.

6. Explosion Proof Overhead Crane:

– Designed for use in hazardous environments with explosive gases or dust.

– Equipped with features to prevent sparks and maintain safety.

7. Magnetic Overhead Crane:

– Equipped with a magnetic lifter for handling metal materials.

– Common in steel mills and scrap yards.

8. Electromagnetic Overhead Crane:

– Uses electromagnets to lift ferrous materials.

– Often employed where quick and frequent lifting activities are required.

9. Manual Overhead Crane:

– Operated manually without the need for electric power.

– Suitable for low-duty, infrequent lifting jobs.

10. Electric Overhead Crane:

– Powered by electricity, providing precise and efficient operation.

– The most common type due to its reliability and ease of use.

These variations cater to specific industrial requirements, ensuring that operations can be carried out efficiently and safely.

List Application of “30 ton overhead crane”

A 30-ton overhead crane is a vital piece of material handling equipment widely utilized in various industries for lifting and transporting heavy loads. Its applications are broad, encompassing diverse sectors such as:

1. Manufacturing: Essential for moving heavy components, machinery, or raw materials within production facilities. They enhance efficiency and safety in automotive, steel, and machinery manufacturing plants.

2. Warehousing and Logistics: Aid in the fast and efficient handling of bulky goods, improving inventory management and reducing manual labor in warehouses and distribution centers.

3. Construction: Utilized to lift and position heavy construction materials and equipment, facilitating the assembly of large structures and reducing manual handling.

4. Shipbuilding: Crucial for lifting large ship components, such as engines, hull sections, and propellers, enabling the assembly and maintenance of vessels.

5. Mining: Used in mine operations to handle heavy mining equipment, machinery, and extracted ores, ensuring safe and efficient material movement.

6. Metal Processing: In steel mills and foundries, they transport molten metal, heavy molds, and finished goods, critical for maintaining continuous production processes.

7. Aerospace: Assist in the handling of large aircraft components during manufacturing, maintenance, and assembly operations, ensuring precise and safe processes.

8. Energy Sector: Employed in power plants and renewable energy facilities for handling heavy generators, turbines, and other equipment essential for energy production and maintenance.

9. Recycling: Used to move and process heavy recyclable materials, aiding in the efficient management of large volumes of scrap metal and other recyclables.

10. Automotive: In vehicle manufacturing, they handle large car parts and machinery, streamlining the assembly process and reducing manual labor.

Overall, a 30-ton overhead crane boosts productivity, enhances safety, and reduces labor costs across various critical industries.

List Buyer Types of “30 ton overhead crane”

When considering the market for a 30-ton overhead crane, the buyer types generally include the following:

1. Manufacturing Industries: This includes automotive, aerospace, metal fabrication, and heavy machinery manufacturers. These industries require overhead cranes to handle large components with precision during production processes.

2. Construction Companies: Firms engaged in large-scale infrastructure projects such as bridges, buildings, and industrial complexes often need overhead cranes for lifting and positioning heavy materials and equipment on site.

3. Warehousing and Distribution Operations: Large warehouses and distribution centers utilize overhead cranes for efficient material handling, enabling the movement of heavy goods across vast spaces.

4. Steel and Metal Mills: These facilities require robust overhead cranes to lift and transport heavy loads of raw materials, semi-finished, and finished metal products during their manufacturing processes.

5. Energy Sector: Power plants, oil refineries, and wind turbine manufacturers use overhead cranes for the installation, maintenance, and transportation of heavy machinery and components.

6. Shipyards and Maritime Operations: Shipbuilding and repair services leverage overhead cranes to handle large ship parts and equipment, ensuring precise and safe operations.

7. Railway Industry: Rail yards and train manufacturing units utilize these cranes to handle heavy train components and materials during assembly and maintenance.

8. Mining and Mineral Processing: Mines and processing plants require overhead cranes to manage the heavy and cumbersome materials extracted from the earth and to move them through various stages of refinement.

9. Municipal and Government Projects: Municipalities and government entities involved in public infrastructure projects, like the development of bridges or large public buildings, often require overhead cranes for material handling.

10. Recycling and Waste Management: Large recycling centers use overhead cranes to handle bulky recyclable materials efficiently, streamlining the sorting and processing of these materials.

Understanding these buyer types can aid crane manufacturers and suppliers in tailoring their marketing strategies and product offerings to meet the specific needs of each industry sector.

List “30 ton overhead crane” Project Types for Different Industries

Certainly! A 30-ton overhead crane is a versatile piece of equipment used in various industries to lift and move heavy materials. Below are some project types across different industries where these cranes are essential:

1. Manufacturing: Used for handling large components during assembly processes.

2. Steel Mills: Essential for lifting and transporting molten steel, large steel plates, and structural components.

3. Automotive: Employed in moving heavy parts such as engines, chassis, and assemblies.

4. Shipbuilding: Critical for lifting and positioning large ship parts and machinery.

5. Warehousing: Facilitates efficient handling of heavy inventory and materials.

6. Construction: Ideal for moving heavy building materials, precast concrete, and steel structures.

7. Mining: Used for lifting heavy mining equipment, and materials, and assisting in maintenance.

8. Railways: Assists in lifting and placing heavy rail components and train car parts.

9. Power Plants: Utilized for maintaining and assembling large turbines, generators, and transformers.

10. Chemical Plants: Vital for moving heavy reactors, storage tanks, and equipment.

11. Pulp and Paper: Helps in the lifting and maintenance of heavy rollers and paper machines.

12. Oil and Gas: Used for handling large pipes, drilling components, and sub-sea equipment.

13. Aerospace: Crucial for assembly of large aircraft components and engines.

14. Renewable Energy: Employed in lifting and assembling large wind turbine components and solar panels.

15. Logistics: Facilitates the loading and unloading of heavy shipments and containers.

These cranes offer enhanced productivity, safety, and precision, making them indispensable across various heavy-load industries.

30 ton overhead crane Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing a 30-ton overhead crane can significantly enhance its performance, safety, and adaptability to specific tasks. Here are key accessories, upgrades, and custom manufacturing options to consider:

1. Remote Control Systems: Incorporate advanced radio or infrared remote control systems to facilitate safe, efficient crane operations from a distance, minimizing operator exposure to hazardous environments.

2. Variable Frequency Drives (VFDs): Install VFDs to ensure smooth acceleration and deceleration, reducing mechanical stress and enhancing precision in load handling.

3. Anti-Sway Technology: Implement anti-sway systems to enhance load stability during movement, critical for delicate or hazardous load manipulation.

4. Load Monitoring Systems: Integrate load cells or sensors to provide real-time data on load weights, ensuring operations remain within safe limits and preventing overloading.

5. Hoist Upgrades: Opt for higher-capacity or dual-hoist systems to increase versatility and adaptability for various lifting requirements.

6. Tandem Operation Capability: Enable tandem operation, allowing two cranes to work in synchrony for lifting particularly large or heavy loads.

7. Improved Safety Features: Add emergency stop buttons, span guards, overload protection systems, and fail-safe braking mechanisms to enhance overall safety.

8. Automated Positioning Systems: Use GPS or laser-guided systems for precise positioning and repeatable accuracy in complex lifting operations.

9. Custom End Effectors: Design and manufacture specialized spreader beams, grabs, or magnets tailored to specific load types and shapes for enhanced efficiency.

10. Enhanced Lighting: Upgrade to LED lighting for better visibility and reduced energy consumption during operations in low-light conditions.

11. Temperature and Moisture Resistance: Customize components to withstand extreme environmental conditions, ensuring reliable operation in demanding industries.

12. Durability Coatings: Apply anti-corrosive and wear-resistant coatings to extend crane longevity, particularly in harsh industrial environments.

By selecting these upgrades and custom manufacturing options, a 30-ton overhead crane can be transformed into a more efficient, reliable, and safer piece of equipment tailored to meet specific operational needs.

List Quality Control and The Manufacturing Process of “30 ton overhead crane”

Quality Control:

1. Material Verification: Ensure all raw materials meet specifications before production.

2. Design Inspection: Cross-check design blueprints and conformity with standards.

3. Component Testing: Test key components (e.g., motors, cables) for functionality.

4. Welding Inspection: Perform non-destructive tests (NDT) on welded joints.

5. Assembly Check: Confirm all parts are correctly assembled and secured.

6. Load Testing: Conduct load tests to verify the crane can safely lift and transport 30 tons.

7. Operational Testing: Run comprehensive operational checks for movements and controls.

8. Final Inspection: Perform a full-system inspection before delivery.

9. Compliance Verification: Ensure the crane meets all regulatory and safety standards.

Manufacturing Process:

1. Design and Engineering: Detailed designs using CAD software, ensuring compliance with technical standards. Obtain necessary approvals.

2. Material Procurement: Source high-quality steel and other materials according to specifications.

3. Fabrication:

– Cutting: Laser-cut steel plates and structural components.

– Forming: Use forming presses and bending machines to shape components.

4. Welding: Join components using certified welding processes. Perform NDT on welds.

5. Machining: Precision machining of parts like gears, shafts, and motor housings.

6. Assembly:

– Bridge Assembly: Construct the main bridge and end trucks.

– Trolley Assembly: Assemble the hoisting mechanism including motors, brakes, and cables.

– Control Systems: Incorporate electrical and control systems.

7. Surface Treatment: Apply anti-corrosion coatings and paint for durability.

8. Pre-Assembly Testing: Test sub-assemblies for functionality individually.

9. Load and Operational Testing: Assemble the entire crane and perform rigorous load and operational tests.

10. Disassembly for Shipping: Disassemble and package components safely for transport.

11. Installation and Commissioning: Deliver, install, and perform final commissioning on-site.

These steps ensure the production of a reliable and safe 30-ton overhead crane, capable of meeting industrial standards and customer specifications.

How to use “30 ton overhead crane”

Using a 30-ton overhead crane safely and efficiently involves several key steps:

1. Pre-Operation Inspection:

– Visually inspect the crane for any damage or wear.

– Check the hoist, trolley, and bridge for proper operation.

– Ensure that the load hook, ropes, and chains are in good condition.

– Examine the control panel and test the emergency stop.

2. Preparation:

– Clear the area of unnecessary personnel and obstructions.

– Verify that the load weight does not exceed the crane’s 30-ton capacity.

– Secure the load properly with appropriate slings, hooks, or lifting devices.

3. Operation:

– Power on the crane using the main control panel.

– Use the control pendant or remote to maneuver the crane.

– Raise the load a few inches to ensure it is balanced.

– Move the load slowly to avoid swaying or jerking motions.

– Use smooth and controlled movements for lifting and lowering.

– Follow designated travel paths and avoid moving loads over people.

4. Post-Operation:

– Lower the load to a safe resting position.

– Turn off the power and secure the crane.

– Perform a final inspection to ensure no damage occurred during use.

– Report any issues to maintenance staff.

Safety Tips:

– Always wear appropriate PPE (Personal Protective Equipment).

– Never exceed the crane’s weight limit.

– Ensure only trained personnel operate the crane.

– Be mindful of overhead clearances and avoid obstacles.

By following these guidelines, you can ensure the safe and efficient use of a 30-ton overhead crane.

“30 ton overhead crane” Comparative Analysis

A 30-ton overhead crane is a robust lifting solution widely used in manufacturing, construction, and warehousing. This equipment is pivotal for moving heavy loads efficiently within a fixed space. When conducting a comparative analysis of a 30-ton overhead crane, several factors need to be considered: design, efficiency, safety, and cost.

1. Design: Overhead cranes can be classified into single girder and double girder designs. Single girder cranes have one bridge girder, are lighter, and suitable for smaller spans and lighter applications. Double girder cranes, with two girders, offer greater durability and the ability to handle heavier loads over larger spans, making them ideal for the 30-ton capacity.

2. Efficiency: Efficiency pertains to how well the crane can handle loads and its operational speed. Double girder cranes generally provide higher lifting heights compared to single girder variants, which can be crucial in high-ceiling environments. Additionally, modern overhead cranes come with variable frequency drives (VFDs) that enhance performance by allowing smoother acceleration and deceleration.

3. Safety: Safety systems are fundamental. Overload protection, emergency stop mechanisms, and anti-collision systems are vital components. Remote control operations and advanced diagnostics are also increasingly prevalent, reducing the risk of accidents by allowing operators to manage the crane from a safe distance.

4. Cost: The initial investment for a 30-ton overhead crane can be substantial. Single girder cranes are typically less expensive than double girder models. However, considering long-term benefits such as lower maintenance costs, higher operation speeds, and increased durability, double girder cranes often provide better value for heavy-duty applications.

In summary, while single girder cranes might be more cost-effective for lighter applications, double girder cranes offer superior performance and safety for handling 30-ton loads, making them a preferred choice in demanding industrial environments. The optimal choice depends on specific operational requirements and budget constraints.

“30 ton overhead crane” Warranty and Support

Warranty and Support for 30 Ton Overhead Crane

When investing in a 30-ton overhead crane, it’s critical to understand the warranty and support options available. Here are the key elements you should expect:

Warranty Coverage:

1. Duration: Most manufacturers offer a standard warranty period, typically ranging from 1 to 2 years.

2. Scope: The warranty generally covers faults due to manufacturing defects, material flaws, and mechanical failures under normal operation conditions.

3. Parts and Labor: Coverage should include replacement parts and labor costs. Some manufacturers may offer extended warranties at an additional cost.

4. Exclusions: Wear and tear, misuse, improper maintenance, and unauthorized modifications may void the warranty. Always review the terms carefully.

Support Services:

1. Technical Support: Manufacturers provide technical support via phone or online to troubleshoot and resolve issues. Quick-response times are essential.

2. On-site Service: Some suppliers offer on-site inspection and repair services. It’s beneficial to opt for firms with a comprehensive service network.

3. Preventive Maintenance: Regular maintenance services can be part of the support package to ensure longevity and optimal performance. This might include inspections, lubrication, and adjustments.

4. Training: Proper training on operation and maintenance for your staff can also be part of the support services. This helps in minimizing misuse and potential downtimes.

5. Spare Parts Availability: Reliable support includes the prompt supply of genuine spare parts, reducing downtime due to repairs.

6. Documentation: Detailed manuals and warranty documentation should be provided, outlining operational guidelines and troubleshooting tips.

Before finalizing the purchase, discuss these aspects with your supplier to ensure you receive comprehensive support to maximize the lifecycle and efficiency of your 30-ton overhead crane.

List “30 ton overhead crane” FAQ

30 Ton Overhead Crane FAQ

1. What is a 30-ton overhead crane?

A 30-ton overhead crane is a type of heavy-duty lifting equipment designed to move, lift, and displace loads up to 30 tons. It typically runs on rails mounted on the ceiling or side supports of a building.

2. What industries use 30-ton overhead cranes?

Industries such as manufacturing, warehousing, steel plants, shipyards, and construction sectors frequently use 30-ton overhead cranes for material handling.

3. What are the types of 30-ton overhead cranes?

The main types include single girder and double girder cranes. Double girder cranes offer higher lifting height and capacity, making them suitable for extreme heavy-duty applications.

4. What is the span of a 30-ton overhead crane?

The span can vary based on application requirements but typically ranges from 10 to 40 meters.

5. What is the lifting height of a 30-ton overhead crane?

The lifting height can range from 6 to 40 meters or more, depending on specific operational necessities.

6. Can a 30-ton overhead crane be customized?

Yes, these cranes can be customized based on load requirements, span, lifting height, operating environment, and specific client needs.

7. What safety features are included in a 30-ton overhead crane?

Safety features may include overload protection, emergency stop functions, anti-collision devices, and limit switches.

8. How is a 30-ton overhead crane powered?

It can be powered electrically, typically using a three-phase power source.

9. What maintenance is required for a 30-ton overhead crane?

Regular inspections, lubrication of moving parts, checking electrical systems, and replacing worn-out components are essential for optimal performance.

10. How much does a 30-ton overhead crane cost?

The cost varies greatly based on specifications and customizations, ranging from $50,000 to upwards of $200,000.

11. What are the installation requirements?

Proper structural support, sufficient space, appropriate power supply, and adherence to safety standards are essential for installation.

12. Can a 30-ton overhead crane be operated manually?

Typically, no. Due to its size and capacity, it is operated using an electric control system.

By addressing these common questions, businesses can better understand the capabilities and requirements of 30-ton overhead cranes, ensuring they select the right crane for their operations.

Top 10 FAQ with answer about 30 ton overhead crane for Buyer Sourcing from China

1. What is the lead time for a 30-ton overhead crane from China?

– The lead time typically ranges between 6 to 12 weeks, depending on customization requirements and manufacturer workload.

2. What are the shipping costs for a 30-ton overhead crane from China?

– Shipping costs vary based on the destination, mode of transportation, and current freight rates. It’s advisable to get quotes from multiple logistics providers for accurate pricing.

3. Are Chinese overhead cranes compliant with international standards?

– Yes, many Chinese manufacturers produce cranes that adhere to international standards such as ISO, FEM, and ANSI. Always request certification proof from the supplier.

4. What are the key features of a 30-ton overhead crane from China?

– Key features typically include a robust steel structure, reliable hoisting mechanism, advanced control systems, and safety features such as overload protection and emergency stop.

5. How customizable are 30-ton overhead cranes from Chinese suppliers?

– Chinese manufacturers offer high customization levels, including different spans, lifting heights, speeds, and control options to meet specific operational needs.

6. What is the warranty period for a 30-ton overhead crane from China?

– Warranties generally range from 1 to 2 years. Some manufacturers may offer extended warranties for an additional cost.

7. Do Chinese manufacturers provide installation services for 30-ton overhead cranes?

– Many suppliers offer installation services either through their own teams or local partners. Verify this service and associated costs during negotiations.

8. What after-sales support can be expected?

– Reputable Chinese manufacturers provide comprehensive after-sales support, including technical assistance, spare parts supply, and maintenance guidance.

9. Can we inspect the 30-ton overhead crane before shipment?

– Yes, most manufacturers welcome buyers to perform on-site inspections or can facilitate third-party inspections to ensure quality and compliance.

10. What are the payment terms for sourcing a 30-ton overhead crane from China?

– Common payment terms include 30% advance payment with the balance paid before shipment. Letter of Credit (L/C) and Trade Assurance through platforms like Alibaba are also popular options.

These answers should provide a clear understanding to buyers considering sourcing their 30-ton overhead crane from China.