5 ton crane Safety Certifications

A 5-ton crane, like other industrial lifting equipment, requires several safety certifications to ensure it meets rigorous industry standards and is safe for operation. These certifications vary by region and specific application but generally include the following:

1. OSHA Compliance: In the United States, cranes must comply with OSHA (Occupational Safety and Health Administration) standards, particularly OSHA 1926.1400 for cranes in construction and OSHA 1910.179 for overhead and gantry cranes.

2. ASME B30 Compliance: The American Society of Mechanical Engineers (ASME) provides safety standards for cranes under the B30 series. This includes guidelines for the design, inspection, testing, maintenance, and operation to ensure safe performance.

3. ANSI Standards: The American National Standards Institute (ANSI) offers additional safety standards that supplement OSHA and ASME guidelines, focusing on safe operation and maintenance of lifting equipment.

4. ISO Certification: Internationally, the International Organization for Standardization (ISO) provides the ISO 9927 and ISO 23815 standards for the periodic inspection and maintenance of cranes, as well as safety guidelines for operation.

5. Load Testing: Periodic load testing, often required by regulatory bodies, ensures that the crane can handle its maximum rated capacity safely. This typically involves lifting a load of at least 125% of the crane’s rated capacity.

6. CE Marking: In Europe, cranes must have CE marking, demonstrating compliance with the EU Machinery Directive, which includes comprehensive safety assessments and adherence to essential health and safety requirements.

7. NCR (National Crane Certification): Certifications from recognized bodies such as the National Commission for the Certification of Crane Operators (NCCCO) indicate that operators are qualified to handle cranes safely.

Regular inspections, maintenance, and adherence to these certifications help mitigate risks, ensuring safe and efficient crane operation.

List Reference Technical Parameters of “5 ton crane”

A 5-ton crane is utilized in various industrial applications for lifting and moving loads up to 5,000 kg. The technical parameters are critical to ensuring safe and efficient operation. Key parameters include:

1. Load Capacity:

– Maximum Lifting Capacity: 5 tons (5,000 kg).

2. Span:

– Distance between the runway rails. Common spans range from 10 to 30 meters, depending on the application.

3. Lifting Height:

– Maximum height the hook can reach, generally between 6 to 30 meters.

4. Lifting Speed:

– Variable lifting speeds (e.g., 0.8-8 m/min) to accommodate precision and efficiency in lifting operations.

5. Travel Speed:

– Crane travel speed (e.g., 10-40 m/min) and trolley travel speed for the horizontal movement of the load.

6. Power Supply:

– Voltage and phase, commonly 380V/50Hz (or 60Hz for other regions), three-phase.

7. Motor Power:

– Motors for lifting, trolley movement, and crane travel, with each having specific power ratings, e.g., 5-20 kW, based on operational requirements.

8. Control System:

– Options include pendant controls, radio remote controls, and cab controls for safe and easy operation.

9. Duty Class:

– Classification per ISO or FEM standards; common classes include A5 (ISO) or M5 (FEM) for moderate use.

10. Safety Features:

– Overload protection, emergency stop button, limit switches, and anti-collision devices to ensure operational safety.

11. Material of Components:

– Heavy-duty steel for the structure, corrosion-resistant materials for specific parts, depending on the operating environment.

12. Maintenance:

– Regular maintenance schedules, including lubrication, inspection of wear and tear, and replacement of critical components.

These parameters ensure the crane meets the demands of various industrial environments while maintaining safety and efficiency.

List Product features of “5 ton crane”

A 5-ton crane is a versatile lifting machine used in various industrial and construction applications. Below are the key product features:

1. Load Capacity

– 5 Ton Lift Capacity: Designed specifically to lift and move loads up to 5 tons (10,000 lbs).

2. Structural Design

– Robust Construction: Built with high-grade steel for maximum durability and longevity.

– Compact Design: Suitable for confined spaces without compromising on strength.

3. Mobility

– Mobility Options: Available in both stationary and mobile versions, including overhead, gantry, and jib configurations.

4. Operating Mechanisms

– Electric and Manual Operation: Options for electric-powered cranes with various control mechanisms and manual operation for more straightforward tasks.

5. Safety Features

– Overload Protection: Equipped with sensors and alarms to prevent overloading.

– Safety Locks: Mechanical and electronic safety locks to ensure the load stays secure while in motion.

– Emergency Stop: Quick-stop feature for immediate halting in emergency situations.

6. Hoisting Mechanism

– Wire Rope or Chain Hoist: Available with durable wire rope or chain hoists depending on the application.

7. Control Systems

– Advanced Control Panels: Includes user-friendly interfaces, often with touchscreen options.

– Remote Control: Wireless remote operation to improve safety and ease of use.

8. Versatility

– Customizable: Can be tailored with additional features like extended booms, specialized hooks, and lifting accessories.

9. Efficiency

– High Efficiency Motors: Equipped with energy-efficient motors to reduce operational costs.

– Smooth Operation: Advanced mechanisms for smooth and precise lifting and movement.

10. Maintenance

– Easy Maintenance: Designed for minimal maintenance with accessible components for regular inspections.

– Durable Parts: High-quality, wear-resistant parts to reduce downtime and extend life.

11. Compliance

– Standards Compliance: Built according to international safety and quality standards, such as OSHA, ASME, and ISO.

12. Additional Features

– Variable Speeds: Adjustable lifting and travelling speeds for various applications.

– Noise Reduction: Quiet operation due to advanced engineering techniques.

These features make a 5-ton crane a valuable addition to any setting requiring heavy lifting, combining versatility, safety, and efficiency into one robust machine.

List Various Types of “5 ton crane”

Certainly! A 5-ton crane can come in various forms, each designed for specific applications. Here are some types of 5-ton cranes:

1. Overhead Crane (Bridge Crane):

– Single Girder Overhead Crane: Features a single bridge beam where the hoist trolley runs. Ideal for light to moderate lifting tasks.

– Double Girder Overhead Crane: Equipped with two parallel bridge beams. These are more robust and offer greater stability and lifting height.

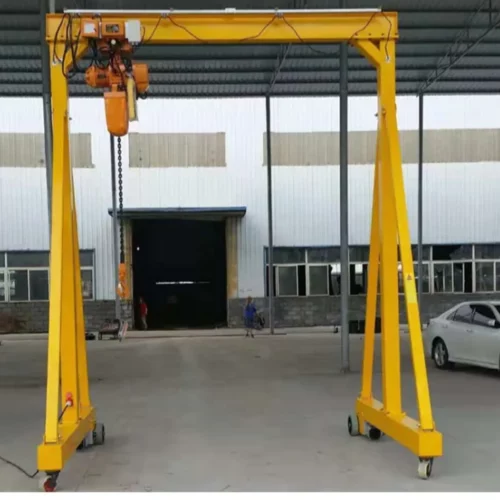

2. Gantry Crane:

– Full Gantry Crane: Has two legs that run on a rail system on the floor, suitable for outdoor applications like shipyards.

– Semi-Gantry Crane: One end runs on the ground rail while the other end runs on an elevated rail. It’s useful in areas with space constraints.

3. Jib Crane:

– Wall-Mounted Jib Crane: Fixed on a wall, it offers slewing (rotation) ability and is optimal for localized lifting tasks.

– Freestanding Jib Crane: Independent structure that can be placed at different locations. It’s versatile and can handle various lifting operations.

4. Mobile Crane:

– Truck-mounted Crane: Mounted on a truck, offers mobility to reach different locations quickly.

– Rough Terrain Crane: Has large, rugged wheels designed for off-road and rough terrain conditions, providing flexibility for construction sites.

5. Monorail Crane:

– Runs along a single fixed rail, offering straightforward linear movement. Ideal for assembly line and production environments.

6. Tower Crane:

– Often used in construction for high-rise buildings, although rare for a 5-ton capacity, they may be designed for smaller scale structures.

Each type of 5-ton crane serves unique operational needs, from manufacturing plants to construction sites, and offers different mobility, flexibility, and lifting capabilities.

List Application of “5 ton crane”

A 5-ton crane is a versatile piece of equipment widely used in various industries for lifting and moving heavy loads. Below are some key applications:

1. Construction Sites:

– Primarily used for moving heavy construction materials such as steel beams, concrete blocks, and other large structural components.

– Ideal for setting up and dismantling temporary structures and formwork.

2. Manufacturing and Assembly Plants:

– Employed to move large machinery, raw materials, and finished products.

– Essential for the assembly line processes, especially in the automotive and heavy equipment industries, where precise and efficient lifting is required.

3. Warehousing and Storage Facilities:

– Used for stacking and arranging heavy pallets and goods.

– Enhances the efficiency of storage operations by enabling vertical stacking and optimal use of space.

4. Maintenance and Repair Work:

– Facilitates the lifting and replacement of heavy machine parts during repair and maintenance activities.

– Useful in workshops and garages for managing large vehicle components and industrial machinery.

5. Ports and Logistics Hubs:

– Integral for loading and unloading heavy cargo from ships and trucks.

– Speeds up the process of shifting goods, thereby improving turnover times in logistical operations.

6. Mining and Mineral Processing:

– Assists in the assembly of heavy mining machinery and transport of mined materials.

– Vital for the maintenance of large equipment used in extraction and processing operations.

7. Utility and Energy Sectors:

– Used for the installation and maintenance of heavy electrical components like transformers and generators.

– Helpful in handling large pipes and equipment in the oil and gas industry.

8. Aviation Industry:

– Crucial for the maintenance and assembly of aircraft components.

– Helps in positioning large parts like engines and wings accurately during assembly and repair.

These applications underline the importance of a 5-ton crane in operations requiring the safe and efficient handling of heavy loads.

List Buyer Types of “5 ton crane”

When considering the purchase of a 5-ton crane, various types of buyers come to mind, each representing different industries and needs. Here are some common buyer types:

1. Construction Companies:

– Usage: For erecting buildings, lifting heavy materials, and general construction tasks.

– Benefits: Enhanced efficiency in material handling and reduced labor costs.

2. Manufacturing Plants:

– Usage: For moving heavy machinery, equipment, and parts within the production facility.

– Benefits: Improved workflow and enhanced safety in material transport.

3. Steel and Metal Fabrication Shops:

– Usage: For handling heavy metal sheets, beams, and assembled structures.

– Benefits: Precision in material positioning and improved productivity.

4. Warehousing and Distribution Centers:

– Usage: For loading and unloading heavy goods and materials.

– Benefits: Streamlined logistics and reduced manual handling.

5. Mining Operations:

– Usage: For lifting heavy mining equipment, minerals, and other materials.

– Benefits: Enhanced operational efficiency and safety in handling large loads.

6. Automotive Industry:

– Usage: For assembling and moving vehicle parts and machinery.

– Benefits: Increased production speed and minimized risk of damage to components.

7. Shipyards and Marine Operations:

– Usage: For lifting and positioning ship components, materials, and cargo.

– Benefits: Facilitates large assembly processes and cargo handling.

8. Energy Sector:

– Usage: For lifting and installing heavy components like turbines, transformers, and pipelines.

– Benefits: Essential for maintaining and setting up large-scale energy projects.

9. Rental Companies:

– Usage: Renting cranes to various industries for short-term projects.

– Benefits: Flexibility and capitalizing on varying client needs.

10. Municipalities and Public Works:

– Usage: For infrastructure projects like bridge construction, road maintenance, and public utilities.

– Benefits: Efficient handling of heavy components for public infrastructure development.

Each buyer type seeks to enhance operational efficiency, improve safety standards, and reduce labor costs by incorporating a 5-ton crane into their respective workflows. The specific advantages and applications depend on the unique requirements of their industries.

List “5 ton crane” Project Types for Different Industries

A 5-ton crane is a versatile lifting mechanism employed across various industries for diverse project requirements. Here’s a brief overview of its applications in different sectors:

1. Manufacturing and Assembly:

– Production Lines: Used for moving heavy components between different stages of manufacturing.

– Machinery Installation: Assists in installing and positioning heavy equipment and machinery.

– Material Handling: Facilitates the seamless transport of raw materials and finished products within the facility.

2. Construction:

– Building Construction: Helps in lifting and placing construction materials such as steel beams, concrete blocks, and other heavy elements.

– Bridge Construction: Utilized for assembling large bridge components, like girders and box beams.

– Infrastructure Projects: Key in handling piping, panels, and support structures in large-scale infrastructure endeavors.

3. Warehousing and Logistics:

– Inventory Management: Eases handling of bulk inventory, including pallets and large storage containers.

– Loading and Unloading: Streamlines the movement of heavy goods onto trucks and docks, enhancing operational efficiency.

– Stacking: Assists in the stacking of goods in optimized configurations for storage.

4. Energy Sector:

– Power Plants: Facilitates installing and maintaining heavy equipment such as turbines and generators.

– Oil and Gas: Supports the assembly of rigs and handling large piping systems.

– Renewables: Crucial for installing wind turbines and solar panels.

5. Mining and Quarrying:

– Material Transport: Used for moving large quantities of mined ore and rock.

– Equipment Handling: Essential for the setup and maintenance of mining machinery and equipment.

– Pit Operations: Assists in extracting and processing raw materials from excavation sites.

In each of these industries, a 5-ton crane enhances productivity, safety, and efficiency, making it an indispensable tool for modern industrial operations.

5 ton crane Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing a 5-ton crane can significantly enhance its efficiency, safety, and versatility. Here are key accessories and options to consider:

1. Remote Control Systems: Implementing wireless or radio remote controls allows operators to maneuver the crane from a safe distance, improving safety and precision.

2. Anti-Sway Technology: Adding anti-sway systems minimizes load swing, allowing for safer and more accurate load positioning.

3. Variable Frequency Drives (VFDs): Upgrading to VFDs ensures smoother operation, reducing mechanical stress and prolonging equipment life. They also provide energy savings and better speed control.

4. Load Indicators and Limiters: Installing load moment indicators (LMI) and load limiters prevents overloading, protecting both the crane and the workforce.

5. Custom Hoisting Solutions: Custom hooks, slings, and spreader bars can be tailored to specific lifting requirements, providing more versatility for unique tasks.

6. Lighting and Safety Alarms: Incorporating high-visibility LED lights and audible alarms enhances safety in low-light conditions and alerts personnel to crane movements.

7. Ergonomic Operator Cabins: For cranes with cabins, ergonomic designs and climate control systems improve operator comfort and productivity.

8. Telemetry and Monitoring Systems: These systems provide real-time data on crane operations, enabling better maintenance planning and operational efficiency.

9. Enhanced Mobility Options: Adding track or wheel systems can increase mobility for cranes that need to navigate varied terrains or confined spaces.

10. Payload Management Software: Implementing advanced software can optimize load handling and improve inventory tracking.

11. Weather Protection: Customized covers and enclosures protect the crane’s critical components from harsh weather conditions, ensuring durability and reliability.

Each upgrade or customization can be tailored to meet specific operational needs, enhancing the crane’s functionality and extending its lifespan. Whether retrofitting an existing crane or enhancing a new one, these options ensure that a 5-ton crane operates at peak performance.

List Quality Control and The Manufacturing Process of “5 ton crane”

Quality Control of 5 Ton Crane

1. Materials Inspection: Initial quality checks ensure all raw materials (steel, cables, motors) meet specific standards.

2. Dimensional Verification: Precise measurements verify all parts match specified dimensions before assembly.

3. Welding Inspection: Non-destructive testing (NDT) methods like X-ray or ultrasonic tests examine weld integrity.

4. Load Testing: The crane is subjected to load tests at various weights, exceeding the rated 5 tons to ensure capability.

5. Safety Systems Check: Functional tests confirm the reliability of safety mechanisms (limit switches, emergency stops).

6. Operational Testing: The crane undergoes a series of operational trials, checking all movements and functions.

7. Documentation & Certification: Inspection results are documented, and necessary certifications are provided.

Manufacturing Process of 5 Ton Crane

1. Design and Planning: Engineers create detailed design specifications, ensuring compliance with regulations and customer requirements.

2. Cutting and Forming: Raw materials are cut and formed into precise shapes using laser cutting, bending, and machining processes.

3. Component Fabrication: Key components such as the crane boom, girders, and trolley are fabricated.

4. Welding and Assembly: Parts are welded and assembled; welders follow approved procedures and standards to ensure durability.

5. Machining: Precision machining ensures that components fit together seamlessly.

6. Surface Treatment: Anti-corrosion treatments like painting or galvanization enhance durability.

7. Electrical Assembly: Electric motors, control panels, and wiring are installed.

8. Subassembly Testing: Individual components and systems are tested before full assembly.

9. Final Assembly: All parts are assembled into the final crane structure.

10. Load and Functional Testing: The fully assembled crane is load-tested and its operational performance is verified.

11. Inspection and Certification: Final inspection checks every aspect, and the crane is certified fit for use.

12. Delivery and Installation: The crane is disassembled if necessary, transported, and reassembled on-site.

By adhering to stringent quality control measures and a well-structured manufacturing process, a 5-ton crane is produced to meet high safety and performance standards.

How to use “5 ton crane”

Operating a 5-ton crane requires a fundamental understanding of crane operation and strict adherence to safety guidelines. Below is a step-by-step guide:

1. Pre-Operation Checks:

– Inspect the Crane: Ensure all parts are in good condition. Check for any visible damage or wear and tear on the hook, wire ropes, and other critical parts.

– Test Controls: Verify that the control panel is functioning correctly. Test all movements (up, down, left, right) without a load.

– Load Capacity: Confirm that the load does not exceed the crane’s capacity of 5 tons.

2. Preparation:

– Choose the Right Sling: Select the appropriate sling or lifting device for the load.

– Secure the Load: Ensure the load is securely fastened with proper rigging techniques. Balance the load to avoid tipping.

– Communication: Establish clear communication signals with your team or ground personnel.

3. Operation:

– Lift Slowly: Begin lifting gradually to ensure the load is stable. Avoid sudden jerks.

– Keep Clear: Ensure all personnel are clear of the load and crane movement path.

– Monitor Load: Keep an eye on the load constantly, and avoid any swinging.

– Use Smooth Movements: Move the crane controls smoothly to prevent oscillation or instability.

4. Placement:

– Lower Slowly: Gently lower the load to the desired location.

– Guide: Use tag lines to help guide the load into position.

– Secure: Once the load is in place, ensure it is stable and secured before releasing the slings.

5. Post-Operation:

– Shutdown: Turn off the crane and secure it when not in use.

– Inspect Again: Conduct a brief inspection of the crane after use to catch any potential issues early.

6. Safety First:

– Always wear appropriate personal protective equipment (PPE).

– Follow all manufacturer guidelines and local safety regulations.

– Never exceed the crane’s rated capacity.

Proper training and certification are essential for crane operators to ensure safe and efficient operation.

“5 ton crane” Comparative Analysis

When evaluating 5-ton cranes, several key factors should be considered to ensure you select the appropriate crane for your specific needs. Here’s a comparative analysis based on types, lifting capacity, mobility, applications, and cost-effectiveness:

Types of 5-Ton Cranes

1. Overhead Cranes: These are fixed cranes designed for indoor industrial environments, often used in factories and warehouses. They provide high stability and precise control.

2. Mobile Cranes: These include truck-mounted cranes and rough terrain cranes. They offer flexibility and can be transported to various sites.

3. Gantry Cranes: Similar to overhead cranes but typically movable on runways, they are ideal for outdoor applications and heavy lifting in shipyards or large warehouses.

Lifting Capacity and Height

For all 5-ton cranes, the maximum lifting capacity is 5 tons. However, lifting heights can vary:

– Overhead Cranes: Typically have flexible lifting heights, customizable based on the building’s structure.

– Mobile Cranes: Often have limited lifting heights compared to gantry and overhead cranes due to their compact design.

– Gantry Cranes: Generally offer significant lifting heights and spans, suitable for large-scale projects.

Mobility

– Overhead Cranes: Fixed installation with limited mobility, though they can cover extensive areas within a facility using a system of rails.

– Mobile Cranes: Most versatile in terms of mobility; can easily move from one site to another.

– Gantry Cranes: While not as mobile as truck-mounted options, they can still be relocated within a certain range using tracks or wheels.

Applications

– Overhead Cranes: Ideal for repetitive tasks in manufacturing, assembly lines, and heavy industries.

– Mobile Cranes: Suitable for construction, infrastructure development, and scenarios requiring frequent relocation.

– Gantry Cranes: Best for outdoor applications, shipbuilding, and storage operations where movement of heavy goods over short distances is required.

Cost-Effectiveness

– Overhead Cranes: Typically involve a higher initial investment but offer long-term operational savings through durability and efficiency.

– Mobile Cranes: Lower initial costs with added operational expenses due to frequent transportation and potential maintenance.

– Gantry Cranes: Mid-range cost with high flexibility and operational savings in large-scale applications.

“5 ton crane” Warranty and Support

Our 5-ton crane comes with a comprehensive warranty and robust support system, designed to give you peace of mind and ensure the longevity of your investment.

Warranty:

The 5-ton crane is covered by a 2-year limited warranty from the date of purchase. This warranty includes coverage for defects in materials and workmanship under normal use and service conditions. During this period, we will repair or replace any defective parts or units at no additional charge. The warranty excludes wear and tear parts, misuse, and any damages resulting from improper installation, maintenance, or unauthorized modifications.

Support:

Customer satisfaction is our top priority, and our support services are structured accordingly:

1. 24/7 Customer Service: Our dedicated customer service team is available around the clock to assist you with any queries or concerns. Whether it’s troubleshooting issues or answering technical questions, our team is always ready to help.

2. Technical Assistance: We offer expert technical support to ensure your crane operates efficiently. Our technical support team can provide guidance on installation, maintenance, and operation via email, phone, or video call.

3. On-Site Service: For more complex issues that cannot be resolved remotely, we provide on-site service through our network of certified technicians. Our technicians are well-trained and equipped to handle any repairs or maintenance tasks professionally.

4. Spare Parts Availability: We maintain a comprehensive inventory of spare parts to minimize downtime. Our parts are readily available and can be shipped promptly to ensure your crane remains operational.

5. Training and Resources: We provide extensive training materials and resources, including manuals and instructional videos, to help you and your staff operate and maintain the crane safely and effectively.

By combining a solid warranty with exceptional support, we are committed to ensuring that your 5-ton crane meets all your operational needs and provides reliable service for years to come.

List “5 ton crane” FAQ

5 Ton Crane FAQ

#### 1. What is a 5 ton crane?

A 5 ton crane is a type of lifting equipment designed to handle loads up to a maximum capacity of 5 tons (10,000 pounds). These cranes are commonly used in industrial settings, factories, construction sites, and warehouses for lifting and moving heavy materials.

#### 2. What types of 5 ton cranes are available?

Common types of 5 ton cranes include:

– Overhead Cranes: Typically used in industrial environments for lifting within facilities.

– Gantry Cranes: Similar to overhead cranes but feature a bridge supported by two legs and can be mobile.

– Jib Cranes: Feature a horizontal arm (jib) attached to a vertical mast for lifting within a circular area.

– Portable Cranes: Smaller, mobile units for easy transport and flexible use in various locations.

#### 3. What are the power options for 5 ton cranes?

5 ton cranes can be powered using:

– Electric: Most common in industrial settings for consistent and reliable power.

– Hydraulic: Often used for mobile or portable units, offers powerful lifting capability.

– Manual: Lever or hand-operated systems, typically for smaller, portable cranes.

#### 4. What safety features are included in 5 ton cranes?

Safety features may include:

– Overload protection: Prevents lifting beyond the crane’s rated capacity.

– Emergency stop buttons: Allows immediate shutdown in case of an emergency.

– Limit switches: Stop the crane’s movement at preset points to avoid collisions.

– Anti-collision systems: Prevents accidents in environments with multiple cranes.

#### 5. How should a 5 ton crane be maintained?

Regular maintenance is crucial for safety and efficiency. Recommendations include:

– Routine Inspections: Check for wear and tear, and ensure all components are functioning correctly.

– Lubrication: Regularly lubricate moving parts to prevent wear.

– Load Testing: Periodically conduct load tests to ensure the crane can handle its rated capacity.

– Training: Ensure operators are trained in proper use and safety procedures.

Top 10 FAQ with answer about 5 ton crane for Buyer Sourcing from China

Sure! Below are the top 10 frequently asked questions regarding sourcing a 5-ton crane from China, along with their concise answers:

1. Q: What is the typical delivery lead time for a 5-ton crane from China?

– A: The lead time typically ranges from 30 to 60 days, depending on the customization requirements and the manufacturer’s backlog.

2. Q: What certifications should I look for in a 5-ton crane?

– A: Ensure the crane has CE, ISO9001, and CCC certifications to comply with international safety and quality standards.

3. Q: Can I customize the crane specifications to suit my needs?

– A: Yes, most manufacturers offer customization options for lifting height, span length, and operating controls.

4. Q: What are the payment terms generally accepted by manufacturers in China?

– A: Common payment terms include 30% T/T deposit with the balance paid before shipment, or L/C at sight.

5. Q: How will the crane be shipped, and what are the associated costs?

– A: Cranes are usually shipped via sea freight. Costs depend on the destination, shipping method (FCL/LCL), and additional services like insurance.

6. Q: What is the warranty period for a 5-ton crane?

– A: Most manufacturers offer a warranty period of one year, covering parts and technical support.

7. Q: How can I ensure the quality before shipment?

– A: You can request pre-shipment inspections, factory audits, and third-party quality checks.

8. Q: Are spare parts and after-sales services readily available?

– A: Reputable manufacturers provide a list of spare parts and a robust after-sales service network, including online support, within the warranty period.

9. Q: What are the main safety features of a 5-ton crane?

– A: Key safety features include overload protection, emergency shutdown, and limit switches for hoist and trolley.

10. Q: Can I get installation and training support?

– A: Many manufacturers offer installation services and operator training either on-site or via detailed guides and video tutorials.

These answers should help streamline the decision-making process when sourcing a 5-ton crane from China.