5 ton overhead crane Safety Certifications

Ensuring the safe operation of a 5-ton overhead crane involves adhering to various safety standards and certifications. Compliance with these benchmarks is essential to mitigate risks and ensure the safety of personnel and property. The key safety certifications and standards to consider include:

1. OSHA (Occupational Safety and Health Administration):

– OSHA regulations (29 CFR 1910.179) provide comprehensive safety guidelines for overhead and gantry cranes. Compliance with these regulations ensures that the crane’s operation, maintenance, and inspections meet minimum safety requirements.

2. ASME (American Society of Mechanical Engineers) B30.2:

– This standard specifies the safety rules governing the design, construction, installation, operation, inspection, and maintenance of overhead and gantry cranes. Adherence to ASME B30.2 helps ensure mechanical reliability and operator safety.

3. ANSI (American National Standards Institute):

– ANSI conducts rigorous assessments, setting standards to ensure the design and functionality of cranes meet high safety and performance criteria. ANSI B30.2 aligns closely with ASME standards.

4. CMAA (Crane Manufacturers Association of America):

– CMAA Specification 70 and 74 outline requirements for the design, manufacture, and service of overhead traveling cranes and monorail systems. They offer guidelines on load handling, equipment ratings, and duty classifications.

5. ISO (International Organization for Standardization):

– ISO 9001 certification, although not specific to cranes, ensures that the manufacturer follows a quality management system that consistently delivers safe and reliable products.

6. Periodic Inspections and Load Testing:

– Regular inspections by certified professionals, along with load tests as per the mentioned standards, are crucial for detecting potential issues before they lead to accidents.

Owners and operators should consistently comply with these standards, ensuring regular training, equipment checks, and adherence to operational guidelines to maintain a high safety level.

List Reference Technical Parameters of “5 ton overhead crane”

Sure, here is a concise list of the key technical parameters for a 5-ton overhead crane:

1. Load Capacity:

– Maximum Load: 5 Tons

2. Span:

– Span Length: Varies typically from 5 to 30 meters, depending on design and applications

3. Lift Height:

– Lifting Height: Generally between 6 to 30 meters, customizable based on requirements

4. Speed:

– Hoisting Speed: Typically ranges from 4 to 8 meters per minute

– Trolley Traveling Speed: Typically about 20 to 30 meters per minute

– Bridge Traveling Speed: Typically about 40 to 75 meters per minute

5. Power Supply:

– Voltage: Usually 380V, 50Hz, 3-phase (customizable as per region)

– Power Source: Electrical

6. Duty Class/Service Class:

– Rated according to FEM/ISO/ASME standards, commonly ranges from Class A1 (light) to Class A5 (moderate duty)

7. Control Method:

– Options: Pendant control, Remote control, Cabin control

8. Operating Temperature:

– Generally between -20°C to 40°C, can be customized for extreme conditions

9. Crane Weight:

– Total weight varies depending on design and materials, usually several tons

10. Construction Material:

– Crane girder material typically high-strength low-alloy steel

11. Safety Features:

– Overload limiter, limit switches, emergency stop button, anti-collision devices

12. Compliance Standards:

– Meets various global standards like ISO, FEM, CMAA, and applicable local regulations

13. Installation:

– Typically requires professional installation and regular maintenance for optimal performance

In summary, a 5-ton overhead crane is designed to lift and transport loads up to 5 tons over variable spans and lift heights, with various speed controls and safety features tailored to industrial needs. The crane’s power requirements, materials, and additional features can be customized based on specific operational requirements and compliance standards.

List Product features of “5 ton overhead crane”

Sure, here are the product features of a 5-ton overhead crane:

1. Load Capacity: Designed to lift and transport loads up to 5 tons, making it suitable for various industrial applications.

2. Span and Design: Available in multiple span lengths to fit specific workspace dimensions. Can be single girder or double girder types.

3. Construction: Made with high-strength steel structures providing durability and long service life.

4. Hoist Mechanism: Equipped with a reliable hoist that ensures smooth lifting and lowering of loads. Options include electric, chain, or wire rope hoists.

5. Control Options: Can be operated using a pendant control, wireless remote control, or a stationary control panel for precise handling.

6. Travel Mechanism: Features motorized end trucks for smooth and efficient movement along the runway beams.

7. Safety Features: Includes overload protection, emergency stop functions, limit switches, and anti-collision technology to ensure safe operation.

8. Customization: Can be customized with additional features like variable speed controls, specialized hooks, and load indicators.

9. Ease of Installation: Pre-engineered components facilitate quick and easy installation with minimal disruptions.

10. Maintenance-Friendly: Designed for easy access to critical components, reducing downtime for maintenance and repairs.

11. Energy Efficiency: Incorporates energy-saving motors and systems to minimize power consumption.

12. Environmental Adaptability: Suitable for various environments, including indoor settings and outdoor applications with weatherproof features.

13. Compliance: Adheres to industry standards and safety regulations, ensuring reliable and compliant performance.

14. Versatility: Useful in diverse industries such as manufacturing, warehousing, construction, and logistics for material handling and assembly operations.

These features make the 5-ton overhead crane an essential tool for enhancing productivity, efficiency, and safety in material handling environments.

List Various Types of “5 ton overhead crane”

A 5-ton overhead crane is a versatile lifting solution used in various industrial applications. Different types of 5-ton overhead cranes cater to specific operational needs. Here are some common types:

1. Single Girder Overhead Crane:

– Configuration: Features one main girder, often simpler and less expensive.

– Application: Ideal for light to medium-duty lifting.

– Advantages: Quick installation, cost-effective.

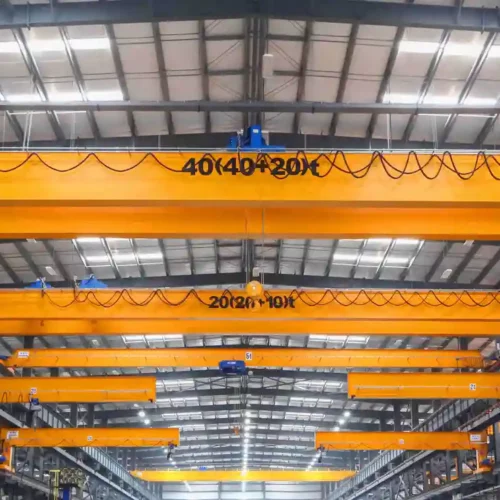

2. Double Girder Overhead Crane:

– Configuration: Has two main girders, providing additional strength.

– Application: Suitable for heavy-duty tasks and longer spans.

– Advantages: Higher lifting capacities and greater hook height.

3. Top Running Overhead Crane:

– Configuration: The crane runs on rails mounted on top of the runway beams.

– Application: Common in industries with high ceilings.

– Advantages: Maximizes lift height and travel distance.

4. Under Running (Underslung) Overhead Crane:

– Configuration: The crane runs on the bottom flange of the runway beams.

– Application: Suitable for buildings with low headroom.

– Advantages: Flexible installation, can be hung from the roof.

5. Explosion Proof Overhead Crane:

– Configuration: Specifically designed with materials and components to operate safely in hazardous environments.

– Application: Used in industries such as chemical, petrochemical, and mining.

– Advantages: Enhanced safety features to prevent ignition.

6. European Standard Overhead Crane:

– Configuration: Incorporates advanced technology and compact design.

– Application: Ideal for precise lifting tasks and maximized workspace.

– Advantages: Higher efficiency, easy maintenance.

7. Workstation Overhead Crane:

– Configuration: Generally lighter and more ergonomic.

– Application: Used in smaller work areas for assembly, manufacturing, and finishing tasks.

– Advantages: Easy to move, increases productivity.

Each type of 5-ton overhead crane offers specific benefits tailored to different operational requirements, ensuring optimal performance in diverse industrial environments.

List Application of “5 ton overhead crane”

A 5-ton overhead crane is a versatile piece of industrial equipment utilized across various sectors for efficient material handling and lifting. Below are the primary applications:

1. Manufacturing Facilities: Used for transporting heavy components along the production line, improving workflow efficiency and reducing manual labor.

2. Warehousing: Facilitates the stacking and unstacking of heavy products, optimizing space utilization and ensuring the safe handling of goods.

3. Automotive Industry: Essential for lifting engines, transmissions, and other heavy automotive components during the assembly and maintenance processes.

4. Construction: Aids in moving large building materials such as steel beams, concrete blocks, and prefabricated sections, enhancing construction speed and safety.

5. Steel Mills: Critical for handling raw materials, semi-finished, and finished products, such as steel bars, coils, and plates, contributing to efficient production processes.

6. Shipbuilding: Utilized for lifting large ship sections, heavy equipment, and materials, facilitating vessel assembly and repair.

7. Electric Power Plants: Essential for installing, maintaining, and replacing heavy components such as transformers, turbines, and generators.

8. Mining: Helps in the lifting and transporting of extracted materials, equipment, and maintenance tools in mining operations.

9. Aerospace: Used for moving aircraft parts, engines, and assembling large sections, ensuring precision and safety in handling delicate components.

10. Maintenance Operations: Assists in the regular maintenance of heavy machinery by lifting parts and tools, enhancing operational efficiency and safety.

By streamlining the lifting process and reducing manual effort, a 5-ton overhead crane significantly enhances productivity, safety, and operational efficiency across these industries.

List Buyer Types of “5 ton overhead crane”

Certainly! Buyers of a 5-ton overhead crane typically come from various industries and sectors. Here are some of the primary types:

1. Manufacturing Companies:

– Automotive Manufacturing: For handling heavy components and assemblies.

– Metal Fabrication: To move heavy metal sheets and products.

– Machinery Manufacturing: For lifting large machinery and parts.

2. Warehousing and Logistics:

– Distribution Centers: To aid in the efficient movement of heavy goods.

– Storage Facilities: For organizing and stacking bulky items.

3. Construction Companies:

– Used on construction sites to lift and transport heavy materials like steel beams and concrete slabs.

4. Energy Sector:

– Power Plants: For routine maintenance tasks and the movement of heavy equipment.

– Oil and Gas: Deployed in refineries for pipeline installation and maintenance.

5. Transport and Shipping:

– Ports and Docks: To handle heavy cargo during loading and unloading.

– Rail Depots: For the maintenance and assembly of train components.

6. Mining and Minerals:

– Utilized in mines to transport heavy mineral extractions and machinery.

7. Aerospace Industry:

– For the handling of large aircraft components and assemblies in manufacturing facilities.

8. Public Sector and Municipalities:

– Used by public works departments for heavy lifting tasks such as infrastructure maintenance.

9. Recycling and Waste Management:

– For moving and sorting large volumes of recyclable materials and heavy waste.

Each of these buyers requires a crane to streamline operations involving the movement and handling of heavy loads, enhancing efficiency and safety standards in their respective facilities.

List “5 ton overhead crane” Project Types for Different Industries

5-Ton Overhead Crane Project Types for Different Industries

1. Manufacturing Plants:

– Assembly Line Support: Cranes assist in transferring heavy components along the production line, enhancing workflow efficiency and reducing manual labor.

– Loading and Unloading Materials: Used for moving raw materials into the production area and finished products to storage or shipping zones.

2. Warehousing and Distribution:

– Inventory Management: Facilitates the organization and retrieval of heavy items, improving warehouse operations.

– Goods Transfer: Enables efficient loading and unloading from trucks, reducing handling time and labor costs.

3. Metalworking and Fabrication:

– Material Handling: Essential for moving large metal sheets, beams, and other heavy materials within the facility.

– Precision Lifting: Assists in positioning heavy components accurately for cutting, welding, or assembly tasks.

4. Automotive Industry:

– Engine and Component Lifting: Ideal for lifting and precisely placing engines, transmissions, and other heavy automotive parts during assembly.

– Chassis Handling: Used to transport vehicle chassis and large components through various stages of manufacturing.

5. Construction Sites:

– Building Material Movement: Facilitates the lifting and placement of construction materials like steel beams, concrete blocks, and prefabricated sections.

– Site Management: Improves organization by moving heavy equipment and materials efficiently around the construction site.

6. Aerospace Industry:

– Aircraft Assembly: Supports lifting of aircraft parts, engines, and components for assembly and maintenance.

– Maintenance Facilities: Aids in the repair and refurbishment of aircraft by hoisting engines, landing gear, and other heavy parts.

7. Energy Sector:

– Power Plants: Used for lifting and installing heavy equipment like turbines, generators, and transformers.

– Oil and Gas: Assists in handling and positioning heavy drilling equipment, pipelines, and other materials.

8. Mining Operations:

– Equipment Handling: Vital for moving heavy mining machinery and parts, ensuring safe and efficient operations.

– Ore Processing: Supports the lifting and transporting of ore and other materials within the processing area.

In each industry, the integration of a 5-ton overhead crane significantly enhances productivity, safety, and the overall efficiency of material handling processes.

5 ton overhead crane Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing a 5-ton overhead crane enhances its performance, safety, and versatility. Here’s a brief overview of accessories and custom manufacturing options:

1. End Trucks and Wheel Assemblies: Upgrading these components improves movement precision and load distribution, increasing crane longevity and efficiency.

2. Wire Ropes and Hoist Chains: Opting for high-quality, abrasion-resistant ropes or chains ensures better durability and reliability, reducing maintenance needs and downtime.

3. Control Systems: Implementing advanced control systems like radio remote controls or pendant controls provides enhanced operator safety and convenience.

4. Variable Frequency Drives (VFDs): VFDs enhance operational flexibility by allowing variable speed control, improving positioning accuracy, and reducing mechanical stress.

5. Load Cells and Weighing Systems: Integrating load cells offers real-time load monitoring, ensuring safe lifting operations and preventing overloads.

6. Anti-Sway Technology: Incorporating anti-sway technology stabilizes loads during transit, minimizing the risk of accidents and increasing handling precision.

7. Craneways and Structures: Customizing crane girder and structure design meets specific site requirements, load capacities, and space constraints.

8. Runway Rail System: Upgrading to a high-quality rail system enhances smooth crane movement and reduces wear and tear on wheels and tracks.

9. Lifting Magnets and Grabs: Custom-designed lifting magnets or grabs cater to specific material handling needs, such as scrap handling or coil lifting.

10. Safety Features: Adding safety enhancements like emergency stop buttons, limit switches, and anti-collision systems prevents accidents and ensures operational safety.

11. Motor and Drive Upgrades: High-efficiency motors and drives improve performance, energy efficiency, and reduce operational costs.

12. Lighting and Warning Systems: Installing LED lighting and audible/visual warning systems increases workplace safety and visibility.

Customizing and upgrading these accessories and components tailors the crane to your specific operational requirements, boosting productivity and ensuring a safer working environment.

List Quality Control and The Manufacturing Process of “5 ton overhead crane”

Quality Control:

1. Material Inspection: Inspect raw materials for compliance with specifications, including steel quality and electrical components.

2. Supplier Assessment: Evaluate and select suppliers based on quality standards, reliability, and consistency.

3. In-Process Inspection: Conduct regular inspections during production, such as welding quality checks, dimension verification, and alignment.

4. Non-Destructive Testing (NDT): Apply NDT methods like ultrasonic testing, radiographic testing, or magnetic particle inspection to check the integrity of welded joints and critical components.

5. Load Testing: Perform load tests to ensure the crane can handle the intended load capacity, including static and dynamic load tests.

6. Electrical Testing: Inspect electrical systems for proper function, including control panels, limit switches, and wiring.

7. Final Inspection: Conduct a comprehensive final inspection to ensure compliance with design, safety standards, and customer specifications.

8. Documentation: Maintain thorough documentation, including inspection reports, test results, and compliance certificates.

—

Manufacturing Process:

1. Design and Engineering: Develop detailed design plans and engineering drawings, including load calculations and safety features.

2. Material Procurement: Source high-quality materials, such as structural steel, motors, and control systems, based on specifications.

3. Cutting and Machining: Cut and machine steel components to precise dimensions using CNC machines, laser cutters, and other tools.

4. Welding and Fabrication: Weld and assemble structural components, ensuring alignment and strength. Fabricate the crane’s main body, bridges, trolleys, and hoists.

5. Surface Treatment: Apply surface treatments like sandblasting, painting, or galvanizing to protect against corrosion and enhance durability.

6. Component Assembly: Assemble the crane’s structural components with hoists, motors, gears, and electrical systems.

7. Electrical Wiring: Install and secure all electrical components, ensuring proper connections and integration with the control system.

8. Testing and Calibration: Conduct detailed testing and calibration of mechanical, electrical, and safety features to ensure optimal performance.

9. Packaging and Delivery: Disassemble as necessary, package securely, and transport to the installation site.

10. Installation and Commissioning: Assemble and install the crane at the customer’s location, followed by commissioning tests to ensure proper functioning.

How to use “5 ton overhead crane”

Using a 5-ton overhead crane involves several essential steps to ensure safety and efficiency:

1. Preparation:

– Training: Ensure the operator is trained and certified to use the overhead crane.

– Inspection: Inspect the crane for any visible damage or wear. Ensure that all safety devices are operational.

– Load Assessment: Verify the weight of the load and ensure it does not exceed the crane’s capacity (5 tons). Check the load for stability and secure it properly with appropriate rigging.

2. Operation:

– Controls Familiarization: Familiarize yourself with the crane’s control panel, including the hoist, trolley, and bridge movement controls.

– Clear the Area: Ensure the path of the crane is clear of obstructions and personnel. Use warning signs or barriers if needed.

– Lifting the Load:

– Position the crane directly over the load.

– Lower the hook and secure the load with slings or chains.

– Slowly lift the load a few inches to test the balance and security.

– Movement:

– Use smooth, gradual motions to move the load.

– Avoid sudden stops or changes in direction.

– Keep the load as low to the ground as practical while moving.

3. Setting Down the Load:

– Position the load in the desired location.

– Slowly lower the load to the ground or onto a stable surface.

– Unhook and inspect the rigging equipment after use.

4. Post-Operation:

– Park the crane in its designated location.

– Turn off the power supply.

– Conduct a final inspection for any signs of wear or damage incurred during usage.

Safety Precautions:

– Always follow the manufacturer’s guidelines and safety protocols.

– Never lift loads over personnel or allow anyone to stand under a suspended load.

– Use hand signals or a spotter when necessary to enhance communication.

By following these steps, you can efficiently and safely operate a 5-ton overhead crane.

“5 ton overhead crane” Comparative Analysis

A 5-ton overhead crane is a versatile lifting device used extensively in industrial settings for material handling. They are crucial for increasing productivity and ensuring safety during lifting heavy loads. Here’s a comparative analysis of various types of 5-ton overhead cranes:

1. Single Girder Overhead Crane:

– Pros:

– Cost-effective due to simpler construction.

– Requires less space and has a lower deadweight.

– Easier to install and maintain.

– Cons:

– Limited to lighter duty cycles and shorter spans.

– Reduced hook height since the hoist is generally under the girder.

2. Double Girder Overhead Crane:

– Pros:

– Higher load capacity and longer spans.

– Greater hook height as the hoist is between the girders.

– Suitable for more frequent and heavier lifting tasks.

– Cons:

– More expensive and complex to install.

– Requires robust support and more maintenance.

3. Top Running Overhead Crane:

– Pros:

– Can handle maximum load capacities and long spans.

– Provides better hook height as the crane runs on rails fixed on top of the runway beams.

– Cons:

– Higher structural requirements and increased costs.

– May necessitate structural modifications in existing buildings.

4. Under Running Overhead Crane:

– Pros:

– More flexible installation in buildings with limited headroom.

– Lighter and less structural support required.

– Cons:

– Generally limited to lighter loads compared to top-running cranes.

– Increased risk of track wear and alignment issues.

In conclusion, choosing the right type of 5-ton overhead crane depends on specific operational requirements. Single girder cranes are ideal for cost-sensitive, lower duty operations. Double girder cranes offer enhanced performance for heavier and more frequent use. Top-running cranes provide superior capacity and hook height, while under-running cranes are better suited to environments with spatial constraints. Each type has distinct advantages and potential drawbacks, making it crucial to evaluate based on the specific industrial application.

“5 ton overhead crane” Warranty and Support

When purchasing a 5-ton overhead crane, warranty and support are crucial aspects to consider to ensure the longevity and reliability of your investment. Here’s what you should typically expect:

Warranty

1. Standard Warranty Period: Most reputable manufacturers offer a standard warranty period ranging from 12 to 24 months from the date of delivery or installation. This warranty typically covers defects in materials and workmanship.

2. Extended Warranty: Some suppliers provide options for extending the warranty period at an additional cost. This can be beneficial if you plan to use the crane in demanding environments or extended operations.

3. Warranty Inclusions: Coverage usually includes repairs or replacements of defective parts, labor costs for such repairs, and sometimes even travel expenses for technicians. Always check the specifics of what’s covered.

4. Exclusions: Normal wear and tear, misuse, unauthorized modifications, and lack of proper maintenance are commonly excluded from warranty coverage.

Support

1. Technical Support: Manufacturers often provide 24/7 technical support through phone, email, or an online portal. This can help troubleshoot minor issues and understand maintenance needs.

2. On-Site Service: Many suppliers offer on-site service for both routine maintenance and emergency repairs. Ensure your supplier has a network of qualified technicians available in your area.

3. Training: Comprehensive training for operators and maintenance personnel can be provided. Some suppliers include this in the purchase package, while others may charge extra.

4. Documentation: Detailed user manuals, maintenance guides, and troubleshooting documents are typically supplied. These resources are invaluable for keeping your crane operational.

5. Spare Parts Availability: A reliable supplier should guarantee the availability of spare parts for a certain period, usually extending several years post-purchase. Check the ease and speed of obtaining these parts.

Always read the fine print in the warranty and service agreements to fully understand your coverage and obligations. Properly utilized, a 5-ton overhead crane can be a robust and long-lasting asset to your operations.

List “5 ton overhead crane” FAQ

5 Ton Overhead Crane FAQ

1. What is a 5 ton overhead crane?

A 5 ton overhead crane is a type of lifting equipment used to lift and move loads up to 5 tons. It typically consists of a bridge that traverses a runway, a hoist, and a trolley. It’s ideal for warehouses, manufacturing plants, and other industrial settings.

2. What are the types of 5 ton overhead cranes?

There are several types:

– Single-Girder Overhead Crane: Features a single bridge girder supported by end trucks.

– Double-Girder Overhead Crane: Has two bridge girders for added strength and stability.

– Top-Running and Under-Running: Top-running cranes run on rails mounted on the top of runway beams, while under-running cranes operate on the bottom flange of the runway beams.

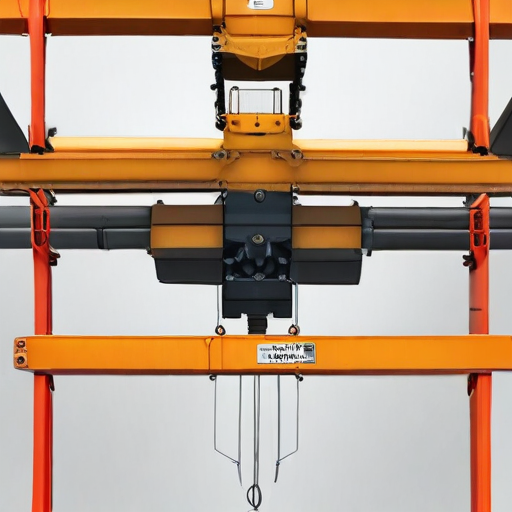

3. What are the key components?

– Bridge: The main horizontal beam.

– Hoist: Mechanism for lifting and lowering.

– Trolley: Moves the hoist along the bridge.

– Runway: Tracks that the bridge travels on.

– End Trucks: House the wheels that allow the bridge to move.

4. How do I maintain a 5-ton overhead crane?

Regular maintenance includes:

– Inspecting and lubricating moving parts.

– Checking the alignment of the bridge and trolley.

– Ensuring all safety mechanisms like limit switches and emergency stops are functional.

– Conducting periodic load tests.

5. What safety features are important?

– Limit Switches: Prevent overloading.

– Emergency Stop: Quickly halts the operation.

– Overload Protection: Prevents lifting beyond capacity.

– Buffer and Rail End Stops: Prevents the crane from derailing.

6. How to choose the right 5 ton overhead crane?

Consider factors like the type of load, lifting height, span, operating environment, and duty cycle. Consult with a crane supplier to match your specific needs.

By addressing these FAQs, you can ensure you select and maintain an appropriate 5 ton overhead crane for your operational requirements.

Top 10 FAQ with answer about 5 ton overhead crane for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions (FAQ) about sourcing 5-ton overhead cranes from China, along with concise answers:

1. Q: What is the typical lead time for a 5-ton overhead crane?

A: The lead time often ranges from 4 to 8 weeks, depending on manufacturer production schedules and customization requirements.

2. Q: Are Chinese manufacturers compliant with international standards?

A: Yes, many Chinese manufacturers comply with international standards like ISO, CE, and FEM, ensuring quality and safety.

3. Q: What types of 5-ton overhead cranes are available?

A: Common types include Single Girder, Double Girder, Top Running, and Under Running cranes, each suited for specific applications.

4. Q: How do I ensure the quality of a crane from China?

A: Conduct thorough due diligence, request proof of compliance to standards, inquire about quality control processes, and consider third-party inspections.

5. Q: What is the shipping process for a 5-ton overhead crane?

A: Cranes are typically shipped in disassembled parts by sea freight. Proper packaging and securement ensure safe transport.

6. Q: Do I need to worry about after-sales service?

A: Many reputable manufacturers offer after-sales services, including installation guidance, training, maintenance, and parts replacement.

7. Q: How do I handle installation and commissioning?

A: Manufacturers often provide detailed manuals and may offer on-site or remote support. Hiring experienced local technicians is also recommended.

8. Q: What are the customizations available for a 5-ton overhead crane?

A: Customizations can include crane span, lift height, speed control, remote control systems, and environmental adaptations.

9. Q: What is the cost range for a 5-ton overhead crane from China?

A: Prices vary based on specifications and customizations, typically ranging from $3,000 to $25,000, excluding shipping and installation.

10. Q: What payment terms are generally accepted by Chinese manufacturers?

A: Common terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), or a combination, with an initial deposit and balance before shipment.

Sourcing a 5-ton overhead crane from China involves detailed planning and communication, but offers substantial cost savings and access to high-quality products.