5 ton overhead gantry crane Safety Certifications

Ensuring safety and compliance for a 5-ton overhead gantry crane involves adhering to several critical certifications and standards. Here are some key safety certifications and guidelines:

1. OSHA (Occupational Safety and Health Administration): OSHA’s guidelines and regulations, particularly OSHA 29 CFR 1910.179, govern the use of cranes in general industry. Compliance ensures a safe working environment by addressing operational safety, inspections, and maintenance.

2. ASME (American Society of Mechanical Engineers): ASME B30.2 encompasses the safety standards for overhead and gantry cranes, providing detailed guidelines on design, construction, installation, inspection, and testing.

3. ANSI (American National Standards Institute): ANSI standards, often aligned with OSHA and ASME guidelines, further reinforce safety for crane operations. ANSI/ASSP B30.2 is particularly relevant for overhead and gantry cranes.

4. NFPA (National Fire Protection Association): NFPA 70, known as the National Electrical Code (NEC), specifies the electrical safety requirements essential for crane operation and installation, reducing risks of electrical hazards.

5. ISO (International Organization for Standardization): ISO 23814 and ISO 9927 pertain to the safe operation and inspection of cranes, presenting a global perspective on maintaining rigorous safety standards.

6. CMAA (Crane Manufacturers Association of America): CMAA Specification No. 70 outlines the guidelines for the construction of overhead and gantry cranes. This standard ensures cranes are built to the highest safety standards.

7. Regular Inspections and Training: Beyond certifications, regular inspections and operator training are crucial. Ensure operators are adequately trained and certified to handle the crane safely, and that crane systems are frequently inspected to identify and address any potential issues.

By adhering to these certifications and guidelines, you can significantly reduce the risk of accidents and ensure the safe and efficient operation of a 5-ton overhead gantry crane.

List Reference Technical Parameters of “5 ton overhead gantry crane”

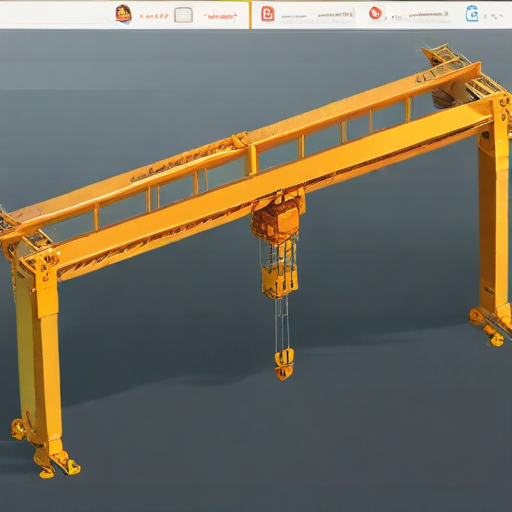

A 5-ton overhead gantry crane is a versatile lifting device widely used in various industrial settings for material handling. Key technical parameters that define its performance and suitability for different applications include:

1. Load Capacity: 5 tons (5000 kg) – This specifies the maximum weight the crane can lift.

2. Span Length: Typically ranges between 10 to 30 meters or more depending on the application – the span is the width between the two end trucks of the crane.

3. Lift Height: Generally varies from 6 to 20 meters – it indicates the maximum height the hook can be raised from the floor level.

4. Hoist Type: Electric hoist or manual chain hoist – electric hoists are more common for higher efficiency and ease of use.

5. Trolley Speed: Usually between 10 to 20 meters per minute – the speed at which the hoist moves along the bridge.

6. Bridge Speed: Typically ranges from 20 to 40 meters per minute – the speed of the crane moving along the runway.

7. Power Supply: Commonly 380V, 50Hz, 3-phase for industrial settings, but can vary depending on region and installation.

8. Control Type: Options include pendant control, radio remote control, or cabin control, providing flexibility in operation.

9. Duty Classification: As per FEM/ISO standards – indicative of the expected life cycle and the intensity and frequency of use; typically ranges from A3 (light duty) to A5 (moderate duty) for a 5-ton crane.

10. Girder Type: Single or double girder – single girder is lighter and more cost-effective, while double girder offers higher stability and lift height.

11. End Carriages: Equipped with rail wheels that allow movement along the runway.

12. Safety Features: Limit switches, overload protection, emergency stop, and anti-collision devices are standard safety features.

13. Installation: Can be freestanding with steel columns or mounted on an existing structure, depending on space and operational requirements.

Ensuring these technical parameters match the specific needs of the application is crucial for efficient, safe, and cost-effective crane operation.

List Product features of “5 ton overhead gantry crane”

The “5 ton overhead gantry crane” is a robust lifting solution designed for various industrial applications. Below is a concise list of its key features:

1. Capacity: Supports a lifting capacity of up to 5 tons, catering to heavy-duty material handling.

2. Construction:

– Frame: Sturdy steel construction ensures high strength and durability.

– Cross Beam: Reinforced cross beam provides stability and minimizes deflection.

3. Mobility:

– Gantry Design: Incorporates a freestanding structure, allowing easy relocation within the facility.

– Wheels/Casters: Equipped with high-quality wheels or casters for smooth movement along the floor.

4. Lift and Travel Mechanism:

– Hoist: Integrated electric or manual hoist for efficient lifting and lowering operations.

– Trolley: Motorized or manual trolley for horizontal movement along the beam.

5. Span and Height: Customizable span and height dimensions to fit specific workspace requirements.

6. Controls:

– Remote Operation: Wireless remote control options for safe and convenient operation.

– Control Panel: User-friendly control panel with easily accessible buttons and emergency stop.

7. Safety Features:

– Load Limit Switches: Prevents overloading and ensures safe operation.

– Emergency Stop: Integrated emergency stop button for immediate halt in case of any mishap.

– Locking Mechanism: Secure locking mechanisms to hold the crane in place during lifting operations.

8. Durability and Maintenance:

– Corrosion Resistance: Coated with anti-corrosive paint for enhanced durability.

– Easy Maintenance: Designed for straightforward maintenance with accessible components.

9. Versatility: Suitable for diverse applications including manufacturing, warehousing, construction, and logistics.

10. Compliance: Meets relevant industry standards and safety regulations for reliable and safe performance.

Each of these features collectively contributes to the efficiency, reliability, and safety of the 5 ton overhead gantry crane, making it an optimal choice for a variety of lifting tasks across different environments.

List Application of “5 ton overhead gantry crane”

A 5-ton overhead gantry crane is a versatile piece of lifting equipment used in various industries for its ability to move heavy loads efficiently and safely. Below are some applications:

1. Manufacturing Facilities:

– Used for assembly lines to move large components.

– Transferring heavy parts between workstations.

– Loading and unloading materials from trucks.

2. Warehouses and Storage:

– Stacking heavy inventory items.

– Organizing storage racks.

– Loading and unloading large bulk materials.

3. Construction Sites:

– Lifting and placing heavy building materials like steel beams, pre-cast concrete elements, etc.

– Assisting in assembly of large structures.

4. Shipyards and Marine Operations:

– Handling large ship components.

– Loading and unloading cargo onto ships.

– Repair and maintenance tasks requiring heavy lifts.

5. Automotive Industry:

– Lifting car bodies and engines during assembly or repairs.

– Moving large automotive parts in production lines.

6. Mining and Minerals Processing:

– Transferring mining equipment and extracted material.

– Servicing and maintaining large mining machinery.

7. Power Plants:

– Handling heavy equipment during maintenance operations.

– Moving parts for repairs or replacement.

8. Aerospace:

– Transporting aircraft parts.

– Assembling large components, such as wings and fuselage sections.

9. Metalworking Shops:

– Handling heavy sheets of metal.

– Moving metal products through various stages of production.

10. Railway Maintenance:

– Lifting and positioning railway components such as tracks and carriages.

– Assisting with heavy maintenance tasks on railway systems.

The 5-ton overhead gantry crane’s design allows for flexible handling of heavy loads within confined spaces, making it indispensable across these diverse applications.

List Various Types of “5 ton overhead gantry crane”

Certainly! Here are various types of 5-ton overhead gantry cranes, each suited to different applications and environments:

1. Single Girder Gantry Crane:

– Description: Features a single horizontal beam (girder) supported by two A-frame legs.

– Applications: Ideal for light to medium-duty lifting tasks in small workshops, manufacturing units, and assembly operations.

2. Double Girder Gantry Crane:

– Description: Consists of two horizontal beams, providing greater strength and stability.

– Applications: Suitable for heavier and more demanding lifting operations, often used in large industrial settings and construction sites.

3. Semi-Gantry Crane:

– Description: One side operates on a runway system attached to a building, and the other side runs on a ground rail.

– Applications: Frequently used in factories and warehouses where part of the crane needs to move within a confined space.

4. Full Gantry Crane:

– Description: Both ends of the crane ride on ground rails, providing full mobility across large areas.

– Applications: Ideal for shipyards, container yards, and large outdoor storage facilities.

5. Portable Gantry Crane:

– Description: Lightweight and designed for mobility within a specific area.

– Applications: Perfect for workshops and garages where the crane needs to be moved to different locations frequently.

6. Adjustable Height Gantry Crane:

– Description: Allows height adjustment to accommodate different lifting needs.

– Applications: Useful in environments where varying heights are required, such as maintenance areas and construction sites.

7. Trackless Gantry Crane:

– Description: Operates without fixed rails, offering flexibility in movement.

– Applications: Common in applications requiring mobility on flat, unobstructed floors, like warehouses and fabrication shops.

8. Cantilever Gantry Crane:

– Description: Features extended beams on one or both sides, providing additional clearance.

– Applications: Suitable for environments with obstacles or restricted space, such as ports and loading docks.

These 5-ton overhead gantry cranes vary in design and functionality, allowing them to meet diverse lifting requirements across various industries.

5 ton overhead gantry crane Accessories Upgrades and Custom Manufacturing Options

When selecting a 5-ton overhead gantry crane, a variety of accessories, upgrades, and custom manufacturing options can enhance functionality, safety, and efficiency. Here are some key considerations:

1. Hoist Options: You can opt for electric or manual hoists, depending on operational needs. An electric chain hoist or wire rope hoist provides quicker and more efficient lifting.

2. Control Systems: Upgrade to remote control systems for better maneuverability and safety. Wireless remote controls and radio controls offer operators the ability to maintain a safe distance from the load.

3. Variable Frequency Drives (VFD): Incorporating VFDs allows for smooth acceleration and deceleration, reducing mechanical stress and enhancing load control.

4. Anti-Collision Systems: Sensors can be installed to prevent collisions between cranes or with structural obstacles, enhancing operational safety.

5. Load Displays and Indicators: Digital load display systems provide real-time data on the load weight, helping to prevent overloading and ensuring safe operation.

6. Specialized End Effectors: Custom lifting attachments like spreader beams, magnetic lifters, and vacuum lifters can be engineered to handle specific types of loads more efficiently.

7. Weather Protection: If the crane is used outdoors, weatherproofing elements such as covers, anti-corrosion coatings, and stainless steel components can be added.

8. Adjustable Height Columns: These allow for the crane’s height to be modified according to specific operational needs, adding versatility.

9. Crane Scales: Integrated crane scales provide accurate load weight measurements, which is essential for compliance and safety.

10. Custom Paint and Finishes: Tailor the crane’s aesthetic to match corporate branding or to meet particular environmental conditions (e.g., corrosion resistance).

By thoughtfully selecting these accessories and custom manufacturing options, a 5-ton overhead gantry crane can be optimized for enhanced performance, safety, and compliance with industry standards.

List Quality Control and The Manufacturing Process of “5 ton overhead gantry crane”

Quality Control and the Manufacturing Process of a 5-Ton Overhead Gantry Crane

#### Quality Control

1. Material Inspection:

– Raw Materials: Inspect for compliance with predetermined specifications (steel grades, tensile strength).

– Components: Check parts like motors, cables, and beams for quality certificates and defect-free status.

2. Design Verification:

– Blueprint Approval: Review and approve engineering designs.

– Simulation: Use CAD and Finite Element Analysis (FEA) to simulate performance and stress tests.

3. Fabrication Monitoring:

– Welding Quality: Conduct non-destructive tests (NDT) like ultrasonic tests on weld joints.

– Dimensional Accuracy: Use jigs, fixtures, and measuring instruments to ensure precision.

4. Assembly Inspection:

– Component Fit: Verify the proper fitting and alignment of assembled parts.

– Load Testing: Perform load tests to ensure structural integrity and performance.

5. Electrical and Safety Testing:

– Electrical Systems: Inspection of wiring, control panels, and safety mechanisms.

– Standards Compliance: Verify adherence to standards such as ISO, ANSI, and OSHA.

#### Manufacturing Process

1. Design and Planning:

– Requirement Analysis: Define load, span, lifting height, and application.

– Engineering Design: Create detailed CAD drawings specifying all technical requirements.

2. Material Procurement:

– Order high-grade steel, motors, and electrical components from certified suppliers.

3. Fabrication:

– Cutting: Use plasma or laser cutting machines for precision cutting of steel sections.

– Welding and Machining: Employ automated welding machines and CNC machines for critical parts.

– Surface Treatment: Conduct sandblasting and apply anti-corrosive coatings and paint.

4. Assembly:

– Assemble the main girder, hoist mechanism, end trucks, and wiring, ensuring alignment and fit.

5. Quality Tests:

– Perform load testing, NDT welding checks, and electrical safety tests.

6. Shipping:

– Package the crane system securely and arrange transportation to the customer’s facility.

By maintaining rigorous quality control measures throughout the manufacturing process, the reliability and safety of the 5-ton overhead gantry crane are assured.

How to use “5 ton overhead gantry crane”

A 5-ton overhead gantry crane is essential for lifting heavy materials in industrial settings such as warehouses, factories, and construction sites. Here’s a concise guide on how to use it safely and effectively:

Preparation:

1. Training: Ensure that only certified operators who have undergone proper training control the crane.

2. Inspection: Conduct a visual inspection for any signs of wear, damage, or malfunctions. Check the hoist, hooks, ropes, controls, and limit switches.

3. Work Area: Clear the work area of any obstacles and ensure the load path is free of obstructions. Mark or cordon off the operational area to prevent unauthorized access.

Operation:

1. Power On: Turn on the power supply to the gantry crane. Follow the manufacturer’s guidelines regarding startup procedures.

2. Control Check: Test all controls including raising/lowering, trolley motion, and bridge travel to ensure they are functioning properly.

3. Attaching Load:

– Position the Crane: Move the crane directly above the load.

– Secure the Load: Use appropriate slings, chains, or lifting devices. Ensure the load is balanced and securely fastened.

– Lift Slightly: Lift the load a few inches to check for stability.

4. Transporting the Load:

– Slow and Steady: Move the load at a controlled, slow pace.

– Horizontal Travel: Use the trolley to move the load horizontally across the span.

– Monitor Load: Continuously monitor the load to prevent swinging or instability.

5. Lower and Unload: Lower the load gently into the desired position. Detach the lifting devices carefully.

After Use:

1. Shutdown: Turn off the power supply.

2. Inspect: Perform a post-operation inspection. Report any issues.

3. Clean-Up: Tidy up the area and store the crane as advised in the operational manual.

Safety Tips:

– Always adhere to the crane’s weight limits.

– Avoid sudden movements or jerks.

– Never lift loads over people.

By following these steps and maintaining safety protocols, the 5-ton overhead gantry crane can be used efficiently and safely.

“5 ton overhead gantry crane” Comparative Analysis

Comparative Analysis of 5 Ton Overhead Gantry Cranes

Overhead gantry cranes with a 5-ton capacity are pivotal for various industrial applications. Here’s a comparative analysis based on four critical parameters:

1. Design and Configuration:

– *Single Girder vs. Double Girder*: Single girder cranes are more cost-effective and have a simpler design, making them ideal for light to moderate lifting operations. Conversely, double girder cranes can support larger spans and heavier lifting at higher lifting heights, offering increased stability and flexibility.

– *Fixed vs. Adjustable Height*: Fixed-height cranes are simple and durable, suited for operations with consistent height requirements. Adjustable-height cranes provide versatility for varying load heights and site conditions, enhancing flexibility but at a higher cost.

2. Mobility:

– *Stationary vs. Mobile*: Stationary overhead gantry cranes are ideal for repetitive tasks within a defined area, providing stability and precision. Mobile gantry cranes, often equipped with wheels or tracks, offer greater flexibility to move across different areas, making them suitable for diverse operational requirements.

3. Power Source:

– *Manual vs. Electric*: Manual cranes, though less expensive and simpler, are labor-intensive and best for occasional and light lifting tasks. Electric cranes, powered by motors, offer higher efficiency, precision, and are essential for frequent and heavy-duty operations. However, they are more costly and require maintenance of electrical components.

4. Application and Industry:

– *Indoor vs. Outdoor Use*: Indoor cranes typically have compact designs to fit within building constraints and often have features to minimize noise and environmental impact. Outdoor cranes are built robustly to withstand weather conditions and generally have features like weatherproofing and enhanced stability.

In conclusion, a 5-ton overhead gantry crane should be chosen based on specific operational needs, budget, and environmental conditions. Single girder, electric, and mobile configurations often offer the most flexibility and efficiency for varied industrial applications, while stationary or manual cranes can be more cost-effective for simpler, less frequent tasks.

“5 ton overhead gantry crane” Warranty and Support

When purchasing a 5-ton overhead gantry crane, it’s crucial to understand the warranty and support details offered by the manufacturer or supplier.

Warranty

Most reputable manufacturers provide a standard warranty period, typically ranging from one to three years, covering defects in materials and workmanship. This warranty often includes:

1. Parts and Repairs: Free replacement or repair of faulty parts.

2. Labor: In some cases, labor costs for repairs are covered.

3. Exclusions: Regular wear and tear, misuse, or unauthorized modifications may void the warranty.

Always read the warranty terms carefully and consult the manufacturer for specifics.

Support

Proper support services are essential for the crane’s optimal performance and longevity. Key support services include:

1. Technical Support: Assistance with installation, troubleshooting, and operational guidance, often available via phone, email, or online portals.

2. Maintenance Services: Scheduled maintenance programs can be offered, either as a part of the purchase package or as an add-on service.

3. Training: Operational and safety training for your personnel to ensure the crane is used effectively and safely.

4. Emergency Services: Access to emergency repair services to minimize downtime in case of unexpected failures.

5. Spare Parts Availability: Assurance of ready availability of genuine spare parts, vital for timely repairs and maintenance.

Ensure you discuss these aspects with the sales representative to fully understand the scope and limitations. A comprehensive warranty and robust support system will safeguard your investment and ensure your 5-ton overhead gantry crane operates efficiently for years to come.

List “5 ton overhead gantry crane” FAQ

FAQs for 5-Ton Overhead Gantry Crane

1. What is a 5-ton overhead gantry crane?

A 5-ton overhead gantry crane is a lifting device designed to move heavy materials and equipment across a workspace. It has a lifting capacity of 5 tons (10,000 lbs) and typically runs on a track system, offering overhead lifting without the need for permanent structure alterations.

2. Where can I use a 5-ton overhead gantry crane?

Ideal for warehouses, factories, assembly lines, and shipping yards, these cranes are versatile and can be used both indoors and outdoors wherever heavy material handling is required.

3. What are the key components?

The main components include the bridge (horizontal beam), trolley (with hoist), end trucks (support the bridge), and often the track or rail system on which the crane travels.

4. Is the crane easy to install?

Yes, gantry cranes are generally simpler to install compared to fixed overhead cranes. They require less structural modification and can often be set up and operational in a shorter time frame.

5. Can the gantry crane be moved?

Many gantry cranes feature wheels or casters, making them mobile and allowing them to be moved to different workstations as needed.

6. What types of hoists are compatible?

They are typically compatible with electric, manual, or pneumatic hoists, depending on the specific needs and power sources available.

7. How do I maintain the crane?

Regular inspection and maintenance include checking for wear and tear on the tracks, wheels, and hoist mechanism, ensuring all parts are lubricated as needed, and verifying the integrity of the crane’s structural components.

8. What safety measures should be in place?

Safety measures include load testing, regular inspections, operator training, the use of limit switches, and adherence to safety standards like OSHA guidelines.

9. Are there any customization options?

Yes, gantry cranes can be customized in terms of height, length, and additional features like motorized travel or specialized hooks and attachments.

10. How does a gantry crane compare to a jib crane?

While both are used for lifting, gantry cranes offer more flexibility in covering large areas since they run on tracks, whereas jib cranes have a fixed radius and are more suitable for smaller, localized lifting tasks.

Top 10 FAQ with answer about 5 ton overhead gantry crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQs) regarding sourcing a 5-ton overhead gantry crane from China, along with concise answers:

1. What is the typical cost of a 5-ton overhead gantry crane in China?

The cost can range from $3,000 to $10,000 depending on specifications, materials, and additional features.

2. What are the key specifications to consider?

Important specs include lifting capacity (5 tons), span length, lifting height, speed, power supply, and control system type.

3. How long is the delivery time?

Standard delivery times range from 30 to 60 days, depending on the manufacturer’s production schedule and customization needs.

4. Are Chinese gantry cranes compliant with international standards?

Yes, many manufacturers comply with international standards like ISO, CE, and others. Always request certifications.

5. Can I get custom designs?

Absolutely. Most Chinese manufacturers offer custom designs to meet your specific requirements.

6. What about after-sales service and warranty?

Typically, manufacturers offer 12-24 months warranty and some provide after-sales service including technical support, installation assistance, and spare parts supply.

7. How is the quality control managed?

Reputable manufacturers have stringent quality control processes including material checks, manufacturing process inspections, and final product testing.

8. What are the payment terms?

Common payment terms include T/T (Telegraphic Transfer) with a 30% deposit and 70% balance before shipment, but terms can vary.

9. Is installation support available?

Yes, many companies offer installation support either through on-site technicians or detailed guides and remote assistance.

10. What shipping options are available?

Cranes are typically shipped by sea in containers. FOB (Free on Board) and CIF (Cost, Insurance, and Freight) are common shipping terms.

When sourcing a 5-ton overhead gantry crane from China, thoroughly research potential suppliers, verify certifications, and clearly communicate your requirements to ensure you receive a quality product that meets your needs.