500 ton crane Safety Certifications

When operating a 500-ton crane, several safety certifications and regulations must be adhered to, ensuring safe operation and compliance with industry standards. Here are the key certifications and considerations:

1. OSHA Compliance: The Occupational Safety and Health Administration (OSHA) sets the framework for crane operation safety in the U.S. Operators must comply with OSHA 29 CFR 1926 Subpart CC, which covers cranes and derricks in construction.

2. Cranes and Derricks in Construction (29 CFR 1926 Subpart CC): This includes specific requirements for assembly/disassembly, operation, inspections, and qualifications of operators.

3. ANSI/ASME B30 Standards: The American Society of Mechanical Engineers (ASME) provides comprehensive standards for cranes through the B30 series, which include detailed safety protocols for all crane types.

4. Certification by Accredited Bodies: Crane operators in the U.S. must be certified by a recognized body such as the National Commission for the Certification of Crane Operators (NCCCO). This involves passing written and practical exams.

5. Annual Inspections: Cranes must undergo annual inspections performed by qualified personnel to ensure all components are functioning correctly. These inspections should be documented as per ASME B30.5.

6. Load Testing: A load test may be required after installation or modification to verify the crane’s capability to handle its rated capacity safely.

7. Operator Training: Operators should receive rigorous training that includes understanding crane controls, load charts, safety devices, and emergency procedures.

8. Site-Specific Considerations: Safety assessments must be conducted at each job site to address unique hazards. This includes factors such as ground stability, overhead power lines, and wind conditions.

9. Personal Protective Equipment (PPE): Operators and ground crew must wear PPE such as helmets, high-visibility vests, safety boots, and gloves.

Ensuring these certifications and safety measures are in place helps mitigate risks and ensures the safe and efficient operation of a 500-ton crane.

List Reference Technical Parameters of “500 ton crane”

Certainly! Here are some key technical parameters typically associated with a 500-ton crane:

1. Lifting Capacity

– Maximum Capacity: 500 tons (or 1,000,000 lbs).

– Load Chart: Varies with boom length and radius, critical for lifting capabilities at different positions.

2. Boom Specifications

– Main Boom Length: Typically ranges from 40 to 140 feet.

– Lattice Boom: Optional, extends reach up to 300+ feet depending on configuration.

– Jib Attachments: Auxiliary jibs can provide additional height and reach.

3. Dimensions

– Overall Length: Usually around 50-70 feet (depends on crane model).

– Overall Width: Generally about 10-12 feet for transportability.

– Height: Approximately 12-14 feet in transport mode.

4. Mobility

– Chassis Type: Available in truck-mounted, crawler, and all-terrain options.

– Travel Speed: Up to 40-50 mph for truck-mounted types.

– Gradeability: Typically ranges from 30-50%, important for site access.

5. Outriggers and Stabilization

– Outriggers Spread: Up to 35-45 feet for maximum stability.

– Stabilizers: Hydraulic or pneumatic options available.

6. Engine and Power

– Engine Type: Diesel engines, usually compliant with emission standards (Tier 4 or equivalent).

– Horsepower: Typically between 400-600 HP, depending on the model.

– Fuel Capacity: Around 100-200 gallons.

7. Hydraulics and Controls

– Hydraulic System Pressure: Usually around 5000 psi.

– Control System: Modern cranes utilize computerized load moment indicators (LMI) and joystick controls.

8. Safety Features

– Load Moment Indicator (LMI): Essential for preventing overload.

– Anti-Two-Block System: Prevents collisions between hook block and boom tip.

– Emergency Stop: Easily accessible in operator cab and remote controls.

9. Operational Range

– Lifting Radius: Generally between 10 to 90 feet, though this can extend with boom and jib configurations.

– Lifting Height: Can reach up to 400+ feet with full attachments.

10. Auxiliary Features

List Product features of “500 ton crane”

A 500-ton crane is a powerful, versatile heavy-lifting machine used in many industries such as construction, shipping, and heavy engineering. Here are some key features:

1. Massive Lifting Capacity: Designed to lift up to 500 tons, ideal for large-scale projects.

2. Telescopic Boom: Extendable boom that can reach significant heights, sometimes up to 200 feet or more.

3. Hydraulic Systems: Advanced hydraulics for precise and efficient lifting operations.

4. Mobility: Often mounted on wheels or tracks for ease of movement on different terrains.

5. Stabilizers and Outriggers: Enhanced stability during lifting tasks with adjustable outriggers.

6. Operator Cab: Ergonomic and climate-controlled cab providing operator comfort and better controls.

7. Safety Features: Equipped with load moment indicators, anti-two block systems, and overload protection.

8. Remote Control Capability: Some models offer remote operation for added safety and precision.

9. Diesel Engine: Typically powered by a robust diesel engine, ensuring high torque and reliability.

10. Customizable Attachments: Can be fitted with different hooks, jibs, and other attachments to suit various tasks.

11. Advanced Controls: Modern control systems with touchscreen interfaces, diagnostics, and automation features.

12. Durability: Built with high-strength steel and designed to withstand harsh environments.

13. Fast Setup and Teardown: Designed for quick assembly and disassembly, reducing downtime.

14. Eco-Friendly Options: Some models offer eco modes or hybrid technologies for reduced emissions.

15. Regulatory Compliance: Meets or exceeds industry safety and environmental standards.

These features make the 500-ton crane invaluable for heavy-duty lifting tasks, combining power, precision, and versatility.

List Various Types of “500 ton crane”

A 500-ton crane represents a powerful piece of machinery used in heavy lifting and large-scale construction projects. Here are various types of 500-ton cranes, categorized based on their design and application:

1. Mobile Cranes

– All-Terrain Cranes: These cranes are versatile and can be used on various terrains, both on-road and off-road. Example: Liebherr LTM 1500-8.1.

– Rough Terrain Cranes: Designed specifically for off-road operations with enhanced maneuverability. Example: Terex RT 100US.

– Truck-Mounted Cranes: Crane units mounted on a truck carrier, facilitating quick transport to the job site. Example: Grove GMK5250L.

2. Crawler Cranes

– These cranes move on tracks (crawlers), providing stability and mobility on uneven surfaces. They are ideal for long-term projects where the crane needs to be stationary for extended periods. Example: Liebherr LR 1500.

3. Tower Cranes

– Typically used in the construction of tall buildings. While not typically described by weight capacity, some heavy-lift tower cranes can reach up to and beyond 500 tons by incorporating modular components. Example: Favelle Favco M2480D.

4. Barge Cranes

– Also known as floating cranes, these are mounted on a barge and used for marine construction projects, such as bridge building over water bodies. Example: Manitowoc 21000.

5. Fixed Cranes

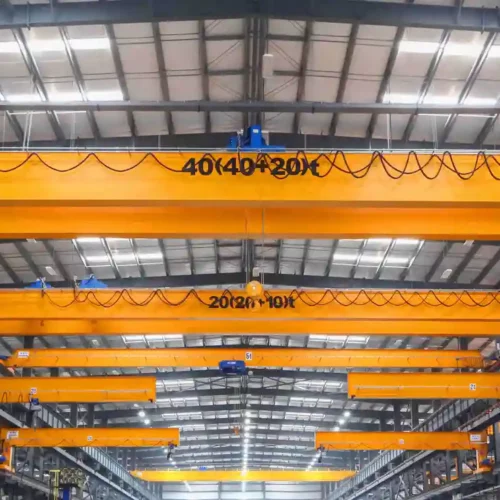

– Gantry Cranes: These cranes have a hoist that moves horizontally along rails, often used in shipyards for lifting heavy loads. Example: Konecranes Goliath Crane.

– Overhead Cranes: Common in industrial environments, they consist of a hoist attached to a horizontal beam. Example: Demag ZKKE Double-Girder Overhead Crane.

Each type of 500-ton crane is designed for specific applications, providing unique benefits to enhance efficiency in varying construction and lifting tasks.

List Application of “500 ton crane”

A 500-ton crane is a highly versatile and powerful piece of equipment with a wide range of applications across various industries. Here are some key applications:

1. Construction:

– Skyscraper Assembly: Lifting heavy steel beams, concrete panels, and other construction materials to great heights.

– Bridge Construction: Installing large bridge sections and supporting structures.

– Wind Turbine Installation: Erecting tall wind towers and heavy turbine components.

2. Industrial:

– Manufacturing Plants: Positioning of heavy machinery and equipment during plant setup or maintenance.

– Power Plants: Lifting and placing large generators, transformers, and other critical components.

3. Shipping and Logistics:

– Shipbuilding: Moving heavy ship sections and components during assembly or repair.

– Port Operations: Unloading and handling oversized and heavy cargo like containers, machinery, and vehicles.

4. Oil and Gas:

– Offshore Rigs: Installing heavy drilling equipment and modules on oil platforms.

– Refineries: Lifting and positioning large pipes, tanks, and industrial units.

5. Infrastructure Development:

– Railways: Installing bridges, tracks, and other heavy railway infrastructure.

– Road Projects: Lifting and installing large pre-cast concrete elements like beams and pillars.

6. Emergency and Recovery Operations:

– Disaster Recovery: Removing large debris after natural disasters like hurricanes, earthquakes, or floods.

– Accident Recovery: Uprighting overturned vehicles or heavy equipment involved in accidents.

7. Entertainment and Events:

– Event Setup: Assembling large stages, sets, and other structures for major events, concerts, or exhibitions.

– Film Industry: Positioning large set pieces, props, and even creating dynamic effects for action scenes.

These applications underscore the importance of a 500-ton crane in advancing numerous heavy-duty tasks across diverse sectors efficiently and safely.

List Buyer Types of “500 ton crane”

When it comes to purchasing a 500-ton crane, the buyers typically fall into several categories based on their industry, needs, and usage scenarios. Here’s a concise overview:

1. Construction Companies:

– These firms commonly use heavy cranes for building high-rise structures, bridges, and large infrastructures. The cranes are crucial for lifting large building materials and prefabricated sections.

2. Oil and Gas Industry:

– Companies in this sector utilize 500-ton cranes for tasks such as installing and maintaining oil rigs and refineries. The cranes’ ability to handle massive loads is invaluable in these complex operations.

3. Heavy Manufacturing:

– Manufacturers of large machinery and industrial equipment often require heavy-duty cranes to move materials within their production facilities or to transport finished products.

4. Shipbuilding and Maritime:

– Shipyards use these cranes to assemble ship components, launch ships into the water, and manage heavy materials and equipment.

5. Wind Energy Sector:

– The installation of wind turbines, which can be very tall and heavy, often necessitates the use of 500-ton cranes. These cranes are essential for both assembling and maintaining wind farms.

6. Mining Operations:

– Large mining projects may employ heavy cranes to lift heavy mining equipment and to assist in the construction of necessary infrastructure, such as conveyor systems and processing plants.

7. Rental and Leasing Companies:

– Companies that specialize in leasing heavy machinery to other businesses often buy 500-ton cranes to rent them out on a project-by-project basis.

8. Logistics and Transportation Firms:

– These companies may utilize heavy cranes for loading and unloading heavy transport goods, particularly in ports and large distribution centers.

9. Infrastructure Development Firms:

– Municipal and governmental bodies working on large-scale infrastructure projects, such as highways, dams, and airports, often require the capabilities of a 500-ton crane.

Each buyer type is driven by the specific demands of their industry, the scale of operations, and the nature of the projects they undertake.

List “500 ton crane” Project Types for Different Industries

A 500-ton crane is a versatile piece of heavy machinery used across various industries for lifting and moving heavy loads. Here are some project types for different industries where a 500-ton crane might typically be employed:

Construction

1. High-Rise Building Construction: Lifting steel beams and large concrete panels.

2. Bridge Construction: Erecting bridge segments and placing large precast deck units.

3. Wind Farm Installation: Setting up heavy wind turbine components.

Oil & Gas

1. Offshore Platforms: Lifting modules and equipment on oil rigs and platforms.

2. Refinery Maintenance: Moving heavy machinery and materials during turnarounds.

3. Pipeline Construction: Laying large sections of pipeline and associated infrastructure.

Power Generation

1. Nuclear Plants: Handling reactor components and heavy shielding materials.

2. Thermal Power Stations: Lifting heavy boiler components and turbines.

3. Hydroelectric Projects: Installing large turbines and generators.

Shipping & Logistics

1. Shipbuilding: Positioning large sections of the hull and superstructure.

2. Port Operations: Moving heavy cargo containers and oversized equipment.

3. Material Handling: Loading and unloading heavy cargo from ships and trucks.

Mining

1. Equipment Installation: Placing large mining drills and earthmoving equipment.

2. Relocation Projects: Moving heavy machinery between sites.

3. Infrastructure Development: Erecting heavy-duty structures for mining operations.

Aerospace

1. Aircraft Assembly: Positioning large components during airplane assembly.

2. Spacecraft Construction: Handling large modules and spacecraft components.

3. Facility Setup: Installing heavy equipment in aerospace manufacturing plants.

Infrastructure

1. Telecom Towers: Erecting large communication towers and antennas.

2. Water Treatment Plants: Lifting heavy filter units and storage tanks.

3. Railways: Placing heavy rail bridges and track-laying machinery.

Each of these project types leverages the immense lifting capacity and versatility of a 500-ton crane, ensuring efficient and safe handling of heavy-load tasks.

500 ton crane Accessories Upgrades and Custom Manufacturing Options

When optimizing the performance and versatility of a 500-ton crane, various accessories, upgrades, and custom manufacturing options can greatly enhance capability and efficiency. These include:

1. Boom Extensions: Extended boom lengths can reach greater heights and distances, enhancing the crane’s operational range.

2. Jib Attachments: Fixed or luffing jib attachments increase the lifting versatility and are invaluable for complex hoisting tasks in confined spaces.

3. Hydraulic Configurations: Upgraded hydraulic pumps and cylinders improve lifting speed and precision, enhancing overall efficiency.

4. Safety Enhancements: Custom safety features such as anti-collision systems, load moment indicators, and advanced rigging sensors ensure operational safety and compliance.

5. Wireless Controls: Remote operation capabilities allow for more precise maneuvering from a safe distance, enhancing flexibility and safety.

6. Customized Counterweights: Tailored counterweight configurations can optimize stability and lift performance for specific tasks.

7. Enhanced Mobility: Upgraded undercarriages, like all-terrain configurations or tracked options, provide better maneuverability across different terrains.

8. Cabin Comfort: Operator cabins can be customized for better ergonomics, featuring climate control, advanced interface systems, and improved visibility.

9. Eco-Friendly Options: Options such as hybrid power systems and energy-efficient components can reduce the environmental footprint.

10. Specialized Lifting Attachments: Custom hooks, spreader beams, and lifting fixtures can be designed for unique lifting requirements, accommodating a wider array of tasks.

11. Software Upgrades: Advanced control software with diagnostics, maintenance scheduling, and performance analytics ensure optimal operation and reduce downtime.

12. Material Handling Systems: Integration of specialized material handling systems like conveyor belts or lifting magnets can expedite specific tasks.

Leveraging these accessories, upgrades, and custom manufacturing options ensures that a 500-ton crane remains versatile, efficient, and capable of meeting diverse operational needs.

List Quality Control and The Manufacturing Process of “500 ton crane”

Quality Control in 500 Ton Crane Manufacturing

1. Material Inspection: Verify that steel and other raw materials meet industry standards.

2. Welding Inspection: Use techniques like ultrasonic testing to ensure weld integrity.

3. Dimensional Checks: Confirm that all parts fit precisely through CAD and physical measurements.

4. Load Testing: Simulate loads to verify strength and stability.

5. Hydraulic System Testing: Test cylinders, valves, and hydraulic lines for leaks and performance.

6. Electrical System Testing: Ensure all electrical components and circuits function correctly.

7. Non-Destructive Testing (NDT): Use NDT methods to detect internal flaws.

8. Final Inspection: Comprehensive review of the assembled crane, including a functional test.

Manufacturing Process of a 500 Ton Crane

1. Design and Engineering: Create detailed designs using CAD software, considering weight and load specifications.

2. Material Procurement: Source high-quality steel and other essential materials.

3. Cutting and Shaping: Use CNC machines to cut and shape steel components.

4. Welding and Assembly: Weld parts, ensuring structural integrity; assemble sub-components like the boom, jib, and base.

5. Machining: Precision machining for critical components like gears and bearings.

6. Hydraulic System Assembly: Integrate hydraulic components, ensuring seamless function.

7. Electrical System Integration: Install and wire electrical components, including control systems.

8. Surface Treatment: Apply anti-corrosive coatings and paint.

9. Pre-Assembly Inspection: Inspect and test individual sub-assemblies.

10. Final Assembly: Combine all parts into the fully functional crane.

11. Testing: Perform rigorous functional and load testing to ensure safety and performance.

12. Quality Assurance: Conduct a final quality check before dispatch.

Adhering to these quality control measures and manufacturing steps ensures that the 500-ton crane meets stringent industry standards, ensuring safety, reliability, and performance.

How to use “500 ton crane”

Using a 500-ton crane safely and effectively requires adhering to strict guidelines and procedures. Here’s a step-by-step guide:

Pre-Operation Steps:

1. Training & Certification:

– Ensure all operators are certified and experienced in handling heavy-duty cranes.

2. Inspection:

– Conduct a thorough inspection of the crane, including checks for mechanical and structural integrity.

– Verify the crane’s load chart for capacity limits and boom configurations.

3. Planning:

– Collaborate with engineers to develop a lift plan, taking into account the weight, dimensions, and center of gravity of the load.

– Conduct a risk assessment to identify potential hazards.

4. Site Preparation:

– Ensure the ground is stable and level to support the crane’s weight.

– Set up barricades and signage to restrict unauthorized access to the lift area.

Operation Steps:

1. Setup:

– Position the crane so that it is stable and properly balanced.

– Extend outriggers fully and secure them to provide maximum stability.

2. Rigging:

– Use proper slings and rigging equipment rated for the load’s weight.

– Double-check all connections to ensure they are secure and well-distributed.

3. Communication:

– Establish clear communication protocols with ground personnel. Use hand signals or radios for clarity.

4. Test Lifts:

– Perform a test lift to check for balance and stability before proceeding with the actual lift.

5. Lifting:

– Gradually lift the load, keeping movements smooth to avoid unnecessary swinging.

– Maintain a slow and steady pace, constantly monitoring stress and strain on the crane.

6. Setting Down:

– Lower the load slowly and precisely onto its designated spot.

– Once in place, disconnect rigging carefully to avoid sudden shifts.

Post-Operation Steps:

1. Inspection:

– Conduct a post-operation inspection to identify any wear or damage to the crane.

2. Documentation:

– Document the lift with detailed records, including any incidents and the performance of the crane.

3. Maintenance:

– Schedule routine maintenance to keep the crane in optimal condition.

Safety Tips:

– Regularly update and refresh your training.

– Always adhere to manufacturer guidelines.

– Never exceed the crane’s rated capacity.

Adhering to these steps ensures safe, efficient, and effective use of a 500-ton crane.

“500 ton crane” Comparative Analysis

A “500 ton crane” signifies a crane with a lifting capacity of 500 tons. Such cranes are critical in heavy lifting and large-scale construction projects. Comparative analysis of different 500-ton cranes can focus on key aspects like design, mobility, operational efficiency, and technological integration.

Design and Build:

– Crawler Cranes: These cranes use tracks for mobility, making them ideal for uneven terrains. They offer stability without the need for outriggers but are slower to move.

– Mobile Cranes: Mounted on truck chassis, these cranes provide excellent mobility on roads and faster set-up times, enhancing operational flexibility.

Mobility:

– Crawler: Limited to site movement; relocation requires disassembly and transport via trailers.

– Mobile: Can travel on public roads, making them more versatile for multi-site projects.

Operational Efficiency:

– Setup Time: Mobile cranes typically have shorter setup times owing to their built-in hydraulic systems.

– Cost and Logistics: Crawler cranes entail higher initial setup costs and complex logistics due to disassembly requirements, but they offer superior lifting capacities in challenging environments.

Technological Integration:

– Control Systems: Advanced models feature computer-aided controls for precision lifting, load monitoring, and enhanced safety.

– Telematics: Modern cranes incorporate telematics for real-time monitoring of performance, usage metrics, and predictive maintenance, reducing downtime and operational costs.

In summary, 500-ton cranes, whether crawler or mobile, are indispensable in heavy lifting scenarios. The choice between them hinges on project-specific requirements such as site conditions, mobility needs, and setup constraints, with each type offering unique benefits tailored to varied industrial applications.

“500 ton crane” Warranty and Support

Warranty and Support for 500 Ton Crane

#### Warranty

Our 500-ton crane comes with a comprehensive warranty to ensure peace of mind and optimal performance. The standard warranty period covers 24 months from the date of delivery or 2,400 operational hours, whichever comes first. This warranty includes coverage for manufacturing defects in materials and workmanship. All major components such as the engine, hydraulic systems, and structural frame are included under this warranty. Any repair or replacement of defective parts will be performed free of charge during this period, provided that the crane is operated under normal conditions and in compliance with the manufacturer’s guidelines.

#### Support

Technical Assistance: Our skilled technicians and engineers are available 24/7 to provide remote support and guidance. We offer swift diagnostic services to minimize downtime and keep your operations running smoothly.

On-Site Service: In the event of a more complex issue, our team of certified professionals is equipped to provide on-site service and repairs. We have a global network of service centers and highly trained technicians to respond promptly to your needs.

Training Programs: We offer extensive operator and maintenance training programs to ensure that your staff is fully equipped to handle the crane proficiently and safely. Training can be conducted at our facilities or on-site.

Spare Parts Availability: Our global inventory of genuine spare parts ensures quick availability and delivery, minimizing downtime.

Maintenance Contracts: Flexible maintenance contract options are available, ranging from regular inspections to comprehensive service agreements tailored to your operational requirements.

Our commitment is to provide unparalleled support and service to maximize your crane’s efficiency and longevity. For detailed terms and conditions, please refer to the warranty document provided with your purchase.

List “500 ton crane” FAQ

500 Ton Crane FAQ

1. What is a 500-ton crane?

– A 500-ton crane is a type of heavy-duty lifting machinery capable of lifting loads up to 500 tons. They are often used in construction, heavy industry, and infrastructure projects.

2. What types of 500-ton cranes are available?

– There are mobile cranes (truck-mounted and all-terrain), crawler cranes, and tower cranes with different configurations tailored for specific needs.

3. How high can a 500-ton crane lift?

– Lifting height depends on the crane type and configuration. Generally, a 500-ton crane can reach heights exceeding 100 meters (328 feet) with the appropriate boom and jib attachments.

4. What is the maximum reach of a 500-ton crane?

– The maximum reach varies, but it can extend up to 100 meters (328 feet) horizontally in optimal conditions.

5. What are the common applications for a 500-ton crane?

– These cranes are used for large-scale construction projects, installing heavy equipment, bridge construction, wind turbine installation, and other tasks requiring significant lifting power.

6. What are the transportation requirements?

– Due to their size, transporting a 500-ton crane often requires disassembling it into smaller parts and using multiple trucks. Logistics planning is crucial to ensure timely and safe delivery.

7. How long does it take to set up?

– Setup time can range from several hours to a couple of days, depending on the crane type, site conditions, and the complexity of the project.

8. What are the safety considerations?

– Critical safety measures include proper rigging, load calculations, regular maintenance, operator training, and adherence to manufacturer guidelines and safety regulations.

9. Do I need special permits to operate a 500-ton crane?

– Yes, operating a crane of this capacity typically requires special permits and adherence to local or national regulations. Ensure your operators are certified and that all legal requirements are met.

10. How much does it cost to rent a 500-ton crane?

– The rental cost can vary widely depending on the type, duration, and location but typically ranges from several thousand to tens of thousands of dollars per day.

Understanding these FAQs will help in making informed decisions when utilizing a 500-ton crane for any project.

Top 10 FAQ with answer about 500 ton crane for Buyer Sourcing from China

Certainly! Here are the top 10 FAQs about sourcing a 500-ton crane from China, along with concise answers:

1. What is the lead time for manufacturing and delivery?

– Answer: The typical lead time for manufacturing a 500-ton crane ranges between 3 to 6 months. Shipping takes another 4 to 8 weeks depending on the destination and shipping method.

2. What are the key specifications to look for?

– Answer: Ensure the crane meets your load capacity (500 tons), lifting height, boom length, and mobility requirements. Verify compliance with international standards like CE, ISO, or ASME.

3. What is the cost range of a 500-ton crane?

– Answer: The price varies significantly based on specifications and brand, but typically ranges from $500,000 to $1,200,000. This can vary with additional features or customization.

4. How can I verify the credibility of a Chinese manufacturer?

– Answer: Look for certifications (ISO, CE, etc.), request past client references, check reviews, and consider visiting their factory if possible. Use third-party inspection services for additional verification.

5. Are there financing options available?

– Answer: Many Chinese manufacturers offer financing options or can recommend trusted financial partners. Terms vary, so it’s advisable to discuss directly with the supplier.

6. What are the warranty and after-sales support terms?

– Answer: Warranties typically range from 1 to 2 years. Ensure the manufacturer provides comprehensive after-sales support including spare parts, maintenance, and training.

7. What about customs clearance and import duties?

– Answer: Import duties vary by country. It’s crucial to work with a reliable freight forwarder and customs broker to handle clearance. Ensure all paperwork, including a bill of lading and commercial invoice, is in order.

8. Can the crane be customized to specific needs?

– Answer: Yes, many manufacturers offer customization options such as specific boom lengths, cabin designs, and additional safety features.

9. What are the shipping and logistics considerations?

– Answer: Shipping is typically via sea in specialized containers or as deck cargo due to size. Ensure you discuss logistics early to plan for smooth import handling.

10. How do I ensure proper installation and training?

– Answer: Many suppliers offer on-site installation and training services, often included in the purchase agreement. Ensure these services are clearly outlined in the contract.