all terrain gantry crane Safety Certifications

All terrain gantry cranes are indispensable tools in construction, manufacturing, and logistics due to their versatility and capacity to lift heavy loads. Ensuring their safe operation is paramount. Here are key safety certifications and standards relevant to all terrain gantry cranes:

1. ISO 9001: This international standard specifies requirements for a quality management system (QMS). Companies manufacturing all terrain gantry cranes should be ISO 9001 certified to ensure consistent product quality and customer satisfaction.

2. OSHA (Occupational Safety and Health Administration): In the United States, OSHA standards are critical. Compliance ensures that cranes meet necessary safety requirements. OSHA regulations, particularly those outlined in 29 CFR 1910.179, pertain to overhead and gantry cranes.

3. ASME B30.2: The American Society of Mechanical Engineers (ASME) provides comprehensive safety standards within the B30 series specifically for overhead and gantry cranes, addressing design, inspection, maintenance, and operation.

4. EN 14439: The European standard for cranage covering general-purpose cranes, including all terrain types, ensuring they meet stringent safety and performance requirements in EU countries.

5. CSA B167: In Canada, the Canadian Standards Association (CSA) B167 standard applies to overhead and gantry cranes, providing guidelines for safe operation and construction.

6. LOLER (Lifting Operations and Lifting Equipment Regulations): In the UK, LOLER requires that lifting equipment is used safely, ensuring regular inspections and proper training for operators.

7. FEM (Fédération Européenne de la Manutention): Provides technical guidelines and standards for the design and safe operation of cranes within Europe.

Ensuring adherence to these certifications and standards not only promotes safety but also enhances the reliability and lifespan of all terrain gantry cranes. Operators and supervisors must be trained and vigilant to maintain compliance and avoid accidents.

List Reference Technical Parameters of “all terrain gantry crane”

All terrain gantry cranes are versatile lifting solutions designed for various challenging environments and industries. Below are the key reference technical parameters:

1. Lifting Capacity:

– Ranges typically from 10 tons to over 400 tons depending on the model and design specifications.

2. Span:

– The horizontal distance between the wheels or supports ranges from 5 meters to over 100 meters, tailored to specific application needs.

3. Lifting Height:

– Generally varies from a few meters to more than 50 meters, configured according to operational requirements.

4. Travel Speed:

– Operational travel speed can vary, with loaded speeds typically between 2 to 20 meters per minute and unloaded speeds between 10 to 30 meters per minute.

5. Crane Speed:

– Horizontal movement speed ranges from 10 to 30 meters per minute, dependent on task urgency and crane design.

6. Hoist Speed:

– The lifting speed can range from 1 to 15 meters per minute, with adjustable settings for various load types.

7. Power Supply:

– Electrical power requirements often range from 220V to 440V (3-phase), and may use diesel engines for remote or off-grid applications.

8. Environmental Resistance:

– Designed to operate in temperatures from -40°C to +45°C, and in humid, dusty, or corrosive environments, with specific models equipped for particular adverse conditions.

9. Control System:

– Modern cranes may feature remote control, automated operations, and fail-safe mechanisms, including emergency stop functions and overload protections.

10. Mobility:

– Equipped with robust rubber tires or tracks for movement on uneven terrain, with capabilities for both manual and powered propulsion.

11. Construction Materials:

– Built from high-strength steel or specialized alloys to ensure durability and resilience under heavy load conditions.

12. Safety Features:

– Integrated with anti-sway mechanisms, load cells for weight monitoring, and automatic braking systems.

These parameters ensure the operational efficiency, reliability, and safety of all terrain gantry cranes across diverse applications, from maritime and construction to mining and heavy industry.

List Product features of “all terrain gantry crane”

An all-terrain gantry crane is a versatile and robust lifting solution designed to operate across diverse environments and handle various lifting needs. Here are some key product features:

1. Versatility in Movement: Equipped with rugged wheels and adjustable height capabilities, all-terrain gantry cranes can easily navigate uneven terrain and transition smoothly from indoor to outdoor settings.

2. Adjustable Height and Span: These cranes usually come with adjustable height and span features, allowing users to modify the crane dimensions to suit specific lifting tasks and constraints.

3. High Load Capacity: Built to handle heavy loads, these cranes often have impressive lifting capacities, which can range from a few tons to several hundred tons, catering to a wide array of industrial applications.

4. Weather Resistance: Constructed from durable materials such as high-grade steel, these cranes are designed to withstand extreme weather conditions, including high winds, heavy rain, and temperature fluctuations.

5. Ease of Assembly and Disassembly: Many models offer quick and straightforward assembly and disassembly processes, making them suitable for applications requiring frequent relocation or temporary setups, such as construction sites.

6. Advanced Safety Features: They are equipped with safety mechanisms like overload protection, emergency stop buttons, and limit switches to ensure safe operation and prevent accidents.

7. Motorized and Manual Options: Depending on the application, users can choose between motorized cranes for automated operations or manual versions for hands-on control.

8. Customizable Designs: Manufacturers often provide options to tailor the crane to specific needs, including custom spans, heights, and additional attachments like hoists, trolleys, and specialized rigging.

9. Portability: Designed for mobility, these cranes can be easily transported from one site to another, thanks to features like collapsible legs and detachable components.

10. User-Friendly Controls: Modern models come with intuitive control systems, such as remote controls or integrated control panels, enabling precise and efficient operation.

Overall, all-terrain gantry cranes combine durability, adaptability, and safety, making them essential tools for many industrial and construction sectors.

List Application of “all terrain gantry crane”

All Terrain Gantry Cranes are versatile lifting machines designed to operate in various conditions and terrains. Their flexibility and durability make them suitable for numerous applications across different industries. Here are some common uses:

1. Construction Sites: Ideal for lifting and moving heavy materials such as steel beams, concrete panels, and other construction components over uneven or rough terrain.

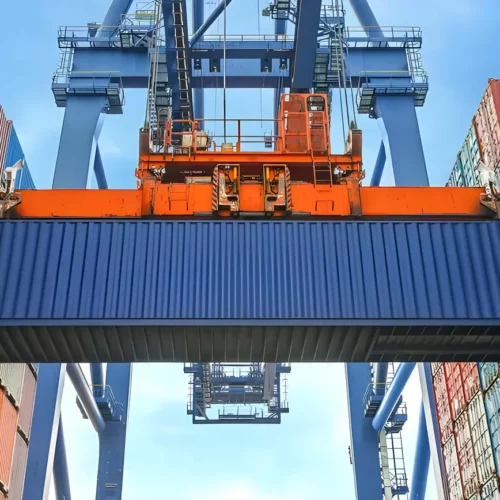

2. Logistics and Warehousing: Utilized for handling large, heavy cargo and containers efficiently, especially in outdoor storage areas where ground conditions may vary.

3. Manufacturing Plants: Employed for moving heavy machinery and parts within factories, particularly those with complex layouts requiring the crane to move across different shop floors.

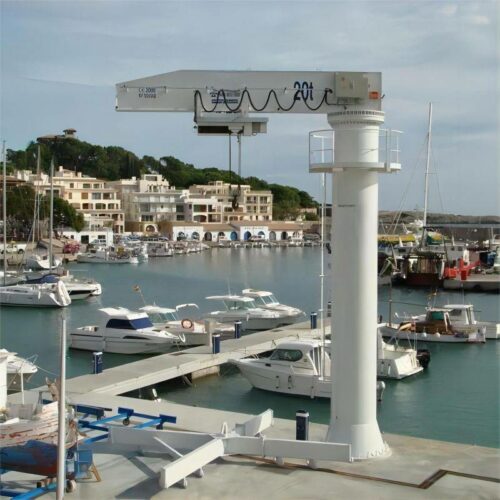

4. Shipyards and Ports: Crucial for transferring oversized ship components, heavy equipment, and containers from docks to storage or transportation vehicles, often dealing with variable ground conditions.

5. Mining Operations: Useful for transporting mining equipment, raw materials, and other large loads across uneven and challenging terrain typical of mining sites.

6. Wind Energy Sector: Deployed for the installation and maintenance of wind turbines, including lifting heavy components like towers, nacelles, and blades in remote or rugged locations.

7. Pipeline Construction: Essential for handling and placing large pipeline sections and related equipment across varied terrain, ensuring efficient and safe construction processes.

8. Bridge and Infrastructure Projects: Critical for the assembly and placement of large structural elements such as girders and pre-cast sections over difficult and varied terrains.

9. Military Applications: Used for handling military vehicles, equipment, and supplies in bases or deployment zones with diverse and sometimes challenging terrains.

All Terrain Gantry Cranes are invaluable across numerous sectors due to their adaptability, robustness, and ability to efficiently handle massive loads in varied and often challenging environments.

List Various Types of “all terrain gantry crane”

All-terrain gantry cranes are versatile units designed to move and lift heavy loads across various ground conditions. Here are some common types:

1. Mobile Gantry Cranes: These cranes are mounted on wheels, allowing easy movement across different terrains, including uneven and rough surfaces. They are ideal for outdoor construction sites and shipping yards.

2. Rubber-Tired Gantry Cranes (RTG): Typically used in container terminals, these cranes feature rubber tires for mobility. They are capable of lifting heavy loads and navigating through tough, uneven ground conditions.

3. Rail-Mounted Gantry Cranes (RMG): These cranes run on fixed rails, providing stability and precision for heavy lifting tasks. While their movement is restricted to rail tracks, they handle heavy loads efficiently in environments like rail yards and ports.

4. Portable Gantry Cranes: Lightweight and easily assembled, these cranes can be dismantled and transported to various locations. They are usually used for less heavy loads but can adapt to various challenging surfaces.

5. Overhead Travelling Gantry Cranes: Typically found in large industrial sites, these combine the features of traditional gantry cranes with enhanced mobility. They move over an overhead track system, making them suited for both indoor and outdoor use on prepared surfaces.

6. Hydraulic Gantry Cranes: These cranes use hydraulic power for lifting and moving loads. They are highly adaptable to uneven terrains and are effective in projects requiring precise placement of heavy objects.

Each type of all-terrain gantry crane offers unique advantages depending on the specific requirements of the job site and the nature of the loads being handled.

all terrain gantry crane Accessories Upgrades and Custom Manufacturing Options

All-terrain gantry cranes are versatile and robust lifting solutions for various industrial applications. To enhance their functionality and adaptability, several accessories, upgrades, and custom manufacturing options are available.

1. Lifting Accessories:

– Spreader Beams: Distribute load evenly, preventing damage to the lifted object.

– Lifting Clamps and Magnets: Securely attach to diverse materials like steel plates and beams.

– Wire Ropes and Chains: Various grades and capacities to meet specific lifting requirements.

– Slings: Available in different materials such as nylon, polyester, and chain for versatile lifting options.

2. Mobility Enhancements:

– Swivel Lock and Pneumatic Tires: For improved maneuverability on uneven terrain.

– Motorized Trolleys: Facilitate easy movement of heavy loads along the gantry.

3. Safety Features:

– Load Indicators and Sensors: Monitor and display load weights to prevent overloading.

– Anti-Collision Systems: Prevent accidents by halting crane movement when detecting obstacles.

– Emergency Stop Buttons: Immediate shutdown capability for enhanced safety during operation.

4. Operational Upgrades:

– Remote Control Systems: Provide operators with flexibility and safe distance operation.

– Variable Speed Drives: Offer precise control over lifting and moving speeds.

– Automatic Lubrication Systems: Reduce maintenance efforts by ensuring consistent lubrication of critical components.

5. Custom Manufacturing Options:

– Height, Span, and Capacity Customization: Tailored to meet specific application requirements.

– Material Choices: Options like aluminum or steel for different durability and weight needs.

– Weatherproofing: For operations in extreme climates, cranes can be equipped with weather-resistant coatings and components.

By leveraging these accessories, upgrades, and custom options, all-terrain gantry cranes can be optimized for efficiency, safety, and specific application requirements, ensuring they meet the diverse needs of various industries.

List Quality Control and The Manufacturing Process of “all terrain gantry crane”

Quality Control

1. Design Validation: Ensure structural integrity and compliance with industry standards.

2. Material Inspection: Verify the quality and specifications of steel and other raw materials.

3. Welding Inspection: Perform non-destructive testing (NDT) like ultrasonic and x-ray exams to ensure weld quality.

4. Component Testing: Test hydraulic systems, motors, and electronics for performance and safety.

5. Load Testing: Simulate real-world conditions to confirm lifting capacity and stability.

6. Alignment and Calibration: Ensure precise alignment of all moving parts and correct calibration of sensors.

7. Final Inspection: Conduct a comprehensive check of the entire crane, including safety features.

8. Documentation: Maintain records of all tests and inspections for traceability.

Manufacturing Process

1. Design and Prototyping: Engineers use CAD software to design the crane and produce initial prototypes for testing.

2. Material Procurement: Source high-quality steel and other materials according to specified standards.

3. Cutting and Shaping: Use CNC machines and plasma cutters to cut and shape components accurately.

4. Welding and Assembly: Skilled welders assemble the mainframe, ensuring strong, reliable joints.

5. Machining: Precision machines finish and drill holes necessary for assembly.

6. Surface Treatment: Apply corrosion-resistant coatings like paint or galvanization.

7. Hydraulic and Electrical Installation: Assemble hydraulic cylinders, pumps, motors, and integrate control systems.

8. Functional Testing: Conduct operational tests to ensure all systems work coherently.

9. Load Testing and Certification: Perform load tests and certify the crane meets safety and performance standards.

10. Final Assembly and Inspection: Add finishing touches, inspect the overall build, and ensure all safety measures are intact before shipping.

This streamlined process emphasizes meticulous quality checks and robust manufacturing techniques to produce reliable, high-performance all-terrain gantry cranes.

How to use “all terrain gantry crane”

An all-terrain gantry crane is versatile and mobile, making it suitable for lifting and transporting heavy loads across different surfaces. Here’s a brief guide on how to safely and effectively use one:

1. Pre-Operational Checks:

– Inspect the Crane: Ensure all components, such as hoists, cables, and wheels, are in good condition. Check for any signs of wear or damage.

– Review Load Capacity: Be aware of the crane’s load limits. Do not exceed the maximum capacity.

2. Site Assessment:

– Evaluate the Terrain: Ensure the operating surface is stable and free of obstacles. Identify any uneven areas and take precautions.

– Plan the Path: Determine the best route for the crane to travel, avoiding sharp turns and steep inclines.

3. Setting Up:

– Position the Crane: Move the crane to the desired location using its motorized or manual drive system. Ensure it’s on stable ground.

– Stabilize: If equipped, deploy outriggers and stabilize pads to secure the crane.

4. Lifting Operations:

– Attach the Load: Secure the load using appropriate lifting gear, ensuring it’s balanced and secure.

– Lift Safely: Use the control panel or remote control to lift the load slowly, ensuring it’s stable before moving.

– Transport: Move the crane and load smoothly, avoiding sudden movements to prevent the load from swaying.

5. Lowering and Unloading:

– Position the Load: Carefully move the crane to the unloading area.

– Lower the Load: Gradually lower the load, ensuring it’s placed securely and safely.

6. Post-Operational Steps:

– Inspect Again: After use, inspect the crane for any issues.

– Store Properly: Park the crane in a designated storage area and secure it to prevent unauthorized use.

By following these steps, you can safely and efficiently operate an all-terrain gantry crane for various lifting tasks.

“all terrain gantry crane” Comparative Analysis

All-terrain gantry cranes serve the dual purpose of offering robust lifting capabilities and mobility across various environments. Here’s a comparative analysis focusing on key differentiators:

1. Mobility vs. Stability:

– Lighter Models: These are ideal for sites with relatively smooth surfaces and limited space. They offer greater mobility but may compromise on the lifting capacity and stability.

– Heavier Models: Designed for uneven or rough terrains, these cranes provide excellent stability and higher lifting capabilities but are less mobile and may require additional setup time.

2. Load Capacity:

– Standard Cranes: Typical all-terrain gantry cranes can lift loads ranging from 5 to 50 tons. They are suitable for moderate construction sites or warehouses.

– Heavy-duty Cranes: For more intensive tasks, heavy-duty models can handle over 100 tons. These are crucial for industrial or large-scale infrastructural projects.

3. Setup Time:

– Simpler Models: Easier and quicker to set up, these cranes are optimal for short-term projects or when frequent relocations are necessary.

– Sophisticated Models: With more complex set-up processes, these cranes offer higher performance and are better suited for long-term projects where setup time is less of a concern.

4. Adaptability to Environment:

– Basic Models: These models may struggle on highly irregular terrains or in adverse weather conditions, limiting their operational window.

– Advanced Models: Equipped with advanced suspension and stabilizing systems, these can operate effectively in diverse and challenging environments, including extreme weather conditions.

5. Cost Consideration:

– Budget-friendly Models: While economical, these cranes may incur higher operational risks and maintenance costs if used in unsuitable terrains.

– Premium Models: Higher upfront costs are offset by durability, fewer operational disruptions, and potentially lower long-term maintenance costs.

6. Technological Integration:

– Basic Models: Limited technological features, focused mainly on essential functionalities.

– Advanced Models: Incorporate GPS, remote control, and automation features to enhance precision, safety, and ease of use.

Selecting the right all-terrain gantry crane involves balancing these factors against the specific requirements of the task, site conditions, budget constraints, and project duration.

“all terrain gantry crane” Warranty and Support

Our All-Terrain Gantry Crane is backed by a comprehensive warranty and support package designed to ensure maximum uptime and reliable operation.

Warranty:

We provide a robust standard warranty for a period of 24 months from the date of delivery or 2000 operational hours, whichever comes first. This warranty covers defects in materials and workmanship under normal use. Components such as structural frames, electrical systems, hydraulic systems, and drive motors are included within the warranty scope. For additional peace of mind, extended warranty options are available for purchase, allowing you to prolong coverage.

Claims Process:

To facilitate easy processing of warranty claims, simply contact our customer service team with the crane’s serial number, a detailed description of the issue, and any relevant supporting documents. Our team will coordinate the inspection, repair, or replacement of defective parts swiftly, minimizing downtime.

Support:

Our dedication to support goes beyond the warranty period. We offer a range of services to ensure your crane operates at peak efficiency throughout its life cycle.

– Technical Support: Available 24/7, our expert technicians can troubleshoot issues remotely or guide you through on-site repairs.

– Maintenance Services: Regular maintenance schedules can be arranged to keep the crane in optimal condition. Preventative maintenance plans are also available.

– Spare Parts: We maintain a comprehensive inventory of spare parts, ensuring quick availability to reduce any operational delays.

Training:

Comprehensive operator and maintenance training programs are provided upon delivery of your crane. These programs are designed to enhance safety and operational efficiency.

Customer Portal:

Access our exclusive customer portal to track service history, schedule maintenance, order parts, and download manuals and updates.

Choose our All-Terrain Gantry Crane and benefit from robust warranty coverage and unparalleled support to keep your operations running smoothly and efficiently.

List “all terrain gantry crane” FAQ

All Terrain Gantry Crane FAQ

What is an all terrain gantry crane?

An all terrain gantry crane is a versatile lifting device designed to move heavy loads across various surfaces, including uneven or rough terrains. It is mobile and often features wheels or tracks that enable it to traverse diverse environments.

What are the key features?

– Mobility: Can operate on different terrains, including gravel, dirt, and asphalt.

– Lifting capacity: Ranges from a few tons to several hundred tons.

– Adjustable height and width: Customizable to fit various lifting needs and space constraints.

– Durability: Built to withstand outdoor conditions and heavy-duty usage.

Where is it commonly used?

– Construction sites

– Shipyards

– Industrial facilities

– Outdoor warehouses

How does it operate?

The crane is powered either by electricity, diesel, or a combination of both. Controls can be manual, remote, or automated, allowing for flexible operation depending on the load and the environment.

What safety features are included?

– Load limit indicators

– Emergency stop buttons

– Anti-collision systems

– Stabilizers and outriggers for enhanced balance

How do I choose the right one for my needs?

Consider the following factors:

– Load capacity

– Terrain type

– Operational environment

– Height and width adjustments required

– Power source preference

What maintenance is required?

Regular inspections for wear and tear, lubricating mechanical parts, checking electrical systems, and ensuring safety mechanisms are functional.

Are there any certifications needed?

Compliance with industry standards and certifications like OSHA (Occupational Safety and Health Administration) may be required. Check local regulations for specific certification requirements.

How do I get training for operating one?

Training programs are often provided by manufacturers or certified training institutes. It’s crucial for operators to be trained and certified to ensure safe operation.

What are the cost factors?

Costs vary based on lifting capacity, customization, power source, and additional features like automation and safety enhancements. Maintenance and operational costs should also be considered.

Feel free to contact manufacturers or suppliers for specific questions and detailed requirements.

Top 10 FAQ with answer about all terrain gantry crane for Buyer Sourcing from China

1. What is an All Terrain Gantry Crane?

An all-terrain gantry crane is a mobile crane equipped with rubber tires and outriggers, capable of operating on various surfaces like rough terrain, paved roads, and more. It combines the mobility of a wheeled crane with the lifting capacity of a gantry crane.

2. What Are the Key Specifications to Consider?

Key specifications include lifting capacity, span length, lifting height, wheelbase, travel speed, and power source. Ensure these match your operational needs and site conditions.

3. Are These Cranes Compliant with International Standards?

Yes, most reputable manufacturers in China design all terrain gantry cranes in compliance with international standards like ISO, ANSI, and CE. Verify certifications before purchasing.

4. How Reliable are Chinese Manufacturers?

Chinese manufacturers vary in reliability. It is crucial to research and select reputable ones with good track records, robust quality control processes, and positive customer reviews.

5. What is the Average Lead Time for Delivery?

Lead times can vary based on order quantity and complexity, but generally, it ranges from 4 to 12 weeks. Always confirm this with the supplier considering manufacturing and shipping times.

6. What Inspection and Testing are Done?

Reputable manufacturers typically conduct extensive quality inspections and testing, including load testing, stability testing, and electrical component checks before delivery. Request detailed reports.

7. What is the Warranty Period?

Warranty periods vary but usually range from 12 to 24 months. Confirm this with the supplier along with what parts and services are covered under the warranty.

8. How is After-Sales Support Managed?

Many suppliers provide online and on-site support. Ensure they offer comprehensive after-sales services, including spare parts availability, technical support, and maintenance training.

9. How is Shipping and Installation Handled?

Suppliers usually handle shipping logistics and can provide installation and commissioning services or detailed installation manuals. Discuss these details beforehand.

10. Are Customizations Available?

Yes, most manufacturers offer customization to meet specific requirements such as special lifting capacities, dimensions, and additional features. Clearly communicate your needs to the supplier.

By addressing these questions, buyers can make more informed decisions when sourcing all terrain gantry cranes from China.