aluminium gantry crane Safety Certifications

When selecting or operating an aluminium gantry crane, it is essential to ensure adherence to relevant safety certifications to secure a safe working environment and to comply with regulatory mandates. Below are key certifications and guidelines:

1. OSHA (Occupational Safety and Health Administration):

– 29 CFR 1910.179: Outlines overhead and gantry cranes’ safety requirements, including design, maintenance, inspection, and operation protocols.

2. ANSI/ASME (American National Standards Institute/American Society of Mechanical Engineers):

– ASME B30.17: Establishes safety requirements for the construction, installation, inspection, testing, maintenance, and operation of overhead and gantry cranes.

3. EN 15011 (European Norm):

– Specifies safety requirements for the design, calculations, stability, and testing of bridge and portal cranes.

4. ISO 9927-1:

– Sets guidelines for the inspection, testing, and maintenance of cranes, ensuring interoperability across different countries.

5. CE (Conformité Européene) Marking:

– Serves as a declaration by the manufacturer that the crane conforms to applicable European health, safety, and environmental protection standards.

6. LOLER (Lifting Operations and Lifting Equipment Regulations) 1998:

– UK regulation that places duties on people and companies who own, operate, or have control over lifting equipment. It covers the need for safe installation, use, and maintenance.

Regular audits, operator training, and consistent maintenance checks conforming to these standards are critical for the safety and longevity of an aluminium gantry crane. Ensuring compliance with these certifications helps in mitigating risks, preventing accidents, and fostering a safe working environment.

List Reference Technical Parameters of “aluminium gantry crane”

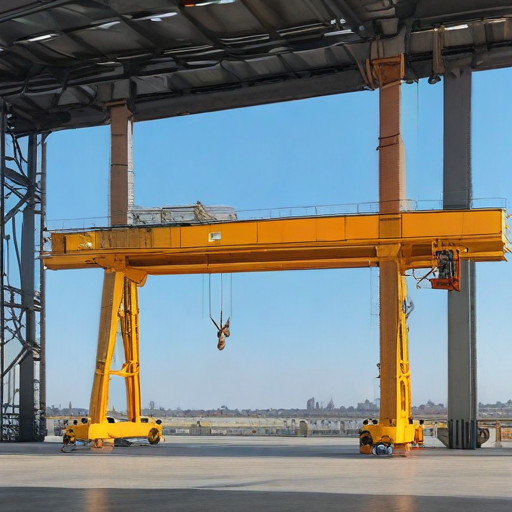

An aluminium gantry crane is a versatile lifting device used in various industries for heavy lifting and material handling. The reference technical parameters critical to its functionality include:

1. Load Capacity: Defined in tons, common capacities range from 0.5 to 5 tons, indicating the maximum weight the crane can safely lift.

2. Span: The horizontal distance between the runway rails, typically ranging from 2 meters to 10 meters. This determines the width of the area that can be served by the crane.

3. Lifting Height: The maximum vertical distance the hoist can lift an object, usually between 2 meters and 6 meters, dependent on application needs.

4. Adjustable Height: Many aluminium gantry cranes offer adjustable height features, allowing flexibility in lifting operations, with typical ranges from 2 meters to 5 meters.

5. Material Construction: Primarily constructed from high-strength aluminium alloy for a combination of lightweight and high load-bearing capacity, which also provides corrosion resistance and ease of mobility.

6. Portability: Lightweight design facilitates relocation and setup, often featuring collapsible or modular construction for ease of transport.

7. Wheel Type: Equipped with polyurethane or rubber wheels for smooth movement and reduced floor damage, often with lockable casters to stabilize the crane during operation.

8. Beam Type: The horizontal beam is generally an I-beam or H-beam, optimized for strength and minimal deflection under load.

9. Height Under Beam: The distance from the floor to the lowest point of the beam, which helps in determining the maximum size of the load that can be moved without hitting the beam.

10. Hoist System: Either manual, electric, or pneumatic hoists are used, depending on the lifting requirements. Electric hoists often come with variable speeds for precise control.

11. Safety Features: Includes overload protection, emergency stop controls, and safety latches on hooks to prevent unintentional load release.

12. Compliance Standards: Adherence to industry standards like ASME, OSHA, and ISO ensures safety, reliability, and performance.

These parameters collectively define the operational scope and efficiency of an aluminium gantry crane, making it an essential tool in manufacturing, construction, and warehousing environments.

List Product features of “aluminium gantry crane”

Certainly! Here are the product features of an aluminium gantry crane, concisely listed:

1. Lightweight Design: Aluminium construction makes the crane significantly lighter than steel alternatives, facilitating easier transportation and maneuverability.

2. Adjustable Height: Many models offer height adjustability to cater to different lifting requirements, providing versatility in various work environments.

3. Corrosion Resistance: The aluminium build ensures resistance to rust and corrosion, making it suitable for both indoor and outdoor applications, even in harsh environments.

4. Easy Assembly and Disassembly: Typically designed for tool-less or minimal-tool assembly, allowing for quick setup and teardown, enhancing portability and storage convenience.

5. Load Capacity: Despite their lightweight structure, aluminium gantry cranes can often support substantial loads, ranging from a few hundred kilograms to several tons.

6. Mobility: Equipped with caster wheels, often lockable, for easy movement around the workspace, enhancing flexibility in positioning.

7. Wide Applications: Suitable for various industries including manufacturing, warehousing, automotive, and maintenance operations, offering a broad range of utility.

8. Safety Features: Often equipped with safety mechanisms such as locking pins and secure fasteners to ensure stable and secure lifting operations.

9. Customizable Options: Some manufacturers offer customization options to tailor the crane to specific job requirements, including different beam lengths, heights, and load capacities.

10. Forklift Pockets: Some models feature forklift pockets for easy lifting and transport of the gantry crane by a forklift, adding to the ease of mobility.

11. Durability: Made from high-strength aluminium alloys that provide long-lasting durability and reliability under frequent use.

An aluminium gantry crane is an advantageous tool offering strength, versatility, and ease of use, making it a valuable asset in many heavy-duty applications.

List Various Types of “aluminium gantry crane”

Certainly! Aluminium gantry cranes are popular for their lightweight and corrosion-resistant properties, making them versatile and easy to maneuver. Here’s a list of various types of aluminium gantry cranes:

1. Adjustable Height Aluminium Gantry Cranes: These cranes allow for vertical adjustment, making it convenient to lift loads at different heights according to the specific requirements of a job.

2. Adjustable Span Aluminium Gantry Cranes: Featuring adjustable beam lengths, these cranes provide flexibility in handling loads with varying widths, enhancing adaptability in diverse working environments.

3. Fixed Height Aluminium Gantry Cranes: Known for their robustness and simplicity, fixed height cranes are ideal for applications where a constant lifting height is sufficient, ensuring consistent performance.

4. Adjustable Height and Span Aluminium Gantry Cranes: Combining both adjustable height and adjustable span features, these cranes offer maximum versatility, making them suitable for a wide range of tasks and operational settings.

5. Portable Aluminium Gantry Cranes: Lightweight and easy to dismantle, portable gantry cranes are designed for ease of transportation and rapid assembly, perfect for tasks that require mobility and quick setup.

6. Workstation Aluminium Gantry Cranes: Engineered for specific tasks within a dedicated area, workstation cranes enhance productivity in assembly lines, manufacturing units, and repair facilities by providing reliable lifting solutions.

7. Motorized Aluminium Gantry Cranes: Equipped with motorized mechanisms, these cranes offer powered lifting and traversing, reducing manual effort and increasing efficiency, especially in high-volume operations.

8. Foldable Aluminium Gantry Cranes: Designed for easy storage and portability, foldable gantry cranes can be collapsed when not in use, making them ideal for limited spaces and ease of transportation.

Each type of aluminium gantry crane has its unique features tailored to specific industrial or manufacturing needs, ensuring a suitable option is available for varied operational requirements.

List Application of “aluminium gantry crane”

An aluminium gantry crane is a versatile lifting device characterized by its lightweight, portable nature, and robust lifting capabilities. Here are several key applications:

1. Construction Sites: Aluminium gantry cranes facilitate the lifting and positioning of construction materials like beams, panels, and mechanical components, enhancing efficiency and reducing manual labor.

2. Manufacturing Plants: Used to move heavy machinery parts, tools, and products along assembly lines. They are vital in handling bulky equipment without causing damage or requiring long setup times.

3. Warehousing and Storage: Ideal for loading and unloading heavy pallets, boxes, and containers. They enhance the operational flow in warehouses, ensuring quick and safe material handling.

4. Automotive Industry: Essential for lifting engines, transmissions, and other heavy car components during assembly, maintenance, or repairs, ensuring precise positioning and improved safety.

5. Aircraft Maintenance: In the aerospace sector, these cranes aid in the inspection, repair, and assembly of aircraft components, including engines and landing gear, due to their maneuverability and strength.

6. Water Treatment Plants: Employed to lift and position pumps, valves, and other heavy machinery involved in water and wastewater treatment processes, ensuring maintenance and operational efficiency.

7. Mining Operations: Used to handle heavy mining equipment and materials, making the extraction, transport, and processing tasks more manageable and less time-consuming.

8. Event Setup: Useful in setting up stages, lighting rigs, and sound systems during events and exhibitions. They enable the rapid and precise installation of equipment in venues.

9. Cleanrooms and Laboratories: In scientific and technological research facilities, these cranes handle sensitive equipment like reactors, microscopes, and cleanroom apparatus without contamination risks.

10. Relocation Services: Aid in the safe movement of heavy furniture, machinery, and equipment during office or industrial relocations, ensuring minimal downtime and damage.

Overall, aluminium gantry cranes are invaluable across various industries due to their portability, ease of use, and strong load-bearing capabilities.

List Buyer Types of “aluminium gantry crane”

Certainly! When it comes to purchasing an aluminium gantry crane, various types of buyers can be identified:

1. Construction Companies: These enterprises often need portable lifting solutions to handle heavy materials on job sites. An aluminium gantry crane is ideal for its lightweight and corrosion-resistant properties, beneficial in outdoor or rugged environments.

2. Manufacturing Plants: This includes factories producing machinery, automotive parts, or any heavy equipment. Gantry cranes enable efficient material handling, assembly line processes, and transport of bulky items within the facility.

3. Warehouses and Logistics Providers: Operations requiring frequent moving and lifting of goods benefit from the crane’s mobility and ease of assembly. This includes third-party logistics providers (3PLs) that manage goods for multiple clients.

4. Maintenance Facilities: Industries such as aviation, marine, and automotive where routine maintenance and repair tasks necessitate lifting of engines, airframes, or other substantial components.

5. Pharmaceutical and Chemical Industries: These sectors often require clean, non-corrosive environments. Aluminium gantry cranes meet stringent hygiene and safety standards, making them suitable for handling delicate and hazardous materials.

6. Utility and Energy Companies: Power plants, water treatment facilities, and renewable energy firms often need to lift and transport heavy equipment, such as turbines or generators, making gantry cranes essential.

7. Rental Businesses: Companies specializing in renting out heavy machinery for various industrial applications also invest in portable gantry cranes to offer flexible lifting solutions to their clients.

8. Small Workshops and Artisans: Individual craftsmen or small-scale industrial operations may also invest in these cranes for tasks that require precision and manual handling of heavy objects.

9. Educational and Research Institutions: Universities and research labs where advanced testing and prototyping require the precise handling of various materials and components.

Each of these buyer types seeks the advantages of an aluminium gantry crane, such as lightweight construction, versatility, corrosion resistance, and ease of mobility to enhance their operational efficiency.

List “aluminium gantry crane” Project Types for Different Industries

Aluminium gantry cranes are versatile lifting solutions known for their lightweight, corrosion resistance, and ease of assembly. They find applications across various industries, each requiring specialized project types tailored to specific needs. Here are the primary project types for different industries:

1. Manufacturing Plants

– Assembly Line Support:

Lightweight and quick to set up, ideal for transporting components along the production line.

– Equipment Maintenance:

Portable models for ease in moving around large machinery for repair and general maintenance.

2. Warehousing and Logistics

– Material Handling:

Efficiently move heavy pallets and materials across loading docks and warehouse floors.

– Inventory Management:

Support picking processes by lifting and transferring inventory items.

3. Construction Sites

– On-Site Assembly:

Temporary lifting solutions for assembling and disassembling structural components.

– Component Lifting:

Essential for hoisting beams, pipes, and other construction materials.

4. Aerospace

– Aircraft Component Assembly:

Precision lifting of aircraft parts within assembly hangars.

– Maintenance, Repair, and Overhaul (MRO):

Support in lifting heavy components during aircraft maintenance.

5. Automotive Industry

– Engine and Transmission Lifting:

Facilitate the installation and removal of heavy automotive components.

– Body Shop Operations:

Help in maneuvering large panels and sections during repairs and assembly.

6. Marine and Shipbuilding

– Dry Dock Operations:

Lift and move parts of vessels under repair or construction.

– Component Assembly:

Useful for assembling small to medium-sized boat components.

7. Chemical and Pharmaceutical Plants

– Process Equipment Handling:

Lifting sensors, reactors, and other delicate equipment with minimal risk of contamination due to aluminium’s non-corrosive properties.

– Maintenance Support:

Efficient for periodic equipment maintenance and replacements.

8. Power Generation

– Turbine and Generator Maintenance:

Transport heavy, bulky parts like turbines and generators for repair.

– Component Installation:

Assist in the precise placement of power generation components.

Each industry leverages the unique attributes of aluminium gantry cranes, ensuring safe, efficient, and flexible lifting solutions tailored to their specific operational requirements.

aluminium gantry crane Accessories Upgrades and Custom Manufacturing Options

Aluminum gantry cranes are versatile lifting solutions ideal for various applications due to their lightweight and corrosion-resistant properties. To enhance their functionality, a range of accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Hoists and Trolleys: Available in manual, electric, and pneumatic models to suit different lifting requirements.

2. End Stops: Safety accessories that prevent the trolley or hoist from rolling off the beam.

3. Adjustable Height Kits: Allow the crane height to be adjusted to accommodate different lifting environments.

4. Cable Management Systems: Organize and protect cables and hoses, minimizing clutter and enhancing safety.

5. Outriggers and Stabilizers: Improve stability, especially for mobile gantry cranes, ensuring safe operation.

Upgrades:

1. Motorized Travel: Enhance mobility by integrating motorized trolleys for horizontal movement along the beam.

2. Increased Load Capacity Kits: Kits available to upgrade the load-bearing capacity of the crane for heavier lifting.

3. Weatherproofing: Protective coatings and materials to make the crane suitable for outdoor and harsh environments.

4. Remote Control Systems: Enable wireless operation of the crane, improving safety and convenience.

5. Safety Features: Load sensors, overload protection devices, and anti-sway systems to enhance operational safety.

Custom Manufacturing Options:

1. Beam Length and Height Customization: Tailor the dimensions of the crane to fit specific workspace requirements.

2. Specialized Attachments: Custom-designed hooks, spreader bars, and lifting beams for unique lifting tasks.

3. Paint and Finish Options: Custom colors and finishes to meet corporate branding or environmental resistance needs.

4. Portable and Foldable Designs: Custom crates and frames that can be easily dismantled and transported for temporary job sites.

5. Integration with Existing Systems: Design modifications to integrate seamlessly with pre-existing equipment or workflows.

Embracing these accessories, upgrades, and custom manufacturing options can significantly enhance the adaptability, efficiency, and safety of aluminum gantry cranes, making them an indispensable tool in various industrial applications.

List Quality Control and The Manufacturing Process of “aluminium gantry crane”

Quality Control in Aluminium Gantry Crane Manufacturing

1. Material Inspection:

– Raw Material Testing: Ensure the aluminium meets the required grade and specifications.

– Supplier Audit: Regularly assess suppliers for reliability and quality consistency.

2. Design Verification:

– Engineering Review: Validate designs through simulations and stress testing.

– Prototype Testing: Build and test prototypes to identify potential design flaws.

3. Manufacturing Process Control:

– Machining Inspection: Check precision of CNC-machined parts and components.

– Welding Quality: Perform non-destructive tests like X-ray or ultrasonic testing on weld joints.

4. Assembly Verification:

– Dimensional Check: Ensure all parts fit accurately according to design specifications.

– Functional Testing: Test assembled units for operational efficiency and load-bearing capacity.

5. Final Inspection:

– Surface Finish Inspection: Check for uniform coating and absence of defects.

– Load Testing: Conduct rigorous load tests to ensure the crane functions safely under maximum load conditions.

6. Compliance and Certification:

– Regulatory Compliance Verification: Ensure adherence to relevant industry standards like ISO 9001.

– Documentation and Traceability: Maintain detailed records for every stage of production for quality audits.

Manufacturing Process of Aluminium Gantry Crane

1. Design and Engineering:

– Computer-Aided Design (CAD): Use CAD software to create detailed designs and specifications.

– Simulation: Perform simulations to predict performance and identify issues.

2. Material Preparation:

– Cutting: Aluminium sheets and profiles are cut to size using laser or water jet cutting.

– Machining: CNC machines shape and drill components with high precision.

3. Component Fabrication:

– Welding: Assemble structural components using MIG or TIG welding.

– Surface Treatment: Apply anodizing or powder coating to enhance corrosion resistance.

4. Assembly:

– Part Integration: Assemble the main frame, wheels, and lifting mechanisms.

– Bolting and Fastening: Secure components with bolts, nuts, and other fasteners.

5. Quality Testing:

– Dimensional and Functional Checks: Verify measurements and test moving parts.

– Load Testing: Subject the crane to static and dynamic load tests.

6. Packaging and Delivery:

– Protective Packaging: Pack components to prevent damage during transit.

– Logistics Coordination: Plan and execute the transportation to the customer site.

How to use “aluminium gantry crane”

Using an aluminium gantry crane involves several steps to ensure safe and efficient operation. Here’s a concise guide on how to use one:

1. Pre-Operation Checks:

– Inspect the Crane: Examine the crane for any visible damage or wear. Check the structural integrity and ensure all bolts and fasteners are secure.

– Check the Workspace: Ensure the ground is stable and free of obstacles. The working area should be clear of unauthorized personnel.

2. Assembly:

– Read the Manual: Always refer to the manufacturer’s instructions for specific assembly guidelines.

– Set Up: Position the crane’s legs at the desired location and ensure they are locked in place. Attach and secure the horizontal beam (also called the girder) across the legs. Use appropriate tools for tightening bolts and connections.

3. Operation:

– Load Attachment: Ensure the load is properly secured using appropriate lifting gear, such as slings, hooks, or chains.

– Hoisting: Use the crane’s hoist to lift the load. Operate the hoist slowly to ensure the load is balanced and stable. Never lift loads beyond the crane’s rated capacity.

– Moving the Load: If the crane is on wheels, carefully move it to transport the load. Ensure the path is clear and move at a controlled pace.

4. Safety Precautions:

– Stay Alert: Always keep an eye on the load and the crane’s surroundings.

– Avoid Overloading: Never exceed the crane’s maximum load capacity.

– Use Proper PPE: Wear personal protective equipment (PPE) like gloves, helmets, and safety boots.

5. Post-Operation:

– Lower the Load: Carefully lower the load at its destination.

– Disassemble if needed: If you need to store the crane, disassemble it following the manufacturer’s guidelines.

– Maintenance: Regularly check the crane for maintenance needs and keep it clean.

By following these steps, you can efficiently and safely use an aluminium gantry crane for lifting and moving heavy loads.

“aluminium gantry crane” Comparative Analysis

A comparative analysis of aluminium gantry cranes reveals distinct advantages and some limitations when juxtaposed with their steel counterparts.

Weight and Portability:

Aluminium gantry cranes are significantly lighter than steel cranes. This reduced weight translates to improved portability and ease of assembly. Ideal for workshops, maintenance, and light manufacturing tasks, aluminium variants can often be handled by fewer personnel, reducing labor costs and setup times.

Corrosion Resistance:

Aluminium boasts inherent resistance to corrosion, making aluminium gantry cranes suitable for environments exposed to moisture and chemicals. This attribute extends the lifespan of the crane, ensuring consistent performance with minimal maintenance. Conversely, steel cranes are prone to rust unless treated with protective coatings, which add to maintenance costs and effort.

Strength and Load Capacity:

Steel cranes generally offer superior load-bearing capacity compared to their aluminium counterparts. This makes steel the preferred choice for heavy lifting applications prevalent in large-scale manufacturing, construction, and shipping industries. Aluminium gantry cranes, while robust for their weight, cater primarily to lighter loads, which may limit their usage in heavy industrial settings.

Price:

Aluminium gantry cranes are typically more expensive upfront due to the material cost of aluminium. However, their longevity and reduced maintenance requirements can offset initial expenses over time. Steel cranes, while cheaper initially, might incur higher maintenance and operational costs, especially in corrosive environments.

Customization and Versatility:

Both aluminium and steel gantry cranes offer broad customization possibilities. Aluminium cranes’ ease of assembly and disassembly provides an added advantage for operations necessitating frequent relocation or adjustment. Steel cranes, though less portable, often feature modular designs adaptable to diverse heavy-duty tasks.

In conclusion, the choice between aluminium and steel gantry cranes hinges on specific application needs. For tasks requiring high mobility, corrosion resistance, and moderate load capacities, aluminium cranes are ideal. Conversely, steel cranes excel where maximum strength and cost-effectiveness for heavy loads are paramount.

“aluminium gantry crane” Warranty and Support

Warranty and Support for Aluminium Gantry Crane

When investing in an aluminium gantry crane, understanding the warranty and support offerings is crucial for long-term satisfaction and operational efficiency. Typically, manufacturers offer a comprehensive warranty period that can range from 1 to 5 years, covering defects in materials and workmanship. During this period, any malfunction or damage caused by manufacturing errors is usually repaired or replaced at no additional cost to the customer.

Support services are equally vital and generally include technical assistance, customer service, and maintenance support. Most reputable manufacturers provide 24/7 customer support through various channels—phone, email, and online chat—to address immediate concerns or troubleshooting needs. Some companies extend their support by offering on-site visits from qualified technicians, especially for complex issues that cannot be resolved remotely.

Preventive maintenance packages are also commonly available, which can help prolong the crane’s lifespan and ensure safety. These packages often include routine inspections, lubrication, and adjustments to key components. Additionally, manufacturers may offer training programs for operators to ensure safe and efficient use of the crane, as well as to minimize the risk of operator-related errors.

For added peace of mind, extended warranty options and service contracts can sometimes be purchased to cover the crane for a longer period. This is an advisable option for businesses that rely heavily on their equipment for daily operations.

Overall, the warranty and support services for an aluminium gantry crane are designed to ensure that your investment remains a valuable and reliable asset for years to come. Always review the specific terms and conditions provided by the manufacturer to fully understand what is covered and any exclusions that may apply.

List “aluminium gantry crane” FAQ

Aluminium Gantry Crane FAQ

1. What is an aluminium gantry crane?

An aluminium gantry crane is a lightweight, portable lifting solution designed for various applications, including construction, manufacturing, and maintenance. It is made primarily of aluminium, which ensures it is both strong and corrosion-resistant.

2. What are the advantages of using an aluminium gantry crane?

The key benefits include portability, ease of assembly, corrosion resistance, and lightweight construction. These cranes are easier to transport and set up compared to their steel counterparts, making them suitable for field applications.

3. What are the typical weight capacities?

Aluminium gantry cranes typically have weight capacities ranging from 500 lbs to 6,000 lbs, depending on the model and design. Always check the manufacturer’s specifications for exact capacities.

4. Are aluminium gantry cranes height-adjustable?

Yes, many aluminium gantry cranes come with height-adjustable features, allowing the user to adapt the crane to different working conditions and requirements.

5. What are the common uses?

Common applications include vehicle maintenance, HVAC installation, construction, machinery loading and unloading, and marine service.

6. How easy is it to transport an aluminium gantry crane?

These cranes are designed for portability. They can typically be disassembled into smaller parts, making them easy to transport in trucks or vans.

7. Do I need special training to operate an aluminium gantry crane?

While no special certification is generally required, it is highly recommended that operators receive training in safe lifting practices and the specific controls of the crane they will be using.

8. How do I maintain an aluminium gantry crane?

Regularly inspect for signs of wear, corrosion, or mechanical issues. Lubricate moving parts as recommended by the manufacturer and ensure all bolts and fasteners are properly tightened.

9. Are there safety features included?

Yes, many aluminium gantry cranes come with safety features such as locking casters, adjustable height settings with secure locking mechanisms, and overload protection systems.

10. Can these cranes operate in outdoor environments?

Yes, the corrosion-resistant properties of aluminium make these cranes well-suited for outdoor environments, though precautions should still be taken in extreme weather conditions.

This FAQ should address the most commonly asked questions about aluminium gantry cranes within a concise format. For specific details, always refer to the manufacturer’s guidelines.

Top 10 FAQ with answer about aluminium gantry crane for Buyer Sourcing from China

Sure! Here are the top 10 FAQs about sourcing aluminium gantry cranes from China, along with concise answers:

1. What are the key benefits of using an aluminium gantry crane?

Aluminium gantry cranes are lightweight, corrosion-resistant, and easy to assemble and disassemble. They offer excellent mobility and versatility for various applications.

2. How do I ensure the quality of an aluminium gantry crane when sourcing from China?

Look for suppliers with ISO 9001 certification and check for compliance with international safety standards. Request for sample products, conduct factory audits, and seek customer reviews.

3. What are the common capacities and sizes available?

Aluminium gantry cranes typically come in capacities ranging from 500 kg to 5 tons. Height and span can vary, so communicate your specific requirements to the supplier.

4. What is the typical lead time for manufacturing and delivery?

The lead time usually ranges from 4 to 8 weeks, depending on customization requirements and order quantity. Always confirm with the supplier.

5. Can I get custom-built aluminium gantry cranes?

Yes, many Chinese manufacturers offer customization options for dimensions, capacity, and additional features to meet specific needs.

6. What certifications should I look for when sourcing?

Ensure that the supplier provides CE, ISO, and other relevant certifications to guarantee product quality and safety standards.

7. What is the cost range for aluminium gantry cranes?

The cost can vary significantly based on capacity, size, and customization options, typically ranging from $1,000 to $10,000.

8. What kind of after-sales support can I expect?

Reliable suppliers often offer a warranty period, technical support, and spare parts availability. Clarify these details beforehand.

9. Are there any specific import duties or regulations for aluminium gantry cranes?

Import duties vary by country. Check your local regulations and discuss with the supplier to understand any compliance requirements.

10. How can I ensure reliable shipping and delivery?

Work with reputable freight forwarders and confirm the Incoterms (e.g., FOB, CIF) with the supplier. Ensure proper packaging to avoid damage during transit.

These answers should assist buyers in making informed decisions while sourcing aluminium gantry cranes from China.