boat crane Safety Certifications

Boat cranes, integral to maritime operations, require strict adherence to safety certifications to ensure the well-being of personnel and equipment. Notable certifications and standards include:

1. ISO 9001: This international standard specifies requirements for a quality management system (QMS) and ensures that boat cranes are designed and manufactured to consistently meet customer and regulatory requirements.

2. ISO 45001: Focused on occupational health and safety (OH&S), this certification helps organizations reduce workplace risks and create safer working conditions.

3. EN 13852: Specific to offshore cranes, this European standard addresses safety requirements for lifting appliances used in hazardous environments, like offshore platforms.

4. API Specification 2C: The American Petroleum Institute establishes guidelines for the design, construction, and operation of offshore pedestal-mounted cranes, ensuring they can withstand harsh conditions.

5. ASME B30.5: The American Society of Mechanical Engineers outlines safety standards for mobile and locomotive cranes, which can be applicable to certain types of boat cranes.

6. DNV GL ST-0378: This standard by Det Norske Veritas Germanischer Lloyd provides criteria for the certification and verification of offshore and platform lifting appliances, focusing on enhancing safety.

7. CE Marking: Essential for meeting European Union (EU) safety, health, and environmental requirements, CE marking indicates conformity with European standards.

8. Crane Operator Certification: In many jurisdictions, crane operators must obtain certification from recognized bodies such as NCCCO (National Commission for the Certification of Crane Operators) to demonstrate competency in safely operating crane equipment.

These certifications are crucial for mitigating risks and ensuring the safe operation of boat cranes in various maritime contexts. Regulatory compliance not only enhances operational safety but also maximizes efficiency and reliability in lifting operations.

List Reference Technical Parameters of “boat crane”

Boat cranes, also known as marine or shipboard cranes, are specifically designed for hoisting and handling loads on boats and offshore installations. The following are reference technical parameters often considered in the design and selection of boat cranes:

1. Load Capacity: The maximum weight the crane can handle, typically measured in tonnes or pounds.

2. Boom Length: The length of the crane’s boom, which determines the reach of the crane.

3. Lifting Height: The maximum height to which the crane can lift a load, usually specified in meters or feet.

4. Working Radius: The horizontal distance from the center of rotation to the lifting hook.

5. Slewing Range: The angle through which the crane can rotate around its base, typically given in degrees (e.g., 360° continuous rotation).

6. Hoisting Speed: The speed at which the crane can lift or lower a load, measured in meters per minute or feet per minute.

7. Slewing Speed: The rate at which the crane can rotate, usually indicated in degrees per second.

8. Luffing Speed: The speed at which the boom can be raised or lowered.

9. Power Source: The type of power used, such as hydraulic, electric, or diesel engines.

10. Control System: The type of control mechanism, which might be manual, semi-automatic, or fully automatic.

11. Material: The construction materials used for the crane, often high-strength steel or corrosion-resistant materials, essential for marine environments.

12. Safety Features: Includes overload protection systems, emergency stop functions, and anti-collision systems.

13. Environmental Ratings: Resistance to environmental factors like saltwater, wind, and temperature extremes.

14. Compliance Standards: Adherence to international and local standards and certifications, such as ABS, DNV-GL, and others.

These parameters guide the selection of the appropriate boat crane for specific maritime applications, ensuring efficiency, safety, and durability in demanding marine environments.

List Product features of “boat crane”

Sure! Here are the key product features of a boat crane:

1. Load Capacity: Boat cranes come with varying load capacities, typically ranging from a few hundred kilograms to several tons, allowing for the lifting of different sizes and weights of boats.

2. Material Construction: High-quality, corrosion-resistant materials such as stainless steel or marine-grade aluminum are often used, ensuring durability and longevity even in harsh maritime environments.

3. Hydraulic System: Equipped with a robust hydraulic system that provides smooth and precise lifting and lowering operations. This system often includes hydraulic cylinders, pumps, and controls.

4. Boom Length and Reach: Adjustable boom lengths and reach capabilities enable flexibility in lifting boats from varying distances and heights, enhancing operational efficiency.

5. Rotational Capability: Many boat cranes offer 360-degree rotation, allowing easy maneuvering and placement of the boat in tight or restricted spaces.

6. Control Options: Advanced models may feature wireless remote controls, allowing operators to handle the crane from a safe distance. Manual and joystick controls are also common.

7. Safety Features: Includes safety mechanisms such as overload protection, emergency stop buttons, and stability sensors to prevent accidents and ensure safe operation.

8. Mounting Options: Various mounting configurations are available, such as deck-mounted or dock-mounted setups, to suit different installation needs.

9. Portability: Some models are designed to be portable, featuring wheels or collapsible designs for easy transport and storage.

10. Ease of Maintenance: Engineered for low maintenance with easily accessible components and parts, ensuring minimal downtime and long-term reliability.

11. Customizable Options: Available with optional features such as different hook attachments, winches, and lighting, allowing customization to meet specific user requirements.

By integrating these features, boat cranes provide essential support for marine operations, facilitating the efficient and safe handling of boats for both professional and recreational purposes.

List Various Types of “boat crane”

Certainly! Boat cranes are essential for lifting and transporting boats and other heavy equipment within marinas, shipyards, and ports. Here are various types of boat cranes:

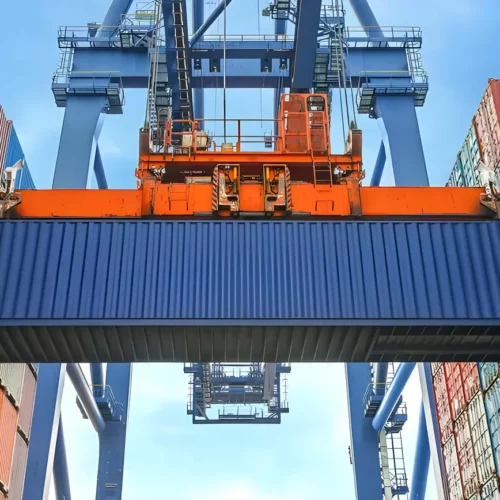

1. Gantry Crane:

– Travel Lift (Mobile Boat Hoist): A mobile crane with a gantry structure, ideal for lifting and transporting boats horizontally within marinas and shipyards.

– Fixed Gantry Crane: A stationary structure used for lifting boats in and out of the water or onto trailers.

2. Jib Crane:

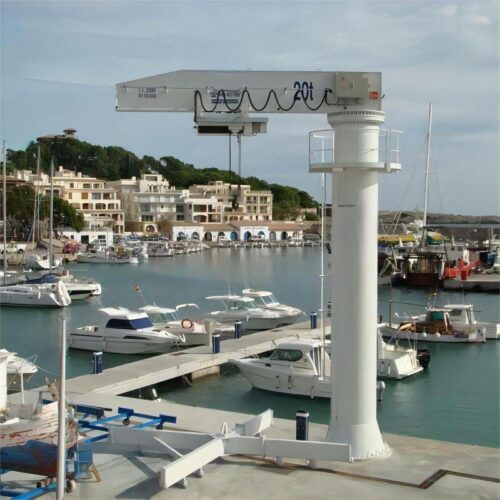

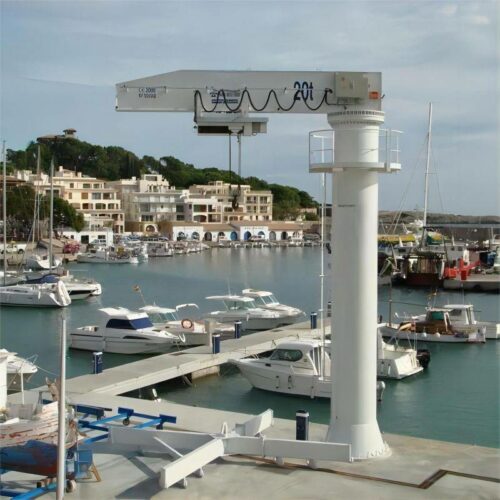

– Stationary Jib Crane: Mounted on a fixed base, often used for lifting smaller boats onto trailers or into the water.

– Portable Jib Crane: Mobile and versatile, used for various lifting tasks within a marina or shipyard.

3. Tower Crane:

– Luffing Jib Crane: Designed with an adjustable jib that allows for precise lifting and placement, frequently used in dockyards for assembling and disassembling boat components.

– Hammerhead Crane: Features a fixed horizontal jib and is commonly used for lifting heavy materials in shipyards.

4. Davit Crane:

– Yachting Davits: Small cranes found on yachts for lifting dinghies or jet skis.

– Dock Davits: Used for lifting boats from water to dry dock.

5. Knuckle Boom Crane:

– Utilized on larger ships and vessels for handling equipment and boats, recognized for their articulated arms that provide flexibility in movement.

6. Telescopic Boom Crane:

– Feature extendable arms and are used for precise placement of boats, often mounted on trucks for mobility.

7. Overhead Crane:

– Used within large shipyard facilities for moving heavy components across the roofing structure, valuable in boat manufacturing or repair operations.

8. Pedestal Crane:

– Permanently mounted on piers or docks, primarily for loading and unloading boats.

Each type of boat crane is designed to meet specific needs based on the size and location of the operations, enhancing efficiency and safety in marine environments.

List Application of “boat crane”

Boat cranes, also known as marine or shipboard cranes, are versatile pieces of equipment used in various maritime environments for numerous applications. Below are the primary uses of boat cranes:

1. Cargo Loading and Unloading:

– Ports and Harbors: Boat cranes facilitate the efficient transfer of cargo between ships and the shore, crucial in commercial shipping.

– Offshore Platforms: They are essential for moving supplies and equipment between supply vessels and offshore oil rigs.

2. Maintenance and Repairs:

– Shipyards: Boat cranes are used to lift parts for repair and maintenance, ensuring vessels remain operational.

– Onboard Maintenance: They assist in moving heavy machinery and performing maintenance tasks on board.

3. Rescue Operations:

– Search and Rescue Missions: Deployed on rescue ships, boat cranes can lift survivors from the water during emergency operations.

– Salvage Operations: They help recover wreckage or sunken vessels, crucial for maritime safety.

4. Marine Construction:

– Bridge and Dock Construction: Boat cranes are instrumental in constructing marine infrastructure by lifting construction materials.

– Underwater Projects: They assist divers by lowering tools and equipment to underwater construction sites.

5. Recreational and Personal Use:

– Yacht and Marina Services: Smaller boat cranes in marinas are used to launch and retrieve yachts and pleasure boats.

6. Scientific Research:

– Research Vessels: Boat cranes enable the deployment and retrieval of scientific instruments, research submersibles, and other equipment during marine research expeditions.

7. Military Operations:

– Naval Warfare Support: Used on naval vessels for logistical support, including deploying and retrieving equipment and supplies.

– Amphibious Operations: Essential for loading and unloading military hardware during amphibious assaults.

Boat cranes are essential for ensuring operational efficiency and safety in various maritime operations, highlighting their versatility and indispensability in the marine industry.

List Buyer Types of “boat crane”

Boat cranes are specialized pieces of equipment used to lift and move boats, and they appeal to a variety of buyers across different industries and sectors. Here are some primary types of buyers for boat cranes:

1. Marinas and Boatyards: These facilities require reliable boat cranes to lift and move vessels for storage, maintenance, and repairs. The ability to efficiently handle boats of various sizes ensures smoother operations and customer satisfaction.

2. Commercial Shipping Companies: Companies engaged in commercial shipping activities often use boat cranes to load and unload smaller boats and tenders from larger cargo or passenger vessels. Efficiency and safety are primary concerns for these buyers.

3. Naval and Coast Guard Bases: Military and law enforcement agencies utilize boat cranes for deploying and recovering patrol boats and other maritime equipment. These cranes must meet stringent safety and operational standards.

4. Yacht Clubs: These recreational facilities use boat cranes for lifting yachts in and out of the water, especially during off seasons or for events. The precision and gentle handling of the cranes are essential to protect high-value vessels.

5. Fishing Industries: Commercial fishing enterprises may need boat cranes to manage a fleet of fishing boats. These cranes support operations by facilitating quick and safe transfers of boats between water and land.

6. Construction Companies: Firms involved in waterfront construction projects, such as building docks, marinas, or waterfront properties, require boat cranes to move barges, workboats, and other heavy equipment.

7. Rescue and Emergency Services: Organizations responsible for water rescue operations often use boat cranes to deploy rescue boats quickly and safely, ensuring rapid response times in emergencies.

8. Boat Manufacturers and Dealers: These businesses need boat cranes to handle the movement of boats during manufacturing, testing, and delivery. Ensuring the safe and damage-free transfer of boats is crucial to maintaining product quality.

By catering to these diverse buyer types, manufacturers and sellers of boat cranes can effectively address various operational requirements and enhance efficiencies across multiple maritime activities.

List “boat crane” Project Types for Different Industries

Various industries employ boat cranes for specific needs, and the type of crane used can vary significantly based on the application. Here are some project types across different industries that utilize boat cranes:

1. Maritime Industry

– Shipbuilding: Gantry cranes and tower cranes are essential for assembling large ship sections.

– Cargo Handling: Container cranes and floating cranes load and unload cargo from ships efficiently.

2. Oil and Gas

– Offshore Drilling: Offshore cranes mounted on rigs handle supplies, equipment, and personnel transfer.

– Subsea Engineering: ROV (Remotely Operated Vehicle) launch and recovery systems on support vessels assist in underwater projects.

3. Tourism and Recreation

– Marinas and Yacht Clubs: Mobile boat hoists and davit cranes launch and retrieve yachts and recreational boats.

4. Fishing Industry

– Commercial Fishing Boats: Deck cranes handle heavy nets, cages, and large catches.

– Aquaculture: Cranes assist in the maintenance of fish farms, including feeding and harvesting equipment.

5. Military and Defense

– Naval Operations: Cranes on naval ships for loading armaments, mission equipment, and supplies.

– Rescue Operations: Search and rescue boats often employ cranes for equipment deployment.

6. Construction

– Bridge Construction: Floating cranes are used for constructing piers and bridge segments.

– Port Infrastructure: Heavy-lift cranes construct and maintain port facilities.

7. Research and Exploration

– Oceanographic Research Vessels: Cranes handle scientific equipment for marine studies.

– Arctic/Antarctic Expeditions: Special cranes are designed to operate in extreme environments, handling icebreaking and supply tasks.

Each project type requires specific crane features tailored to the unique demands of the industry, ensuring efficiency, safety, and operational effectiveness.

boat crane Accessories Upgrades and Custom Manufacturing Options

Boat cranes are critical for managing heavy loads aboard vessels, ensuring seamless operations. Modernizing these cranes with the right accessories and upgrades can significantly enhance their functionality, safety, and efficiency. Here are some noteworthy options to consider:

Accessories

1. Remote Controls: Allow operators to manage crane operations from a safer distance, improving safety and precision.

2. Load Indicators: Real-time weight measurements prevent overloading and potential accidents.

3. Anti-Sway Systems: Reduce the sway of loads, crucial for operations in rough seas.

4. Boom Extension Kits: Increase the reach and versatility of existing cranes.

5. Quick-Release Hooks: Facilitate faster and safer load disengagement.

Upgrades

1. Hydraulic Systems: Enhance power and control, offering smoother and more efficient operations compared to older, mechanical systems.

2. Electric Winches: Provide quieter and more energy-efficient load management.

3. Corrosion-Resistant Materials: Upgrade components to stainless steel or specialized coatings for improved durability in harsh marine environments.

4. Advanced Safety Features: Integrate automatic emergency shut-off systems and overload protection mechanisms.

5. Enhanced Control Panels: Modern, user-friendly interfaces for better operational control and diagnostics.

Custom Manufacturing Options

1. Tailored Lift Capacities: Design cranes specific to the vessel’s operational needs, optimizing performance.

2. Compact Designs: Custom-built cranes to fit spatial constraints without sacrificing functionality.

3. Specialized Winches: Manufacture winches tailored to particular tasks, such as high-speed or high-load operations.

4. Integrated Storage Solutions: Custom-built storage solutions for stowing the crane when not in use.

5. Aesthetic Customization: Paint and finish options to match the vessel’s color scheme for a cohesive look.

Investing in these accessories, upgrades, and custom manufacturing options can drastically improve your boat crane’s operational efficiency, safety, and longevity. By doing so, you ensure that your vessel remains equipped to handle the demands of contemporary marine operations.

List Quality Control and The Manufacturing Process of “boat crane”

Quality Control for Boat Cranes:

1. Material Inspection: Verify that raw materials meet specifications.

2. Component Checks: Inspect critical components (hoses, hydraulic systems, etc.) for defects.

3. Welding Inspection: Ensure welds meet safety and strength standards.

4. Dimensional Accuracy: Use precision tools to check the dimensions of parts.

5. Load Testing: Perform stress tests to ascertain load-bearing capacities.

6. Operational Checks: Test the operational features, including lifting, rotation, and control functionalities.

7. Safety Inspections: Verify compliance with safety regulations and standards.

8. Final Inspection: Conduct a comprehensive review before the final approval.

Manufacturing Process for Boat Cranes:

1. Design and Engineering: Develop technical drawings and specifications. Use CAD software for precision.

2. Material Procurement: Acquire high-grade materials like steel, hydraulic components, and cables.

3. Cutting and Shaping: Use lasers and CNC machines to cut and shape materials.

4. Welding and Fabrication: Assemble the main framework and structure. Precision welding ensures strength.

5. Machining: Machine parts to required tolerances on lathes and milling machines.

6. Surface Treatment: Apply protective coatings like galvanizing or painting to prevent corrosion.

7. Assembly: Combine all components, including hydraulic systems, motors, and control units.

8. Installation of Controls: Install and program control systems (manual or electronic).

9. Testing: Conduct functional tests to ensure all systems operate correctly.

10. Finishing: Finalize with detail work and quality finishing touches.

11. Packaging and Shipping: Securely package the boat crane for transportation to the customer.

These steps ensure that the boat crane is not only functional but also safe and durable, aligning with industry standards and customer expectations.

How to use “boat crane”

A boat crane, also known as a boat lift or marine hoist, is a crucial piece of equipment for safely lifting and moving boats out of the water for maintenance, repair, or storage. Here’s a concise guide on how to use one efficiently:

1. Preparation:

– Inspect the boat crane for any signs of wear or damage.

– Ensure the crane is on stable ground and can handle the weight of your boat.

– Verify that all safety mechanisms are functioning correctly.

2. Position the Crane:

– Align the crane with the boat using the mobile controls or trolleys if applicable.

– Position the boat under the hoist, ensuring it’s centered for even weight distribution.

3. Attach Sling Belts/Sling:

– Carefully place the sling belts or straps under the boat’s hull, generally at the reinforced lifting points.

– Ensure the belts are not twisted and are positioned according to the boat manufacturer’s instructions to avoid damage.

4. Lift the Boat:

– Start lifting slowly, paying attention to the boat’s balance.

– Keep clear of the load at all times and ensure no one is underneath the boat.

– Make any necessary adjustments to maintain balance during the lift.

5. Transport the Boat:

– Once lifted, use the crane controls to carefully move the boat to the desired location.

– Maintain a slow and steady pace to ensure safety.

6. Lower the Boat:

– Position the boat gently over its intended resting place.

– Begin lowering slowly, ensuring the boat settles evenly.

– Once the boat touches the ground or cradle, detach the sling belts carefully.

7. Post-Operation:

– Conduct a final check to ensure the boat is securely in place.

– Inspect the crane for any wear or damage incurred during the operation.

Following these steps will ensure that you use the boat crane safely and efficiently. Always refer to the manufacturer’s guidelines for specific instructions related to your equipment.

“boat crane” Comparative Analysis

Boat cranes, integral to marine operations, come in various types, each suited for specific needs. The choice between them depends on several factors such as lifting capacity, operational range, cost, and environmental impact. Here, we’ll compare three common types: gantry cranes, jib cranes, and knuckle boom cranes.

Gantry Cranes:

Ideal for shipyards, gantry cranes offer immense lifting capacities and extensive reach. Their structure, straddling the workspace, enables them to handle heavy loads and transport them over large distances. However, they are costly to install and maintain, and their fixed position limits flexibility. Their large footprint is also a drawback in space-constrained areas.

Jib Cranes:

Jib cranes, characterized by their horizontal jib or boom, offer versatility and ease of use. They are best suited for smaller vessels where precise load positioning is essential. With a relatively lower installation cost, they can be mounted on walls or floors, saving space. Nonetheless, their lifting capacity and reach are limited compared to gantry cranes, making them less suitable for heavy-duty tasks.

Knuckle Boom Cranes:

Known for their articulated arms, knuckle boom cranes excel in versatility and compactness. They can operate in tight spaces, making them ideal for various maritime applications, from loading cargo to rescue operations. With moderate installation and maintenance costs, they offer a balanced solution between power and maneuverability. However, their lifting capacity is generally lower than that of gantry cranes, and they require skilled operators due to their complex movements.

Conclusion:

Gantry cranes are unmatched for heavy lifting and large-scale operations but come with high costs and space requirements. Jib cranes provide cost-effective, versatile solutions for smaller tasks but are limited in power and reach. Knuckle boom cranes offer a middle ground with their flexibility and moderate cost, though they require skilled handling. The choice largely depends on the specific operational requirements and constraints.

“boat crane” Warranty and Support

Warranty and Support for Boat Crane

Our boat crane products come with a comprehensive warranty and support package to ensure your investment is protected and you have peace of mind while using our equipment.

#### Warranty

We offer a standard one-year limited warranty from the date of purchase. This warranty covers any defects in material or workmanship under normal use during the warranty period. During this period, we will repair or replace, at no extra cost, any part that proves defective because of improper material or workmanship, under normal use and maintenance. The warranty does not cover any damage caused by misuse, abuse, accidents, or unauthorized modifications.

Extended warranty options are available. Please contact our sales team for more information on extended plans and pricing.

#### Support

Our dedicated support team is here to help you with any issues you may encounter. We offer multiple channels for support, ensuring you receive prompt and efficient assistance:

1. Customer Service Hotline: Available 24/7, our hotline connects you with trained professionals who can help troubleshoot issues, provide operational guidance, and answer any questions.

2. Email Support: Send detailed descriptions of your issues or queries to our support email, and receive a response within one business day.

3. Online Resources: Access our extensive library of manuals, how-to videos, and FAQ sections on our official website.

4. On-site Support: For more complex issues, we can dispatch our certified technicians to your location for repairs and maintenance (additional charges may apply).

By providing a robust warranty and efficient support system, we are committed to ensuring your boat crane operates smoothly and reliably for years to come. For more detailed terms and conditions, please refer to the warranty document provided at the time of purchase or visit our website.

List “boat crane” FAQ

Sure, here are some frequently asked questions (FAQ) about boat cranes:

1. What is a boat crane?

A boat crane, also known as a marine crane or yacht crane, is a mechanical device used for lifting and transporting boats in and out of the water. These cranes are typically seen in marinas, shipyards, and boat storage facilities.

2. How do boat cranes work?

Boat cranes use hydraulic or electric winches to lift a boat via slings or straps placed under the boat’s hull. Once lifted, the crane can swivel to move the boat to the desired position.

3. What are the different types of boat cranes?

Common types include jib cranes, gantry cranes, and portable cranes. The choice depends on factors such as boat size, weight, and the specific lifting requirements.

4. How much weight can a boat crane lift?

The lifting capacity varies by model, ranging from a few tons for small portable cranes to hundreds of tons for large gantry cranes.

5. Are boat cranes safe?

Yes, when operated according to manufacturer guidelines. Regular maintenance and inspections are crucial for safety.

6. Do I need a special license to operate a boat crane?

Yes, most regions require operators to have specific training and certification to ensure safe operation.

7. Can a boat crane be used for other purposes?

While primarily designed for lifting boats, they can also be used for lifting other heavy objects, provided they are within the crane’s weight capacity and specifications.

8. How often should a boat crane be inspected?

Regular inspections are recommended, typically every six months, along with pre-operation checks and annual comprehensive reviews.

9. What maintenance is required for a boat crane?

Routine maintenance includes checking hydraulic fluid levels, inspecting cables and slings, lubricating moving parts, and ensuring all safety mechanisms are functional.

10. How do I choose the right boat crane?

Consider the weight and size of your boat, the lifting height needed, the frequency of use, and specific site conditions before making a decision. Consulting with a marine crane specialist can also be helpful.

This summary addresses common questions and aids in understanding the essential aspects of boat cranes.

Top 10 FAQ with answer about boat crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQs) about sourcing boat cranes from China, complete with concise answers:

1. What types of boat cranes are available in China?

– Chinese manufacturers offer various types including gantry cranes, jib cranes, davit cranes, and hydraulic boat lifts to cater to different maritime needs.

2. How do I verify the quality of a Chinese boat crane manufacturer?

– Ensure the manufacturer has ISO certifications, request client testimonials, inspect previous works, and consider third-party inspection services.

3. Are Chinese boat cranes compliant with international standards?

– Yes, many Chinese boat cranes are designed to meet international standards like CE, ISO, and ABS. Confirm compliance with the supplier.

4. Can I customize the boat crane as per my requirements?

– Most manufacturers offer customization options for dimensions, load capacity, and features to match specific needs. Discuss the details with the supplier.

5. What is the typical lead time for manufacturing and delivery?

– Lead times can vary but generally range from 4 to 12 weeks depending on the complexity of the crane and current orders. Always confirm with the supplier.

6. What are the shipping options and costs?

– Shipping can be done via sea freight, with costs depending on the crane size, weight, and destination. Request a detailed shipping quote from the supplier.

7. What about after-sales service and warranty?

– Chinese manufacturers typically offer warranties ranging from 12 to 24 months. Ensure they provide adequate after-sales service including parts replacement and technical support.

8. How do I handle installation and commissioning?

– Many suppliers offer on-site installation and commissioning services or provide detailed manuals and remote assistance to facilitate self-installation.

9. What are the payment terms commonly accepted?

– Common payment terms include T/T (Telegraphic Transfer) with a deposit upfront and the balance upon shipment. L/C (Letter of Credit) is also accepted by some suppliers.

10. How do I address communication barriers?

– Most reputable manufacturers have English-speaking staff. However, using clear, simple language and confirming key points multiple times can mitigate misunderstandings.

These answers should help you navigate the process of sourcing a boat crane from China efficiently.