boat gantry crane Safety Certifications

Boat gantry cranes, often used in marinas and shipyards for lifting and transporting boats, must meet stringent safety certifications to ensure safe operation. Key certifications include:

1. OSHA Compliance (Occupational Safety and Health Administration): In the United States, gantry cranes must comply with OSHA regulations, specifically OSHA 1910.179, which outlines general requirements for overhead and gantry cranes.

2. ASME B30.2: The American Society of Mechanical Engineers (ASME) provides safety standards for the construction, installation, inspection, testing, maintenance, and operation of overhead and gantry cranes in ASME B30.2.

3. CE Marking (European Conformity): For cranes used in Europe, compliance with the Machinery Directive (2006/42/EC) is mandatory, ensuring the equipment meets EU safety, health, and environmental protection requirements.

4. ISO Certification: The International Organization for Standardization (ISO) offers standards like ISO 9001 for quality management systems and ISO 23853 for crane operator requirements, ensuring consistent performance and safety.

5. ANSI/ALI (American National Standards Institute / Automotive Lift Institute): These standards apply primarily to vehicle lifts but are important references for safe lifting practices that can be analogous to boat gantry cranes.

6. CSA Standards: In Canada, the Canadian Standards Association (CSA) provides specifications for the design and operation of cranes, such as CSA B167, offering guidelines on safety and performance.

7. Periodic Inspections: Regular inspections are critical. The Lifting Operations and Lifting Equipment Regulations (LOLER) 1998 in the UK, for example, mandate regular thorough examinations by a competent person.

8. Training and Certification for Operators: Ensuring operators are properly trained and certified according to regional standards (e.g., NCCCO in the U.S.) is vital for safe crane operation.

Adhering to these safety certifications helps mitigate risks associated with lifting operations and enhances the overall safety of gantry crane operations in marine environments.

List Reference Technical Parameters of “boat gantry crane”

Certainly! Here are the reference technical parameters of a boat gantry crane, summarized within 300 words:

1. Lifting Capacity:

– Commonly ranges from 10 tons to 800 tons, customized models can lift even more.

2. Span:

– Distance between the legs/gantry structure, typically between 6m to 35m.

3. Lifting Height:

– Standard heights vary from 3m to 30m, adjustable based on requirements.

4. Working Class:

– Classification based on usage: e.g., A5 (medium duty) to A7 (heavy duty), depending on operational frequency and load capacity.

5. Traveling Speed:

– Crane traveling speed: around 20m/min to 95m/min.

– Trolley traveling speed: generally ranges from 2m/min to 20m/min.

6. Lifting Speed:

– Generally, 0.5m/min to 10m/min, adjustable for controlled lifting.

7. Power Supply:

– Typically electrical, utilizing a three-phase supply usually ranging from 380V to 440V (50/60Hz).

8. Control Method:

– Options include cabin control, remote control, or pendent control, depending on operational safety and convenience needs.

9. Material of Construction:

– High-quality steel for the main structure, often Q235B or Q345B steel.

10. Safety Features:

– Anti-collision devices, overload limiters, emergency stop, wind resistance measures, and limit switches.

11. Operational Environment:

– Designed for various weather conditions, providing resilience against wind, rain, and saltwater corrosion.

12. Crane Components:

– Basic components include the main girder, end beams, trolley, lifting mechanism, and electrical systems.

13. Installation and Maintenance:

– Can be fixed or mobile, with mobile units featuring tires or rails for movement along the dock.

14. Customization Options:

– Tailored specifications can be designed for specific maritime applications.

These parameters ensure that boat gantry cranes are versatile, reliable, and capable of handling the maritime industry’s heavy-duty lifting requirements.

List Product features of “boat gantry crane”

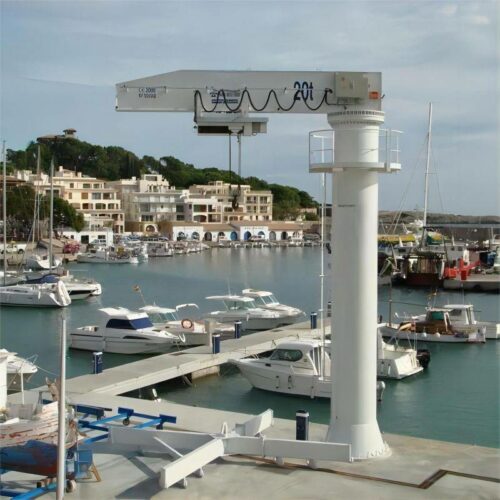

A boat gantry crane is a specialized piece of equipment designed for lifting and moving boats and yachts within marinas, shipyards, and docking areas. Essential features of a boat gantry crane include:

1. Capacity and Range: Capable of handling various weights, typically ranging from a few tons to over a hundred tons, catering to small boats to heavy yachts.

2. Adjustable Width and Height: Provides flexible lifting mechanics to accommodate different boat sizes and hull shapes.

3. Precision Controls: Equipped with sophisticated control systems for accurate maneuvers, ensuring precise lifting and positioning of boats.

4. Wireless Remote Control: Many cranes include wireless remote controls for enhanced operational flexibility and safety.

5. Terrain Adaptability: Features all-terrain wheels or tracks, often accompanied by robust rubber tires, enabling movement over diverse ground conditions, including uneven surfaces.

6. Rotating Hook and Spreader Beams: Incorporates rotating hooks and adjustable spreader beams for better weight distribution and secure lifting.

7. Anti-Sway Technology: Reduces swing through advanced stabilization systems, enhancing operational safety and efficiency.

8. Hydraulic System: Employs a powerful hydraulic system for smooth lifting operations, often coupled with electric or diesel engines.

9. Corrosion Resistance: Constructed with high-grade, corrosion-resistant materials, ensuring longevity in marine environments.

10. Safety Features: Includes overload protection, emergency stop buttons, and safety alarms to prevent accidents and injuries.

11. Eco-Friendly Operations: Advanced models may offer energy-efficient engines or electric power systems, minimizing environmental impacts.

12. Customizable Options: Allows modifications and add-ons to meet specific operational needs, including different lifting accessories and custom dimensions.

These features collectively enhance the functionality, safety, and versatility of boat gantry cranes, making them an indispensable asset in maritime settings.

List Application of “boat gantry crane”

A boat gantry crane, also known as a boat lift or marine travel lift, is a specialized type of crane designed primarily for the marine industry. It is used to lift, transport, and launch boats and other heavy marine vessels. Though its main application is within the maritime environment, its versatility allows for use in various other settings. Below are some key applications of a boat gantry crane:

1. Boat Lifting and Launching:

– Used in boatyards, marinas, and harbors to lift boats out of the water for maintenance, repair, or storage.

– Enables the safe and efficient launching or retrieval of boats from water bodies.

2. Boat Transportation:

– Facilitates the horizontal transport of boats around boatyards or marinas, allowing for easy movement from one point to another.

– Assists in the precise placement of vessels onto trailers for overland transport or into specific dock spaces.

3. Maintenance and Repair:

– Provides access to the underside of vessels for hull cleaning, painting, and other maintenance activities.

– Utilized in shipyards for comprehensive boat repairs, refurbishments, and inspections.

4. Boat Storage:

– Helps in stacking or organizing boats in dry storage facilities, optimizing space usage.

– Aids in winter storage preparation by lifting and placing boats into storage areas.

5. Construction and Manufacturing:

– Integral in shipbuilding yards for the assembly and construction of new vessels.

– Used in manufacturing facilities for loading and unloading heavy marine components.

6. Emergency Services:

– Employed in rescue operations to lift damaged or stranded boats out of the water.

– Vital in disaster response for the quick recovery of vessels to prevent further damage or environmental harm.

7. Specialized Applications:

– Occasionally used in non-marine settings like lifting large structures or objects that require similar capabilities, such as heavy machinery in industrial sectors.

Boat gantry cranes are indispensable in maritime operations for their ability to handle heavy loads with precision and safety, making them essential tools in various marine and related industries.

List Various Types of “boat gantry crane”

Boat gantry cranes come in various types, each designed for specific applications and loads. Here are some common types:

1. Single Beam Gantry Crane (Single Girder Gantry Crane):

– Single Beam with Hoist: Typically used in small to medium-sized boat lifting operations.

– Portable Single Beam: Ideal for small marinas or boat storage areas.

2. Double Beam Gantry Crane (Double Girder Gantry Crane):

– Rail-Mounted Double Beam: Common in shipyards for larger boats and yachts.

– Rubber-Tired Double Beam: Offers mobility and is used in areas without fixed rails.

3. Portable Boat Gantry Crane:

– Manual Portable: For smaller boats, offering flexibility and ease of use.

– Motorized Portable: Provides higher lifting capacity and requires less manual effort.

4. Rubber-Tired Gantry Crane (RTG):

– Standard RTG: Used for medium to large boat lifting, easy to move and position.

– Heavy-Duty RTG: Designed for very large vessels, offering significant load capacity.

5. Rail-Mounted Gantry Crane (RMG):

– Standard RMG: For operations requiring fixed paths and heavy load handling.

– Specialized RMG: Customized for specific lifting operations and environments.

6. Travel Lift (Marine Hoist):

– Standard Travel Lift: Suitable for marinas and boatyards.

– Heavy-Duty Travel Lift: For lifting very large vessels, it’s often equipped with hydraulic systems.

7. Custom Gantry Cranes:

– Custom-Designed Solutions: Tailored to specific requirements of a boatyard or marina.

– Hybrid Cranes: Combining features from various types to meet unique needs.

Each type offers different benefits and is suitable for varying boat sizes, weights, and operational environments.

boat gantry crane Accessories Upgrades and Custom Manufacturing Options

When considering accessories, upgrades, and custom manufacturing options for boat gantry cranes, several key areas enhance performance, safety, and functionality.

Accessories:

1. Remote Controls: Wireless remote control systems provide greater flexibility in crane operation.

2. Spreader Bars: Custom spreader bars can handle various boat sizes, adding versatility.

3. Load Indicators: Digital load cells for real-time weight measurement and monitoring.

4. Protective Covers: Weather-resistant covers for motors and electronic components improve durability.

5. Lighting Systems: LED lighting enhances visibility during nighttime operations.

Upgrades:

1. Automated Systems: Upgrade to semi-automated or fully automated control systems for precision and reduced manual labor.

2. Hydraulic Systems: Improved hydraulic systems offer smoother and more controlled lifting/lowering.

3. Enhanced Mobility: Upgrades such as larger, all-terrain wheels or motorized movement systems.

4. Safety Systems: Addition of advanced safety features like anti-sway mechanisms and emergency stop functions.

5. Energy-efficient Motors: Upgrading to energy-efficient motors can reduce operational costs and environmental impact.

Custom Manufacturing Options:

1. Tailored Capacity: Custom designs to meet specific weight capacities above standard offerings.

2. Adjustable Height and Span: Customizable height and span dimensions to fit unique operational environments.

3. Material Options: Use of materials like aluminum for lightweight applications or stainless steel for corrosion resistance.

4. Special Coatings: Custom anti-corrosive coatings for harsh marine environments.

5. Ergonomic Adjustments: Modifications to control stations for improved operator comfort and efficiency.

By integrating these accessories, upgrades, and customized manufacturing solutions, boat gantry cranes can be tailored to meet specific operational needs, enhance safety, and improve overall efficiency for marine operations.

List Quality Control and The Manufacturing Process of “boat gantry crane”

Quality Control of Boat Gantry Cranes

1. Material Inspection: Ensure the raw materials, like steel, comply with required standards for durability and strength.

2. Welding Quality: Use non-destructive testing (NDT) methods, such as ultrasonic or radiographic testing, to check weld integrity.

3. Dimensional Accuracy: Verify that all parts meet design specifications using precision measuring tools.

4. Load Testing: Perform load tests to ensure the crane can handle its maximum rated capacity safely.

5. Electrical Systems Check: Inspect all electrical components and wiring for proper installation and functionality.

6. Coating and Corrosion Protection: Ensure protective coatings are applied correctly to prevent rust and environmental damage.

7. Operational Testing: Conduct comprehensive checks on all movements and functionalities, including lifting, lowering, and travel mechanisms.

8. Quality Audits: Regularly perform internal and third-party audits to maintain and improve quality standards.

Manufacturing Process of Boat Gantry Cranes

1. Design and Engineering: Create detailed technical drawings and 3D models. Perform simulations to predict performance under various conditions.

2. Material Procurement: Source high-quality materials, ensuring they meet the specified standards for strength and durability.

3. Cutting and Shaping: Use CNC machines and cutting tools to precisely shape metal components according to design specifications.

4. Welding and Assembly: Utilize skilled welders to join metal pieces. Assemble structural components and subassemblies.

5. Machining: Finish and refine components using lathes, mills, and other machines to achieve precise dimensions and smooth finishes.

6. Surface Treatment: Apply anti-corrosive treatments, such as galvanizing or painting, to protect against environmental elements.

7. Component Integration: Install electrical systems, motors, winches, and other mechanical parts. Ensure proper alignment and fit.

8. Quality Inspections: Conduct rigorous inspections at different stages of assembly to ensure compliance with quality standards.

9. Final Assembly and Testing: Assemble the final product and conduct comprehensive functionality tests, including load testing and safety checks.

10. Packaging and Delivery: Securely package the crane components for transportation, ensuring protection against any potential damage during transit.

How to use “boat gantry crane”

A boat gantry crane, also known as a travel lift or marine hoist, is a specialized piece of equipment used to lift and transport boats or yachts in marinas, shipyards, and harbors. Here are the key steps to operate a boat gantry crane:

1. Preparation:

– Inspection: Conduct a thorough inspection of the crane to ensure all components are in good working condition.

– Safety Gear: Ensure all operators and personnel wear appropriate safety gear, including helmets and life vests.

2. Positioning:

– Align Crane: Position the crane over the boat to be lifted, ensuring the crane’s span aligns with the boat’s width.

– Adjust Slings: Adjust the slings or lifting straps to the correct positions under the boat, ensuring they are evenly spaced and secure.

3. Lifting:

– Check Balance: Verify the boat is balanced and the slings are not twisted.

– Lift Slowly: Gradually lift the boat out of the water using the crane’s control system. Monitor for any signs of instability or shifting.

– Pause and Inspect: Once the boat is off the water, pause the lift and inspect to ensure it’s secure.

4. Transporting:

– Move Carefully: Slowly transport the boat to the desired location, avoiding sudden movements that could destabilize the load.

– Communicate: Maintain constant communication with ground personnel to navigate the path safely.

5. Lowering:

– Position Boat: Position the boat accurately over the target area (e.g., maintenance area, transport trailer).

– Lower Gently: Gradually lower the boat, ensuring it settles smoothly onto the supports or stands.

– Release Slings: Once the boat is securely positioned, carefully release and remove the slings.

6. Post-Operation:

– Inspect Equipment: After use, inspect the crane and slings for any wear or damage.

– Secure Crane: Properly secure the crane and stow away any movable parts.

Always follow the manufacturer’s guidelines and standard operating procedures for safe and efficient use. Regular training and adherence to safety protocols are essential.

“boat gantry crane” Comparative Analysis

A boat gantry crane, also known as a boat hoist or travel lift, is a versatile piece of equipment essential for handling boats in marinas, shipyards, and dry docks. Two common variations are the mobile boat gantry crane and the stationary boat gantry crane. Here’s a comparative analysis of the two:

Mobility and Flexibility:

– Mobile Boat Gantry Crane: Highly flexible, this crane can move within the yard and transport boats over varying distances. It’s ideal for facilities needing to frequently shift boats between water and storage or maintenance areas.

– Stationary Boat Gantry Crane: Fixed at one location, these cranes offer limited flexibility and are typically used for repetitive lifting tasks at a specific spot, such as launching ramps or maintenance berths.

Capacity and Range:

– Mobile Boat Gantry Crane: Generally designed to handle a wide range of boat sizes, with lifting capacities from a few tons to several hundred tons. The adjustable height and width make it versatile for different boat sizes and hull shapes.

– Stationary Boat Gantry Crane: While they can manage heavy loads, their capacity is usually specified based on the most frequent types of vessels handled. They lack the adaptability of mobile units.

Operational Efficiency:

– Mobile Boat Gantry Crane: Offers high operational efficiency in crowded marinas where moving vessels around is necessary. However, it can be slower in setting up and securing for each lift compared to stationary types.

– Stationary Boat Gantry Crane: Provides efficient and quick lifting operations at its designated location, since it is always set up and ready, reducing operational time for repetitive tasks.

Cost and Maintenance:

– Mobile Boat Gantry Crane: Higher initial cost due to its mobility and design complexity. Maintenance costs can also be higher given the mechanical and structural wear associated with frequent movement.

– Stationary Boat Gantry Crane: Typically cheaper to install and maintain, as there are fewer moving parts and less structural stress compared to mobile versions.

Conclusion:

Choosing between a mobile and stationary boat gantry crane depends on specific facility needs. Mobile cranes offer unparalleled flexibility and range, whereas stationary cranes provide cost-effective, efficient, and robust solutions for regular, location-specific tasks.

“boat gantry crane” Warranty and Support

When considering the purchase of a boat gantry crane, it is essential to evaluate the warranty and support options provided by the manufacturer. A robust warranty and reliable support can significantly enhance the longevity and performance of your equipment.

Warranty:

Most reputable manufacturers offer a comprehensive warranty for boat gantry cranes, typically covering structural components for several years and mechanical/electrical parts for a shorter period. For example, a standard warranty might include a 10-year coverage on the crane’s structure and 1 to 2 years on electrical components and moving parts. Ensure that the warranty covers critical elements such as winches, motors, and cables.

Support:

Customer support is crucial for addressing issues that may arise during the crane’s operational life. Look for manufacturers that provide:

1. Technical Support: Accessible via phone or online, offering troubleshooting guidance and technical assistance.

2. On-site Service: Availability of trained technicians to perform on-site diagnostics, maintenance, and repairs.

3. Spare Parts Availability: Quick delivery of genuine spare parts to minimize downtime.

4. Training Programs: Operator and maintenance training courses to ensure safe and efficient use of the crane.

5. Regular Maintenance Plans: Scheduled maintenance services that can prevent breakdowns and prolong the crane’s operational life.

In summary, a robust warranty coupled with comprehensive support services can provide peace of mind and ensure that your boat gantry crane remains in optimal condition, maximizing your investment’s value and performance. Always review and compare the warranty and support options from multiple manufacturers to make an informed decision.

List “boat gantry crane” FAQ

Boat Gantry Crane FAQ

1. What is a boat gantry crane?

A boat gantry crane is a type of overhead lifting device specifically designed for managing boats and other marine vessels. These cranes are often used in shipyards, marinas, and dockyards for lifting, transporting, and positioning boats safely and efficiently.

2. How does a boat gantry crane differ from a marine travel lift?

While both are used to handle boats, a boat gantry crane generally operates on fixed tracks or rails and is used within a smaller, more confined area. A marine travel lift, conversely, is a mobile crane that uses wheels and is capable of transporting boats over larger distances and different terrains.

3. What weight capacities do boat gantry cranes have?

The weight capacity of boat gantry cranes can vary significantly based on their design and application. They commonly range from a few tons to hundreds of tons, depending on the specific requirements and size of the vessels they are planned to handle.

4. What safety measures are implemented in boat gantry cranes?

Boat gantry cranes are equipped with various safety features, including overload protection systems, emergency stop mechanisms, anti-sway controls, and precise load positioning technologies. Regular maintenance and operator training further enhance safety.

5. Can boat gantry cranes be used in all types of weather?

Boat gantry cranes are designed to operate in various weather conditions; however, extreme weather such as strong winds, heavy rain, or storms can affect their operation. It is crucial to follow manufacturer guidelines and safety protocols during adverse weather.

6. What materials are typically used to construct boat gantry cranes?

High-strength steel is commonly used for the construction of boat gantry cranes to provide durability and resistance to the harsh marine environment, including exposure to saltwater and various weather conditions.

7. Are boat gantry cranes customizable?

Yes, boat gantry cranes can be customized to suit specific operational needs, including adjustments to height, span, lifting capacity, and additional features like remote control systems and advanced automation.

8. How do you maintain a boat gantry crane?

Regular inspections, lubrication, and replacement of worn-out parts are essential for maintaining a boat gantry crane. Following the manufacturer’s maintenance schedule and guidelines ensures optimal performance and safety.

Top 10 FAQ with answer about boat gantry crane for Buyer Sourcing from China

Sure! Here are the top 10 frequently asked questions (FAQ) and their answers regarding sourcing boat gantry cranes from China:

1. What is a boat gantry crane?

A boat gantry crane is a type of overhead crane specifically designed for lifting and transporting boats in marinas, shipyards, and construction sites.

2. Why should I source a boat gantry crane from China?

China offers cost-effective solutions, high-quality products, and a wide range of manufacturers with extensive experience in producing gantry cranes.

3. How do I ensure the quality of the gantry crane from China?

Check for international certifications such as CE, ISO, and BV. Look for reputable manufacturers with positive reviews and ask for client references.

4. What are the key specifications to consider?

Consider load capacity, span length, lifting height, travel speed, and power requirements based on your specific needs and operational conditions.

5. Can I get customization for the gantry crane?

Yes, many Chinese manufacturers offer customization options to meet specific requirements such as size, lifting capacity, and additional features.

6. What is the typical lead time for manufacturing and delivery?

Lead times can vary, but it typically takes 30-60 days for manufacturing and shipping, depending on the order complexity and destination.

7. How do I handle the shipping and logistics?

Manufacturers often provide CIF (Cost, Insurance, and Freight) terms. Utilize a reliable freight forwarder and ensure all necessary import documentation is prepared.

8. What about installation and after-sales service?

Most manufacturers offer installation services either directly or through local partners. Ensure they provide after-sales support, including maintenance and spare parts.

9. How do I handle payment terms with Chinese suppliers?

Common payment methods include T/T (Telegraphic Transfer) and L/C (Letter of Credit). A typical arrangement is 30% upfront and 70% upon shipment.

10. Are there any import duties or taxes?

Duties and taxes vary by country. Check with local customs authorities to understand applicable import duties, VAT, and other relevant fees.

This concise list should guide you through the process of sourcing a boat gantry crane from China with the essential information required.