ceiling crane Safety Certifications

Ceiling cranes, essential for material handling in various industries, must adhere to safety certifications to ensure workplace safety and operational efficiency. The primary standards and certifications include:

1. OSHA (Occupational Safety and Health Administration): OSHA regulations (29 CFR 1910.179) specify requirements for overhead and gantry cranes, ensuring they meet safety standards in the United States. Compliance involves regular inspections, proper labeling, and operational guidelines.

2. ASME B30.2: Published by the American Society of Mechanical Engineers, this standard provides comprehensive safety guidelines for the construction, installation, operation, inspection, and maintenance of overhead and gantry cranes.

3. ISO 9001: While not specific to cranes, ISO 9001 certification ensures that the manufacturer maintains a high-quality management system, which indirectly guarantees that the products, including ceiling cranes, meet safety and performance standards.

4. FEM (Fédération Européenne de la Manutention) Standards: These European standards offer guidelines on the design and construction of cranes, focusing on safety, reliability, and performance. FEM 1.001 is particularly relevant for crane safety.

5. CMAA (Crane Manufacturers Association of America) Specifications: CMAA Specification No. 70 for multiple girder cranes and No. 74 for single girder cranes outline recommended practices for safety and performance.

6. EN 15011: This European Norm details the safety requirements for bridge and gantry cranes, covering aspects from mechanical design to stability and safety devices.

7. ANSI (American National Standards Institute): ANSI standards, such as ANSI B30.2, align with ASME standards and provide additional safety guidelines for ceiling crane operations.

Adhering to these certifications and standards ensures that ceiling cranes operate safely and efficiently, minimizing risks and enhancing the safety of personnel and equipment. Regular audits and proper training for operators are also crucial in maintaining compliance.

List Reference Technical Parameters of “ceiling crane”

A ceiling crane, also known as an overhead crane, is a crucial piece of equipment used in industries for lifting and moving heavy materials. The following are key reference technical parameters of ceiling cranes:

1. Load Capacity:

– Rated Load Capacity: The maximum weight the crane can safely lift, usually measured in tons (e.g., 5 tons, 10 tons).

2. Span:

– Crane Span: The distance between the two rails on which the crane operates, typically measured in meters.

3. Lift Height:

– Max Lifting Height: The maximum vertical distance the hook can travel, measured in meters.

4. Travel Speed:

– Hoist Speed: Speed at which the crane hoist can lift or lower the load, commonly measured in meters per minute.

– Trolley Speed: Speed of the trolley moving along the bridge.

– Bridge Speed: Speed at which the entire crane moves along the rails.

5. Duty Class:

– Service Classification: Indicates the operational conditions the crane is designed for, such as intermittent or continuous use (e.g., FEM, CMAA classes).

6. Power Supply:

– Voltage: Typical operational voltage required, such as 380V, 50Hz.

– Phase: Single-phase or three-phase power.

7. Controls:

– Control Type: Methods of controlling the crane, such as a radio remote, pendant control, or automated systems.

8. Safety Features:

– Limit Switches: Preventing over-travel beyond designated limits.

– Overload Protection: Automatically stops crane operation if load exceeds rated capacity.

9. Environmental Considerations:

– Temperature Range: Operational temperature conditions for the crane.

– Corrosion Resistance: Materials and coatings used to protect against environmental factors.

10. Structural Components:

– Bridge: Main structure spanning the load area.

– Trolley: Moving part carrying the hoist.

– Hoist: Mechanism for lifting, often an electric wire rope or chain type.

These parameters are vital for ensuring that ceiling cranes are selected and operated safely and efficiently within their designated applications.

List Product features of “ceiling crane”

A ceiling crane, also known as an overhead crane or bridge crane, is a highly efficient lifting system utilized in industrial environments for material handling and transportation. Here are some key product features:

Main Features

1. High Load Capacity:

– Capable of lifting heavy loads, often ranging from several tons to hundreds of tons depending on the model.

2. Versatile Applications:

– Suitable for a variety of industries including manufacturing, warehousing, shipbuilding, and construction.

3. Robust Construction:

– Built with high-strength steel and durable components to withstand harsh working conditions and prolonged use.

4. Precision Controls:

– Equipped with advanced control systems for precise movement and positioning of loads, including variable speed drives and wireless remote controls.

5. Wide Span Coverage:

– Designed to cover a large working area, with bridges that can span the entire width of a facility.

6. Height Adjustment:

– Adjustable hoist mechanisms that allow for a range of lifting heights, accommodating different project requirements.

Safety Features

1. Overload Protection:

– Integrated safety features that prevent the crane from lifting loads beyond its accredited capacity.

2. Emergency Stop Mechanism:

– Quick-response emergency stop buttons to halt operations instantly in case of emergencies.

3. Anti-Collision Systems:

– Sensors and systems to automatically prevent collisions with obstacles and other machinery.

4. Maintenance Alerts:

– Built-in diagnostics and alert systems to inform operators of required maintenance and system checks.

Customization and Efficiency

1. Modular Design:

– Modular components that allow for easy customization and scalability to meet specific operational demands.

2. Energy Efficiency:

– Energy-efficient motors and components aimed at reducing power consumption and operational costs.

3. Automated Operations:

– Options for partial or full automation, enhancing productivity and reducing manual labor.

4. Integration Capabilities:

– Compatible with various types of hooks, grabs, and other lifting accessories for increased versatility.

Environmental Adaptability

1. Indoor and Outdoor Use:

– Applicable in both indoor and outdoor settings with special coatings and weatherproof features for outdoor models.

2. Low Noise Operation:

– Designed for minimal noise generation, contributing to a quieter working environment.

By incorporating these features, ceiling cranes provide reliable, efficient, and safe material handling solutions across diverse industrial settings.

List Various Types of “ceiling crane”

Ceiling cranes are essential tools for lifting and transporting heavy loads in industrial settings. Here are the various types of ceiling cranes:

1. Bridge Cranes:

– Single Girder Bridge Cranes: Feature one main bridge girder supported on two end trucks and are suitable for lighter loads and shorter spans.

– Double Girder Bridge Cranes: Incorporate two girders for additional strength, enabling the handling of heavier loads and broader spans.

2. Monorail Cranes:

– Comprise a single rail installed on the ceiling, ideal for straightforward, linear lifting tasks. They are commonly used in production or assembly lines.

3. Gantry Cranes:

– Full Gantry Cranes: Include two supporting structures connected by a bridge that travels along tracks.

– Semi-Gantry Cranes: Have one side riding on a rail fixed to the floor and the other side supported by an elevated rail.

4. Jib Cranes:

– Wall-Mounted Jib Cranes: Attached to the wall, offering a rotational range for lifting objects within a specific area.

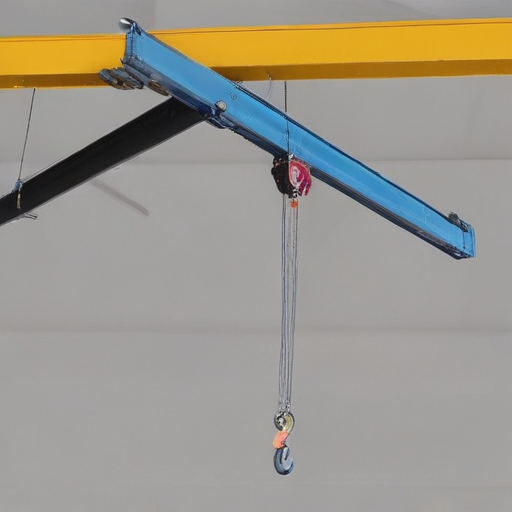

– Ceiling-Mounted Jib Cranes: Connected directly to the ceiling for unobstructed lifting within set zones.

5. Underhung Cranes:

– Designed with a trolley that rides on the bottom flange of the bridge girder, useful for facilities with limited headroom.

6. Workstation Cranes:

– Lightweight, ergonomic cranes that enhance productivity in smaller work areas with lower lifting requirements.

These ceiling crane types facilitate diverse lifting needs, enhancing workflow efficiency and safety in industrial environments.

List Application of “ceiling crane”

Ceiling cranes, also known as overhead cranes or bridge cranes, are widely utilized in various industries to facilitate the lifting, moving, and positioning of heavy loads with precision and efficiency. Below are some key applications of ceiling cranes:

1. Manufacturing and Assembly:

– Moving raw materials to production lines.

– Positioning heavy components during assembly processes.

– Handling finished products in automotive, aerospace, and machinery industries.

2. Warehousing and Distribution:

– Organizing storage areas by lifting and placing heavy pallets and containers.

– Loading and unloading trucks and shipping containers efficiently.

– Optimizing space utilization through vertical storage capabilities.

3. Metalworking and Fabrication:

– Transporting large metal sheets, beams, and fabricated parts.

– Positioning workpieces for welding, cutting, and machining.

– Ensuring safety and precision in handling heavy and awkwardly-shaped items.

4. Construction and Infrastructure:

– Assisting in the lifting and placement of construction materials such as steel beams and concrete panels.

– Facilitating the movement of heavy equipment and tools on construction sites.

– Supporting prefabrication processes by moving massive components.

5. Power and Energy Sector:

– Handling large and heavy components such as turbines, generators, and transformers.

– Facilitating maintenance and repair activities in power plants and substations.

– Supporting installation activities in renewable energy projects like wind turbines and solar panels.

6. Shipbuilding and Marine Industry:

– Moving large ship components and modules during construction.

– Assisting in the maintenance and repair of vessels by lifting engines, propellers, and other heavy parts.

– Facilitating dry-docking operations by lifting and positioning parts accurately.

7. Paper and Pulp Industry:

– Handling large rolls of paper and heavy machinery components.

– Assisting in the maintenance of large-scale equipment to ensure continuous production flow.

8. Warehouse Automation:

– Integrating with automated systems for efficient warehouse logistics.

– Enhancing precision and speed in material handling tasks.

Overall, ceiling cranes contribute significantly to productivity, efficiency, and safety across various sectors by enabling the smooth handling of bulky and heavy loads.

List Buyer Types of “ceiling crane”

When discussing buyer types for ceiling cranes, potential market segments can be categorized based on their specific needs and contexts. Here are the primary types of buyers:

1. Manufacturing Plants: These facilities require ceiling cranes for handling heavy machinery, raw materials, and finished goods. Industries like automotive, aerospace, and steel production frequently invest in these cranes to streamline their processes.

2. Warehouses and Distribution Centers: To optimize storage space and facilitate the movement of heavy loads, these establishments use ceiling cranes for efficient inventory management and order fulfillment.

3. Construction Companies: For large construction projects, ceiling cranes are crucial for lifting and positioning heavy materials like steel beams, precast concrete, and other structural components.

4. Mining Operations: These operations often utilize ceiling cranes for handling heavy mining equipment and raw materials, providing a safe and efficient method for lifting and moving materials in harsh environments.

5. Shipyards and Ports: To handle large containers, ship components, and heavy cargo, these facilities depend on ceiling cranes for their high load capacity and operational efficiency.

6. Chemical and Petrochemical Plants: Handling hazardous materials and large equipment is a routine necessity in these plants, making ceiling cranes essential for ensuring safety and operational efficiency.

7. Power Plants: Maintenance and operations in power generation facilities often involve heavy-duty lifting tasks, for which ceiling cranes are ideal.

8. Railway and Transportation Hubs: These buyers employ ceiling cranes for the maintenance and assembly of rail components, as well as cargo handling.

9. Heavy Equipment Repair Shops: These shops need ceiling cranes to lift and maneuver large equipment parts during maintenance and repair activities.

10. Custom and Special Projects Firms: Companies in niche markets or with unique requirements may seek tailored ceiling crane solutions to meet specific project needs.

Each of these buyer types values ceiling cranes for their ability to improve workflow efficiency, enhance safety, and handle heavy loads in a controlled manner. The precise specifications and requirements may vary, but all share a common need for robust, reliable, and efficient lifting solutions.

List “ceiling crane” Project Types for Different Industries

Ceiling cranes, also known as overhead cranes or bridge cranes, are versatile lifting solutions used in a variety of industries to enhance productivity and safety. Here’s a list of ceiling crane project types tailored to different sectors:

1. Manufacturing:

– Assembly Line Cranes: Used to move components across different stages of assembly.

– Materials Handling Cranes: Facilitate the transport of raw materials and finished products within the facility.

2. Automotive:

– Engine Assembly Cranes: Assist in lifting heavy engine blocks and components.

– Body Shop Cranes: Enable the movement of car bodies and large parts through various manufacturing stages.

3. Warehousing & Distribution:

– Order Picking Cranes: Aid workers in accessing and retrieving items from high shelves.

– Loading/Unloading Cranes: Speed up the process of transferring goods to and from trucks or storage areas.

4. Aerospace:

– Aircraft Assembly Cranes: Support in the precise positioning of large aerospace components.

– Maintenance Cranes: Used for the lifting and movement of aircraft parts during repair and maintenance.

5. Construction:

– Concrete Handling Cranes: Help in transporting and positioning concrete blocks and panels.

– Structural Assembly Cranes: Facilitate lifting heavy steel beams and other building materials.

6. Shipbuilding:

– Hull Fabrication Cranes: Move large sections of ship hulls during construction.

– Maintenance Dock Cranes: Provide lifting solutions for ship repairs and component replacements.

7. Steel Manufacturing:

– Slab Handling Cranes: Used in moving heavy steel slabs and ingots.

– Coil Handling Cranes: Specialized for transporting steel coils within the manufacturing plant.

8. Pulp and Paper:

– Paper Roll Handling Cranes: Designed to move large rolls of paper from production lines to storage areas.

– Maintenance Cranes: Assist in the upkeep and repair of heavy machinery.

9. Mining:

– Equipment Maintenance Cranes: Facilitate the lifting and repair of mining machinery.

– Ore Processing Cranes: Used in the extraction and processing of raw materials.

Each ceiling crane project type is engineered to meet the specific needs and regulations of the industry, ensuring efficient, safe, and reliable operations.

ceiling crane Accessories Upgrades and Custom Manufacturing Options

Ceiling cranes are indispensable in various industries for their ability to move heavy loads efficiently and safely. To maximize their functionality, several accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Lifting Attachments: Devices such as spreader beams, lifting magnets, and vacuum lifters enhance handling specific loads.

2. Controls: Options include wireless remote controls and ergonomic pendant stations for improved maneuverability and safety.

3. Hoists: Electric, manual, or air-powered hoists come in various capacities to suit different operational needs.

4. Load Indicators: These provide real-time load data to prevent overloading and ensure safety.

5. End Trucks: Various types for single or double girders, facilitating smooth crane movement.

Upgrades:

1. Automation: Implementing automated systems like PLC controllers and sensors can improve precision and reduce human error.

2. Speed Control: Variable frequency drives (VFDs) enable adjustable lifting and travel speeds, enhancing control.

3. Anti-Sway Systems: Utilized to stabilize loads during transit, reducing the risk of swinging and potential accidents.

4. Maintenance Monitoring: Systems that track usage and predict maintenance needs can extend the crane’s lifespan and reliability.

Custom Manufacturing Options:

1. Tailored Dimensions: Custom crane spans, heights, and lifting capacities to meet specific operational requirements.

2. Material Choices: Selection of materials like stainless steel for specialized environments, such as clean rooms or corrosive atmospheres.

3. Weather-Proofing: Customized cranes for outdoor applications include weather-resistant coating and components.

4. Heavy-Duty Designs: For industries like steel mills or shipyards, cranes can be built to handle extreme conditions and continuous use.

By integrating these accessories, upgrades, and custom options, ceiling cranes can significantly improve operational efficiency and safety, tailored to specific industrial needs.

List Quality Control and The Manufacturing Process of “ceiling crane”

Quality Control and Manufacturing Process of Ceiling Cranes

Quality Control:

1. Material Inspection:

– Verify raw materials for compliance with specifications.

– Test for tensile strength, durability, and corrosion resistance.

2. Dimensional Accuracy:

– Use precision measuring tools to ensure components meet design tolerances.

– Perform alignment checks on key parts.

3. Welding and Fastening:

– Inspect welds using Non-Destructive Testing (NDT) methods like X-ray or ultrasonic tests.

– Ensure bolts and fasteners meet torque specifications.

4. Load Testing:

– Conduct static and dynamic load tests to evaluate safety under maximum load conditions.

– Perform stress analysis to detect potential weak points.

5. Electrical Systems Checks:

– Test electrical components for functionality and safety compliance.

– Inspect control panels, wiring, and connections for adherence to standards.

6. Final Inspection:

– Perform a comprehensive review of the assembled crane.

– Validate operational efficiency and safety mechanisms.

Manufacturing Process:

1. Design and Engineering:

– Develop detailed blueprints and CAD models.

– Ensure designs comply with industry standards and client specifications.

2. Procurement:

– Source high-quality materials such as steel beams, motors, and electrical components.

– Validate material certifications and traceability.

3. Cutting and Machining:

– Cut steel beams to required lengths using CNC machines.

– Machine components to precise dimensions.

4. Assembly:

– Assemble structural components including girders, end trucks, and trolleys.

– Install motors, gearboxes, and electrical systems.

5. Welding and Fastening:

– Use automated and manual welding techniques.

– Secure parts with bolts and assembles using torque wrenches.

6. Surface Treatment:

– Apply corrosion-resistant coatings or paint.

– Conduct surface finish inspections.

7. Installation:

– Transport the crane to the site.

– Perform installation including track layout and electrical hookups.

8. Commissioning:

– Calibrate and test all functions.

– Train operators on safe and efficient use.

By adhering to stringent quality control measures and a systematic manufacturing process, ceiling cranes are produced to meet high safety and performance standards.

How to use “ceiling crane”

Using a ceiling crane involves several crucial steps to ensure safety and efficiency. Here’s a concise guide:

1. Inspection and Preparation:

– Check Equipment: Inspect the crane for any signs of wear, damage, or malfunction. Ensure all safety features are operational.

– Work Area: Clear the area of obstructions and ensure adequate lighting and visibility.

– Training: Only trained and authorized personnel should operate the crane.

2. Setup:

– Load Assessment: Evaluate the weight and dimensions of the load. Never exceed the crane’s maximum lifting capacity.

– Rigging: Choose appropriate slings, hooks, and other rigging equipment. Properly attach the rigging to the load, ensuring balance and security.

3. Operation:

– Controls Familiarization: Understand the crane’s control panel, including movement (up, down, left, right) and emergency stop functions.

– Lifting: Gently lift the load a few inches to test the balance and rigging. If stable, proceed to the desired height.

– Movement: Slowly and steadily move the load horizontally, keeping it as low as safely possible. Avoid sudden starts, stops, or turns.

4. Placement:

– Positioning: Lower the load carefully at its destination. Ensure it is properly aligned and stable before detaching rigging.

– Disconnection: Remove rigging equipment after confirming the load is secure.

5. Post-Operation:

– Shut Down: Park the crane in its designated position, turn off the power, and ensure it’s locked or secured.

– Inspection: Conduct a post-operation inspection for any wear or damage incurred during use.

6. Documentation:

– Records: Log the operation details, including any issues encountered, for maintenance and safety reviews.

Safety should always be the top priority when operating a ceiling crane. Proper preparation, cautious operation, and following established protocols can prevent accidents and ensure successful use.

“ceiling crane” Comparative Analysis

A ceiling crane, also known as an overhead crane, is an essential lifting mechanism commonly used in industrial environments such as factories, warehouses, and workshops. Below is a comparative analysis focusing on various key factors: efficiency, safety, versatility, and cost.

Efficiency:

Ceiling cranes offer significant efficiency by allowing the vertical and horizontal movement of heavy loads. They optimize space usage by eliminating the need for floor-based lifting equipment. Compared to traditional forklifts, ceiling cranes can handle larger capacities and streamline operations, enhancing productivity.

Safety:

Safety is paramount when handling heavy loads. Ceiling cranes minimize human involvement in lifting operations, reducing the risk of workplace injuries. Modern ceiling cranes are equipped with advanced features such as overload protection, emergency stop functions, and precise control systems, making them safer than other lifting mechanisms like chain hoists or manual pulleys.

Versatility:

Ceiling cranes are highly versatile and can be customized for various applications. They come in different types, including bridge cranes, gantry cranes, and jib cranes, each catering to specific needs. For example, bridge cranes are ideal for widespread areas, while jib cranes are suitable for localized lifting. This adaptability makes ceiling cranes preferable for a wide range of industrial activities compared to fixed-path transportation systems like conveyor belts.

Cost:

Although the initial investment for ceiling cranes can be high, considering installation and customization, the long-term benefits often outweigh the costs. Their durability and efficiency lead to reduced operational expenses over time. In contrast, equipment like forklifts may require frequent maintenance and fuel, adding to ongoing costs.

In conclusion, ceiling cranes stand out in terms of efficiency, safety, and versatility, making them a valuable investment for industries that require reliable and effective lifting solutions. While the initial cost may be higher, the long-term advantages provide a compelling case for their adoption over alternative lifting methods.

“ceiling crane” Warranty and Support

When purchasing a ceiling crane, ensuring robust warranty and support services is crucial for maintaining operational efficiency and minimizing downtime. Typically, ceiling crane manufacturers offer warranties that range from one to five years, depending on the specific components. For instance, structural components such as beams and tracks might come with a longer warranty compared to electrical parts and hoists. It’s important to read the warranty terms carefully to understand what is covered and what may be excluded, such as wear and tear or misuse.

Support services are equally critical and are often provided through a combination of online resources, telephone support, and in-person technician visits. Many manufacturers offer 24/7 customer service to address emergency breakdowns and ensure quick resolutions to technical issues. Regular maintenance services and periodic inspections might also be included in a comprehensive support package to enhance the lifespan and reliability of the crane.

Furthermore, some manufacturers provide training sessions for your staff to ensure proper operation and basic troubleshooting, which can be invaluable for day-to-day efficiency and safety. In cases where parts need replacement, expedited shipping options and a reliable inventory management system are essential to minimize the downtime.

Overall, when selecting a ceiling crane, thoroughly evaluate the warranty and support offerings to ensure they align with your operational needs and provide peace of mind. Effective and prompt support services not only extend the lifespan of your equipment but also safeguard your investment.

List “ceiling crane” FAQ

Ceiling Crane FAQ

1. What is a ceiling crane?

A ceiling crane, also known as an overhead or bridge crane, is a type of industrial equipment used to lift and transport heavy materials across a workspace. It consists of a hoist trolley that moves along a bridge, which is mounted on a runway system secured to the ceiling.

2. What are the types of ceiling cranes?

Two primary types of ceiling cranes are single-girder and double-girder cranes. Single-girder cranes have one bridge girder supporting the trolley and hoist, while double-girder cranes have two girders, offering greater strength and capacity.

3. Where can ceiling cranes be used?

Ceiling cranes are commonly used in manufacturing plants, warehouses, shipping facilities, and various industrial settings. They are ideal for environments where floor space is limited, and precision is required in lifting operations.

4. What are the advantages of using a ceiling crane?

Advantages include efficient space utilization, improved safety, enhanced load handling, greater versatility, and reduced labor costs. Ceiling cranes also minimize floor obstructions, allowing for streamlined workflows.

5. How much weight can a ceiling crane lift?

The lifting capacity of a ceiling crane varies widely, ranging from a few hundred pounds to several hundred tons, depending on the crane type and design. Custom configurations can be made to meet specific requirements.

6. What maintenance is required for ceiling cranes?

Regular maintenance includes inspecting the hoist, trolley, bridge, runway, and electrical systems for wear and damage. Lubrication, alignment checks, and routine testing of safety mechanisms are also essential.

7. What safety measures should be taken when operating a ceiling crane?

Operators should be thoroughly trained and adhere to safety guidelines, including load testing, regular inspections, proper signaling, and use of personal protective equipment (PPE). Overloading and unauthorized use should be strictly avoided.

8. How much does a ceiling crane cost?

The cost varies based on factors such as crane type, lifting capacity, installation complexity, and customization. Prices can range from a few thousand to several hundred thousand dollars.

9. Can ceiling cranes be customized?

Yes, ceiling cranes can be tailored to specific operational needs, including custom lifting capacities, spans, lifts, and control systems. Consulting with a crane manufacturer will ensure the equipment meets exact requirements.

10. Is professional installation required?

Professional installation is highly recommended to ensure safety, compliance with regulations, and optimal performance. Incorrect installation can lead to operational hazards and reduced equipment lifespan.

Top 10 FAQ with answer about ceiling crane for Buyer Sourcing from China

Certainly! Here are the top 10 Frequently Asked Questions (FAQ) about sourcing ceiling cranes from China, along with concise answers:

1. What are the benefits of sourcing ceiling cranes from China?

– Competitive Pricing: Lower labor and manufacturing costs can result in more affordable prices.

– Technological Advancements: Many Chinese manufacturers use advanced technology and equipment.

– Wide Range of Products: There’s a vast variety of models and specifications available to meet different needs.

2. How can I ensure the quality of the ceiling crane?

– Certification: Look for ISO, CE, and other relevant certifications.

– Factory Visits: If possible, conduct on-site inspections.

– Third-Party Inspections: Employ third-party agencies to inspect and test the machinery before shipment.

3. What are typical lead times for delivery?

– Standard Models: Usually 30-45 days.

– Custom Orders: 45-60 days, depending on complexity.

4. Are Chinese ceiling cranes compliant with international standards?

– Yes, many manufacturers comply with international standards such as ISO, CE, and ANSI to ensure quality and safety.

5. What is the minimum order quantity (MOQ)?

– The MOQ varies by manufacturer but usually ranges from 1 to 5 units.

6. How do I handle shipping and logistics?

– Incoterms: Familiarize yourself with common incoterms like FOB, CIF, and DDP.

– Freight Forwarders: Consider hiring a freight forwarder experienced in handling heavy machinery.

7. What after-sales services do Chinese manufacturers offer?

– Warranty: Typically, a 1-year warranty, but it can extend up to 3 years.

– Parts and Maintenance: Many offer spare parts and maintenance services.

– Technical Support: Remote or on-site technical support is often available.

8. How can I assess the credibility of a Chinese supplier?

– Business License: Check for a valid business license.

– References: Ask for customer testimonials or references.

– Online Reviews: Search for reviews and ratings on platforms like Alibaba or Made-in-China.

9. What payment terms are generally accepted?

– Common Terms: T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes D/P (Documents against Payment) are widely accepted.

– Payment Schedule: Often 30% upfront and 70% before shipment.

10. Can I get customized solutions?