collapsible gantry crane Safety Certifications

Collapsible gantry cranes, like other lifting equipment, must adhere to stringent safety standards and certifications to ensure they operate safely and reliably. Key safety certifications for collapsible gantry cranes typically include:

1. OSHA Compliance (Occupational Safety and Health Administration):

– OSHA sets the baseline standards for workplace safety in the United States. Compliance with OSHA regulations ensures the crane is safe for operation in various industrial environments.

– OSHA Standards: 29 CFR 1910.179 (Overhead and Gantry Cranes).

2. ASME B30.2 and B30.17:

– The American Society of Mechanical Engineers (ASME) provides detailed guidelines for the safe construction and operation of cranes.

– ASME B30.2 covers overhead and gantry cranes, while B30.17 covers smaller cranes such as monorails and underhung cranes. These standards specify requirements for design, construction, installation, inspection, testing, maintenance, and operation.

3. ISO 9001:

– This certification indicates that the manufacturer follows international standards for quality management systems.

– Ensuring ISO 9001 compliance demonstrates a commitment to consistent manufacturing quality and customer satisfaction.

4. CE Marking (European Conformity):

– For gantry cranes used in the European Economic Area (EEA), the CE marking ensures compliance with EU safety, health, and environmental requirements.

– Directives include the Machinery Directive 2006/42/EC, which sets essential health and safety requirements.

5. ANSI (American National Standards Institute):

– ANSI standards, often harmonized with ASME and OSHA, provide additional benchmarks for safe crane manufacturing and usage.

6. LMI (Load Moment Indicator):

– Some cranes incorporate an LMI system, which ensures that operations stay within the safe load limits.

Adherence to these certifications and standards helps ensure that collapsible gantry cranes are safe for industrial and commercial use, maintaining operational integrity and minimizing risks to personnel and property. Regular inspections and maintenance, in line with these regulations, are critical for ongoing safety and efficiency.

List Reference Technical Parameters of “collapsible gantry crane”

A collapsible gantry crane is a versatile lifting device designed to provide mobility and flexibility in various industrial applications. Here are some key technical parameters:

1. Load Capacity:

– Ranges from 0.5 tons to 10 tons, depending on the model and application requirements.

2. Span Length:

– Typically varies from 2 meters to 12 meters, allowing adaptation to different workspace sizes.

3. Adjustable Height:

– The lifting height can usually be adjusted between 2 meters and 10 meters, accommodating various lifting demands.

4. Material:

– Constructed from high-strength steel or aluminum for durability, depending on the specific application and load requirements.

5. Wheelbase:

– Configurable wheelbase usually ranges between 2 meters to 5 meters, allowing stability and easy maneuverability.

6. Mobility:

– Equipped with swivel casters with locking mechanisms, enabling easy relocation and stationary positioning when needed.

7. Power Options:

– Available with manual hoists, electric hoists, or pneumatic hoists, catering to different operational preferences.

8. Folding Mechanism:

– Features a design that allows the crane to be folded or collapsed, enabling easy storage and transportation when not in use.

9. Assembly Time:

– Designed for quick assembly and disassembly, typically within 30 minutes to an hour, facilitating rapid deployment.

10. Safety Features:

– Includes overload protection, emergency stop functions, and certified lifting mechanisms to ensure safe operation.

11. Compliance:

– Built to meet or exceed industrial standards like ISO, OSHA, and ANSI, ensuring reliability and safety in various environments.

12. Operating Environment:

– Suitable for indoor and outdoor use, with temperature and weather-resistant features depending on the model.

13. Customizability:

– Available options for customization such as adjustable beam lengths, additional safety features, and specialized attachments for specific tasks.

These parameters ensure that a collapsible gantry crane can meet diverse operational needs while providing safety, efficiency, and convenience in material handling tasks.

List Product features of “collapsible gantry crane”

A collapsible gantry crane is a versatile piece of lifting equipment designed for various industrial and construction settings. Here are its key product features:

1. Portability:

– Lightweight and easy to transport.

– Suitable for both indoor and outdoor use.

– Features retractable legs for convenient storage and mobility.

2. Adjustable Height and Width:

– Telescoping mechanisms allow for adjustable height.

– Some models offer adjustable widths to accommodate different loads and spaces.

3. Quick Assembly and Disassembly:

– Can be quickly set up and taken down without specialized tools.

– Ideal for on-the-go operations and temporary sites.

4. Sturdy Construction:

– Made from durable materials such as steel or aluminum.

– Capable of lifting heavy loads while maintaining structural integrity.

– Resistant to corrosion, ensuring longevity.

5. Load Capacity:

– Available in various load capacities to suit different applications.

– Typically ranges from a few hundred pounds to several tons.

6. Mobility:

– Some models include caster wheels with brakes for easy movement and stability.

– Allows for smooth relocation within a workspace.

7. Safety Features:

– Equipped with secure locking mechanisms.

– Often includes load limit warnings and stability features to prevent tipping.

8. Versatility:

– Ideal for a wide range of industries, including manufacturing, warehousing, and maintenance.

– Can be used for lifting and positioning machinery, equipment, and other heavy loads.

9. Ease of Use:

– User-friendly design requires minimal training.

– Compatible with various lifting accessories like hoists and trolleys.

10. Cost-Effective:

– A cheaper alternative to permanent or semi-permanent lifting systems.

– Low maintenance costs compared to traditional cranes.

These features make collapsible gantry cranes a practical and efficient solution for many lifting and material handling tasks.

List Application of “collapsible gantry crane”

A collapsible gantry crane is a versatile lifting solution characterized by its ability to be disassembled or folded for easy transport and storage. Its applications span various industries due to its flexibility and efficiency. Here are some key uses:

1. Construction Sites: Often employed for lifting heavy materials like steel beams, concrete blocks, and other construction components. Its mobility allows it to be easily moved across different sections of a site.

2. Warehouses: Ideal for loading and unloading goods, as well as for moving heavy items within confined spaces. The collapsible feature allows for efficient storage when not in use.

3. Workshops and Manufacturing: Used to transport machine parts, engines, and other heavy equipment. Its adjustable height and portability make it suitable for different tasks within the same facility.

4. Marine and Boating: Essential for lifting boats, engines, and other heavy marine equipment. The crane’s collapsibility is beneficial for transport and storage near docks or marinas.

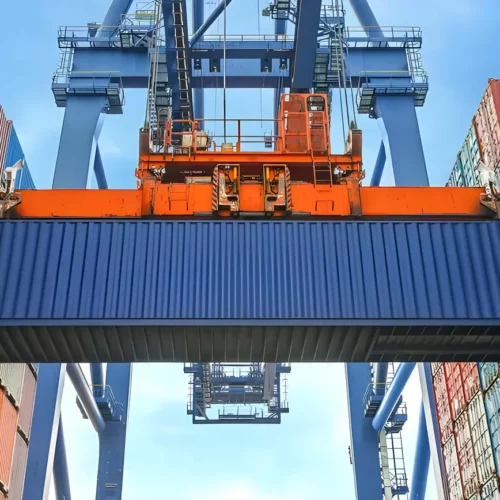

5. Logistics and Freight Handling: Deployed in loading docks and freight yards to handle containers and large packages. Easily collapsible, it can be transported to various locations as needed.

6. Automotive Repair Shops: Used to lift car engines, transmissions, and other heavy auto parts, providing an efficient solution for automotive repairs and maintenance.

7. Event Setup and Breakdown: Ideal for assembling and disassembling heavy equipment used in concerts, festivals, or other large-scale events. Its portability ensures quick setup and dismantling.

8. Aerospace Industry: Facilitates the movement and assembly of large aircraft components. Its precision and ease of handling make it indispensable in assembling non-standard parts.

9. Utility and Maintenance Services: Employed by utility companies for servicing power lines, pipelines, and other infrastructure requiring heavy lifting in remote or difficult-to-reach areas.

The collapsible gantry crane is indispensable for tasks requiring heavy lifting, portability, and space-efficiency, making it a critical asset across multiple sectors.

List Various Types of “collapsible gantry crane”

Certainly! Collapsible gantry cranes come in varied types tailored for different industrial needs. Here are some common types:

1. Portable Collapsible Gantry Cranes

– Description: Lightweight and easy to move, these cranes are ideal for light-duty applications.

– Applications: Workshops, maintenance facilities, and smaller construction sites.

2. Adjustable Height Collapsible Gantry Cranes

– Description: These cranes allow height adjustments to suit different working environments and load sizes.

– Applications: Warehouses, repair shops, and areas requiring different lifting heights.

3. Folding Gantry Cranes

– Description: These cranes can be folded down efficiently for storage and transport when not in use.

– Applications: Mobile maintenance teams, temporary worksites, and remote locations.

4. Telescoping Collapsible Gantry Cranes

– Description: Equipped with telescoping legs, these cranes can extend to various heights and retract when not needed.

– Applications: Varied industrial sites requiring flexible height settings.

5. Knockdown Gantry Cranes

– Description: These are designed for easy assembly and disassembly, making them simple to transport and store.

– Applications: Temporary job sites, field operations, and emergency service use.

6. Aluminum Collapsible Gantry Cranes

– Description: Made of lightweight aluminum, these cranes are corrosion-resistant and easy to maneuver.

– Applications: Facilities where weight and ease of movement are critical, such as aerospace and aviation sectors.

7. Motorized Collapsible Gantry Cranes

– Description: These include motorized elements for easier lifting, moving, and collapsing functions.

– Applications: Heavy-duty industrial environments and areas where manual lifting is impractical.

8. A-Frame Collapsible Gantry Cranes

– Description: Featuring an A-frame design, these cranes provide sturdy and balanced lifting options and can be collapsed when not needed.

– Applications: Construction sites, manufacturing units, and large-scale warehouses.

Conclusion

Each type of collapsible gantry crane has unique features catering to specific industrial needs, enhancing efficiency and flexibility in material handling.

collapsible gantry crane Accessories Upgrades and Custom Manufacturing Options

Collapsible gantry cranes are versatile and efficient for various material handling applications. Accessorizing and upgrading these cranes can significantly enhance their functionality, efficiency, and safety. Here are some popular options:

1. Motorized Movement: Upgrading manual push-pull systems to motorized travel enhances the ease of movement, particularly for heavy loads, reducing operator strain and increasing productivity.

2. Adjustable Height: Collapsible gantry cranes with adjustable heights provide flexibility to handle different load sizes and workspaces. Hydraulic or manual adjustment systems can be integrated based on operational needs.

3. Telescoping I-Beams: These allow for variable spans, accommodating different load requirements and workspace constraints, thus maximizing the crane’s versatility.

4. Wireless Remote Control: Implementing wireless controls facilitates safer and more precise operation from a distance, minimizing the risk to operators.

5. Custom End Trucks: Tailored end trucks cater to specific rail or floor conditions, ensuring smoother movement and stability during operations.

6. Swivel Locking Casters: Upgrading to heavy-duty swivel locking casters enhances mobility and stability, allowing for precise positioning and secure stationary operation.

7. Custom Paint and Coatings: Special coatings, like corrosion-resistant or powder coatings, extend the lifespan of the crane, particularly in harsh environments, ensuring longevity and safety compliance.

8. Load Indicators and Sensors: Integrating digital load indicators, limit switches, and sensors helps monitor load weight and positioning, preventing overloading and improving operational safety.

9. Ergonomic Lifts and Hoists: Custom lifts and hoists, including electric and pneumatic options, can be installed for specific material handling needs, boosting efficiency and safety.

10. Safety Features: Adding features like anti-drop plates, warning alarms, and emergency stop buttons enhances safety during operations.

For custom manufacturing, businesses can choose specific materials, dimensions, and configurations to perfectly match their operational demands. Working with a reputable manufacturer ensures these upgrades and customizations are seamlessly integrated, optimizing performance and durability.

List Quality Control and The Manufacturing Process of “collapsible gantry crane”

Quality Control in Collapsible Gantry Crane Manufacturing

1. Design Validation:

– CAD Review: Ensuring all components are designed to specifications.

– Simulation: Stress tests and load distribution analysis via software.

2. Material Inspection:

– Supplier Verification: Raw materials sourced from certified suppliers.

– Material Testing: Mechanical properties, weldability, and corrosion resistance checks.

3. Fabrication:

– CNC Machining: Precision cutting and drilling.

– Welding: Only certified welders perform welding; joints inspected using Non-Destructive Testing (NDT).

– Surface Treatment: Application of anti-corrosion paint, galvanizing, or other coatings.

4. Assembly:

– Component Matching: Ensuring all parts fit together precisely.

– Torque Testing: Bolts and fasteners checked for proper torque settings.

– Lubrication: Moving parts are adequately lubricated.

5. Pre-Delivery Inspection:

– Load Testing: Verify load capacities with simulated weights.

– Functional Tests: Check for smooth operation, including raising, lowering, and mobility.

– Safety Checks: Ensuring all safety features are operational, such as brakes and emergency stops.

6. Documentation and Training:

– User Manuals: Comprehensive guides provided for assembly, operation, and maintenance.

– Training Sessions: Conducted for operators and maintenance personnel.

Manufacturing Process of Collapsible Gantry Crane

1. Concept and Design:

– Initial concepts are drawn up based on customer needs.

– CAD models and simulations are created for feasibility studies.

2. Material Procurement:

– High-quality materials like steel are sourced and inspected upon arrival.

3. Fabrication:

– Raw materials are cut and shaped using CNC machines.

– Welders assemble primary structures, ensuring all joints are robust.

– Surface treatments like painting or galvanizing are applied for corrosion protection.

4. Part Assembly:

– Pre-fabricated components are assembled, including the gantry frame, hoist, and wheels.

– Precision checks are conducted to ensure all parts fit perfectly.

5. Quality Assurance:

– Rigorous testing including load and stress testing.

– Inspection teams review dimensional accuracy and functional reliability.

6. Final Assembly and Testing:

– The crane is fully assembled and undergoes final checks.

– Operational tests include movement, lifting, and safety feature verification.

7. Packaging and Delivery:

How to use “collapsible gantry crane”

A collapsible gantry crane is a versatile lifting device used for moving heavy loads in workshops, warehouses, or construction sites. Here’s a concise guide on how to use it:

1. Unfolding and Setup:

– Position the crane on a flat and stable surface.

– Unfold the legs by releasing the locking pins and extending each leg until it locks into place.

– Ensure the legs are fully extended and the frame is stable.

2. Adjusting the Height:

– Some models feature adjustable heights. Release the locking mechanism and adjust the vertical beams to the desired height, then secure the locks.

3. Attaching the Hoist:

– Secure the hoist or trolley to the horizontal beam (sometimes called the I-beam).

– Ensure it is properly attached and moves smoothly along the beam.

4. Positioning the Load:

– Place the load directly beneath the I-beam.

– Attach the load using appropriate lifting slings or chains.

5. Lifting the Load:

– Operate the hoist to lift the load. Make sure to lift slowly and steadily to avoid swinging.

– Once lifted, use the trolley to move the load horizontally along the I-beam.

6. Transporting:

– If your gantry crane is mobile, you can push or pull the crane to transport the load to the desired location within the workspace.

– Ensure the pathway is clear of obstacles and the floor is even to prevent tipping.

7. Lowering the Load:

– Once at the desired location, use the hoist to slowly lower the load.

8. Collapsing and Storage:

– After use, lower the crane height, disengage the locks, and fold the legs.

– Store the crane in a secured location.

Safety Notes:

– Always check the crane’s weight capacity before use.

– Wear appropriate PPE (Personal Protective Equipment).

– Regularly inspect the crane for wear and damage.

By following these steps, you can effectively and safely use a collapsible gantry crane for various lifting tasks.

“collapsible gantry crane” Comparative Analysis

Comparative Analysis: Collapsible Gantry Crane

#### Overview

A collapsible gantry crane is a versatile lifting solution commonly used in various industries such as shipping, construction, and manufacturing. It stands out due to its portability and ease of storage compared to standard gantry cranes.

#### Design & Portability

– Standard Gantry Crane: Typically robust and constructed from heavy-duty materials. They are permanently installed or have limited mobility.

– Collapsible Gantry Crane: Designed with foldable components, making it lightweight and easily transportable. It can be disassembled for convenient storage and relocation.

#### Load Capacity

– Standard: Standard gantry cranes can handle significantly heavier loads, often exceeding several tons.

– Collapsible: Generally supports lighter loads, suitable for smaller projects and operations. Despite this, some heavy-duty collapsible models can still handle substantial weights.

#### Installation & Flexibility

– Standard: Requires a permanent or semi-permanent installation with a dedicated space. Installation can be complex and time-consuming.

– Collapsible: Quick to assemble and disassemble, providing flexibility for varied and temporary job sites. Ideal for environments where space is a premium or operations are temporary.

#### Cost

– Standard: Higher initial investment due to robust construction and installation requirements.

– Collapsible: More cost-effective initially and when considering potential relocation or reconfiguration costs.

#### Applications

– Standard: Optimal for high-volume, continuous operations such as warehouses, shipyards, and large factories.

– Collapsible: Suits intermittent use, small to medium-sized operations, and scenarios demanding frequent relocation, such as construction sites or smaller workshops.

#### Maintenance

– Standard: Maintenance is generally more intensive due to the larger and more complex structure.

– Collapsible: Easier and typically less frequent maintenance, given the simpler design and structure.

Conclusion

Collapsible gantry cranes offer significant advantages in portability, flexibility, and cost-efficiency for small to medium-scale operations requiring intermittent use. In contrast, standard gantry cranes are better suited for heavy-duty, continuous operations with less emphasis on mobility and storage.

“collapsible gantry crane” Warranty and Support

Warranty and Support for Collapsible Gantry Crane

Our collapsible gantry cranes come with a comprehensive warranty to ensure customer satisfaction and product reliability. Each crane is backed by a two-year warranty covering any defects in materials and workmanship under normal use and maintenance. Should any issues arise during this period, we offer full support, including replacement parts and repair services at no additional cost.

For optimal performance and extended lifespan, regular maintenance is crucial. Therefore, a detailed user manual is provided, outlining the best practices for operation and maintenance. Our technical support team is readily available to assist with any operational queries or troubleshooting. Contact can be made via phone, email, or through our website’s support portal.

In addition to the standard warranty, customers have the option to purchase an extended warranty plan, which includes further coverage for an additional one or two years. This plan also provides priority support and access to certified technicians for onsite inspections and repairs.

We also offer annual maintenance contracts (AMCs) to ensure your gantry crane remains in peak condition. These contracts include periodic inspections, preventive maintenance, and discounted rates on spare parts and labor.

For any service requests or warranty claims, our customer support staff is dedicated to providing prompt and efficient resolutions. We strive to minimize downtime and ensure your crane operates safely and effectively.

In summary, our collapsible gantry cranes come with a robust warranty and thorough support network, ensuring peace of mind and reliable performance. We are committed to delivering exceptional service and maintaining long-term customer relationships.

For more detailed information or specific inquiries, please refer to the user manual or contact our support team directly.

List “collapsible gantry crane” FAQ

Collapsible Gantry Crane FAQ

1. What is a collapsible gantry crane?

A collapsible gantry crane is a type of mobile crane designed for easy assembly and disassembly, featuring a framework that can be folded or collapsed for convenient transport and storage.

2. What are the primary uses of a collapsible gantry crane?

These cranes are commonly used in workshops, warehouses, and construction sites for lifting and moving heavy loads. They’re particularly useful in environments with limited space and where mobility is required.

3. What materials are collapsible gantry cranes made from?

They are typically constructed from steel or aluminum. Steel offers higher load capacity, whereas aluminum models provide the advantage of being lightweight and corrosion-resistant.

4. What load capacities are available for collapsible gantry cranes?

Load capacities can range from a few hundred pounds to several tons, depending on the model and manufacturer. Always consult the crane’s specifications to ensure it meets your lifting requirements.

5. Are collapsible gantry cranes adjustable?

Yes, many models offer height and span adjustments to adapt to various lifting tasks and spaces. This feature adds versatility and efficiency to material handling operations.

6. How do you assemble and disassemble a collapsible gantry crane?

Most models come with detailed assembly instructions and require common tools such as wrenches. Typically, the process involves securing the legs, attaching the crossbeam, and ensuring all bolts and nuts are tightened.

7. Is specialized training required to operate a collapsible gantry crane?

While basic crane operation training is recommended, collapsible gantry cranes are generally user-friendly. Employers should ensure operators are familiar with safety guidelines and operational procedures.

8. How do you ensure safety while using a collapsible gantry crane?

Always adhere to the manufacturer’s guidelines regarding load limits and assembly. Regular inspections for wear and tear, proper weight distribution, and using the crane on a stable, flat surface are crucial for safe operation.

9. Are there any maintenance requirements?

Routine maintenance includes inspecting for structural integrity, checking moving parts for wear, and lubricating components as necessary. Periodic professional inspections can also help maintain long-term safety and functionality.

10. Where can I purchase a collapsible gantry crane?

They are available through industrial equipment suppliers, online marketplaces, and specialized manufacturers. Ensure you choose a reputable source that offers quality equipment and customer support.

By understanding these FAQs, you can make informed decisions about purchasing and using collapsible gantry cranes for various lifting needs.

Top 10 FAQ with answer about collapsible gantry crane for Buyer Sourcing from China

Certainly! Here are the top 10 FAQs with answers for buyers sourcing a collapsible gantry crane from China:

1. What is a collapsible gantry crane?

A collapsible gantry crane is a type of material handling equipment designed for easy assembly, disassembly, and transport. It features a lightweight, modular structure that can be folded for compact storage and mobility.

2. What are the main benefits of using a collapsible gantry crane?

The primary benefits include flexibility, portability, and ease of storage. They are ideal for temporary or frequently changing work sites, offering quick setup and breakdown.

3. What materials are commonly used in collapsible gantry cranes?

Typically, these cranes are made from high-strength steel or aluminum. Aluminum is favored for its lighter weight and corrosion resistance, while steel offers higher load-bearing capacity.

4. What are the load capacities available?

Collapsible gantry cranes come in various load capacities, generally ranging from 0.5 to 10 tons. It’s crucial to choose a crane that meets your specific lifting requirements.

5. How do I ensure the quality of a crane sourced from China?

To ensure quality, look for manufacturers with ISO certifications, check for compliance with international standards (like CE or ANSI), and request third-party inspection reports.

6. What is the typical lead time for manufacturing and delivery?

Lead times can vary, but generally, it takes 4-8 weeks for manufacturing and an additional 2-4 weeks for shipping, depending on your location and the shipping method used.

7. Can I request customization for a collapsible gantry crane?

Yes, many Chinese manufacturers offer customization options to suit specific lifting, height, or mobility needs. Ensure your requirements are clearly communicated during the initial quotation phase.

8. What is the import duty and shipping cost to my country?

Import duties and shipping costs depend on your country’s regulations and the shipping method (air, sea, or land). It’s advisable to consult with a freight forwarder or customs broker for accurate estimates.

9. What kind of after-sales support is available?

Reputable Chinese suppliers offer after-sales support including technical assistance, spare parts, and warranty services. Verify the terms and duration of the warranty provided.

10. How do I handle assembly and maintenance?

Collapsible gantry cranes typically come with detailed assembly guides. Additionally, it’s best to employ trained personnel for assembly and routine maintenance to ensure safety and longevity of the equipment.