diy wooden jib crane Safety Certifications

Building a DIY wooden jib crane requires adherence to safety standards to ensure it is both functional and secure. There’s no universal safety certification for homemade cranes, but several guidelines and regulations can help ensure your project meets necessary safety protocols:

1. OSHA Standards: The Occupational Safety and Health Administration (OSHA) provides comprehensive guidelines on crane safety. Specifically, OSHA 1926 Subpart CC addresses construction crane and derrick standards, which can be adapted for your DIY project. While these standards are designed for larger, commercial cranes, they offer foundational safety principles applicable to smaller, home-built versions.

2. Materials and Design: Use high-quality, treated lumber and avoid materials with visible defects such as knots or cracks. Ensure that the design incorporates proper load distribution and stability. It’s advisable to consult engineering tables and design guides to determine the correct size and strength of the wooden components.

3. Load Testing: Before using the crane for regular tasks, conduct a load test by lifting weights that meet or slightly exceed the crane’s projected maximum load. This helps confirm the structural integrity and balance of the crane.

4. Hardware and Fastening: Use high-strength, corrosion-resistant bolts, screws, and other fasteners. Reinforce joints with metal brackets if necessary to ensure robust connections.

5. Safety Devices: Incorporate safety features such as load limiters and proper rigging equipment. Ensure that the hoisting mechanism (winch, pulley system, etc.) is rated for the intended load and inspected regularly for wear and tear.

6. Inspection and Maintenance: Develop a routine inspection checklist to identify and address any signs of wear, damage, or instability. Regular maintenance and timely repairs are crucial to sustain the crane’s safety and functionality.

7. Training: Ensure all users are trained to operate the crane safely. Familiarize everyone with its limitations and proper use techniques to prevent accidents.

By following these guidelines, you can enhance the safety of your DIY wooden jib crane, thereby minimizing risks and ensuring reliable operation.

List Reference Technical Parameters of “diy wooden jib crane”

A DIY wooden jib crane is a versatile and cost-effective lifting device suitable for workshops, garages, or small-scale construction projects. Here are the key reference technical parameters to consider:

1. Load Capacity: The maximum weight the crane can lift, typically measured in kilograms (kg) or pounds (lbs). Common DIY variants might support loads ranging from 50 kg to 200 kg.

2. Boom Length: The horizontal length of the jib (arm) from the pivot point to the hook, typically between 2 to 4 meters (6 to 13 feet).

3. Height: The vertical distance from the base to the highest point of the structure. It could range from 2 meters (6.5 feet) to 3 meters (10 feet).

4. Swivel Radius: The angular range the jib can rotate, often up to 180 degrees for simpler designs, though some may offer a full 360-degree rotation.

5. Material Specifications:

– Wood Type: Hardwood such as oak or maple is preferred for its strength and durability.

– Dimensions: Beam sizes typically in the range of 4×4 to 6×6 inches, depending on the load requirements.

6. Anchoring System: Details on how the crane is anchored to the ground or base structure. Often involves bolting to a concrete floor or wall anchorage.

7. Pulley and Hoist System: Specifications of the lifting mechanism, including:

– Pulley Materials: Durable metals like steel or aluminum.

– Hoist Type: Manual chain hoist or electric hoist, with capacities matching the load limit.

8. Safety Factors: Includes:

– Load Testing: Regular load testing protocols.

– Safety Margins: Typically, a design safety factor of at least 1.5 times the maximum load capacity.

9. Assembly and Fastening: Quality and type of fasteners (bolts, screws, brackets) needed for secure assembly, preferably galvanized or stainless steel for longevity and strength.

10. Maintenance Requirements: Routine checks for structural integrity, lubrication of moving parts, and inspections for wood degradation.

These parameters ensure the crane is designed safely, meets lifting requirements, and offers longevity in its application.

List Product features of “diy wooden jib crane”

Product Features of DIY Wooden Jib Crane

1. Sturdy Construction: Made from high-quality, durable hardwood that ensures longevity and stability during operations.

2. Adjustable Boom Length: Features an extendable boom allowing for various lengths to accommodate different lifting needs.

3. Swiveling Arm: Equipped with a 360-degree rotating arm for enhanced maneuverability and flexibility in handling loads.

4. Easy Assembly: Comes with pre-drilled holes and comprehensive instructions for straightforward assembly, making it suitable for DIY enthusiasts.

5. Versatile Applications: Ideal for small workshop tasks, garage use, or light construction projects, providing a wide range of potential uses.

6. Load Bearing Capacity: Designed to handle moderate loads, with a specified load limit ensuring safe operation.

7. Compact Size: Space-saving design that fits into small workspaces without sacrificing functionality.

8. Portable: Lightweight construction makes it easy to move and reposition as needed within the work area.

9. Safety Features: Includes locking mechanisms and safety latches to secure the load and minimize risk during operation.

10. Eco-Friendly Materials: Constructed from responsibly sourced wood, promoting environmental sustainability.

11. Cost-Effective: A budget-friendly solution compared to metal cranes, offering excellent value for money.

12. Customizable Design: Allows for modifications and upgrades, such as adding pulley systems or electric winches, to enhance performance.

13. Smooth Operation: Features smooth-running pulleys and bearings that reduce friction, making lifting easier and more efficient.

14. Educational Value: Provides a practical learning experience for DIY enthusiasts, educators, and students interested in engineering and mechanics.

This DIY wooden jib crane blends functionality with the simplicity of assembly, making it a versatile tool for various light-duty lifting tasks while being an enjoyable and educational project.

List Various Types of “diy wooden jib crane”

A DIY wooden jib crane is a versatile lifting device that can be built using basic woodworking skills. Here are various types:

1. Fixed Jib Crane

– Description: This design is anchored to a stable base or wall.

– Uses: Ideal for applications where the lifting range is fixed and predictable.

2. Mobile Jib Crane

– Description: Mounted on a wheeled base.

– Uses: Offers flexibility to move around the workspace for lifting different objects.

3. Adjustable Height Jib Crane

– Description: Features an adjustable vertical post.

– Uses: Suitable for varying lifting heights; beneficial in workshops with diverse projects.

4. Rotating Boom Jib Crane

– Description: Equipped with a rotating boom for enhanced reach.

– Uses: Useful in confined spaces where lateral movement is crucial.

5. Telescopic Boom Jib Crane

– Description: Incorporates a telescopic boom to extend reach horizontally.

– Uses: Adaptable for different load sizes and distances.

6. Workbench-Mounted Jib Crane

– Description: Attached directly to a workbench.

– Uses: Perfect for detailed tasks at the workbench that require lifting and positioning.

7. Gantry-Mounted Jib Crane

– Description: Attached to a gantry frame.

– Uses: Provides a combination of vertical lift and horizontal travel.

8. Counterbalanced Jib Crane

– Description: Employs counterweights to stabilize while lifting.

– Uses: Allows for a more stable and controlled lift, good for delicate objects.

9. Folding Jib Crane

– Description: Can be folded for storage when not in use.

– Uses: Ideal for space-saving in a crowded workshop.

10. Swing Arm Jib Crane

– Description: Features a swing arm for additional articulation.

– Uses: Improves maneuverability around obstacles.

Each type can be customized further based on specific load requirements, space constraints, and lifting range needs, making DIY wooden jib cranes highly adaptable for different tasks and environments.

List Application of “diy wooden jib crane”

A DIY wooden jib crane can offer numerous practical applications, especially for hobbyists, small businesses, and homeowners. Here are some key uses:

1. Workshop Assistance: Ideal for lifting heavy materials and tools around a workshop. It can help in maneuvering large, bulky items like engines, woodworking materials, and metal sheets.

2. Construction Sites: Useful in small-scale construction projects for handling and moving construction materials such as bricks, cement bags, and lumber, improving efficiency and reducing the physical strain on workers.

3. Gardening and Landscaping: Makes it easier to lift and move heavy garden equipment, potted plants, statues, and decorative stones, assisting in the beautification and maintenance of gardens and landscapes.

4. Home Renovations: Crucial for homeowners engaging in DIY renovations. It can help in lifting heavy furniture and appliances, installing beams, and placing drywall or other materials, making the process safer and more manageable.

5. Agriculture and Farming: Assists in handling farm equipment, feed bags, irrigation parts, and bales of hay, contributing to more efficient farm operations.

6. Marine Use: Handy on docks or small boats to lift and maneuver heavy equipment, supplies, or catch of the day, making loading and unloading tasks less strenuous.

7. Storage Organization: In warehouses or storage units, it can help in shifting and organizing bulky items, ensuring better space utilization and easier access to stored goods.

8. Craftsmanship Projects: Beneficial for artisans who work with heavy raw materials or finished products, such as metal sculptures or large woodworking pieces, facilitating safer material handling.

9. Disaster Relief and Recovery: Can aid in lifting debris and salvageable materials during clean-up operations, making it a valuable tool for community-led recovery efforts after natural disasters.

A DIY wooden jib crane is a versatile and practical tool that can significantly enhance productivity and safety in various settings by efficiently handling heavy loads.

List Buyer Types of “diy wooden jib crane”

Understanding the different buyer types for a “DIY wooden jib crane” can help in tailoring marketing strategies and product offerings. Here are the primary buyer types:

1. Hobbyists and DIY Enthusiasts: These buyers enjoy building and creating things on their own. They are drawn to the challenge and satisfaction that comes from completing a project from scratch. They seek detailed guides, clear instructions, and innovative designs.

2. Small Business Owners and Entrepreneurs: Particularly those in industries like construction, agriculture, or craft businesses where a jib crane can aid in lifting and moving heavy materials or products. They look for cost-effective, efficient solutions to enhance their operations.

3. Educational Institutions: Schools, colleges, and technical training centers may purchase DIY jib crane kits for educational purposes. These institutions use them for teaching principles of engineering, mechanics, and physics to students through practical, hands-on experience.

4. Farmers and Rural Area Workers: Individuals in agricultural sectors often need equipment for lifting heavy items like feed, machinery parts, or harvests. They appreciate sturdy, reliable, and easy-to-construct solutions that can be utilized in a barn or workshop setting.

5. Handyman Services and Contractors: Those in the handyman or contracting business can benefit from having a portable and easy-to-assemble jib crane. This buyer seeks reliable tools that can enhance their service offerings and improve efficiency on job sites.

6. Artists and Sculptors: Artists working with large materials or sculptures may find a DIY wooden jib crane to be a versatile tool for their studios. They value the ability to move heavy and often delicate pieces safely.

7. Resellers and Distributors: Retailers or online sellers who cater to the above-mentioned markets might purchase DIY wooden jib cranes in bulk. These buyers look for wholesale prices and high-quality products that they can offer to their customers.

Understanding these buyer types can help vendors customize their product features, marketing messages, and sales strategies to meet diverse needs effectively.

List “diy wooden jib crane” Project Types for Different Industries

Creating a DIY wooden jib crane can be a versatile project applicable to various industries. Here are some project types tailored to different sectors:

1. Construction Industry

– Project: Construction Site Material Handling

– Overview: A robust wooden jib crane can help lift and place heavy construction materials, such as bricks and beams, making it ideal for small to medium construction sites.

2. Film and Photography

– Project: Camera Crane for Film Sets

– Overview: A smaller, lightweight version of a wooden jib crane can be designed to support and maneuver cameras, providing dynamic shots for movies or photography projects.

3. Agriculture

– Project: Farm Equipment Maintenance

– Overview: A wooden jib crane can be used to lift heavy farm machinery parts for maintenance, repairs, or assembly, enhancing farm operations’ efficiency.

4. Manufacturing

– Project: Workshop Tool Handling

– Overview: In a manufacturing workshop, a wooden jib crane can be used to move heavy tools and components, facilitating smoother and safer operations.

5. Warehouse and Storage

– Project: Pallet Loading and Unloading

– Overview: This crane can assist in moving heavy pallets or crates, ensuring safe and efficient material handling in warehouse settings.

6. Maritime Industry

– Project: Boat Maintenance

– Overview: A wooden jib crane can help lift boat parts or other heavy equipment, aiding in routine maintenance and repair tasks.

7. Forestry and Logging

– Project: Timber Handling

– Overview: A wooden jib crane is beneficial for lifting and moving large logs, making it easier for workers to perform tasks like sawing or transportation.

8. Event Management

– Project: Stage Setup

– Overview: Used to lift and position heavy stage equipment and decorations, ensuring the smooth execution of event setups.

In summary, a DIY wooden jib crane offers practical solutions across various industries, highlighting its versatility and cost-effectiveness for lifting and handling heavy loads.

diy wooden jib crane Accessories Upgrades and Custom Manufacturing Options

Creating a DIY wooden jib crane can be an incredibly rewarding project, offering both functionality and a sense of accomplishment. Here are some accessory upgrades and custom manufacturing options to elevate your crane:

Accessories:

1. Pulleys and Winches: Enhance the lifting mechanism by adding a high-quality pulley system and winch. This can increase the weight capacity and ease the lifting process.

2. Swivel Base: Install a heavy-duty metal swivel base to allow for 360-degree rotation. This adds flexibility in the crane’s range of motion.

3. Extendable Boom: Consider adding an extendable boom to increase the crane’s reach. Telescopic designs made from lighter but sturdy materials can be very effective.

4. Safety Latches and Hooks: For added safety, integrate industrial-grade latches and hooks designed to hold significant weight securely.

5. Counterweights: Use adjustable counterweights to balance the load properly, improving both safety and efficiency.

6. Electric Motor: For advanced users, an electric motor can be integrated to automate the lifting and lowering mechanism.

Custom Manufacturing Options:

1. High-Grade Wood: Use high-grade, pressure-treated lumber for greater durability and strength. Hardwoods like oak or maple can bear more weight.

2. Metal Reinforcements: Add metal brackets or plates at critical stress points to enhance structural integrity.

3. Anti-Slip Base: Install rubber pads or a skid-resistant base to prevent the crane from slipping during use.

4. Weatherproofing: Apply waterproof sealants or varnishes to protect the wood from moisture and extreme weather conditions, extending the crane’s lifespan.

5. Modular Design: Opt for a modular design that allows for easy assembly and disassembly. This can facilitate storage and transport.

6. Custom Paint Job: A weather-resistant paint job not only adds an aesthetic touch but also provides an additional layer of protection against the elements.

By incorporating these accessories and custom manufacturing options, your DIY wooden jib crane can become a versatile, efficient, and durable tool tailored to your specific needs.

List Quality Control and The Manufacturing Process of “diy wooden jib crane”

Quality Control in DIY Wooden Jib Crane Manufacturing

1. Material Inspection: Ensure high-quality, defect-free wood, such as oak or birch, is selected. Inspect for knots, cracks, and moisture content. Use high-grade hardware like bolts, nuts, and hinges.

2. Dimensional Accuracy: Check all cut wooden pieces for dimensional accuracy. Ensure they conform to design specifications using calipers or measuring tapes. This prevents misalignment during assembly.

3. Joint Integrity: For critical joints, test the fit and strength. Apply appropriate wood glue and clamps for secure bonding. Monitoring dry times ensures maximum adhesive efficiency.

4. Load Testing: Before deployment, subject the crane to static and dynamic load tests to validate its weight-bearing capacity. Any signs of stress or deformity necessitate design reevaluation.

5. Finishing: Inspect for smooth edges and surfaces post-sanding to avoid splinters. Check that finishes such as varnish or paint are evenly applied and fully dry, enhancing both aesthetics and durability.

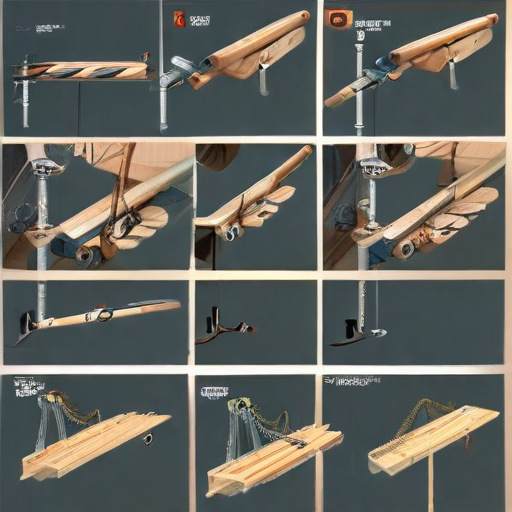

Manufacturing Process for DIY Wooden Jib Crane

1. Design and Plan:

– Create detailed blueprints.

– List all materials and tools needed, like saws, drills, and measuring devices.

2. Material Preparation:

– Select quality wood.

– Cut wooden components to exact dimensions per design using circular or table saws.

3. Assembly:

– Construct the base using precise cut wood pieces, ensuring stability.

– Assemble the jib arm, ensuring it has a secure pivot point.

– Attach the arm to the base using heavy-duty hinges or pivots.

4. Mechanical Integration:

– Integrate pulleys and winches, ensuring they are securely fastened for smooth operation.

– Attach swivels or rotary unions if the jib arm needs rotational capability.

5. Load Attachment:

– Fix hooks or other load-bearing attachments to the jib arm, ensuring they are robust.

6. Final Inspection:

– Conduct thorough final checks on all components.

– Ensure operational safety through load tests and adjustments.

This streamlined process ensures a DIY wooden jib crane that is both functional and safe for use in hobby or light commercial applications.

How to use “diy wooden jib crane”

Using a DIY wooden jib crane can be straightforward and effective for lifting moderate weights in your workshop or construction site. Here’s a guide on how to use it:

1. Inspection:

– Check Stability: Ensure the base is strong and level.

– Inspect Components: Look for any cracks, loose bolts, or wear in the wood and hardware.

2. Setup:

– Position the Crane: Move it to the desired lifting location.

– Secure the Base: If it’s a mobile crane, lock the wheels or secure the base to the ground to prevent movement.

3. Operating the Crane:

– Attach the Load: Secure the item you want to lift using an appropriate hoist, rope, or sling. Ensure the load is balanced and securely fastened.

– Lift Carefully: Use the manual or powered winch to raise the load. Do this slowly to ensure stability and control.

– Swing the Boom: Carefully rotate the jib arm to move the load to the desired location. Keep an eye on the load’s stability during this process.

4. Position the Load:

– Lower the Load: Use the winch to gently lower the load into its new position.

– Detach the Load: Once the load is secure, detach it from the crane.

5. After Use:

– Inspect Again: Check for any wear or damage post-operation.

– Store Properly: If not in use, secure the jib crane in a safe location to prevent damage or accidents.

Safety Tips:

– Always operate within the crane’s weight limits.

– Wear protective gear.

– Keep a clear area around the crane.

– Never leave a suspended load unattended.

By carefully following these steps, a DIY wooden jib crane can be a valuable tool for various lifting tasks.

“diy wooden jib crane” Comparative Analysis

Creating a DIY wooden jib crane offers a cost-effective and customizable option for many hobbyists and professionals. When analyzing the practicality and efficiency of such a project, some key factors emerge.

Cost Efficiency: Building a jib crane from wood significantly reduces costs compared to purchasing a commercially made metal crane. Wooden materials, particularly common varieties like pine or oak, are more affordable and accessible.

Customization: A DIY approach allows for tailoring the jib crane to specific needs, such as height, reach, and load capacity. However, wood has inherent limitations regarding strength and durability compared to metal. Careful selection of high-quality hardwoods and reinforcement techniques can mitigate some of these issues.

Ease of Construction: Woodworking skills are generally more widespread than metalworking skills. The tools required for a wooden jib crane—saws, drills, and clamps—are common in many home workshops. This ease potentially opens the project to a broader audience.

Maintenance and Longevity: Wooden structures are more susceptible to environmental factors such as moisture and pests. Treating the wood with proper finishes and regular maintenance can extend the lifespan but cannot entirely eliminate these vulnerabilities.

Load Capacity: Although wooden cranes can be robust, they generally won’t match the load-bearing capacity of their metal counterparts. This makes wooden jib cranes more suitable for light to moderate lifting tasks. For heavier loads, metal is undeniably superior.

Safety Considerations: Ensuring the structural integrity of a wooden jib crane requires precise calculations and high craftsmanship. Missteps in construction can lead to dangerous failures, emphasizing the need for careful planning and execution.

In conclusion, a DIY wooden jib crane can be an excellent project for those needing moderate lifting capabilities and desiring a low-cost, customizable solution. However, the trade-offs in durability, load capacity, and maintenance must be carefully weighed against the benefits. For higher loads and longevity, a commercial metal alternative might be necessary.

“diy wooden jib crane” Warranty and Support

When embarking on the DIY project of building your own wooden jib crane, understanding the implications related to warranty and support is crucial. Typically, DIY projects do not come with standard warranties that are typical of commercial products. This means if a part fails or an error occurs during construction, you are responsible for repairs and replacements.

1. Warranty:

– Materials: Warranty coverage for materials such as wood, screws, and metal parts depends on the individual suppliers or manufacturers. Ensure you purchase high-quality materials from reputable suppliers who offer a reasonable return or exchange policy.

– Tools & Equipment: Tools used for the assembly may come with their own manufacturer warranties. If a tool fails due to manufacturing defects, it can usually be repaired or replaced under this warranty.

2. Support:

– Design Help: Support for design can be accessed through community forums, DIY websites, and instructional videos. Engaging with DIY communities online can provide you with design advice, troubleshooting tips, and suggestions for improvements.

– Safety Standards: No formal support will ensure your crane meets safety standards unless you consult with an experienced engineer or a professional in structural design. It’s essential to follow guidelines carefully and conduct thorough safety checks.

– Emergency Assistance: In case of an emergency, having contact with a local professional or a DIY expert can be beneficial. It’s advisable to have a resource list beforehand.

Constructing a wooden jib crane can be a rewarding project, provided you manage and understand these aspects effectively. Proactively seeking advice, using reliable materials and tools, and staying informed about best practices will contribute significantly to the success and safety of your project.

List “diy wooden jib crane” FAQ

DIY Wooden Jib Crane FAQ

1. What is a wooden jib crane?

– A wooden jib crane is a simple lifting device made primarily from wood. It uses a horizontal beam (jib) mounted on a vertical support to lift and move heavy objects.

2. What materials do I need?

– Common materials include robust wooden beams, screws or bolts, metal brackets, pulleys, a winch, and sturdy anchors for securing the crane to a foundation or base.

3. What are the weight limits?

– Weight limits vary based on the quality and type of wood, construction, and additional reinforcements. Generally, a wooden jib crane can handle light to moderate loads, but it’s essential to calculate the load capacity before construction.

4. Is wood strong enough for a crane?

– Yes, if properly selected and constructed. Use hardwoods like oak or beech for load-bearing parts, and ensure all connections are secure and well-reinforced.

5. Can I add wheels for mobility?

– Yes, adding a sturdy base with heavy-duty caster wheels can make your crane mobile. Ensure the wheels are lockable to prevent unwanted movement during operation.

6. How do I ensure safety?

– Safety is paramount. Double-check all joints, regularly inspect for wear and tear, and never exceed the maximum load capacity. Using safety gear such as gloves and helmets during operation is also recommended.

7. How tall should it be?

– Height depends on your specific needs, but ensure the vertical support is high enough to lift objects without sacrificing stability. Typical DIY jib cranes stand between 6 to 12 feet tall.

8. Do I need special tools for construction?

– Basic woodworking tools such as a saw, drill, measuring tape, and wrench set are sufficient. However, advanced tools like a miter saw or power drill can make the task easier and more precise.

9. Can I use it indoors?

– Yes, as long as there is enough space and the floor is sturdy enough to support the crane and the load being lifted.

10. Is it cost-effective?

– Building a jib crane from wood can be more affordable than buying a metal one, especially if you have access to quality wood and basic woodworking tools.

Remember, always follow detailed plans and guidelines specific to your design to ensure safety and functionality.

Top 10 FAQ with answer about diy wooden jib crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) with their answers for buyers sourcing DIY wooden jib cranes from China:

1. What is a DIY Wooden Jib Crane?

A DIY wooden jib crane is a manually constructed lifting device using wood, designed for light lifting tasks. It typically features a pivoting arm allowing rotation and some degree of elevation for load handling.

2. Why source a DIY wooden jib crane from China?

China provides competitive pricing, a wide range of suppliers, and the ability to customize designs. Additionally, manufacturers often use efficient production methods ensuring affordability and quality.

3. How to ensure the quality of the wooden jib crane?

To ensure quality, request product samples, review certifications, check supplier ratings, or consider third-party inspections. ISO 9001 certification is often a good indicator of quality management systems.

4. What types of wood are commonly used?

Common types include pine, oak, and other durable hardwoods. Ensure the wood meets structural requirements and is treated to resist pests and environmental factors.

5. Are there customization options available?

Yes, many Chinese suppliers offer customization options including dimensions, load capacity, type of wood, and additional features like swivel bases or enhanced safety mechanisms.

6. What is the typical lead time for an order?

Lead times vary but generally range from 15 to 45 days depending on the complexity of the order and the supplier’s capacity.

7. What is the minimum order quantity (MOQ)?

MOQ varies among suppliers but generally ranges from 10 to 50 units. Some suppliers may offer lower MOQs for trial orders.

8. How can shipping and logistics be managed?

Most suppliers handle basic logistics and shipping. You can choose between sea, air, or rail freight based on your budget and urgency. Using a freight forwarder can also streamline the process.

9. What are the payment terms?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes Western Union or PayPal. A typical arrangement might be a 30% deposit with the balance paid before shipment.

10. Are there any warranties or guarantees?

Many suppliers offer warranties or guarantees ranging from one to three years. It’s crucial to discuss warranty terms, coverage, and claim procedures before finalizing the purchase.

These concise answers should help buyers make informed decisions when sourcing DIY wooden jib cranes from China.