double girder eot crane Safety Certifications

Double girder electrically operated traveling (EOT) cranes are essential in lifting heavy loads in various industries, and safety certifications are imperative to ensure their safe operation. Key safety certifications for such cranes include:

1. ISO 9001: This international standard ensures the crane’s manufacturing process meets quality management system requirements. It ensures the consistency of product quality and the continuous improvement of processes.

2. ISO 14001: This certification focuses on environmental management systems. It certifies that the crane manufacturer operates in an environmentally sustainable manner, reducing harmful environmental impacts.

3. ISO 45001: A crucial certification for occupational health and safety management systems, ISO 45001 ensures the manufacturing process and the crane’s operation prioritize worker safety, reducing workplace risks.

4. CE Marking: In the European Economic Area (EEA), the CE Marking indicates the crane complies with stringent EU safety, health, and environmental protection requirements. It is crucial for market access within EU countries.

5. ASME B30: The American Society of Mechanical Engineers (ASME) offers certifications such as ASME B30 for cranes, incorporating rigorous safety standards for design, construction, inspection, and maintenance.

6. FEM (Fédération Européenne de la Manutention): FEM standards provide guidelines specific to the European manufacturing industry, ensuring cranes meet high safety and performance standards.

7. ANSI/ASME B30.2: This American standard specifies safety requirements for overhead and gantry cranes, and it covers essential aspects like construction, maintenance, and operation safety.

8. CSA (Canadian Standards Association): CSA certifications ensure compliance with Canadian safety standards for industrial products, including cranes.

Manufacturers and operators of double girder EOT cranes should ensure adherence to these certifications to minimize risks, enhance safety, and comply with legal and industry standards. Regular training, maintenance, and inspection regimes also play a critical role in sustaining crane safety and operational integrity.

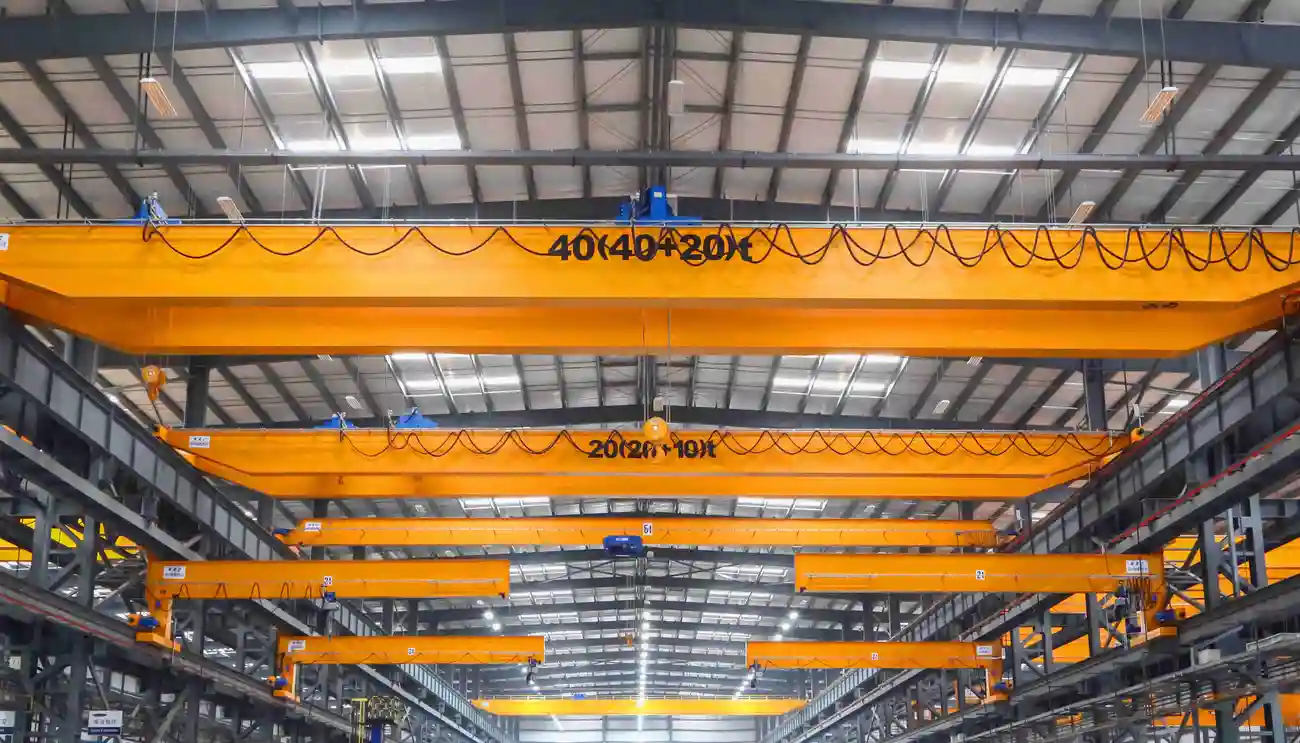

List Reference Technical Parameters of “double girder eot crane”

Sure, here is an outline of the reference technical parameters for a double girder EOT (Electric Overhead Traveling) crane:

1. Load Capacity:

– Range: Usually from 1 ton to over 500 tons.

– Determined by the application requirements and structural design.

2. Span:

– Typically ranges from 5 meters to over 40 meters.

– Defines the distance between the two runway rails.

3. Lifting Height:

– Common values range from 6 meters to over 50 meters.

– Can be customized based on the operational environment.

4. Travel Speed:

– Hoist: 1-20 meters per minute.

– Cross Travel (Trolley): 2-40 meters per minute.

– Long Travel (Crane): 3-100 meters per minute.

– These speeds can usually be adjusted or controlled via variable frequency drives (VFDs).

5. Power Supply:

– Typically 3-phase AC ranging from 220V to 440V, 50/60 Hz.

– Power consumption varies with load capacity and operational speed.

6. Control System:

– Options: Pendant control, wireless remote control, or cabin control.

– Modern systems may use PLCs (Programmable Logic Controllers) for advanced automation and safety features.

7. Duty Class:

– Classification per standards: A1 to A8 (ISO), based on operating frequency and load spectrum.

– E.g., Class A1 for light duty, Class A8 for heavy, continuous duty.

8. Hoisting Mechanism:

– Types: Wire rope hoist or chain hoist.

– Provide smooth and reliable lifting operations.

9. Material:

– Bridge girders made from high-strength structural steel.

– High-grade components for hoisting, traveling mechanisms, and electrical systems.

10. Safety Features:

– Overload protection, limit switches, emergency stop, anti-collision systems.

– Comply with safety standards like OSHA, ANSI, or equivalent regional standards.

These parameters ensure that the double girder EOT crane delivers reliable, safe, and efficient performance tailored to specific needs.

List Product features of “double girder eot crane”

Certainly! Double girder EOT (Electric Overhead Travelling) cranes are robust lifting solutions commonly used in industrial settings for heavy lifting operations. Here are the key features:

1. High Load Capacity:

– Designed to handle heavy loads typically ranging from several tons to over 100 tons.

2. Stability and Durability:

– Offers superior stability and rigidity due to the double girder design, which ensures minimal deflection during lifting.

3. Span and Height:

– Capable of covering a larger span and greater height compared to single girder cranes, making them suitable for extensive workshop areas.

4. Precision Control:

– Equipped with advanced control systems including variable frequency drives (VFD), offering precise lifting and positioning.

5. Hoisting Mechanism:

– Features robust hoisting mechanisms with high lift speeds, ensuring efficient load handling. Often includes dual-speed hoisting motors for enhanced control.

6. Safety Mechanisms:

– Includes multiple safety features such as overload protection, emergency stop buttons, limit switches, and anti-collision devices.

7. Customization Options:

– Can be tailored to meet specific operational requirements including custom lifting capacities, spans, and lifting heights.

8. Ease of Maintenance:

– Designed for easy access to critical components like the hoist, motors, and control panels for streamlined maintenance.

9. Operational Efficiency:

– Enhanced operational efficiency with features like remote control operation, automated lifting sequences, and ergonomic designs to reduce manual effort.

10. Compatibility:

– Compatible with various attachments and accessories such as hooks, magnets, and grabs for versatile material handling.

11. Longer Lifespan:

– Built with high-quality materials and components to withstand rugged industrial environments, ensuring long operational life.

12. Compliance and Standards:

– Conforms to various industry standards and regulations ensuring safety and reliability.

These features make double girder EOT cranes an ideal choice for heavy-duty lifting and material handling tasks in industries like manufacturing, warehousing, and construction.

List Various Types of “double girder eot crane”

Double girder EOT (Electric Overhead Traveling) cranes are essential in industrial applications for their efficiency in material handling. Here’s a rundown of various types:

1. Top Running Double Girder EOT Crane:

– Description: Features two girders that support the crab mechanism on top, running on elevated runway beams.

– Applications: Heavy duty lifting requirements in factories, warehouses, and workshops.

2. Underslung/Suspension Double Girder EOT Crane:

– Description: Runs on tracks suspended from the building structure.

– Applications: Suited for facilities with limited floor space or low headroom.

3. Explosion-Proof Double Girder EOT Crane:

– Description: Designed for environments with high risks of explosion due to the presence of flammable gases or dust.

– Applications: Chemical plants, oil refineries, and other hazardous areas.

4. Magnetic Double Girder EOT Crane:

– Description: Equipped with electro-magnets for lifting and moving magnetic materials.

– Applications: Metal industries, scrap yards, and steel mills.

5. Foundry Double Girder EOT Crane:

– Description: Specially constructed for high heat resistance and durability.

– Applications: Used in foundries to handle molten metal and other high-temperature materials.

6. Gantry Double Girder EOT Crane:

– Description: Combines the features of a gantry crane with double girders for higher stability and load capacity.

– Applications: Outdoor yards, construction sites, and shipyards.

7. Semi-Gantry Double Girder EOT Crane:

– Description: One side of the crane runs on a track at ground level, while the other side runs on an elevated runway beam.

– Applications: Suitable for environments where the combination of floor and elevated space can be utilized effectively.

8. Heavy-Duty Double Girder EOT Crane:

– Description: Built specifically for extremely high load capacities and rigorous industrial use.

– Applications: Mining, manufacturing, large-scale infrastructure projects.

Each type of double girder EOT crane serves unique purposes and is selected based on specific operational requirements, safety standards, and site constraints.

List Application of “double girder eot crane”

Double girder EOT (Electric Overhead Traveling) cranes are widely employed in various industries due to their robust construction and high load-bearing capacity. Their applications include:

1. Manufacturing Facilities:

– Assembly Lines: Assist in moving heavy components and assemblies, improving productivity and safety.

– Machine Shops: Handle large and bulky machine parts during machining, assembly, and installation processes.

2. Steel Plants:

– Material Handling: Efficiently transport raw materials, semi-finished products, and finished goods.

– Casting and Forging: Lift and position heavy molds and castings.

3. Warehousing and Logistics:

– Loading and Unloading: Facilitate loading/unloading of goods from trucks and railcars.

– Storage Management: Move materials to and from high storage racks, optimizing space utilization.

4. Power Plants:

– Maintenance: Handle maintenance tasks involving large and heavy components like turbines, generators, and boilers.

5. Shipbuilding:

– Assembly and Repair: Assist in the assembly of ship parts and repair operations by lifting heavy sections of the ship.

6. Automotive Industry:

– Production Lines: Aid in the assembly of vehicles by transporting large automotive parts.

– Tool and Die Handling: Move heavy dies and molds used in automotive manufacturing.

7. Construction:

– Precast Concrete: Lift and transport precast concrete sections, beams, and girders for construction projects.

– Infrastructure Projects: Assist in the construction of bridges, tunnels, and other major infrastructure.

8. Metallurgical Industry:

– Operations: Move large volumes of raw steel and other metals, aiding in various metallurgical processes.

9. Mining:

– Material Handling: Help in the transportation of extracted materials and heavy mining equipment.

Overall, double girder EOT cranes enhance operational efficiency, safety, and productivity across a range of industrial applications by enabling the precise and reliable handling of heavy loads.

List Buyer Types of “double girder eot crane”

Certainly! Here’s a list of buyer types for “double girder EOT (Electric Overhead Traveling) crane”:

1. Manufacturing Facilities: These buyers need double girder EOT cranes for handling heavy and bulky materials within the production line. The cranes are used for lifting, moving, and positioning materials or products, enhancing efficiency and safety.

2. Warehouses and Distribution Centers: In warehouses, double girder EOT cranes assist in moving large cargo and materials from storage areas to shipping docks, optimizing space and ensuring quick, safe handling of goods.

3. Construction Companies: These firms use the cranes to lift and transport heavy construction materials like steel beams, concrete blocks, and large equipment on construction sites. Their ability to handle heavy loads makes them indispensable in large-scale construction projects.

4. Shipyards and Dockyards: Shipbuilders and dockyard operators use double girder EOT cranes for building and repairing ships. These cranes handle heavy ship components and cargo, ensuring precise placement and movement.

5. Mining Operations: In mines, these cranes are essential for lifting and transporting heavy mining equipment and extracted materials. Their capacity to handle heavy loads is crucial in mining operations.

6. Steel Mills and Foundries: Double girder EOT cranes are used for handling molten metal, steel coils, and other heavy materials in steel mills and foundries. Their reliability and strength are vital for operational efficiency.

7. Automotive Industry: Automotive manufacturers use these cranes to move heavy components like car frames, engines, and other large parts. The cranes aid in assembling various parts of vehicles in a streamlined manner.

8. Power Plants: Power generation facilities utilize double girder EOT cranes for handling heavy equipment such as turbines, generators, and transformers. Their robust lifting capabilities are essential during maintenance and installation.

9. Aerospace Industry: Aerospace manufacturers require these cranes for the precise handling of large aircraft components and heavy machinery used in production processes.

10. Public Infrastructure Projects: Government bodies managing large infrastructure projects, such as bridges, dams, and airports, often use double girder EOT cranes for material handling and construction work.

Each buyer type values the double girder EOT crane for its capacity to handle heavy loads, improve operational efficiency, and ensure safety during material handling.

List “double girder eot crane” Project Types for Different Industries

Sure! Double girder EOT (Electric Overhead Traveling) cranes are versatile lifting solutions used across various industries for handling heavy loads. Here are some project types for different industries:

1. Manufacturing Industry:

– Automobile Manufacturing: Handling assembly line components, engines, and chassis.

– Steel and Metal Fabrication: Transporting metal sheets, coils, and finished products.

2. Construction Industry:

– Precast Concrete: Lifting and moving precast concrete slabs and beams.

– Building Material Supply: Handling large quantities of bricks, tiles, and other construction materials.

3. Energy Sector:

– Power Plants: Moving large turbines, generators, and other critical components.

– Wind Energy: Assembling wind turbine components, including blades and nacelles.

4. Mining Industry:

– Material Handling: Transporting extracted minerals and ore to processing facilities.

– Mine Maintenance: Lifting heavy equipment for repairs and maintenance.

5. Aviation Industry:

– Aircraft Manufacturing: Assembling aircraft parts, engines, and fuselages.

– Airport Maintenance: Handling large cargo containers and ground support equipment.

6. Railway Industry:

– Railcar Maintenance: Lifting and moving railcars and locomotives for maintenance work.

– Track Material Handling: Transporting rails and sleepers for track construction.

7. Marine and Shipbuilding:

– Shipyard Operations: Lifting ship components, such as hull sections and engines.

– Dockyards: Moving heavy cargo and containers.

8. Logistics and Warehousing:

– Bulk Material Handling: Transporting large volumes of goods and raw materials.

– Automated Warehouses: Facilitating the movement of heavy pallets and containerized goods.

9. Chemical and Pharmaceutical:

– Reactor Maintenance: Lifting heavy vessels and reactors for cleaning and repairs.

– Material Handling: Transporting bulk raw materials and chemical containers.

10. Pulp and Paper:

– Paper Roll Handling: Moving large rolls of paper through various stages of production.

– Machine Maintenance: Facilitating maintenance of large machinery used in paper mills.

Double girder EOT cranes are essential in industries that require heavy lifting, precision, and efficiency, making them integral to streamlined operations and enhanced productivity.

double girder eot crane Accessories Upgrades and Custom Manufacturing Options

Double girder EOT (Electric Overhead Traveling) cranes are essential for heavy material handling in various industrial applications. To enhance their functionality and performance, several accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Remote Controls: Wireless and radio remote controls for safe and efficient crane operation.

2. Load Cells: Integrated load cells for precise weight measurement and overload protection.

3. Lights and Alarms: LED lights for visibility and audible alarms for safety.

4. Anti-Collision Systems: Infrared or laser-based systems to prevent collisions in multi-crane environments.

5. CCTV Cameras: For real-time monitoring of the load and operational area.

Upgrades:

1. Variable Frequency Drives (VFDs): Enhances control over crane speed, resulting in smoother operations and energy savings.

2. Advanced Braking Systems: Improved braking for enhanced safety and reduced wear.

3. Automated Positioning Systems: For precise load placement with minimal human intervention.

4. Energy Regeneration Units: Capture and reuse energy during crane braking, boosting efficiency.

5. Anti-sway Technology: Minimizes load sway, improving operational safety and efficiency.

Custom Manufacturing Options:

1. Tailored Capacity and Span: Custom designs to meet specific load capacities and span requirements.

2. Specialized Hoists: Custom hoists for unique lifting needs, such as high-speed or heavy-duty operations.

3. Environmental Modifications: Cranes designed for specific environments like high temperature, corrosion resistance for marine environments, or explosion-proof designs for hazardous industries.

4. Smart Features: Integration of IoT and smart diagnostics for predictive maintenance and real-time performance monitoring.

5. Material Selection: Custom selection of materials to suit specific industrial environments, ensuring longevity and reliability.

By leveraging these accessories, upgrades, and custom manufacturing options, double girder EOT cranes can be optimized for greater efficiency, safety, and operational excellence.

List Quality Control and The Manufacturing Process of “double girder eot crane”

Quality Control for Double Girder EOT Crane:

1. Material Inspection: Ensure all raw materials meet specifications through chemical and mechanical tests.

2. Design Verification: Review and verify design calculations and technical drawings to comply with safety standards.

3. Welding Quality: Conduct inspections and non-destructive testing (NDT) such as ultrasonic, magnetic particle, or radiographic testing to confirm weld integrity.

4. Dimensional Accuracy: Use precise measuring tools to verify dimensions and alignments are according to design specs.

5. Load Testing: Perform static and dynamic load tests to ensure the crane can handle maximum load capacity safely.

6. Electrical Systems Check: Ensure all electrical components are correctly installed and functioning, including wiring, control panels, and safety switches.

7. Final Inspection: Conduct a comprehensive final inspection covering all mechanical and electrical systems before delivery.

Manufacturing Process of Double Girder EOT Crane:

1. Design and Engineering: Create a detailed design plan, including load capacity and compliance with industry standards.

2. Material Procurement: Source high-quality steel and other essential materials based on the designed specifications.

3. Cutting and Fabrication: Cut the materials into required sizes and shapes using CNC machines, laser cutters, or plasma cutters.

4. Welding and Assembly: Weld the components to form the main structure of the crane, including the girders, end trucks, and hoisting mechanism.

5. Machining: Precision machine parts such as wheels, gears, and shafts to ensure smooth operation.

6. Surface Treatment: Apply anti-corrosion treatments such as sandblasting, primer, and painting to enhance durability.

7. Electrical Installation: Install and wire electrical components including motors, control systems, and safety devices.

8. Testing: Conduct rigorous functional and safety tests, including load tests and NDT on welds, to verify the crane’s reliability and safety.

9. Inspection and Quality Assurance: Perform final quality control checks to ensure all aspects meet design and safety standards.

10. Shipping and Installation: Disassemble as needed, pack, and transport the crane to the installation site, where it is reassembled and installed.

By following these steps, manufacturers ensure the quality and safety of double girder EOT cranes.

How to use “double girder eot crane”

Operating a double girder EOT (Electric Overhead Traveling) crane requires adherence to safety protocols and precise steps to ensure efficient material handling. Here’s a condensed guide to using one:

1. Training and Certification: Ensure all operators are trained, certified, and familiar with the crane’s manual.

2. Pre-Operational Checks:

– Inspect Crane: Check for any visual damages or wear and tear.

– Control Systems: Test the control panel and emergency stop buttons.

– Lubrication: Ensure all moving parts are adequately lubricated.

– Load Hook/Bucket: Confirm that the hook is free from deformities and the safety latch functions properly.

3. Load Preparations:

– Weight Verification: Ensure the load does not exceed the crane’s maximum capacity.

– Secure Attachment: Properly secure the load using appropriate slings or lifting devices.

– Balance: Check that the load is balanced to prevent swinging.

4. Crane Operation:

– Power Up: Switch on the crane and conduct system checks from the control panel.

– Lifting: Gradually lift the load to ensure stability. Avoid jerky movements.

– Traversing: Use the controls to move the load horizontally along the bridge. Ensure smooth and slow movements.

5. Load Positioning:

– Lowering: Carefully lower the load to the designated area, ensuring it is stable and secure.

– Detachment: Safely release the lifting device and inspect for any damages.

6. Post-Operational Checks:

– Shut Down: Turn off the crane and secure it in its resting position.

– Inspection: Perform a post-operation inspection to detect any issues or wear signs.

Safety Protocols:

– Clear Communication: Use standardized hand signals or communication devices.

– Alertness: Always stay alert and never leave a suspended load unattended.

– Maintenance: Adhere to regular maintenance schedules to ensure longevity and safety.

By following these steps and prioritizing safety, the use of a double girder EOT crane can be efficient and safe.

“double girder eot crane” Comparative Analysis

A Double Girder Electric Overhead Travelling (EOT) Crane is a type of industrial crane with two main horizontal girders that traverse along gantry rails, and a hoist mechanism that travels along these girders. This crane design is highly efficient for lifting heavy loads in various industrial settings such as warehouses, manufacturing plants, and shipyards. Here’s a comparative analysis of Double Girder EOT Cranes against Single Girder EOT Cranes and Gantry Cranes.

Load Capacity and Span

Double Girder EOT Cranes generally have a higher load capacity and larger span capabilities when compared to Single Girder EOT Cranes. The double-girder design allows for better distribution of weight and increased stability, thus enabling the crane to lift heavier loads, often ranging from 10 to 250 tons or more. Single Girder Cranes, in contrast, typically handle loads up to 20 tons and are suitable for shorter spans and lighter applications.

Structural Strength

Due to the added structural support of a second girder, Double Girder EOT Cranes exhibit enhanced durability and longevity. They are suitable for high-duty cycles and demanding environments. Single Girder Cranes, though simpler and less costly, may not offer the same level of durability for heavy-duty operations.

Hoisting Mechanism and Height of Lift

Double Girder Cranes usually employ a top-running trolley hoist, which allows for maximum hook height, making them ideal for facilities where maximization of vertical space is crucial. Single Girder Cranes typically have an under-running trolley hoist, leading to a lower hook height. This can be a limitation in applications requiring significant lift height.

Installation and Maintenance

Double Girder Cranes are more complex and require more robust structural support for installation. This contributes to a higher initial cost and installation time compared to Single Girder Cranes. However, the maintenance of Double Girder Cranes is often easier due to better accessibility to the hoisting mechanism.

Cost Efficiency

While Double Girder Cranes are generally more expensive due to their complexity and robust design, they offer a higher return on investment in demanding industrial applications. Single Girder Cranes, while more cost-effective for lighter tasks, may incur higher long-term costs if subject to heavy-duty use.

Conclusion

“double girder eot crane” Warranty and Support

Warranty and Support for Double Girder EOT Crane

Our Double Girder EOT Cranes come with a robust warranty to assure you of their superior quality and reliability. We offer a standard one-year warranty from the date of installation or 18 months from the date of shipment, whichever comes first. This warranty covers any defects in materials or workmanship under normal use. During this period, we will repair or replace any defective parts at no cost to the owner, ensuring minimal downtime and operational disruption.

Comprehensive Support Services

1. Installation and Commissioning:

Our qualified technicians are available to manage the installation and commissioning of the crane at your site to ensure it operates optimally from day one.

2. Technical Support:

Receive 24/7 technical assistance through our dedicated support hotline. Our experienced engineers are ready to troubleshoot issues and provide guidance on operating the crane efficiently.

3. Maintenance Plans:

We offer customized preventive maintenance packages designed to extend the lifespan of your crane and reduce the likelihood of unexpected failures. These plans include regular inspections, lubrication, adjustments, and the replacement of worn-out parts.

4. Training Programs:

Operator and maintenance staff training programs are available to ensure your team is well-versed in the safe and efficient operation of the EOT crane. This initiative helps in minimizing operator errors and enhances workplace safety.

5. Spare Parts Availability:

We maintain a comprehensive inventory of spare parts to ensure quick availability and minimal downtime. Genuine spare parts from original manufacturers guarantee the longevity and reliability of your crane.

6. Remote Monitoring:

Utilize our advanced remote monitoring service to keep an eye on the health and performance of your crane in real-time. This proactive approach allows for early detection of potential issues and timely interventions.

For detailed terms and conditions related to the warranty and support services, please refer to your product documentation or contact our customer support team. Your satisfaction and the seamless operation of your machinery are our top priorities.

List “double girder eot crane” FAQ

Double Girder EOT Crane FAQ

1. What is a Double Girder EOT Crane?

– A Double Girder Electric Overhead Traveling (EOT) Crane consists of two parallel girders supporting the crab, which moves horizontally along the girders. It is used for heavy-duty applications.

2. What are the main components?

– The main components are the bridge girders, end trucks, hoist and trolley, runway system, and electrical control system.

3. What are its primary applications?

– These cranes are used in manufacturing plants, warehouses, shipyards, and for heavy machinery installations.

4. What are the advantages over a Single Girder Crane?

– A Double Girder EOT Crane can handle heavier loads, provides higher hook lift, and has greater span and duty cycle capability compared to single girder cranes.

5. What is the typical load capacity?

– Load capacities can range from a few tons up to 500 tons, depending on the design and application.

6. Can it be customized?

– Yes, Double Girder EOT Cranes can be tailored to fit specific operational needs, including size, lifting capacity, and additional features.

7. What type of maintenance is required?

– Regular inspection, lubrication, load testing, and component checks are essential to ensure longevity and safe operation.

8. Is operator training required?

– Yes, operators should be trained in safety protocols, operational guidelines, and emergency procedures.

9. What safety features are included?

– Common safety features include overload protection, emergency stop buttons, limit switches, and anti-collision systems.

10. What is the power supply requirement?

– Typically, a three-phase power supply ranging from 220V to 480V, depending on the system design and regional standards, is required.

11. What are the installation requirements?

– Proper structural support, ample headroom, and alignment of the runway system are crucial for installation.

12. Can it be operated remotely?

– Yes, these cranes can be equipped with remote control systems for enhanced safety and convenience.

13. What is the typical lifespan?

– With regular maintenance, a Double Girder EOT Crane can last 20-30 years or more, depending on usage and environment.

This concise FAQ covers the essentials about Double Girder EOT Cranes, ensuring a clear understanding for those considering their use.

Top 10 FAQ with answer about double girder eot crane for Buyer Sourcing from China

Top 10 FAQ About Double Girder EOT Crane for Buyer Sourcing from China

1. What is a Double Girder EOT Crane?

A Double Girder Electric Overhead Traveling (EOT) Crane consists of two parallel girders supporting the crane’s trolley and hoist. It is used for heavy-duty lifting applications.

2. What are the capacity ranges available?

Double girder EOT cranes typically range from 5 tons to 500 tons capacity, with custom options available based on specific requirements.

3. Which standards do Chinese manufacturers generally follow?

Chinese manufacturers often follow international standards like ISO, FEM, and CMAA. Some also obtain certifications like CE and DIN.

4. What is the typical lead time for manufacturing and delivery?

The lead time can vary but is generally between 6 to 12 weeks, depending on the specifications and order size.

5. How is the quality control maintained?

Reputable Chinese manufacturers follow stringent quality control processes, including material inspection, welding checks, and load testing before shipment.

6. Can I customize my double girder EOT crane?

Yes, most manufacturers offer customizations such as different spans, lifting heights, speeds, and control systems to meet specific needs.

7. What are the main components?

The main components include the double girders, trolley, hoist, end carriages, control systems (either cabin or remote), and electrical panels.

8. How is the crane shipped and installed?

Cranes are usually shipped in disassembled components and can be installed by experienced contractors or the manufacturer’s team usually offers installation support.

9. What support is available post-purchase?

Many manufacturers offer comprehensive after-sales support, including installation guidance, maintenance services, and spare parts supply.

10. How do I ensure the reliability of a Chinese manufacturer?

Conduct thorough research, seek recommendations, check certifications, request references, and review past projects. Visiting the factory or employing a third-party inspection service can also be beneficial.

By understanding these key aspects, you can make a more informed decision when sourcing a double girder EOT crane from China.