double girder overhead crane Safety Certifications

When dealing with double-girder overhead cranes, safety is paramount, and a range of certifications and standards are crucial to ensure the reliable and safe operation of these heavy-duty machines. Here are some of the key safety certifications and standards involved:

1. OSHA Compliance: In the United States, the Occupational Safety and Health Administration (OSHA) sets comprehensive regulations to ensure workplace safety. Double-girder overhead cranes must adhere to OSHA standards, particularly those outlined in OSHA 1910.179, which specifies guidelines for crane operation, maintenance, and inspection.

2. ASME B30 Standards: The American Society of Mechanical Engineers (ASME) provides rigorous standards for cranes and related equipment. ASME B30.2 specifically covers overhead and gantry cranes, detailing requirements for design, construction, installation, inspection, testing, and maintenance.

3. ISO 9001 Certification: Manufacturers of double-girder overhead cranes often pursue ISO 9001 certification, ensuring that their quality management systems meet international standards. This certification underscores a commitment to consistent quality and continuous improvement in manufacturing processes.

4. ANSI Standards: The American National Standards Institute (ANSI) provides additional safety guidelines for crane operations. ANSI/ASME B30.2 is often referenced alongside OSHA and ASME standards to ensure comprehensive safety protocols are observed.

5. CE Marking: For cranes used within the European Economic Area (EEA), CE marking is essential. This indicates that the crane complies with EU safety, health, and environmental protection directives. EN 15011 is the relevant European standard for overhead cranes, ensuring they meet stringent safety and design criteria.

6. FEM Standard: The Federation Europeenne de la Manutention (FEM) provides additional guidelines, particularly the FEM 1.001 standard, that focus on the classification, design, and maintenance of cranes.

Adherence to these certifications and standards is vital for the safe and efficient operation of double-girder overhead cranes, ensuring they comply with national and international safety requirements.

List Reference Technical Parameters of “double girder overhead crane”

Certainly! Here are the reference technical parameters for a double girder overhead crane:

1. Lifting Capacity: Ranges typically from 5 tons up to 500 tons, depending on the design and specific application.

2. Span: The distance between the runway rails. Usually ranges from 10 meters to over 40 meters. Adjustable based on facility dimensions.

3. Lifting Height: The vertical distance the hook can travel. Standard heights range from 6 meters to 30 meters, with customization available.

4. Speed Parameters:

– Hoisting Speed: Typically between 0.5 m/min to 15 m/min.

– Trolley Travel Speed: Between 2 m/min to 40 m/min.

– Crane Travel Speed: Ranges from 5 m/min to 80 m/min.

5. Power Supply: Commonly 3-phase AC, 380V/50Hz or 440V/60Hz. Voltage and phase can be tailored based on regional standards.

6. Control Method:

– Pendant Control: Wired remote control for close operation.

– Cabin Control: An enclosed operator cabin attached to the crane.

– Remote Control: Wireless operation to enhance safety and flexibility.

7. Duty Classifications: According to FEM standards, ranging from light (A1, A2) to extra heavy-duty (A7, A8).

8. Motor Power: Varies with lifting capacity and speed requirements, typically ranging from 5 kW to over 500 kW.

9. Structural Dimensions: Main parameters include the overall girder height, width, and length, customizable based on load and span requirements.

10. Operational Temperature: Can be designed to operate in temperatures ranging from -20°C to 40°C. Special systems available for extreme conditions.

11. Safety Features:

– Overload Protection: Prevents lifting loads beyond rated capacity.

– Limit Switches: To avoid over-hoisting and over-lowering.

– Emergency Stop: Immediate halting of crane operations.

– Anti-sway Technology: Minimizes load swing during travel.

By adhering to these technical parameters, double girder overhead cranes provide tailored, efficient, and safe material handling solutions for various industrial applications.

List Product features of “double girder overhead crane”

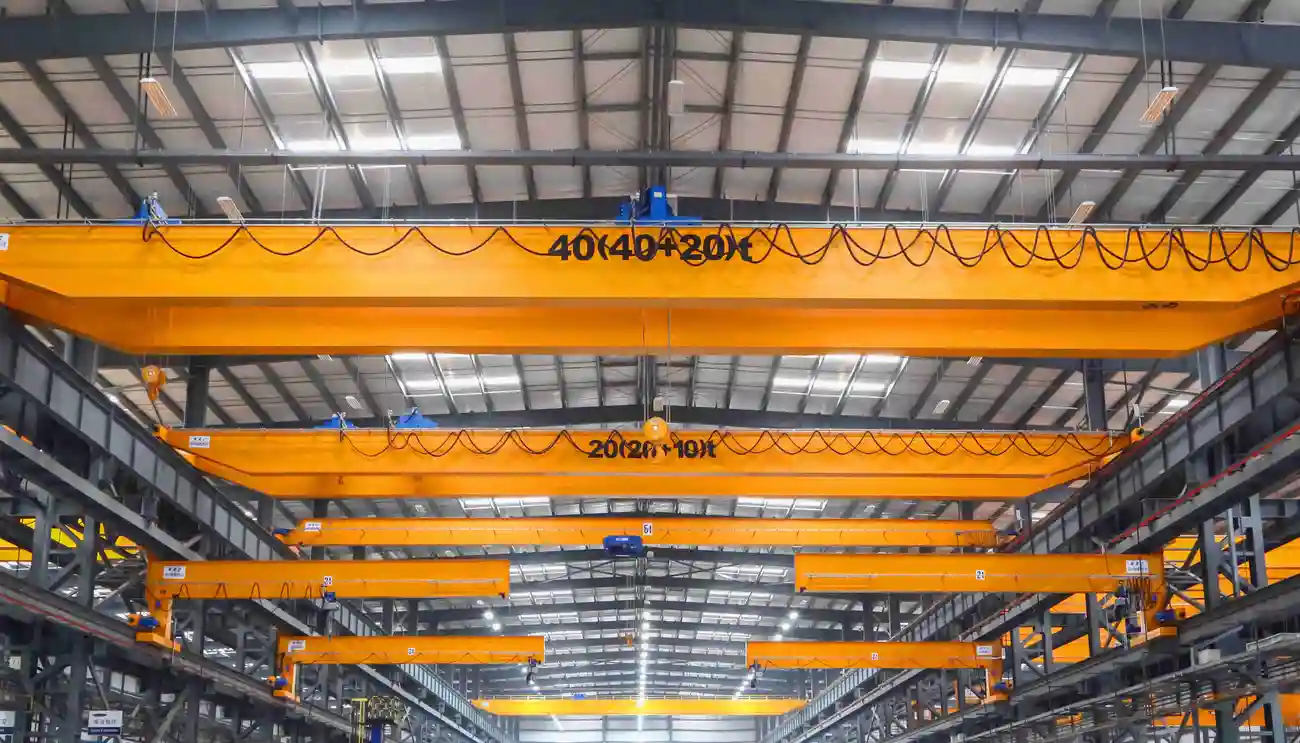

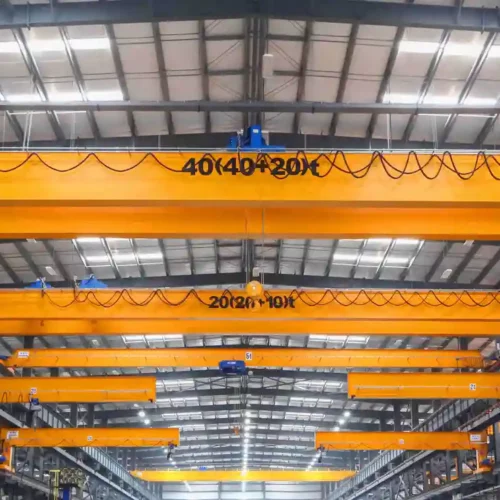

A double girder overhead crane is a sophisticated material handling equipment designed for heavy-duty lifting operations. Below are some key features:

1. Load Capacity: Typically offers high load capacities, ranging from 20 tons to over 500 tons, making it suitable for extremely heavy lifting requirements.

2. Span: Wide spans can be achieved, often ranging from 10 meters to over 30 meters, depending on the requirements of the application.

3. Construction: Comprised of two parallel girders which provide enhanced strength and stability. These girders can be fabricated from high-tensile steel for durability and rigidity.

4. Hoisting Mechanism: Equipped with a powerful hoist system including a trolley that moves along the girders, capable of precise vertical lifting and lowering.

5. Travel Mechanism: Features robust end carriages and wheels designed for smooth and efficient crane travel along the runway beams.

6. Control Options: Can be operated manually or through advanced control systems such as wired pendant controls, wireless remote controls, or automated control systems for optimized operations.

7. Safety Features: Includes multiple safety mechanisms like load limiters, anti-collision devices, emergency stop functions, and overload protection to ensure safe operations.

8. Customization: Can be tailored to meet specific industry needs, including varying speeds, capacities, and specialized lifting attachments.

9. Maintenance: Designed for ease of maintenance with accessible components and diagnostic systems to monitor crane health and performance.

10. Applications: Ideal for environments such as manufacturing plants, steel mills, shipyards, and warehouses where heavy material handling is essential.

11. Durability: Built to withstand harsh industrial environments with corrosion-resistant finishes and robust construction to ensure long-term use.

12. Energy Efficiency: Can be equipped with energy-efficient drive systems to reduce operational costs and environmental impact.

In summary, double girder overhead cranes are versatile, robust, and highly efficient lifting solutions suitable for heavy-duty industrial applications.

List Various Types of “double girder overhead crane”

Double girder overhead cranes are essential for a variety of industrial applications due to their robust design and high lifting capacity. Here are several types:

1. Top Running Double Girder Crane:

– These cranes run on rails mounted on top of the runway beams, offering maximum headroom and hook height. Suitable for heavy loads and long spans.

2. Under Running Double Girder Crane:

– These cranes operate on rails mounted underneath the runway beams. They are ideal for applications where the floor space is restrictive or the existing structure cannot support a top running crane.

3. Double Girder Electric Overhead Travelling Crane (EOT):

– Equipped with electric motors for lifting and horizontal movement. Common in manufacturing and maintenance due to their efficiency and automation capabilities.

4. Explosion-Proof Double Girder Crane:

– Designed for hazardous environments where flammable gases or explosive dust are present. These cranes feature specialized components to prevent ignition.

5. Magnetic Double Girder Crane:

– Utilizes powerful magnets for lifting ferrous materials. Perfect for handling metal sheets, plates, or pipes.

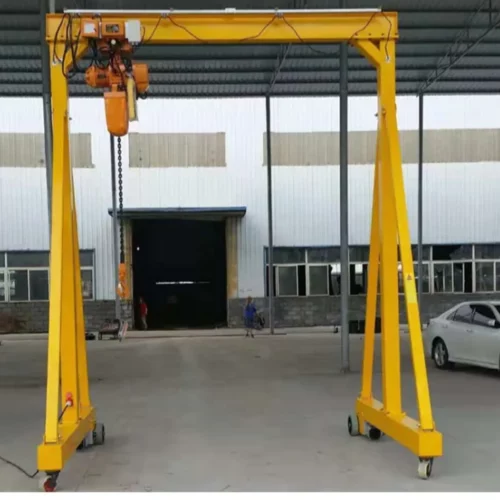

6. Gantry Double Girder Crane:

– Instead of runway beams, these cranes have legs and operate on floor rails. Used in open areas such as shipyards, ports, and storage yards.

7. Semi-Gantry Double Girder Crane:

– One side runs on a runway beam, and the other side has legs travelling on the floor. This design is adaptable to various indoor or outdoor settings.

8. Workstation Double Girder Crane:

– Intended for lighter loads and smaller workspaces. Enhances efficiency in manufacturing lines or assembly stations.

Each type of double girder overhead crane is tailored to specific needs, ensuring versatility and efficiency in various industrial applications.

List Application of “double girder overhead crane”

Double girder overhead cranes are highly versatile and widely used in various industrial and commercial settings due to their robust construction and high load-bearing capacity. Below are some primary applications of double girder overhead cranes:

1. Manufacturing Plants:

– Heavy Machinery Assembly: Used for lifting and assembling heavy machinery parts.

– Production Lines: Facilitates the movement of raw materials, components, and finished products along production lines.

2. Steel Mills and Foundries:

– Material Handling: Ideal for handling heavy and bulky materials such as steel coils, slabs, and castings.

– Molten Materials: Used to transport molten materials in ladles safely.

3. Warehouses and Logistics Centers:

– Storage and Retrieval: Assists in the efficient handling of heavy pallets, containers, and large items.

– Loading and Unloading: Aids in loading and unloading trucks and railway cars.

4. Shipyards and Dockyards:

– Shipbuilding: Facilitates the lifting and positioning of large ship components.

– Cargo Handling: Assists in the moving of heavy cargo and equipment on docks.

5. Automotive Industry:

– Vehicle Assembly: Used in the assembly of vehicles by moving large components such as car bodies and engines.

– Part Storage: Helps in storing and retrieving heavy auto parts.

6. Power Plants:

– Turbine Installation: Essential for lifting and installing heavy components like turbines and generators.

– Maintenance: Supports the maintenance and replacement of large machinery.

7. Mining and Extraction Facilities:

– Ore Handling: Used to transport heavy ore trucks and mining equipment.

– Maintenance: Assists in the maintenance of heavy extraction machinery.

8. Aerospace Industry:

– Aircraft Assembly: Useful in the assembly of aircraft components.

– Maintenance and Repair: Facilitates the maintenance and repair of aircraft.

9. Construction Sites:

– Building Materials: Ideal for lifting and moving heavy construction materials like steel beams and precast concrete.

These applications demonstrate the crucial role of double girder overhead cranes in enhancing operational efficiency, safety, and productivity across various sectors.

List Buyer Types of “double girder overhead crane”

The market for double girder overhead cranes encompasses a range of industries and applications where heavy lifting and precise material handling are essential. Here are some key buyer types for double girder overhead cranes:

1. Manufacturing Plants: Facilities involved in the production of heavy machinery, automotive parts, and large components often require double girder overhead cranes to handle bulky materials and streamline the manufacturing process.

2. Steel Mills: These facilities commonly use double girder cranes for transporting heavy steel coils, plates, and other raw materials across the production floor.

3. Construction Companies: Construction firms engaged in large-scale infrastructure projects, such as bridges, power plants, and high-rise buildings, utilize these cranes for lifting and positioning heavy construction materials.

4. Shipyards: Shipbuilding and repair facilities need double girder overhead cranes for moving large ship components, engines, and hull sections with high precision.

5. Warehouses: Distribution centers and storage facilities that manage large and heavy inventory items, like metal rolls or oversized machinery, benefit from the capabilities of these cranes.

6. Mining Industry: Mining operations use these cranes to handle heavy mining equipment, machinery parts, and extracted raw materials, ensuring efficient operation within mines and processing plants.

7. Energy Sector: Power plants, especially those dealing with nuclear, hydro, and thermal energy, require robust cranes for handling turbines, transformers, and other critical components during installation and maintenance.

8. Aerospace Industry: Aircraft manufacturing and maintenance centers use double girder overhead cranes to lift and assemble large aircraft parts, ensuring safety and precision in handling.

9. Railway Workshops: Facilities involved in the construction and maintenance of trains and railway components employ these cranes for moving heavy train parts and assemblies.

10. Paper Mills: The paper production industry uses double girder cranes to handle large rolls of paper and heavy machinery required for production.

These buyer types leverage double girder overhead cranes for their strength, durability, and ability to handle complex lifting tasks with high precision and safety.

List “double girder overhead crane” Project Types for Different Industries

Double girder overhead cranes are versatile lifting systems widely utilized across various industries due to their strength, durability, and precise load handling capabilities. Here are project types in different industries:

1. Manufacturing:

– Automotive Plants: Used for moving heavy automotive components and assemblies on the production line.

– Steel Mills: Essential for handling coils, slabs, beams, and metal sheets.

– Machining Workshops: Transport large machined parts and materials between different manufacturing stations.

2. Construction:

– Precast Concrete Plants: Hoisting and transporting heavy precast concrete elements.

– Material Yards: Moving construction materials like steel bars, heavy-duty equipment, and pre-assembled components.

3. Warehousing/Logistics:

– Distribution Centers: Handling bulky and heavy packages efficiently.

– Freight Terminals: Loading and unloading cargo including large containers and pallets.

4. Energy:

– Power Plants: Lifting heavy turbines, generators, and other substantial equipment for installation and maintenance.

– Wind Energy: Assembling wind turbine components and maintenance of heavy parts.

5. Mining:

– Material Handling: Hoisting mining equipment and materials, supporting conveyor systems.

6. Shipbuilding:

– Dry Docks: Moving large vessel sections, completed hulls, and heavy machinery parts during ship assembly and repair.

7. Aerospace:

– Aircraft Manufacturing: Precision lifting of parts like wings, fuselage sections which are large and require careful handling.

8. Paper and Pulp:

– Mill Operations: Lifting large paper rolls, machinery, and handling process equipment.

9. Chemical and Petrochemical:

– Heavy Equipment Handling: Moving reactors, pipelines, and heavy process equipment safely.

These examples highlight the adaptability of double girder overhead cranes in addressing the lifting and material handling needs across various sectors, thereby augmenting operational efficiency and safety.

double girder overhead crane Accessories Upgrades and Custom Manufacturing Options

Double girder overhead cranes are renowned for their strength, durability, and efficiency in material handling. Enhancing these cranes with the right accessories and upgrade options can significantly improve their performance and adaptability to various industrial environments. Here’s a quick overview of the available accessories, upgrades, and custom manufacturing options:

1. End Trucks and Drive Units: Upgrading to high-performance end trucks and drive units can enhance the crane’s motion control, stability, and load-handling capabilities.

2. Hoists and Trolleys: Customizing with robust hoists and trolleys tailored to specific lifting requirements ensures precise and reliable lifting operations.

3. Control Systems: Implement advanced control systems like radio remote controls, variable frequency drives (VFDs), and automated systems to streamline operations and improve safety.

4. Safety Features: Integrating safety components such as overload protection devices, anti-collision systems, and fail-safe brakes is crucial for maintaining a secure working environment.

5. Load Handling Attachments: Using specialized attachments such as magnet lifters, spreader beams, vacuum lifters, and grabs can enhance the crane’s versatility in handling various loads.

6. Runway Systems: Custom-designed runway systems including beams, rails, and brackets can improve the crane’s travel path and overall efficiency.

7. Lighting and Warning Devices: LED lighting, warning horns, and flashing beacons can enhance visibility and alert operators and workers to potential hazards.

8. Weather Protection: For outdoor applications, adding weather protection features like covers and enclosures ensures longevity and reliable performance in harsh conditions.

9. Maintenance Platforms: Installing maintenance platforms and walkways facilitates easy access for inspection and repairs.

Custom manufacturing options provide the flexibility to tailor these cranes to specific operational needs. This includes designing cranes with unique span, lifting height, capacity, and specific structural requirements to fit seamlessly into existing facilities or meet particular project demands.

By carefully selecting and integrating these accessories and upgrades, a double girder overhead crane can be effectively optimized for enhanced performance, safety, and efficiency in any industrial setting.

List Quality Control and The Manufacturing Process of “double girder overhead crane”

Quality Control:

1. Material Inspection: Verify raw materials such as steel for structural components, ensuring they meet specified standards through chemical and mechanical testing.

2. Machining Accuracy: Use precision tools to measure and maintain tolerances in machined parts to ensure proper assembly and function.

3. Welding Quality: Inspect welds using non-destructive testing methods like ultrasonic testing or X-ray to detect any flaws that could compromise structural integrity.

4. Component Testing: Test critical components like the hoist, motors, and brakes under load to ensure they perform reliably under operational conditions.

5. Assembly Verification: Conduct thorough inspections during and after assembly to ensure all parts are correctly installed and function as intended.

6. Load Testing: Subject the assembled crane to static and dynamic load tests to verify its lifting capacity and operational stability.

7. Electrical System Check: Inspect all electrical systems, including control panels, wiring, and circuits, for safety and functionality.

8. Final Inspection: Perform a detailed, final inspection of the entire crane system, including alignment, paint finish, and safety features like limit switches and emergency stop functions.

Manufacturing Process:

1. Design and Engineering: Develop detailed design specifications and engineering drawings based on load requirements, span, and site conditions.

2. Material Procurement: Source high-quality raw materials, such as structural steel, electrical components, and mechanical hardware.

3. Fabrication: Cut, shape, and weld steel components in accordance with design specifications. Manufacture the main girder, end trucks, and trolley.

4. Machining: Machine parts to precise dimensions using CNC machines, including creating holes for bolts and other fittings.

5. Welding and Assembly: Weld and assemble the crane’s structural parts, followed by post-weld cleaning and stress-relief processes.

6. Component Integration: Install the hoist, trolley mechanism, motors, and gearboxes. Integrate all electrical wiring and control systems.

7. Surface Treatment: Apply anti-corrosion coatings like primer and paint to all metal surfaces for protection against rust and environmental damage.

8. Testing and Calibration: Perform comprehensive testing on all crane functions, including load testing and safety system checks, followed by necessary calibrations.

9. Quality Inspection: Conduct a final inspection and quality assurance process to ensure the completed crane meets all specified standards and regulations.

10. Delivery and Installation: Package the crane securely for transportation, deliver to the site, and perform on-site installation and commissioning.

How to use “double girder overhead crane”

Using a double girder overhead crane involves several critical steps to ensure safe and efficient operation:

1. Inspection: Before operating, conduct a thorough inspection of the crane. Check for any signs of wear, damage, or defects in the structure, hoist, hooks, and electrical systems.

2. Preparation:

– Ensure the load is within the crane’s capacity.

– Secure the hoist mechanism and make sure it’s functioning properly.

– Clear the area of any obstructions or unauthorized personnel.

3. Load Securing:

– Attach the load securely using appropriate slings, chains, or hooks.

– Verify the load is balanced and stable.

4. Control Check:

– Familiarize yourself with the crane’s controls, including emergency stop functions.

– Perform a test lift to ensure the hoist and crane are operating correctly.

5. Lifting:

– Gradually raise the load a few inches to check for stability.

– Lift the load steadily to avoid swinging or sudden movements.

– Keep a clear line of sight or maintain communication with a spotter.

6. Moving the Load:

– Move the crane along its rails or tracks using the controls, keeping the load as low as safely possible.

– Avoid sudden starts, stops, or changes in direction to prevent the load from swinging.

– Always be mindful of the surroundings and keep a safe distance from other people and equipment.

7. Lowering the Load:

– Position the load over its destination.

– Gradually lower the load into place.

– Ensure the load is stable and secure before detaching the hoist.

8. Post-operation:

– Park the crane in a designated location.

– Turn off the power and secure any controls.

– Conduct a final inspection to ensure everything is in good condition for the next use.

Safety Tips:

– Always follow the manufacturer’s guidelines.

– Wear appropriate personal protective equipment (PPE).

– Never exceed the crane’s rated capacity.

By following these steps, you can safely and effectively use a double girder overhead crane.

“double girder overhead crane” Comparative Analysis

Comparative Analysis of Double Girder Overhead Cranes

Double girder overhead cranes are robust lifting solutions employed in various industrial sectors such as manufacturing, warehousing, and construction. The design features two parallel girders supporting the crane’s hoist and trolley mechanism, providing several advantages and considerations when compared with single girder cranes.

#### Advantages:

1. Higher Load Capacity:

Double girder cranes can manage heavier loads, typically up to 100 tons or more, making them suitable for extensive and demanding operations.

2. Greater Span:

These cranes can cover larger spans, reaching widths up to 40 meters or more, which proves useful in extensive facilities.

3. Enhanced Hook Height:

The hoist is positioned between the two girders, offering increased hook height and enabling the lifting of materials closer to the ceiling.

4. Durability and Strength:

Double girders offer enhanced structural integrity and stability, providing long-term reliability even under heavy and constant usage.

#### Disadvantages:

1. Higher Cost:

The initial investment and maintenance costs for double girder cranes are typically higher compared to single girder models due to their complex structure and heavy-duty capacity.

2. Heavier Structure:

The robust design results in a heavier crane, necessitating stronger support structures and sometimes leading to higher building costs.

3. Complex Installation:

Installation requires more intricate planning and execution, often necessitating specialized skills and longer installation times.

#### Applications and Alternatives:

While double girder cranes are ideal for heavy-duty applications and large-span areas, single girder overhead cranes may be more economical and practical for lighter loads and less demanding operations. In environments requiring even greater load capacities or specialized handling, options like gantry cranes or jib cranes might be considered.

In sum, the choice between double and single girder overhead cranes hinges on factors such as load requirements, budget constraints, and spatial considerations, with double girder cranes offering superior capacity and durability for more intensive industrial needs.

“double girder overhead crane” Warranty and Support

Warranty and Support for Double Girder Overhead Crane

At XYZ Cranes, we pride ourselves on delivering robust, reliable, and high-quality double girder overhead cranes. To ensure your investment is well-protected, we offer a comprehensive warranty and support package.

Warranty Coverage:

Our double girder overhead cranes come with a standard 12-month warranty from the date of installation or 18 months from the date of shipment, whichever comes first. This warranty covers defects in materials and workmanship, ensuring that our products meet the highest standards of performance and reliability.

Key components covered under the warranty include:

– Structural components

– Motors and drives

– Electrical systems

– Mechanical parts

Exclusions:

Normal wear and tear, misuse, improper installation, and unauthorized modifications are not covered under the warranty.

Support Services:

To complement our warranty, we offer a range of support services aimed at ensuring the optimal performance and longevity of your crane:

1. 24/7 Customer Support: Our dedicated support team is available around the clock to address any concerns or issues you may encounter.

2. Preventive Maintenance: Regularly scheduled maintenance to keep your crane in peak operating condition and prevent unexpected downtimes.

3. On-Site Service: Our experienced technicians are available for on-site inspections, repairs, and upgrades.

4. Spare Parts: We maintain a comprehensive inventory of spare parts to minimize downtime and ensure quick repairs.

5. Training Programs: We offer training for your staff on the proper operation and maintenance of the crane to promote safety and efficiency.

Your satisfaction and the operational readiness of your double girder overhead crane are our top priorities. For more information on our warranty and support services, or to schedule a service, please contact our support team at [Support Contact Information].

Investing in an XYZ crane means investing in quality, reliability, and exceptional after-sales support.

List “double girder overhead crane” FAQ

Double Girder Overhead Crane FAQ

1. What is a double girder overhead crane?

A double girder overhead crane features two parallel girders supporting a bridge and trolley mechanism. It is used for heavy-duty industrial applications, offering higher load capacities and greater span lengths compared to single girder cranes.

2. What are the typical applications?

Double girder overhead cranes are commonly used in warehouses, manufacturing plants, shipyards, steel mills, and other industrial environments for lifting and transporting heavy materials.

3. What are the load capacities?

These cranes can handle loads ranging from a few tons to several hundred tons, depending on their design and construction specifications.

4. What are the benefits of using a double girder overhead crane?

– Increased Load Capacity: Can handle heavier weights.

– Greater Stability: Dual girders provide better load distribution.

– Higher Lifting Heights: Can reach greater vertical heights, making them ideal for high-bay buildings.

– Enhanced Safety: Robust design enhances operational safety.

5. What types of hoists can be used?

Double girder cranes can be equipped with various types of hoists, including wire rope hoists and chain hoists, depending on the specific requirements of the operation.

6. What maintenance is required?

Regular inspections and maintenance are crucial for ensuring longevity and safety. This includes checking the structural components, electrical systems, and mechanical parts like the hoist and trolley.

7. Are they customizable?

Yes, double girder overhead cranes can be customized with various features such as specialized hooks, remote controls, and automation systems to meet specific operational needs.

8. What are the installation requirements?

Installation requires a suitable building structure capable of supporting the crane’s weight and load. It also involves precise alignment and secure mounting of the girders and other components.

9. How do they compare to single girder cranes?

Double girder cranes generally offer higher load capacities, greater span lengths, and increased lifting heights but are more complex and costly to install compared to single girder cranes.

10. What safety features are included?

Modern double girder overhead cranes include safety mechanisms like overload sensors, emergency stop buttons, anti-collision systems, and limit switches to ensure safe operation.

By understanding these key aspects, businesses can make informed decisions when selecting and maintaining their double girder overhead cranes.

Top 10 FAQ with answer about double girder overhead crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) with answers about sourcing double girder overhead cranes from China:

1. What is a Double Girder Overhead Crane?

A double girder overhead crane features two bridge girders supported by end trucks. These cranes are used for heavy-duty applications, offering higher load capacities and spans than single girder models.

2. What Load Capacities are Available?

Double girder overhead cranes from China typically support capacities ranging from 5 tons to over 500 tons, suitable for a variety of industrial applications.

3. What are the Advantages of Sourcing from China?

China offers competitive pricing, a wide range of options, and advanced manufacturing capabilities. Many Chinese manufacturers comply with international standards, providing quality assurance.

4. What Standards do Chinese Manufacturers Follow?

Reputable Chinese manufacturers meet international standards such as ISO, FEM, and DIN. Always ask for certifications to ensure compliance.

5. Are Customizations Possible?

Yes, many Chinese suppliers offer customization in terms of span length, lifting height, and control systems to meet specific requirements.

6. What are the Lead Times for Manufacturing and Shipping?

Typically, production can take 30-60 days depending on specifications, and shipping times vary based on the destination, usually taking an additional 3-6 weeks.

7. What Documentation is Required for Importing?

Necessary documents include a commercial invoice, packing list, bill of lading, certificate of origin, and any applicable compliance certificates. Ensure all paperwork is complete to avoid customs delays.

8. What After-Sales Services are Available?

Many manufacturers offer remote support, spare parts, and sometimes on-site services, usually specified in the after-sales agreement. Extended warranties may also be available.

9. How Do I Ensure the Quality of the Crane?

Perform due diligence by checking the supplier’s credentials, requesting quality certifications, and considering third-party inspections during production and prior to shipping.

10. What Payment Methods are Accepted?

Common payment methods include Letters of Credit (L/C), Telegraphic Transfers (T/T), and sometimes Trade Assurance options through platforms like Alibaba.

These answers should give buyers a good starting point when considering sourcing double girder overhead cranes from China. Always engage in thorough research and clear communication with suppliers to ensure a smooth purchasing process.