electric overhead winch Safety Certifications

Electric overhead winches are vital for lifting and moving heavy loads, and ensuring their safe operation is critical. Various safety certifications and standards govern the design, manufacturing, and use of these winches:

1. CE Marking (Europe): This indicates compliance with EU safety, health, and environmental requirements. It is crucial for winches sold within the European Economic Area.

2. ANSI/ASME B30.7 (USA): This standard, established by the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME), provides guidelines for construction, installation, inspection, testing, maintenance, and operation of winches.

3. ISO 9001: This international standard specifies requirements for a quality management system (QMS). Winch manufacturers with ISO 9001 certification demonstrate their commitment to consistently providing products that meet customer and regulatory requirements.

4. UL Certification: Underwriters Laboratories (UL) certification for electric components ensures that the winch has been tested for electrical safety.

5. CSA (Canada): The Canadian Standards Association (CSA) certification ensures that the winch meets Canadian national safety standards.

6. OSH (Occupational Safety and Health) Standards: These are region-specific guidelines (e.g., OSHA in the USA) that ensure workplaces are free from recognized hazards. They provide crucial guidelines for the safe operation of electric overhead winches.

7. IEC Standards: The International Electrotechnical Commission (IEC) develops international standards for electrical technologies. Compliance with IEC standards ensures the winch meets global safety and performance requirements.

8. Load Testing Certifications: Certifications from accredited testing organizations, indicating that the winch has been load-tested to verify safety performance, are also critical.

For optimal safety, always refer to the manufacturer’s operating manual, conduct regular inspections, and ensure operators are trained and certified in the safe use of the equipment.

List Reference Technical Parameters of “electric overhead winch”

Certainly! An electric overhead winch is a versatile lifting device used for hoisting and moving heavy loads in various industrial settings. Here are some essential reference technical parameters you should consider:

1. Load Capacity: The maximum weight the winch can safely lift, often ranging from a few hundred kilograms to several tons.

2. Lifting Height: The maximum vertical distance the load can be lifted, which can vary based on the application needs, generally from a few meters to twenty or more.

3. Lifting Speed: The rate at which the winch can lift a load, typically measured in meters per minute (m/min).

4. Motor Power: The electric motor’s power rating in kilowatts (kW) or horsepower (HP), which influences the winch’s performance and lifting speed.

5. Control System: The type of control mechanism, which could be wireless remote control, pendant control, or automated systems for precision operations.

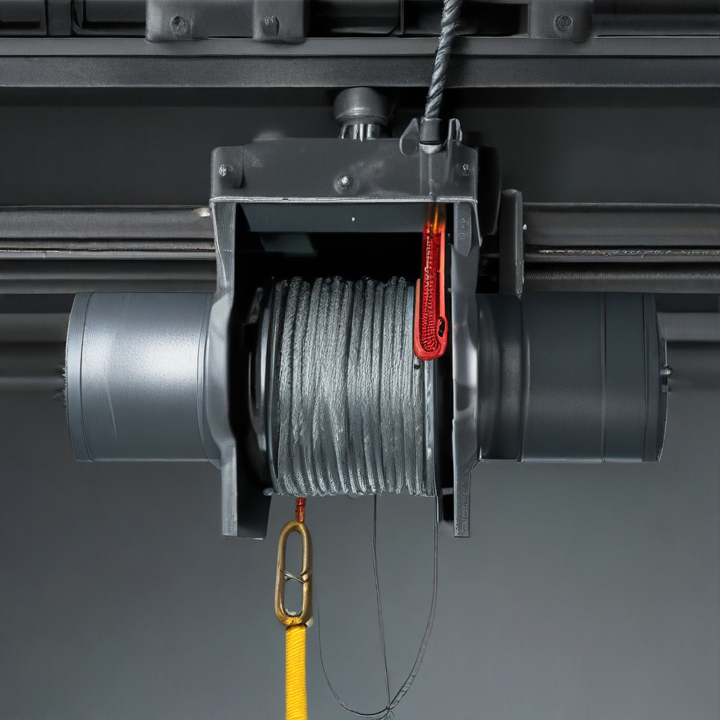

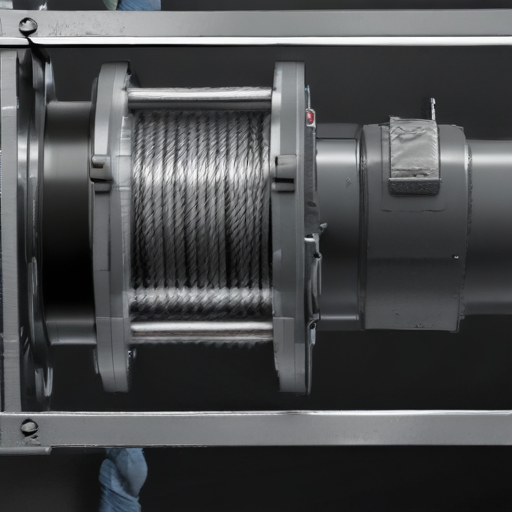

6. Wire Rope Specifications: Diameter, length, and type of wire rope used, critical for determining the load capacity and durability.

7. Drum Capacity: The length of wire rope that can be wound onto the drum, directly affecting the maximum lifting height.

8. Voltage Requirements: The operating voltage needed, commonly available in 220V, 380V, or 415V depending on regional electric standards.

9. Safety Features: Includes overload protection, emergency stop, limit switches for upper and lower travel, and braking systems to ensure safe operations.

10. Duty Cycle: The percentage of time the winch can operate within a given period, reflecting its suitability for continuous or intermittent use.

11. Environmental Conditions: Operating temperature range, ingress protection (IP) rating against dust and moisture, and suitability for specific industrial environments (e.g., hazardous areas).

12. Mounting Options: Types of installations available, such as wall-mounted, floor-mounted, or ceiling-mounted, determining its flexibility in various settings.

These technical parameters provide a comprehensive overview critical for selecting the appropriate electric overhead winch for your specific needs.

List Product features of “electric overhead winch”

An electric overhead winch is a crucial piece of equipment for lifting and moving heavy loads in industrial and construction settings. Here are the primary features:

1. Electric Motor: Powered by an electric motor, ensuring consistent and efficient operation.

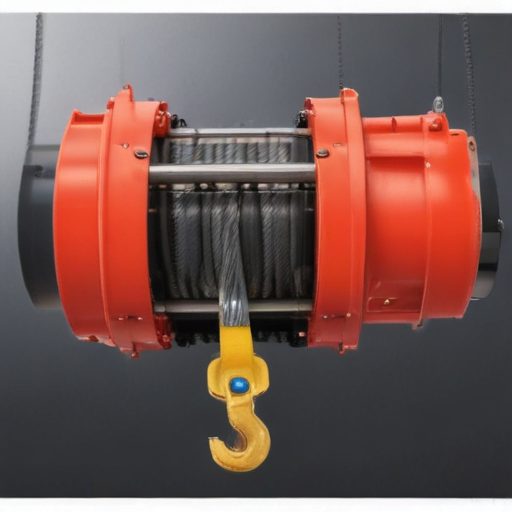

2. Load Capacity: Available in various load capacities (ranging from a few hundred pounds to several tons), offering flexibility for different job requirements.

3. Durable Construction: Made of high-quality materials like steel or aluminum for long-lasting durability and resistance to wear and tear.

4. Control System: Equipped with an easy-to-use control system, often featuring remote control or pendant control options for safe operation.

5. High Lifting Speed: Capable of lifting loads at a faster pace compared to manual or hydraulic winches, enhancing productivity.

6. Safety Features: Includes emergency stop buttons, limit switches, and overload protection to ensure safe operation.

7. Wire Rope or Chain: Utilizes a strong, durable wire rope or chain, designed to handle the maximum load capacity without breaking.

8. Mounting Options: Designed for overhead mounting on I-beams or other structural supports, providing versatile installation possibilities.

9. Brake System: Features an automatic braking system that securely holds the load in place when the winch is not in motion.

10. Thermal Protection: Equipped with thermal overload protection to prevent motor burnout during prolonged use.

11. Compact Design: Often features a compact and space-saving design, allowing it to fit into tight or limited spaces.

12. Smooth Operation: Designed for smooth and precise lifting and lowering of loads, minimizing load swing and enhancing control.

13. Noise Reduction: Incorporates mechanisms to reduce operating noise, creating a quieter work environment.

14. Maintenance-Free: Low-maintenance design with sealed components to reduce the need for frequent servicing.

15. Versatile Use: Suitable for various applications, including warehouses, factories, construction sites, and more.

These features collectively make electric overhead winches highly efficient, safe, and versatile tools for material handling and lifting tasks.

List Various Types of “electric overhead winch”

Electric overhead winches are essential for lifting and moving heavy loads in various industrial, construction, and warehouse applications. They vary in terms of capacity, speed, design, and operational features. Here’s a list of various types:

1. Standard Electric Overhead Winch: Typically used for general purposes, it offers moderate lifting capacities and speeds.

2. Heavy-Duty Electric Winch: Designed for industrial applications, these winches handle very high weights and are built with robust materials for durability.

3. Compact Electric Winch: Smaller in size, these winches are ideal for space-constrained environments while still providing sufficient lifting capability.

4. Variable Speed Winch: Offers adjustable speed settings, allowing for precise control over lifting and lowering operations.

5. Explosion-Proof Electric Winch: Specifically designed for use in hazardous environments where explosive gases or materials are present, ensuring safety and compliance with regulatory standards.

6. Hydraulic-Electric Hybrid Winch: Combines the benefits of hydraulic power for heavy lifting with electric control for precision and ease of use.

7. Wireless Remote-Controlled Winch: Equipped with remote control capabilities, allowing operators to manage the winch from a distance for increased safety and flexibility.

8. Port-Winch: Made for maritime applications, these winches can handle heavy loads and are resistant to corrosion from saltwater environments.

9. Electric Chain Hoist Winch: Utilizes chains instead of ropes, providing better durability and reduced maintenance for heavy-duty lifting tasks.

10. Single Girder Electric Winch: Mounted on a single girder crane, suitable for lighter loads and smaller operations.

11. Double Girder Electric Winch: Installed on double girder cranes, used for very heavy loads and large-scale operations.

12. Trolley-Mounted Winch: Installed on overhead rails or trolleys, these winches can move horizontally along the rail for versatile load positioning.

Understanding the different types of electric overhead winches helps in selecting the right equipment for specific lifting needs, ensuring efficiency, safety, and reliability.

List Application of “electric overhead winch”

An electric overhead winch is a versatile and powerful lifting device that has a wide range of applications across various industries, thanks to its ability to handle heavy loads efficiently and safely. Here are some of the key applications:

1. Manufacturing Industry: Electric overhead winches are used in assembly lines for lifting and positioning heavy components. They facilitate the movement of raw materials, semi-finished, and finished goods within manufacturing plants.

2. Construction Sites: They are essential for lifting heavy construction materials such as steel beams, concrete blocks, and large machinery. This equipment aids in building skyscrapers, bridges, and other large structures.

3. Warehousing and Logistics: In warehouses, electric overhead winches help in the storage and retrieval of goods on high racks, improving space utilization and efficiency, and in loading/unloading trucks and trailers.

4. Shipyards and Marine Industry: Used for mounting and dismounting engines, handling heavy equipment, and other maintenance tasks on ships. They also help in loading and unloading ships’ cargo.

5. Mining Industry: Used to lift equipment, minerals, and personnel in and out of mining shafts. Their ability to handle heavy loads makes them crucial for operations in this industry.

6. Automotive Industry: Essential in assembling heavy auto parts and engines, and also in the maintenance of vehicles where lifting entire vehicles may be necessary.

7. Entertainment and Events: Winches are used to set up stages and rigging for concerts, theatre productions, and other large-scale events, ensuring equipment is securely lifted and held in place.

8. Elevators and Lifts: In commercial and residential buildings, electric winches are integral in operating elevators and lifting systems.

9. Utility Services: They assist in the maintenance and installation of overhead power lines, wind turbines, and other utility infrastructure.

10. Emergency and Rescue Operations: Used by rescue teams to lift debris, vehicles, and other large objects during disaster recovery efforts.

Electric overhead winches enhance safety, efficiency, and productivity in various sectors by allowing the secure and controlled handling of heavy loads.

List Buyer Types of “electric overhead winch”

Sure, here are various buyer types for an electric overhead winch:

1. Construction Companies: These companies often require heavy lifting solutions to handle building materials like steel beams, concrete blocks, and other construction materials.

2. Manufacturing Plants: Factories and production facilities use electric overhead winches to move heavy machinery, equipment, and materials within the plant, such as during assembly line setups or equipment maintenance.

3. Warehousing and Logistics: Warehouses use winches to lift and move heavy pallets or large items that cannot be easily transported with forklifts or pallet jacks, improving operational efficiency.

4. Mining Operations: The mining industry employs electric overhead winches to haul extracted materials, machinery, and other heavy equipment from the depths of mine shafts to the surface.

5. Shipbuilding and Marine Industries: These industries require robust lifting solutions for hoisting large sections of ships, boating equipment, and other materials during construction and maintenance activities.

6. Energy Sector: Power plants, especially those involved in hydroelectric or wind energy, use electric overhead winches to lift and position heavy generators, turbines, and other crucial equipment.

7. Automotive Industry: Automobile manufacturers use this equipment to lift car bodies, engines, and other large components during the assembly process.

8. Railway Maintenance: Rail companies use electric overhead winches to lift and move railway cars, tracks, and other heavy components for repair, installation, and maintenance.

9. Event Management: Large-scale event organizations use winches to set up stages, light rigs, and heavy equipment required for events.

10. Agriculture: Agricultural operations may use electric winches to move heavy farming equipment or large batches of harvested produce.

By identifying the specific needs of these buyer types, sellers can tailor their marketing and sales strategies to better meet the requirements of each sector.

List “electric overhead winch” Project Types for Different Industries

Electric overhead winches are versatile lifting devices used across various industries for lifting, moving, or securing loads. Here are some project types for different industries:

1. Construction Industry:

– Building Construction: Used for lifting construction materials like steel beams, concrete blocks, and windows to higher levels.

– Infrastructure Projects: Helps in the installation of bridges, tunnels, and other large-scale structures.

– Demolition: Assists in tearing down sections safely and efficiently by controlling the descent of demolished parts.

2. Manufacturing Industry:

– Assembly Lines: Used to transport heavy components within assembly lines.

– Plant Maintenance: Essential for maintenance tasks, such as replacing heavy machine parts.

– Raw Material Handling: Facilitates the movement of raw materials for production.

3. Mining Industry:

– Ore Extraction: Helps in lifting mined ore to the surface.

– Mine Shaft Construction: Used for constructing and maintaining mine shafts.

– Equipment Relocation: Assists in moving heavy mining equipment underground.

4. Oil and Gas Industry:

– Rigging Operations: Supports drilling rigs by lifting and positioning heavy components.

– Pipeline Installation: Used for handling pipe sections and aligning them into place.

– Maintenance: Crucial for offshore and onshore equipment repairs and maintenance.

5. Marine Industry:

– Shipbuilding: Used in the assembly and repair of ships by lifting large sections and equipment.

– Dock Operations: Facilitates loading and unloading of cargo.

– Marine Salvage: Assists in recovery operations of sunken vessels or other underwater structures.

6. Utilities:

– Power Plants: Used for maintenance of turbines and generators.

– Telecommunication Towers: Helps in the installation and repair of transmission equipment.

– Water Treatment Facilities: Assists in lifting heavy components during maintenance.

7. Entertainment Industry:

– Event Setup: Used for lifting stage equipment, lighting rigs, and sound systems.

– Theatrical Productions: Supports scenery changes and lifting heavy stage elements.

8. Emergency and Rescue Operations:

– Disaster Relief: Assists in clearing debris and rescue operations.

– Search and Rescue: Employed in hoisting operations during rescue missions in challenging terrains.

These project types demonstrate the electric overhead winch’s utility across various sectors, highlighting its adaptability and essential role in modern industry.

electric overhead winch Accessories Upgrades and Custom Manufacturing Options

Electric overhead winches are indispensable for a wide range of lifting and material handling tasks. Enhancing their functionality and efficiency can be achieved through various accessories, upgrades, and custom manufacturing options.

Accessories:

1. Remote Controls: Wireless remotes enhance operational convenience and safety by allowing operators to control the winch from a distance.

2. Limit Switches: These ensure the winch stops automatically at pre-set upper and lower limits, preventing over-travel.

3. Load Indicators and Sensors: These devices monitor load weight, ensuring it remains within safe operating limits. Overload protection systems can shut down the winch if the load exceeds a predetermined threshold.

4. Wire Rope and Hooks: High-quality, durable wire ropes, and hooks tailored to specific lifting requirements improve safety and efficiency.

5. Swivels and Snatch Blocks: These enhance versatility by allowing for directional change in load lifting, reducing wear and tear on the rope.

Upgrades:

1. Variable Speed Controls: Upgrading to variable speed drives allows for precise control of lifting and lowering speeds, enhancing both safety and efficiency.

2. Enhanced Motors: High-performance motors with increased horsepower can handle more substantial loads and ensure longer operational life.

3. Braking Systems: Upgraded magnetic or regenerative braking systems improve load control and enhance safety.

4. Advanced Control Systems: Integrating smart control systems with programmable settings and fault diagnostics can improve reliability and ease of use.

Custom Manufacturing Options:

1. Capacity Customization: Winches can be manufactured to handle specific load capacities, ranging from a few hundred kilograms to several tons.

2. Dimensional Adjustments: Tailoring the size and dimensions of the winch to fit specific spatial constraints or mounting requirements.

3. Material Specifications: Utilizing corrosion-resistant materials like stainless steel or specialized coatings for harsh environments.

4. Specialized Drum Designs: Custom drums to accommodate non-standard wire rope lengths or diameters.

By investing in these accessories, upgrades, and customized solutions, the performance, safety, and longevity of electric overhead winches can be significantly enhanced, tailored precisely to meet specific operational needs.

List Quality Control and The Manufacturing Process of “electric overhead winch”

Quality Control in Electric Overhead Winch Manufacturing

1. Material Inspection: Incoming materials are inspected for compliance with specifications.

2. Component Testing: Individual components like motors, cables, and gears undergo rigorous testing.

3. Assembly Monitoring: Each stage of the assembly process is monitored for alignment, tolerances, and assembly integrity.

4. Load Testing: Assembled winches are subjected to simulated load conditions to measure performance.

5. Functional Testing: Winches are operated to verify control systems, braking mechanisms, and speed regulation.

6. Final Inspection: A thorough visual and functional inspection ensures the product meets all standards.

7. Certification: Compliance with industry standards (ISO, ASME) is confirmed before shipping.

Manufacturing Process of Electric Overhead Winch

1. Design & Planning: Engineering teams design winches using CAD software, detailing every component and assembly requirement.

2. Material Procurement: High-quality materials are sourced according to the design specifications.

3. Component Manufacturing:

– Machining: Precision machining of structural components like the drum and frame is undertaken.

– Fabrication: Welding and fabricating processes form the structural framework.

– Electrical Assembly: Motors and control units are assembled and tested independently.

4. Sub-Assembly:

– Gearbox Assembly: Gearboxes are assembled and lubricated.

– Braking System: Braking mechanisms are installed and tested.

5. Main Assembly: All sub-assemblies are combined into the main winch assembly. Bolting, welding, and wiring tasks are carried out meticulously.

6. Quality Testing: The assembled winch undergoes load, functional, and safety tests.

7. Surface Treatment: The winch is painted or coated to prevent corrosion and wear.

8. Final Inspection: A comprehensive inspection ensures adherence to design and quality standards.

9. Packaging & Shipping: Winches are safely packaged and dispatched to customers with detailed documentation and user manuals.

How to use “electric overhead winch”

Operating an electric overhead winch requires attention to safety and understanding the equipment. Here’s a concise guide:

1. Read the Manual: Familiarize yourself with the manufacturer’s instructions and safety guidelines.

2. Inspect the Winch and Area:

– Electrical Connection: Ensure the winch is properly connected to a power source.

– Load Capacity: Confirm the winch’s rated load capacity matches your lifting needs.

– Work Area: Clear any obstructions and ensure the path is clear for safe movement.

3. Prepare the Load:

– Securely attach lifting slings, hooks, or chains to the load.

– Ensure the load is balanced and stable.

4. Test the Winch:

– Run a test lift with a small load or without a load to check functionality.

– Listen for unusual sounds and confirm smooth operation.

5. Lifting the Load:

– Position: Stand clear of the load’s path.

– Control: Use the winch’s control pendant to raise the load slowly.

– Monitor: Watch for any signs of strain or imbalance.

6. Moving the Load:

– Once lifted, carefully move the load to its destination.

– Ensure the load remains stable during transit.

7. Lowering the Load:

– Slowly lower the load into place using the control pendant.

– Ensure it is securely positioned and stable before detaching.

8. Post-Operation Check:

– Turn off and disconnect the winch.

– Inspect the equipment for wear or damage.

– Store the winch and any accessories properly.

9. Safety First:

– Always wear appropriate Personal Protective Equipment (PPE).

– Never exceed the rated load capacity.

– Keep bystanders clear of the lifting area.

By adhering to these steps, you can safely and efficiently operate an electric overhead winch.

“electric overhead winch” Comparative Analysis

An electric overhead winch is a powerful and versatile equipment used for lifting and horizontal pulling of heavy loads in various industrial applications. When comparing electric overhead winches, several critical factors must be considered: lifting capacity, speed, power source, ease of use, safety features, and cost.

Lifting Capacity: Winches come in varying capacities, typically ranging from a few hundred kilograms to several tons. The choice depends on the specific requirements of the task. High-capacity winches are preferred for more demanding industrial roles.

Speed: Electric winches usually offer faster lifting and pulling capabilities compared to manual or hydraulic variants. High-speed winches improve efficiency but may compromise on precision.

Power Source: These winches often run on standard electrical power, making them more convenient to use than hydraulic systems requiring additional power sources. The voltage (110V, 220V, or higher) and phase (single or three-phase) should match your facility’s power supply.

Ease of Use: Modern winches often come equipped with remote control systems for safer and more convenient operation. Look for intuitive controls and automated features that can reduce operator fatigue and increase productivity.

Safety Features: Essential safety features include overload protection, emergency stop buttons, and limit switches to prevent over-travel. Some advanced models offer sensors and diagnostic systems to monitor the operational health of the winch continuously.

Cost: While electric overhead winches tend to have a higher upfront cost compared to manual winches, their efficiency and ease of use can result in lower long-term operational costs. Investing in a winch with advanced features and higher reliability may offer better value over time.

In summary, electric overhead winches are indispensable tools in heavy lifting operations, offering superior speed and convenience. However, selecting the right winch requires balancing lifting capacity, speed, power compatibility, usability, safety, and cost considerations to meet specific industrial needs effectively.

“electric overhead winch” Warranty and Support

Warranty and Support for Electric Overhead Winch

When investing in an electric overhead winch, ensuring robust warranty and support is crucial for long-term reliability and satisfaction. Here’s what you can typically expect:

#### Warranty Coverage

1. Duration: Most electric overhead winches come with a warranty ranging from one to five years, depending on the manufacturer and model.

2. Parts Covered: Standard warranties often cover key components such as the motor, gearbox, control systems, and structural parts of the winch.

3. Conditions: It’s essential to adhere to the manufacturer’s specified usage conditions to maintain warranty validity. Misuse, overloading, and unauthorized modifications can void the warranty.

4. Extended Warranty: Some manufacturers offer extended warranties for an additional fee, providing extra peace of mind.

#### Support Services

1. Technical Support: Manufacturers typically provide technical support via phone, email, or online chat to assist with installation, troubleshooting, and maintenance queries.

2. User Manuals and Guides: Comprehensive user manuals and installation guides are usually available in both digital and printed formats, detailing operational procedures and safety precautions.

3. Maintenance Services: Regular maintenance is crucial for optimal performance. Some companies offer maintenance plans, including periodic inspections and servicing by qualified professionals.

4. Spare Parts Availability: Ensure that spare parts are readily available from the manufacturer or authorized dealers to minimize downtime due to repairs.

5. Training Programs: Some manufacturers provide training programs or workshops for users and maintenance personnel to ensure correct usage and upkeep of the winch.

#### Customer Support

1. Customer Service: A responsive customer service team can address general inquiries, warranty claims, and service appointments promptly.

2. Online Resources: Access to a robust online support portal, including FAQs, how-to videos, and user forums, can be invaluable for quick resolutions to common issues.

Conclusion

Choosing an electric overhead winch with comprehensive warranty and support services is essential for ensuring reliability and maximizing the lifespan of your investment. Always review the warranty terms and support offerings thoroughly before purchase to make an informed decision.

List “electric overhead winch” FAQ

Electric Overhead Winch FAQ

1. What is an electric overhead winch?

– An electric overhead winch is a motorized device used to lift, lower, and move heavy loads horizontally. It is often mounted on a crane, gantry, or trolley system for enhanced flexibility and ease of use.

2. How does an electric overhead winch work?

– The winch operates using an electric motor that powers a drum, around which wire rope or cable is wound. The motor provides the necessary force to lift or move the load, and built-in controls allow the user to manage the speed and direction.

3. What are the benefits of using an electric overhead winch?

– These winches provide powerful lifting capabilities, precise control over load movement, increased safety with features like automatic braking, and reduced manual labor, making them ideal for various industrial applications.

4. What should I consider when selecting an electric overhead winch?

– Key considerations include load capacity, lifting height, operating environment, power requirements, speed of operation, and safety features. Always ensure the winch complies with local regulations and standards.

5. What maintenance is required for electric overhead winches?

– Regular maintenance includes inspections for wear and tear, lubrication of moving parts, checking and replacing worn cables or ropes, testing safety features, and ensuring the electrical components are free from damage.

6. Can electric overhead winches be customized?

– Yes, winches can be tailored to meet specific needs, such as varying load capacities, speeds, and control systems. Customization ensures optimal performance for specialized industrial tasks.

7. Are electric overhead winches safe?

– When operated according to manufacturer guidelines and maintained properly, these winches are safe. They typically come with safety features like overload protection, emergency stop buttons, and automatic braking systems.

8. What industries use electric overhead winches?

– Industries such as manufacturing, construction, shipping, mining, and warehousing frequently use these winches for heavy lifting and material handling tasks.

By addressing these frequently asked questions, you can better understand the fundamentals and practical considerations for using an electric overhead winch.

Top 10 FAQ with answer about electric overhead winch for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQs) with concise answers about sourcing an electric overhead winch from China:

1. What is an electric overhead winch?

– An electric overhead winch is a device used for lifting and moving heavy loads using an electric motor. It’s mounted overhead and typically used in construction, warehouses, and factories.

2. What are the main specifications to consider when sourcing an electric overhead winch?

– Key specifications include load capacity, lifting height, lifting speed, power supply, and motor power. Ensure they match your operational requirements.

3. How do I verify the quality of winches from Chinese suppliers?

– Check for international quality certifications like CE, ISO, or RoHS. Also, request for sample units, customer testimonials, and perform factory audits if possible.

4. What are the typical lead times for delivery?

– Lead times vary but generally range from 4 to 6 weeks. Custom orders or high-demand periods may extend this timeframe.

5. Can I customize the winch according to my specific needs?

– Yes, many Chinese manufacturers offer customization options. Clearly communicate your requirements regarding load capacity, dimensions, and additional features.

6. What is the warranty period and what does it cover?

– Most suppliers provide a 1 to 2-year warranty covering manufacturing defects and parts replacement. Always verify warranty terms in the contract.

7. Are there any after-sales services provided?

– Reputable suppliers usually offer after-sales services such as installation assistance, maintenance support, and repair services. Ensure these details are specified.

8. What are the payment terms typically offered?

– Common payment terms are 30% advance deposit and 70% balance before shipment. Letter of Credit (LC) and Trade Assurance (for online platforms like Alibaba) are also options.

9. How do I ensure the supplier is reliable?

– Verify business licenses, check third-party reviews, and use verified sourcing platforms. Performing due diligence is crucial for ensuring reliability.

10. What are the shipping options and associated costs?

– Shipping options include FOB (Free on Board), CIF (Cost, Insurance, and Freight) and Door-to-Door. Costs depend on the shipment size, weight, and destination. Get quotes from multiple freight forwarders for a comparative analysis.

This concise overview should assist buyers in making informed decisions when sourcing electric overhead winches from China.