gantry crane for sale Safety Certifications

When purchasing a gantry crane, ensuring it meets all necessary safety certifications is crucial for operational safety and compliance with regulations. Below are some of the key safety certifications and standards to consider:

1. OSHA (Occupational Safety and Health Administration): In the United States, OSHA provides guidelines and standards for the safe operation of cranes and hoists. Compliance with OSHA ensures that the equipment adheres to national safety rules.

2. ANSI (American National Standards Institute): ANSI standards, particularly those under B30.2 for overhead and gantry cranes, are important as they address safety, construction, and maintenance requirements.

3. ASME (American Society of Mechanical Engineers): ASME B30.17 and B30.20 specifically cover underhung hoists and trolleys, jib cranes, and other related equipment. Compliance with these standards signifies robustness and safety in engineering practices.

4. CE Marking (Conformité Européenne): For operation within the European Union, CE marking indicates that the crane conforms to EU safety, health, and environmental protection standards.

5. ISO (International Organization for Standardization): ISO 9001 for quality management systems and ISO 14001 for environmental management provide a framework for consistent quality and environmental responsibility, indirectly enhancing safety.

6. CSA (Canadian Standards Association): For operations in Canada, CSA standards like CSA B167 cover safety requirements for lifting equipment, ensuring the machinery meets stringent Canadian safety requirements.

Always ensure to request and verify the certificates from the manufacturer or dealer before purchasing. Compliance with these standards not only enhances safety but also ensures that the equipment is reliable and well-constructed. Additionally, regular maintenance and inspections, as stipulated by these standards, are vital to keep the crane in safe working condition.

List Reference Technical Parameters of “gantry crane for sale”

When evaluating a gantry crane for sale, it’s crucial to examine its reference technical parameters to ensure it meets your operational requirements. Here are the key parameters to consider:

1. Load Capacity: The maximum weight the crane can lift, typically ranging from a few tons to several hundred tons.

2. Span Width: The distance between the crane’s legs, impacting the width of the area it can service. Measured in meters or feet.

3. Lifting Height: The maximum height the hook or hoist can reach, crucial for operations with high vertical requirements.

4. Overall Height: The total height of the crane from the ground up, important for indoor or height-restricted environments.

5. Hoist Type and Speed: Identifies whether the hoist is electric, manual, or hydraulic and its lifting speed, which affects operational efficiency.

6. Travel Speed: The speed at which the crane can move along its rails or tracks, often expressed in meters per minute.

7. Control System: Could be a pendant control, wireless remote, or cabin control, influencing the ease of operation and safety.

8. Power Supply: Voltage and phase requirements, which must be compatible with your facility’s electrical system.

9. Duty Cycle: Specifies the operational capacity in terms of load and frequency, commonly noted as A5, A6, etc., based on FEM standards.

10. Material and Protection: Construction materials (steel type) and protective coatings (like rust-resistant finishes), important for durability and specific environments (e.g., maritime, industrial).

11. Compliance and Certification: Ensures the crane meets industry standards and safety regulations, such as ISO, OSHA, or CE certifications.

12. Environmental Adaptability: The crane’s ability to operate under different environmental conditions, including temperature and humidity ranges.

13. Additional Features: Such as anti-sway mechanisms, variable frequency drives, load sensors, and automated systems, which enhance functionality and safety.

Review these parameters carefully to select a gantry crane that aligns with your operational needs and provides optimal performance and safety.

List Product features of “gantry crane for sale”

1. Load Capacity: Designed to handle heavy loads, ranging from several tons to hundreds of tons.

2. Adjustable Height and Span: Provides flexibility to accommodate various lifting requirements and workspace configurations.

3. Durable Construction: Made with high-quality steel and robust materials ensuring longevity and reliability.

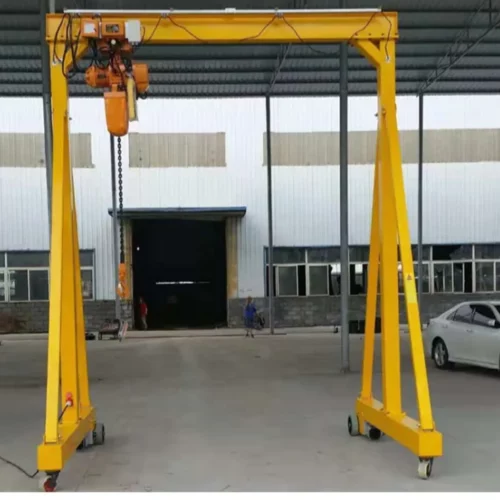

4. Easy Mobility: Equipped with wheels or rails for convenient movement around the worksite, enhancing operational efficiency.

5. Customizable Options: Available in different sizes, specifications, and designs to meet specific industry and application needs.

6. Safety Features: Includes emergency stop buttons, limit switches, overload protection, and anti-sway mechanisms to ensure safe operations.

7. Power Options: Can be powered by electricity, diesel, or manual operation, catering to different operational environments.

8. Remote Control Operation: Many models come with wireless remote controls for ease of use and enhanced safety during operations.

9. Smooth Lifting and Lowering: Advanced hoisting mechanisms offer precise and smooth lifting and lowering of loads.

10. Weather-Resistant Coating: Protected with coatings that resist corrosion and withstand harsh environmental conditions.

11. Low Maintenance: Designed for easy maintenance with accessible components and minimal upkeep requirements.

12. Versatile Applications: Suitable for various industries including construction, manufacturing, shipping, and warehousing.

13. Ease of Installation: Simple to set up with clear instructions and minimal assembly required.

14. Operational Efficiency: Enhances productivity by enabling quick and effective lifting and transport of materials.

15. Warranty and Support: Often comes with a manufacturer’s warranty and customer support for peace of mind and assistance.

These key features contribute to the gantry crane’s effectiveness, making it a valuable investment for businesses requiring efficient and reliable material handling solutions.

List Various Types of “gantry crane for sale”

When seeking a gantry crane for sale, it’s crucial to understand the various types available to match specific needs and applications. Here are the main types:

1. Single Girder Gantry Crane:

– Portable Gantry Crane: Small, lightweight, and mobile; ideal for light lifting tasks.

– Fixed Gantry Crane: Stationary with a single beam; used in light to moderate lifting applications.

2. Double Girder Gantry Crane:

– More robust and capable of handling heavier loads compared to the single girder. It features two main beams and is ideal for heavy-duty lifting.

3. Full Gantry Crane:

– Full-Span Gantry Crane: Suitable for large outdoor spaces, as it spans the full width of a workspace.

– Semi-Gantry Crane: One side runs on a rail at ground level while the other runs on an elevated runway.

4. Adjustable Gantry Crane:

– Features adjustable heights and spans, providing flexibility for various lifting tasks. Ideal for varied tasks in workshops.

5. Container Gantry Crane:

– Specifically designed for handling shipping containers, often seen in ports and rail yards.

6. Heavy-Duty Gantry Crane:

– Suitable for extremely heavy loads and large-scale industrial applications, often found in shipyards and large warehouses.

7. Aluminum Gantry Crane:

– Lightweight and portable, easily assembled and disassembled; suitable for small to medium lifting tasks in various industries.

8. Track-Mounted Gantry Crane:

– Runs on a fixed track, providing stable and precise positioning for heavy lifting.

When choosing a gantry crane, consider the weight capacity, span, lifting height, mobility, and specific application requirements to ensure optimal performance and safety.

List Application of “gantry crane for sale”

A gantry crane is a versatile piece of lifting equipment primarily used in various industrial and construction settings. Below are some key applications of gantry cranes:

1. Manufacturing Plants: Used to lift and move heavy components and machinery, facilitating assembly lines, and production processes.

2. Construction Sites: Ideal for lifting heavy materials such as steel beams, concrete blocks, and other construction components, enhancing efficiency and safety on site.

3. Shipyards and Dockyards: Essential for loading and unloading heavy cargo, containers, and ship parts. Gantry cranes are particularly valuable in building and repairing ships.

4. Warehouses and Distribution Centers: Help in handling large quantities of goods quickly and efficiently, improving inventory management and logistics operations.

5. Mining Operations: Used for lifting heavy mining equipment and minerals, crucial for operational efficiency and safety in mining environments.

6. Railway Yards: Facilitate the movement of heavy cargo and train components, improving the turnaround time and efficiency in railway operations.

7. Utility Companies: Assist in the installation and maintenance of heavy infrastructure components such as transformers, power generators, and large pipelines.

8. Wind Energy Sector: Aid in the assembly and maintenance of wind turbines by lifting heavy components like blades and nacelles.

9. Automotive Industry: Used in assembling vehicles by lifting heavy engines and other critical parts, thereby streamlining the manufacturing process.

10. Aviation Industry: Facilitate the construction and maintenance of aircraft, helping to lift heavy parts like engines and fuselages.

By employing gantry cranes, these industries can enhance their productivity, ensure worker safety, and efficiently manage heavy lifting tasks. Whether purchased new or used, gantry cranes are a significant asset for businesses requiring reliable lifting solutions.

List Buyer Types of “gantry crane for sale”

When considering “gantry crane for sale,” it is critical to identify the various buyer types to tailor marketing, sales, and customer outreach efforts effectively. Here are some common buyer types for gantry cranes:

1. Industrial Manufacturers:

– Description: These buyers operate in industries like automotive, aerospace, and heavy machinery.

– Needs: High-capacity and reliable gantry cranes for handling large components and assemblies in production lines.

2. Construction Companies:

– Description: Firms involved in building infrastructure such as bridges, highways, and large edifices.

– Needs: Mobile and heavy-duty cranes with versatile lifting capabilities to move large materials on site.

3. Logistics and Warehousing Firms:

– Description: Organizations that manage storage facilities and distribution centers.

– Needs: Efficient gantry cranes that improve loading, unloading, and material handling processes.

4. Shipbuilding and Marine Operations:

– Description: Companies engaged in building ships, maintaining docks, and handling port operations.

– Needs: Cranes with high load capacities and extended spans for lifting and moving bulky and heavy marine vessels or parts.

5. Steel and Metal Fabrication Industries:

– Description: Businesses involved in cutting, bending, and assembling steel or metal structures.

– Needs: Precision lifting equipment to handle large metal sheets and parts safely and effectively.

6. Mining and Natural Resource Extraction:

– Description: Operators of mines and quarries.

– Needs: Robust cranes designed for heavy lifting in rugged environments and capable of handling raw materials like ore and coal.

7. Utilities and Energy Providers:

– Description: Companies that construct and maintain power plants, substations, and other energy infrastructure.

– Needs: Specialized cranes for assembling and maintaining heavy equipment and machinery.

8. Rental and Leasing Services:

– Description: Firms that rent out heavy machinery to various industries.

– Needs: Versatile and durable gantry cranes that can cater to a wide range of applications and withstand frequent use.

By pinpointing these specific buyer types, sellers can better understand market demands, tailor their product features to meet industry-specific requirements, and optimize their marketing strategies.

List “gantry crane for sale” Project Types for Different Industries

Gantry cranes, versatile lifting solutions, find applications across various industries. Here’s a list of project types where gantry cranes are commonly employed:

1. Construction Industry:

– Building Construction Projects: For moving heavy materials like steel beams, concrete blocks, and other construction elements.

– Bridge Construction: For handling large components such as prefabricated sections, girders, and deck segments.

– Tunnel Construction: For moving heavy machinery and tunnel linings.

2. Manufacturing Industry:

– Assembly Lines: For lifting and positioning heavy parts during assembly.

– Fabrication Workshops: For moving large metal sheets and fabricated components.

– Automotive Manufacturing: For handling engines, chassis, and other heavy car parts.

3. Transportation and Logistics:

– Port Operations: For loading and unloading shipping containers.

– Railway Yards: For handling train carriages and related components.

– Freight Terminals: For managing heavy cargo.

4. Aerospace Industry:

– Aircraft Manufacturing: For assembling aircraft parts and components.

– Maintenance Hangars: For lifting aircraft engines and other heavy maintenance equipment.

5. Energy Sector:

– Wind Turbine Installation: For lifting turbine components such as blades, nacelles, and towers.

– Oil and Gas Exploration: For handling heavy drilling equipment and subsea structures.

– Power Plants: For maintaining heavy equipment like turbines and generators.

6. Mining Industry:

– Open Pit Mining: For moving extracted minerals and heavy mining equipment.

– Underground Mining: For handling heavy machinery and ore containers.

7. Warehousing and Distribution:

– Large-Scale Warehouses: For moving heavy palletized goods and equipment.

– Cold Storage Facilities: For handling frozen goods in bulk.

8. Shipbuilding:

– Dry Docks: For assembling and repairing ships by lifting heavy hull sections.

– Shipyards: For transporting large ship components during the construction phase.

These project types highlight the indispensability of gantry cranes in enhancing productivity, safety, and efficiency across various sectors.

gantry crane for sale Accessories Upgrades and Custom Manufacturing Options

If you’re in the market for a gantry crane, numerous options for accessories, upgrades, and custom manufacturing can enhance utility and performance to suit your specific needs.

Accessories:

1. Lifting Attachments: From standard hooks to specialized grabs and magnets for handling different materials.

2. Cable Reels and Festoon Systems: Ensure smooth power supply and control line management.

3. Remote Controls: Wireless operation for improved safety and precision.

4. Load Weighing Systems: Integrated scales for real-time weight monitoring.

5. Lighting Kits: Better visibility for night-time and low-light operations.

Upgrades:

1. Motorized Trolleys: Upgrade from manual to motorized trolleys for smoother, faster operation.

2. Inverter Drives: Enhance speed control and energy efficiency.

3. Anti-collision Systems: For preventing accidents in multi-crane environments.

4. Automated Systems: Implement partial or full automation for high efficiency.

5. Weatherproofing: Ensures durability and functionality in harsh outdoor conditions.

Custom Manufacturing:

1. Tailored Dimensions: Custom heights, spans, and capacities to match your facility layout and load requirements.

2. Material Choices: Sturdy options like high-tensile steel or lightweight aluminum, depending on your lifting needs.

3. Paint and Coating Options: Specialized coatings for corrosion resistance or chemical environments.

4. Ergonomic Design: Features that allow for user-friendly operation and maintenance.

5. Integration with Existing Systems: Compatibility with your current infrastructure, conveyor systems, or warehouse management software.

Whether for a warehouse, construction site, or manufacturing facility, these customizable features make a gantry crane a versatile and invaluable asset. Assess your operational requirements and opt for accessories and upgrades to maximize efficiency, safety, and return on investment.

List Quality Control and The Manufacturing Process of “gantry crane for sale”

Quality Control for Gantry Crane

1. Material Inspection: Verify materials’ quality through tests and certifications before production begins.

2. Dimensional Verification: Ensure all components adhere to design specifications through precise measurement tools.

3. Welding Inspection: Use non-destructive testing (NDT) methods like ultrasonic or radiographic testing to assess weld quality.

4. Load Testing: Conduct load tests to confirm the crane can handle specified weights safely.

5. Electrical System Check: Validate electrical installations for compliance and functionality, including control panels and wiring.

6. Paint and Coating Inspection: Examine surface finish for durability and adherence to corrosion resistance standards.

7. Final Assembly Inspection: Inspect the fully assembled crane for defects and operational testing.

8. Documentation and Certification: Compile all test reports and compliance certificates for customer assurance.

Manufacturing Process of Gantry Crane

1. Design and Planning:

– Requirement Analysis: Assess customer specifications and regulatory standards.

– CAD Modeling: Create detailed design models using CAD software.

2. Material Procurement:

– Source Quality Materials: Acquire high-grade steel and other materials from certified suppliers.

– Inventory Check: Ensure all necessary components and materials are available.

3. Fabrication:

– Cutting and Shaping: Use CNC machines to cut and shape steel plates and beams.

– Welding: Assemble components by welding according to design specifications.

– Machining: Perform precision machining on parts like wheels, gears, and shafts.

4. Assembly:

– Sub-Assembly: Assemble sub-components like trolleys and hoists separately.

– Main Assembly: Combine the sub-assemblies to form the primary structure of the crane.

5. Surface Treatment:

– Sandblasting: Clean surfaces to remove rust and impurities.

– Painting/Coating: Apply corrosion-resistant paint or coatings.

6. Installation of Electrical Systems:

– Wiring: Install electrical systems, control panels, and safety mechanisms.

– Testing: Verify the operation of electrical and control systems.

7. Final Inspection and Testing:

– Operational Testing: Perform load and safety tests.

– Quality Assurance: Conduct a comprehensive final inspection and quality check.

8. Packaging and Delivery:

– Secure Packaging: Pack components properly to avoid damage during transport.

How to use “gantry crane for sale”

A gantry crane is an essential piece of equipment in various industries, designed to lift and move heavy loads. If you are searching for a “gantry crane for sale,” here’s a guide to help you through the process:

1. Determine Your Requirements:

– Load Capacity: Understand the maximum weight you need to lift.

– Span and Height: Measure the width and height required for your operations.

– Power Source: Decide between a manual, electric, or hydraulic model based on your needs.

2. Research Suppliers and Manufacturers:

– Look for reputable companies with positive reviews.

– Compare prices and specifications from multiple sources.

– Consider local versus international suppliers based on shipping costs and delivery times.

3. Inspect the Crane:

– If possible, physically inspect the crane for wear and tear.

– Request for maintenance records if purchasing a used crane.

– Ensure all safety features are intact and functioning properly.

4. Verify Compliance:

– Ensure the crane meets industry standards and regulations.

– Check for necessary certifications and conformance to safety protocols.

5. Negotiate the Price:

– Don’t hesitate to negotiate the price. Suppliers often have some flexibility.

– Consider additional costs like delivery, installation, and possible maintenance.

6. Arrange Financing:

– If purchasing outright is not feasible, look into leasing options or financing plans that fit your budget.

7. Plan for Installation and Training:

– Coordinate with the supplier for installation services.

– Train your staff on the proper usage and maintenance of the gantry crane.

Conclusion:

Purchasing a “gantry crane for sale” involves careful consideration of your needs, thorough research, and careful inspection to ensure you get a high-quality, safe, and cost-effective piece of equipment. Always follow through with proper training and maintenance to maximize the lifespan and efficiency of your investment.

“gantry crane for sale” Comparative Analysis

When sourcing a gantry crane for sale, several critical factors must be evaluated, including lifting capacity, span length, application suitability, and cost. Here is a comparative analysis of three popular options: Portable Gantry Cranes, Adjustable Gantry Cranes, and Heavy-duty Gantry Cranes.

Portable Gantry Cranes:

– Lifting Capacity: Typically up to 2 tons.

– Span Length: Up to 20 feet.

– Applications: Ideal for light-duty tasks, workshops, and smaller construction sites.

– Cost: Generally the most affordable option, ranging from $1,000 to $5,000.

– Pros: Easy to move and set up, suitable for small indoor spaces.

– Cons: Limited lifting capacity and less stable for heavy loads.

Adjustable Gantry Cranes:

– Lifting Capacity: Ranges from 1 to 10 tons.

– Span Length: Up to 30 feet, with adjustable height.

– Applications: Versatile for medium-duty requirements, warehouses, and maintenance tasks.

– Cost: Moderately priced, typically between $5,000 and $15,000.

– Pros: Flexibility in both height and span, suitable for varied tasks.

– Cons: More complex setup compared to portable options, may require a larger storage space.

Heavy-duty Gantry Cranes:

– Lifting Capacity: Up to 20 tons or more.

– Span Length: Span can exceed 50 feet.

– Applications: Designed for heavy-duty industries, shipyards, and large-scale construction projects.

– Cost: Higher-priced, often exceeding $20,000, depending on custom specifications.

– Pros: Exceptional lifting capacity and stability for the heaviest loads.

– Cons: High initial cost and increased maintenance complexity, primarily suited for outdoor or industrial settings.

Conclusion:

Choosing the right gantry crane requires a balanced assessment of your specific needs and budget. Portable gantry cranes are suitable for light-duty tasks and indoor use. Adjustable gantry cranes offer a versatile solution for medium-duty applications with varying height requirements. Heavy-duty gantry cranes are the go-to for the most demanding tasks but come with a higher cost and complexity. Each type presents unique advantages and potential drawbacks, necessitating a thorough evaluation of your operational demands.

“gantry crane for sale” Warranty and Support

When considering the purchase of a gantry crane, it’s essential to pay attention to both the warranty and support services offered. Most reputable manufacturers and sellers provide a warranty that typically covers structural components for a range of five to ten years. Electrical components, such as motors and controls, often have a shorter warranty period, typically one to two years. Always check specific warranty terms as they may vary between providers.

Support is another crucial factor. Quality post-sale support can significantly impact the crane’s longevity and your satisfaction. Look for sellers that offer comprehensive customer support including installation assistance, operational training, and routine maintenance services. Many suppliers provide 24/7 technical support, ensuring that any issues can be swiftly addressed to minimize downtime.

Some companies go the extra mile by offering extended warranty options and preventive maintenance programs. These packages often include regular inspections, parts replacement, and even software updates if the crane has advanced control systems.

When evaluating a seller, consider their reputation and read customer reviews or testimonials. A company with a robust support system often has a track record of high customer satisfaction. Make sure they have easy-to-access service centers or a reliable service team that can conduct on-site repairs.

In summary, ensuring robust warranty and support services when purchasing a gantry crane can provide peace of mind and help maintain optimal performance over the long term. Always clarify what is covered under warranty, the duration, and what kind of support services are available, to make an informed investment decision.

List “gantry crane for sale” FAQ

Gantry Crane for Sale: Frequently Asked Questions

1. What is a gantry crane?

– A gantry crane is a type of overhead crane with a single or double girder configuration supported by freestanding legs that move on wheels, rail, or track. They are typically used for lifting heavy loads in outdoor areas, warehouses, and manufacturing facilities.

2. What are the types of gantry cranes available?

– Common types include full gantry cranes, semi-gantry cranes, portable gantry cranes, and adjustable-height gantry cranes. Each type suits different operational needs and environmental conditions.

3. What is the lifting capacity of gantry cranes?

– Lifting capacities vary widely, from small models with capacities of 1-5 tons to large industrial models capable of lifting over 300 tons. It is crucial to choose a crane that matches your specific lifting requirements.

4. Are new and used gantry cranes available for sale?

– Yes, both new and used gantry cranes are available. Used cranes can offer cost savings but should be inspected for wear and compliance with safety standards.

5. What should be considered when buying a gantry crane?

– Consider factors such as load capacity, span, lifting height, duty cycle, operating environment, power requirements, and additional features like mobility, adjustability, and automation.

6. Do gantry cranes require special maintenance?

– Regular maintenance is essential to ensure safety and prolong the crane’s lifespan. This includes routine inspections, lubrication, and replacing worn-out parts as necessary.

7. Can gantry cranes be customized?

– Yes, many manufacturers offer customization options to meet specific operational needs, including custom spans, heights, and lifting capacities, as well as specialized attachments.

8. What are the safety features of gantry cranes?

– Safety features can include overload protection, emergency stop buttons, limit switches, anti-collision devices, and safety locks. Ensuring these features exist and function properly is critical.

9. How do I transport and install a gantry crane?

– Transport and installation require careful planning and possibly the assistance of professionals. Some manufacturers offer installation services or detailed instructions.

10. Are financing or leasing options available?

– Many suppliers offer financing and leasing options to make acquiring a gantry crane more affordable. It’s advisable to discuss these options with the supplier.

Top 10 FAQ with answer about gantry crane for sale for Buyer Sourcing from China

Sure! Here are the top 10 frequently asked questions (FAQ) about sourcing gantry cranes from China, along with concise answers:

1. What are the types of gantry cranes available?

– Single Girder: Lighter loads, economical.

– Double Girder: Heavy-duty, higher capacity and span.

– Portable/Mobile: Easy to move for smaller loads.

– Rail-Mounted: Heavy industrial use, fixed pathways.

2. What is the typical lead time for a gantry crane?

– Lead times can range from 30 to 90 days depending on customization, production schedules, and shipping.

3. How do I ensure the quality of the crane?

– Verify certifications such as ISO, CE, and QS. Engage third-party inspection services, and request documentation on load testing and quality assurance.

4. What details should I provide for a quote?

– Provide load capacity, span, lifting height, power requirements, environment (indoor/outdoor), and any special features.

5. Is it possible to customize the crane?

– Yes, most manufacturers offer customization for capacities, spans, lifting mechanisms, and control systems based on specific needs.

6. What after-sales services are offered?

– Services typically include installation support, training, spare parts supply, maintenance guidelines, and technical support.

7. How is the shipping handled?

– Shipping can be arranged by manufacturers either FOB (Free on Board) or CIF (Cost, Insurance, and Freight), depending on buyer preference. Cranes are typically disassembled and packed securely for ocean freight.

8. What are the payment terms?

– Common terms include a 30% advance payment and 70% balance before shipment. L/C (Letter of Credit) is also an option for safer transactions.

9. How do I handle installation?

– Some manufacturers offer on-site installation support. Alternatively, detailed manuals and remote guidance can be provided for local professional installation.

10. Are there warranty and maintenance guidelines?

– Warranties generally range from 1 to 2 years. Maintenance guidelines are provided, covering periodic checks, lubrication, and troubleshooting steps.

Sourcing gantry cranes from China involves careful consideration of specifications, quality assurance, customization, and post-sale support to ensure a successful purchase.