gantry crane hoist Safety Certifications

When operating a gantry crane hoist, ensuring safety is paramount. Compliance with various safety certifications can help mitigate risks and ensure smooth operations. Key safety certifications and standards that apply to gantry crane hoists include:

1. OSHA (Occupational Safety and Health Administration): U.S. regulations under OSHA establish strict guidelines for the design, use, and maintenance of gantry cranes. Compliance with OSHA ensures the hoist meets essential safety requirements.

2. ASME (American Society of Mechanical Engineers) B30 Standards: These standards cover the safety requirements for various types of cranes, including gantry cranes. Adhering to ASME standards, particularly B30.2 and B30.17, helps ensure proper design, inspection, and operation practices.

3. ANSI (American National Standards Institute): Partnering with other standardization bodies, ANSI provides guidelines that align with OSHA and ASME, ensuring comprehensive safety measures.

4. ISO (International Organization for Standardization): ISO standards, such as ISO 9927 for crane inspections and ISO 4301 for crane classification, provide internationally recognized safety benchmarks.

5. FEM (Fédération Européenne de la Manutention): European guidelines outlined by FEM ensure gantry cranes meet rigorous safety and performance standards specific to the region.

6. CSA (Canadian Standards Association): For operations in Canada, CSA standards like CSA B167 provide safety requirements for gantry cranes.

7. LOLER (Lifting Operations and Lifting Equipment Regulations): In the UK, LOLER mandates regular inspections and assessments to ensure lifting equipment is used safely.

Regular inspections and maintenance checks, along with operator training and certification, further enhance the safety and reliability of a gantry crane hoist. Adhering to these standards and certifications minimizes risks and ensures compliance with legal and regulatory requirements.

List Reference Technical Parameters of “gantry crane hoist”

A gantry crane hoist is an essential component used for lifting and moving heavy loads with precision and efficiency. Below are some critical technical parameters to consider:

1. Load Capacity: The maximum weight the hoist can safely lift; typically ranges from a few tons to several hundred tons.

2. Lifting Height: The vertical distance the hoist can raise a load; varies based on the design and application but generally can be from a few meters to over 30 meters.

3. Span Length: The horizontal distance between the legs or supports of the gantry crane, which influences the area the crane can cover.

4. Hoist Speed: The rate at which the hoist can lift or lower a load, usually measured in meters per minute (mpm); affects operational efficiency.

5. Travel Speed: The speed at which the hoist can move horizontally along the gantry crane’s bridge or runway; typically also measured in meters per minute.

6. Duty Cycle/Class: Indicates the frequency and intensity of the operational cycles the hoist is designed for; classified by standards like FEM or ISO (e.g., M5, M6).

7. Power Supply: Voltage and phase requirements for the hoist’s electrical operations, commonly 3-phase AC power in industrial settings.

8. Control System: Types of control methods available such as pendant control, radio remote control, or automated systems.

9. Safety Features: Emergency stop mechanisms, overload protection, upper/lower limit switches, and anti-collision devices to ensure secure operation.

10. Construction Material: Details about the hoist’s build like the types of metals or alloys used; affecting durability and weight.

11. Environment Adaptation: Ability to operate under specific conditions such as temperature ranges, moisture levels, or corrosive environments.

Understanding these parameters is crucial for selecting the right gantry crane hoist for specific applications, ensuring optimal performance, safety, and longevity.

List Product features of “gantry crane hoist”

A gantry crane hoist is a lifting device used in various industrial and construction settings for moving heavy loads horizontally. Here are key product features:

1. Load Capacity: Typically ranges from a few tons to several hundred tons, catering to different lifting requirements.

2. Adjustable Height: Many models offer adjustable height to accommodate various workspace configurations and lifting needs.

3. Span Length: Available in various span lengths, allowing flexibility to operate in different work environments.

4. Mobile or Stationary: Options for both portable (on wheels) and fixed (stationary) systems to suit specific applications.

5. Construction Material: Built with high-grade steel or aluminum for durability and robustness.

6. Hoist Type: Includes electric, manual, or hydraulic hoists, offering flexibility based on user preference and application.

7. Power Supply: Typically powered via electricity (single-phase or three-phase), ensuring efficient and steady operation.

8. Safety Features: Equipped with load limiters, emergency stop switches, and anti-drop mechanisms to enhance safety during operation.

9. Ease of Assembly: Designed for easy assembly and disassembly, promoting portability and quick set-up times.

10. Control Systems: Available with pendant controls, radio remote controls, or automated systems for precise and convenient operation.

11. Weather Resistance: Some models come with weatherproof features for outdoor use.

12. Versatile Attachments: Compatible with a variety of lifting attachments such as hooks, magnets, and tongs for specialized tasks.

13. Stability: Features robust bases and often equipped with locking casters to ensure stability during operation.

14. Maintenance: Designed for low maintenance, with easily accessible components for quick repairs or replacements.

15. Cost-Efficiency: Offers a cost-effective solution for heavy lifting without the need for permanent infrastructure.

These features contribute to the gantry crane hoist’s versatility, efficiency, and safety in handling heavy materials across various industrial settings.

List Various Types of “gantry crane hoist”

Gantry crane hoists are essential components in material handling and lifting applications, offering versatility and efficiency in various industries. Here’s a succinct overview of different types of gantry crane hoists:

1. Chain Hoist: These hoists use a chain to lift loads, ideal for lighter applications. They offer simplicity and durability, best suited for environments where occasional lifting is required.

2. Wire Rope Hoist: Known for their speed and capacity, wire rope hoists are used for heavier loads and more frequent lifting. They are common in industries like construction and mining.

3. Electric Hoist: Powered by electricity, these hoists can handle a wide range of loads and offer precise control. They are suitable for repetitive tasks and are energy-efficient.

4. Manual Hoist: Operated by hand, manual hoists are cost-effective and perfect for smaller loads or environments without power sources. They offer ease of use and portability.

5. Pneumatic Hoist: Using compressed air, pneumatic hoists are ideal for explosive or otherwise hazardous environments. They are safe, reliable, and can handle heavy-duty tasks.

6. Hydraulic Hoist: These hoists use hydraulic pressure for lifting heavy loads. They offer robust lifting capabilities and are often used in industrial applications requiring significant power.

7. Portable Hoist: Designed for mobility, portable hoists are lightweight and easy to move, perfect for varied job sites or where gantry cranes need to be relocated frequently.

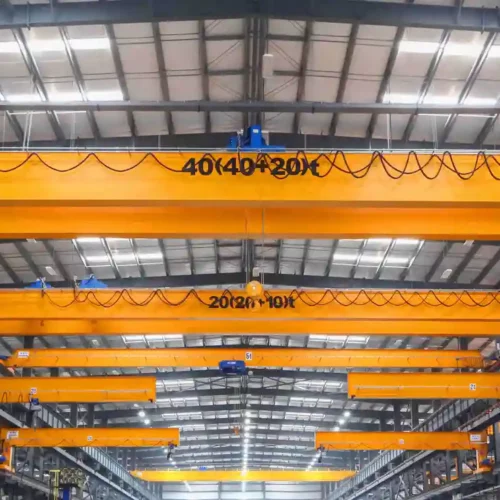

8. Double Girder Hoist: Mounted on a double girder gantry crane, these hoists provide greater stability and can lift heavier loads, making them suitable for industrial and manufacturing environments.

9. Single Girder Hoist: For lighter loads, single girder hoists are mounted on a single girder gantry crane. They offer cost savings and are easier to install and maintain.

10. Automated Hoist: Equipped with automation features, these hoists enhance precision and efficiency, ideal for modern manufacturing and warehousing processes.

Each type of gantry crane hoist serves specific needs, ensuring optimal performance and safety in various lifting scenarios.

List Application of “gantry crane hoist”

A gantry crane hoist is a crucial piece of equipment used in various industries for lifting, moving, and positioning heavy loads with precision. Here are some key applications:

1. Construction Sites:

Gantry crane hoists are used to lift heavy construction materials, machinery, and equipment, facilitating efficient on-site movement and assembly.

2. Warehousing and Distribution Centers:

In warehouses, gantry cranes handle bulky inventory, aiding in the loading and unloading of large items and palletized goods, improving storage efficiency.

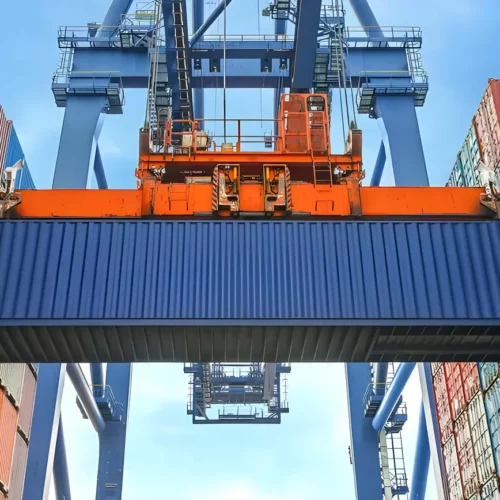

3. Shipping and Marine:

These hoists are vital in shipyards for lifting and positioning heavy ship components, engines, and containers during shipbuilding, maintenance, and cargo handling.

4. Manufacturing and Assembly Lines:

Gantry crane hoists are integral in assembling heavy machinery, automotive parts, and large-scale industrial equipment, enabling precise placement and assembly.

5. Aviation Industry:

In aircraft manufacturing and maintenance facilities, they lift and maneuver aircraft parts, engines, and tools, ensuring safe handling and assembly.

6. Railway Maintenance:

Used in rail yards and maintenance facilities, they lift train components and facilitate repair and maintenance tasks, enhancing operational efficiency.

7. Steel and Metal Fabrication:

Essential in lifting heavy steel beams, plates, and metal structures during fabrication, welding, and assembly processes, ensuring accuracy and safety.

8. Mining Operations:

Gantry cranes assist in lifting and moving heavy mining equipment, machinery, and extracted materials, providing critical support in harsh environments.

9. Power Plants:

Used for handling large turbines, generators, and other heavy components, ensuring precise installation and maintenance in power generation facilities.

10. Automotive Industry:

In vehicle manufacturing plants, they lift and assemble car bodies, engines, and other components, streamlining the production process.

Gantry crane hoists offer flexibility, mobility, and lifting power, making them indispensable across these diverse industrial applications.

List Buyer Types of “gantry crane hoist”

Gantry crane hoists, crucial for heavy lifting and material handling in various industries, attract different buyer types. Here are the primary buyer types:

1. Construction Companies:

– Use gantry crane hoists for heavy lifting on construction sites.

– Seek durable, high-capacity hoists for handling materials like steel beams, concrete blocks, and prefabricated sections.

2. Manufacturing Plants:

– Require hoists for moving raw materials, intermediate products, and finished goods.

– Demand reliable, efficient hoists to minimize downtime and enhance productivity.

3. Warehousing and Logistics Firms:

– Use gantry cranes to move heavy pallets, containers, and large items.

– Focus on hoists with precision and ease of operation to streamline logistics.

4. Shipyards and Ports:

– Need robust hoists for loading and unloading heavy cargo from ships.

– Demand high-capacity, corrosion-resistant systems due to harsh marine environments.

5. Automotive Industry:

– Employ gantry cranes for assembly lines, moving car bodies, engines, and other heavy components.

– Prioritize customizable and precise hoists for specialized tasks.

6. Aerospace Sector:

– Utilize hoists for handling aircraft parts, engines, and assembly work.

– Require high-precision, reliable systems for delicate and critical operations.

7. Mining Operations:

– Use hoists for lifting heavy machinery, ores, and other materials.

– Seek rugged, high-capacity hoists that can withstand challenging conditions.

8. Energy Sector (e.g., Oil & Gas, Wind Farms):

– Require hoists for assembling large structures like wind turbines and oil rigs.

– Need durable, high-performance systems for challenging environments.

9. Railway Industry:

– Employ hoists for handling train components and maintenance work.

– Demand robust, precise systems to ensure safe and efficient operations.

10. Heavy Equipment Repair Shops:

– Use hoists for lifting and maneuvering large machinery and equipment during repairs.

– Focus on versatile, reliable hoists to handle diverse tasks.

Each buyer type prioritizes specific features such as capacity, durability, precision, ease of operation, and environmental resilience based on their unique operational needs.

List “gantry crane hoist” Project Types for Different Industries

Gantry crane hoists are versatile lifting devices used across various industries to elevate and transport heavy loads. Here are project types in different industries that commonly employ gantry crane hoists:

1. Construction:

– Building Construction: Transporting steel beams, concrete blocks, and other heavy materials on construction sites.

– Bridge Construction: Lifting and placing large girders and other bridge components.

2. Manufacturing:

– Assembly Lines: Moving heavy parts and machinery during the production process.

– Maintenance: Facilitating maintenance and repairs of large machines and equipment.

3. Shipping and Ports:

– Container Handling: Loading and unloading shipping containers from vessels.

– Bulk Material Handling: Moving heavy bulk goods such as coal, grain, or minerals.

4. Automotive:

– Vehicle Assembly: Lifting car bodies, engines, and other heavy components.

– Maintenance Facilities: Facilitating the repair and maintenance of vehicles.

5. Railways:

– Track Maintenance: Handling heavy rails and sleepers during track maintenance or construction projects.

– Locomotive Assembly: Assisting in the assembly and repair of locomotives and rail cars.

6. Aerospace:

– Aircraft Assembly: Lifting large components like wings, fuselages, and engines.

– Maintenance Hangars: Facilitating maintenance tasks on large aircraft.

7. Mining:

– Material Transport: Moving ore, equipment, and other heavy materials.

– Maintenance: Assisting in the maintenance of heavy mining machinery.

8. Power Generation:

– Plant Maintenance: Lifting turbines, generators, and other heavy equipment in power plants.

– Wind Energy: Assisting in the assembly and maintenance of wind turbines.

9. Steel Industry:

– Steel Manufacturing: Transporting large steel coils, slabs, and other products.

– Fabrication Plants: Handling heavy steel components during fabrication processes.

Each of these project types leverages the unique capabilities of gantry crane hoists to enhance productivity, improve safety, and streamline operations.

gantry crane hoist Accessories Upgrades and Custom Manufacturing Options

Gantry crane hoist accessories and upgrades can significantly enhance the functionality, safety, and efficiency of your lifting operations. Common accessories include load limiters, which prevent overloading by shutting down the hoist when capacity is exceeded. Radio remote controls enable operators to maneuver cranes from a safe distance, enhancing safety and precision. Variable frequency drives (VFDs) offer smoother and more precise control over hoist speed, reducing wear and tear on components and improving overall efficiency.

For custom manufacturing options, you can tailor your gantry crane to fit specific operational needs. Customizations include adjustable height gantries, which provide versatility for different lifting scenarios, and specialized hooks or grabs designed for unique load types. You may also opt for custom paint finishes to meet both aesthetic and environmental requirements, such as corrosion resistance in harsh environments.

Other useful upgrades include advanced safety features like anti-sway systems, which minimize load swinging, and emergency stop buttons for instant halts. Motorized travel options provide easier and more efficient movement along the gantry, and automated systems can integrate with existing workflows for streamlined operations.

Furthermore, load display systems show real-time weight data, helping operators make informed decisions during lifts. Adding extra trolleys can facilitate multiple lifting operations simultaneously, enhancing productivity.

In summary, upgrading and customizing your gantry crane hoist with the right accessories can substantially improve performance and safety, tailor the equipment to your specific needs, and extend the lifespan of your machinery. Always consult with a professional to ensure compatibility and optimal integration of these enhancements.

List Quality Control and The Manufacturing Process of “gantry crane hoist”

Quality Control in Gantry Crane Hoist Manufacturing:

1. Material Inspection: Raw materials undergo strict quality checks for standards compliance.

2. Component Testing: Each part, such as motors and cables, is tested for strength and durability.

3. Assembly Inspection: During assembly, inspectors check alignment, fastening, and balance.

4. Load Testing: Completed hoists are subjected to load tests to verify lifting capacities.

5. Non-Destructive Testing (NDT): Techniques like ultrasound or X-rays detect hidden flaws.

6. Functional Testing: Every hoist’s performance is checked, including operational speed and safety mechanisms.

7. Compliance Verification: Ensure conformity with industry standards (e.g., ISO, ANSI).

8. Final Inspection: Comprehensive final examination before packaging.

9. Documentation: Maintain detailed records of tests and inspections.

10. Customer Feedback: Gather and analyze for continuous improvement.

Manufacturing Process of Gantry Crane Hoist:

1. Design and Engineering: Engineers create detailed drawings and specifications.

2. Material Procurement: Quality raw materials (steel, motor components) are sourced.

3. Cutting and Shaping: Raw materials are cut and shaped using CNC machines and laser cutters.

4. Machining: Precision machining creates essential parts like gears and shafts.

5. Welding and Assembly: Main frame and structural components are welded and assembled following precise guidelines.

6. Electrical Assembly: Motors, control panels, and wiring are installed.

7. Surface Treatment: Components undergo painting or galvanizing to prevent corrosion.

8. Quality Control: Rigorous inspections and tests at each manufacturing stage.

9. Final Assembly: Fully assemble the hoist, integrating all parts and subassemblies.

10. Testing: Load and functionality tests ensure the hoist meets performance specifications.

11. Packaging: Proper and secure packaging to prevent damage during transport.

12. Shipping: Safely transport the finished product to the customer.

This comprehensive approach in both the quality control and manufacturing processes ensures that gantry crane hoists are reliable, safe, and efficient, meeting all customer and industry standards.

How to use “gantry crane hoist”

A gantry crane hoist is a versatile lifting device used to move heavy loads. Here’s a concise guide on how to use it safely and effectively:

1. Preparation:

– Inspection: Check the crane, hoist, and rigging equipment for any signs of wear, damage, or malfunction. Ensure that all safety devices and brakes are functional.

– Environment: Confirm that the operating area is clear of obstructions and that the ground or floor is stable and level.

2. Load Attachment:

– Positioning: Ensure the crane is centered over the load to prevent swinging.

– Rigging: Use appropriate slings or attachments. Secure the load carefully, ensuring a balanced distribution.

3. Lifting:

– Controls: Familiarize yourself with the crane’s control panel, which may include buttons for lifting, lowering, and directional movement.

– Operation: Engage the hoist to lift the load slowly, keeping an eye on the load’s stability. If it begins to swing or move unpredictably, stop and adjust the rigging.

4. Moving:

– Head Clearance: Maintain a clear path for the load and ensure no personnel are within the moving range.

– Speed: Move the load slowly and smoothly to the desired location. Sudden movements can cause instability.

5. Placement:

– Lowering: Gently lower the load to its destination, ensuring it is placed stably and safely.

– Detachment: Once the load is securely placed, carefully detach the rigging and move the crane to a safe, neutral position.

6. Post-Operation:

– Shutdown: Turn off and secure the crane according to the manufacturer’s guidelines.

– Inspection: Conduct a final inspection to ensure no damage occurred during operation.

Safety Tips:

– Always wear appropriate personal protective equipment (PPE).

– Never exceed the crane’s rated capacity.

– Ensure only trained personnel operate the gantry crane hoist.

By following these steps, you can use a gantry crane hoist effectively while maintaining safety.

“gantry crane hoist” Comparative Analysis

Gantry cranes are essential lifting solutions used in various industries, such as construction, manufacturing, and shipbuilding, for moving heavy loads horizontally. A key component of a gantry crane is the hoist, which performs the actual lifting and lowering of loads.

Types of Gantry Crane Hoists

1. Electric Hoists

– Advantages:

– Efficiency: High speed and precision in lifting operations.

– Ease of Use: Simple controls with remote operation capabilities.

– Capacity: Can handle very heavy loads, making them suitable for industrial applications.

– Disadvantages:

– Cost: Generally more expensive upfront and may incur higher maintenance costs.

– Dependence on Power Supply: Limited to locations with reliable electricity.

2. Manual Hoists

– Advantages:

– Cost-Effective: Cheaper initial investment and minimal maintenance costs.

– Portability: Lightweight and can be easily moved around.

– Independence from Power Supply: Ideal for remote or undeveloped locations.

– Disadvantages:

– Effort and Time: Requires manual labor, leading to slower operations and potential strain on workers.

– Limited Capacity: Typically designed for lighter loads, making them unsuitable for heavy-duty applications.

3. Hydraulic Hoists

– Advantages:

– Power: Capable of lifting very heavy loads.

– Precision: Smooth and controlled lifting and lowering.

– Versatility: Useful in various environments, including underwater.

– Disadvantages:

– Complexity: More complex system requiring specialized maintenance.

– Cost: Higher initial and maintenance costs compared to manual hoists.

Comparative Performance

– Load Capacity and Efficiency: Electric and hydraulic hoists outperform manual hoists.

– Operating Costs: Manual hoists are the most economical, followed by electric, with hydraulic being the most expensive.

– Ease of Use and Setup: Electric hoists offer the most user-friendly experience, while manual hoists are straightforward but labor-intensive.

Conclusion

The choice of gantry crane hoist largely depends on the specific needs of the operation. For heavy-duty, high-frequency tasks, electric hoists are recommended. For budget-conscious or remote operations, manual hoists might be preferable. Hydraulic hoists are ideal for very heavy and precise lifting tasks but come with higher costs and maintenance requirements.

“gantry crane hoist” Warranty and Support

Warranty and Support for Gantry Crane Hoist

When investing in a gantry crane hoist, it’s essential to understand the warranty and support options to ensure long-term reliability and performance.

Warranty:

Typically, gantry crane hoists come with a manufacturer’s warranty that spans between 1 to 5 years, contingent on the brand and model. The warranty generally covers defects in materials and workmanship. It’s crucial to read the specific terms and conditions, as some manufacturers might offer extended warranty options for an additional fee. Routine maintenance and proper use are often required to keep the warranty valid.

Support:

Reputable manufacturers and suppliers provide robust support services. These usually encompass:

1. Technical Assistance: Most companies offer 24/7 technical support to troubleshoot issues or provide guidance on operations.

2. Maintenance Programs: Scheduled maintenance services are often available to ensure the hoist operates at peak efficiency. Some companies might offer discounted or free maintenance during the warranty period.

3. Training: Operators and maintenance personnel can often benefit from training programs offered by the manufacturer, which improve safety and operational efficiency.

4. Spare Parts Availability: Manufacturers typically guarantee the availability of spare parts for a certain period, ensuring that replacements are readily accessible if needed.

5. On-site Support: In case of significant issues, on-site support services can be invaluable. These services may include inspections, repairs, or even replacement of malfunctioning parts.

6. Documentation: Access to detailed manuals, troubleshooting guides, and installation instructions ensures that users have the requisite information to handle the equipment properly.

By choosing a gantry crane hoist with a comprehensive warranty and support package, you safeguard your investment and sustain optimal functionality, ensuring minimal downtime and extending the equipment’s lifespan.

List “gantry crane hoist” FAQ

Gantry Crane Hoist FAQ

1. What is a gantry crane hoist?

A gantry crane hoist is a lifting device used in conjunction with a gantry crane system. It typically consists of a hook, trolley, and motorized mechanism for moving heavy loads vertically and horizontally.

2. What are the primary types of gantry cranes?

Gantry cranes come in various types, including full gantry, semi-gantry, portable, and adjustable height cranes. Each serves different purposes based on lifting capacity and operational environment.

3. How do I determine the right hoist capacity?

Select a hoist with a capacity slightly above your maximum required lifting load. Consider the working environment and any potential future needs.

4. What are the installation requirements?

Installation usually requires a flat, stable surface and adequate space. For larger systems, professional installation is advised, meeting local and industry-specific safety standards.

5. How do I maintain a gantry crane hoist?

Regular inspection and maintenance are crucial. Check for wear and tear, lubricate moving parts, and ensure electrical components are functioning properly. Follow manufacturer guidelines for detailed maintenance schedules.

6. Are there specific safety protocols?

Yes, always adhere to OSHA regulations. Provide operator training, conduct routine inspections, use appropriate PPE, and ensure the area is clear of obstructions and unauthorized personnel during operations.

7. How long does a gantry crane hoist last?

The lifespan varies based on usage, maintenance, and operating environment. Properly maintained hoists can last several decades. Regular inspections can help identify and rectify issues before they become major problems.

8. Can I upgrade my existing system?

Yes, many hoists can be upgraded or modified. Consult with the manufacturer to ensure compatibility and safety compliance.

9. What should I do if my hoist malfunctions?

Immediately stop using the hoist and conduct a thorough inspection. If the issue is complex, consult a professional technician or contact the manufacturer for support.

10. Where can I buy replacement parts?

Replacement parts can be purchased through the original manufacturer, authorized dealers, or specialized industrial suppliers.

This FAQ serves as a basic guide for understanding gantry crane hoists. Always refer to the specific manufacturer’s manual for detailed information and recommendations.

Top 10 FAQ with answer about gantry crane hoist for Buyer Sourcing from China

Absolutely, here are the top 10 frequently asked questions (FAQ) about sourcing gantry crane hoists from China, with concise answers:

1. What is a gantry crane hoist?

A gantry crane hoist is a lifting mechanism mounted on a gantry crane, used for heavy-duty lifting and moving of materials. It is often deployed in warehouses, shipyards, and manufacturing plants.

2. Why source gantry crane hoists from China?

China is renowned for its competitive pricing, advanced manufacturing capabilities, and diverse range of options. Many reputable Chinese manufacturers comply with international standards.

3. How do I ensure the quality of the hoist from a Chinese supplier?

Verify certifications such as ISO 9001, CE, or other international standards. Request third-party inspection reports and customer testimonials. Visiting the factory or using a trusted local agent can also be beneficial.

4. What types of gantry crane hoists are available?

Common types include single and double girder hoists, electric hoists, and manual hoists. Options vary based on lifting capacity, height, and application-specific features.

5. What is the typical lead time for delivery?

Delivery usually takes between 4 to 8 weeks, depending on customization, order size, and supplier workload. Confirm lead times directly with your chosen supplier.

6. What are the key considerations for choosing a suitable hoist?

Consider lifting capacity, lifting height, duty cycle, operating environment, power supply, and safety features. Suppliers can provide guidance based on your specific requirements.

7. How can I verify the supplier’s credibility?

Check the supplier’s business license, industry certifications, and membership in trade associations. Utilize platforms like Alibaba, Made-in-China, and Global Sources, which offer verification services.

8. What are the payment terms usually associated with Chinese manufacturers?

Common terms include T/T (telegraphic transfer), L/C (letter of credit), and occasionally, D/P (documents against payment). Initial down payments typically range from 30% to 50%.

9. What after-sales support will I receive?

Reputable suppliers offer warranties, spare parts availability, remote troubleshooting, and local service partners. Confirm specific after-sales services before purchasing.

10. How detailed should my order specifications be?

Provide clear details on lifting capacity, lifting height, power supply, duty rating, and operational environment. Detailed specifications help avoid misunderstandings and ensure the right product is delivered.