garage overhead crane Safety Certifications

Garage overhead cranes, commonly used for lifting heavy items in automotive workshops and similar environments, must adhere to strict safety standards and certifications to ensure safe operation. Key safety certifications and standards relevant to these cranes include:

1. OSHA (Occupational Safety and Health Administration):

– OSHA provides guidelines for the safe operation of overhead cranes under standards such as 29 CFR 1910.179. These regulations cover the construction, maintenance, and operation of overhead and gantry cranes.

2. ASME (American Society of Mechanical Engineers):

– ASME B30.2 provides safety standards for overhead and gantry cranes. This includes inspection, testing, maintenance, and operation guidelines aimed at promoting safe crane usage.

3. ANSI (American National Standards Institute):

– ANSI/ASSP A10.4 outlines safety requirements for personnel hoists and employee elevators, including overhead cranes, ensuring they meet essential safety criteria.

4. CMAA (Crane Manufacturers Association of America):

– CMAA Specification No. 70 governs overhead and gantry cranes, focusing on proper design and construction standards to maximize safety and reliability.

5. ISO (International Organization for Standardization):

– ISO 9001 certification ensures that a manufacturer’s design, manufacturing, and quality management processes meet global standards, implying a commitment to producing safe, reliable cranes.

6. Periodic Inspections and Testing:

– Regular inspections and testing, as mandated by OSHA and ASME, are crucial. These include pre-operational checks, periodic inspections, and detailed post-incident inspections to ensure ongoing safety and operation integrity.

In summary, ensuring safety for garage overhead cranes requires compliance with various standards and frequent inspections. By adhering to OSHA regulations, ASME and ANSI standards, CMAA specifications, and maintaining ISO 9001 certification, operators can assure safe and effective crane usage in automotive environments.

List Reference Technical Parameters of “garage overhead crane”

Certainly! Below are the key technical parameters to consider for a garage overhead crane:

1. Load Capacity: The maximum weight the crane can lift, typically ranging from 500 kg to 5,000 kg for garage applications.

2. Span: The horizontal distance between the runway rails the crane travels on. This is dependent on the width of the garage.

3. Lift Height: The maximum height the crane can lift the load, important for accommodating different vehicle heights and tasks.

4. Lifting Speed: The speed at which the hook or hoist can raise or lower a load, typically measured in meters per minute (m/min).

5. Travel Speed: The rate at which the crane can move horizontally along the runway, also measured in meters per minute.

6. Hoist Type: Types include electric chain hoists or wire rope hoists, depending on the load and usage frequency.

7. Control System: Options include pendant controls, remote controls, or automated control systems for precision handling.

8. Duty Cycle: Describes the crane’s operational classification, e.g., light, medium, or heavy duty, which influences its lifespan and maintenance requirements.

9. Power Supply: Voltage and phase requirements, typically ranging from 220V to 440V, single or three-phase power.

10. Safety Features: Load limiters, emergency stop buttons, and anti-collision systems enhance safe operations.

11. Construction Material: The build material of the crane components, such as steel or aluminum, impacts durability and load handling.

12. Wheel Type: The type of wheels (rubber, steel) affects travel smoothness and noise levels.

13. Mounting Type: Options include ceiling-mounted, wall-mounted, or freestanding systems based on the garage setup.

14. Environmental Conditions: Resistance to specific conditions like humidity, temperature, or corrosive environments, contingent on the garage’s location.

Selecting the right garage overhead crane involves balancing these parameters to meet specific application needs and safety requirements effectively.

List Product features of “garage overhead crane”

Certainly! Here are the key product features of a garage overhead crane concisely summarized:

1. High Lifting Capacity: Designed to lift and move heavy objects with ease, typical capacities range from a few hundred pounds to several tons.

2. Adjustable Span: Many models feature adjustable spans to fit varying garage widths.

3. Durable Construction: Built with heavy-duty materials like steel to withstand rugged use and ensure long-term durability.

4. Smooth Operation: Equipped with precision-engineered components for smooth and precise lifting and movement.

5. Compact Design: Optimized for garage spaces, offering maximum utility without occupying excessive space.

6. Electric or Manual Options: Available with either electric motors for effortless lifting or manual mechanisms for cost-effectiveness.

7. Safety Features: Includes critical safety components such as overload protection, emergency shut-offs, and sturdy locking systems.

8. Easy Installation: Designed for straightforward assembly and installation, often provided with detailed manuals and minimal special tools required.

9. Height Adjustable: Feature adjustable heights to accommodate various ceiling heights and lifting needs.

10. Versatile Applications: Suitable for lifting engines, heavy automotive parts, machinery, and other substantial objects.

11. Mobility: Some models come with wheels for easy relocation within the garage or between different job sites.

12. Remote Control Options: High-end models may offer remote controls for increased convenience and safety.

13. Maintenance-Friendly: Constructed with easily accessible parts and simple maintenance routines to ensure longevity and reliable performance.

14. Noise Reduction: Designed to operate quietly for a more pleasant working environment.

15. Customizable Add-ons: Options for additional features like different hooks, spreader bars, and lighting fixtures to enhance functionality.

These features collectively make garage overhead cranes indispensable in workshops, garages, and small industrial settings, greatly improving efficiency and safety while handling heavy loads.

List Application of “garage overhead crane”

A garage overhead crane is a versatile and efficient tool used for lifting and moving heavy objects within a garage setting. The applications of a garage overhead crane are numerous and span across various tasks. Here are some key applications:

1. Vehicle Maintenance and Repairs:

– Lifting engines, transmissions, and other heavy car parts for repair or replacement.

– Raising vehicles to access undercarriage components for maintenance tasks.

2. Storage Assistance:

– Efficiently organizing and storing seasonal items or bulky equipment on overhead racks.

– Accessing stored items in high places without the need for ladders.

3. Workshop Operations:

– Assisting in welding, fabrication, and assembly projects by holding parts in place.

– Moving heavy machinery and tools around the workshop for optimal setup and usage.

4. Hobby and Craft Work:

– Handling large materials such as timber or metal for DIY projects.

– Supporting heavy hobbyist equipment, like boat engines or large-scale model components.

5. Loading and Unloading:

– Facilitating the loading and unloading of materials from trucks or trailers.

– Helping with the relocation of heavy items between the garage and other areas.

6. Home Renovation Projects:

– Lifting and installing large home renovation materials such as beams, doors, or windows.

– Transporting construction equipment and supplies within the workspace.

7. Safety Improvement:

– Reducing the risk of personal injury by handling heavy loads with mechanical assistance.

– Providing a stable method for moving potentially hazardous materials safely.

Utilizing a garage overhead crane enhances efficiency, saves time, and significantly reduces the physical strain on individuals performing heavy lifting tasks. This tool is invaluable for anyone frequently dealing with heavy objects in a garage or workshop environment.

List Various Types of “garage overhead crane”

Certainly! Garage overhead cranes are essential tools in many workshops and garages for lifting and moving heavy objects with ease. Here are various types:

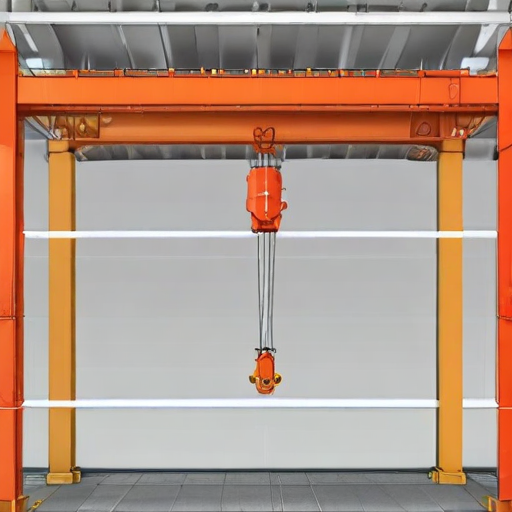

1. Single Girder Overhead Crane

– Description: Features a single beam running across the span for lifting.

– Capacity: Typically up to 20 tons.

– Application: Ideal for small to medium-sized garages due to its lightweight structure and ease of installation.

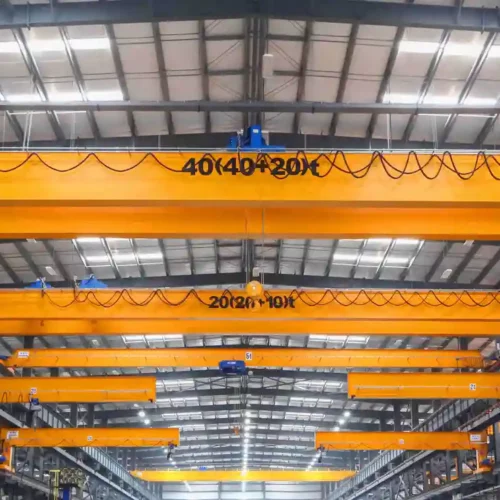

2. Double Girder Overhead Crane

– Description: Incorporates two beams, providing increased strength and stability.

– Capacity: Can lift heavier loads, often over 20 tons.

– Application: Suitable for industrial garages and applications requiring heavy lifting.

3. Gantry Crane

– Description: A crane system supported by freestanding gantry legs, which can be on wheels.

– Capacity: Varies widely, lighter options for smaller workshops, heavier options for industrial use.

– Application: Common in areas where a normal overhead crane structure cannot be installed.

4. Monorail Crane

– Description: A single rail system that moves the hoist trolley along a predetermined path.

– Capacity: Generally lower, up to a few tons.

– Application: Perfect for tasks with straightforward paths and lighter loads.

5. Workstation Crane

– Description: Modular, smaller systems that can easily be configured and reconfigured.

– Capacity: Typically under 2 tons.

– Application: For garages focusing on lighter tasks requiring frequent reconfiguration.

6. Wall-Mounted Jib Crane

– Description: A horizontal beam (jib) attached to a wall or column.

– Capacity: Usually up to 5 tons.

– Application: Adds versatility when space is limited; useful for localized lifting.

7. Freestanding Jib Crane

– Description: A jib mounted on a floor pedestal, independent of existing structures.

– Capacity: Varies, typically up to a few tons.

– Application: Offers 360-degree rotation; useful for expansive garages or open workshops.

8. Custom-Built Cranes

– Description: Tailored to specific needs and space constraints.

– Capacity: Highly variable, based on requirements.

– Application: Fits unique, non-standard applications within specialized garages or industrial settings.

Each type has specific advantages, depending on the garage size, lifting requirements, and overall use-case scenario.

garage overhead crane Accessories Upgrades and Custom Manufacturing Options

Upgrading or customizing a garage overhead crane can significantly enhance its functionality and efficiency. Several accessories and manufacturing options are available to tailor the crane to specific needs:

1. Remote Control Systems: Implement wireless remote controls for more flexibility and better operator safety. This allows for precise movements and reduces the need for manual handling.

2. Variable Frequency Drives (VFD): Integrate VFDs to provide smoother operation, adjust lifting speeds, and reduce motor wear. VFDs also improve energy efficiency.

3. Anti-Sway Technology: Improve load handling with anti-sway systems that minimize load swing, leading to more accurate positioning and safer operations.

4. Load Indicators and Displays: Install digital load indicators to monitor and display the weight being lifted, ensuring that the crane operates within its safe load limits.

5. Custom Hoist Options: Choose customized hoists with specific lifting capacities, speeds, and heights to match the unique requirements of your garage setup.

6. Adjustable Span and Height: Modify the span and height of the crane to fit the exact dimensions of your garage, maximizing the usable space and operational efficiency.

7. Collision Avoidance Systems: Enhance safety with sensors and collision avoidance systems that prevent the crane from coming into contact with obstacles or other equipment.

8. Specialized Lifting Attachments: Use custom-designed lifting attachments like spreader beams, magnets, or vacuum lifters to handle different materials and loads effectively.

9. Enhanced Lighting: Improve visibility with integrated lighting systems on the crane, ensuring better working conditions in dimly lit areas.

10. Maintenance Platforms: Add maintenance platforms or walkways for easier access to the crane for routine inspections and repairs.

By choosing the right accessories and customization options, you can greatly improve the functionality, safety, and efficiency of your garage overhead crane.

List Quality Control and The Manufacturing Process of “garage overhead crane”

Quality Control and Manufacturing Process of Garage Overhead Crane

*Manufacturing Process:*

1. Design & Engineering: The process starts with designing the crane, including load calculations, material selection, and creating detailed blueprints.

2. Material Procurement: High-quality steel and other materials are sourced based on specifications to ensure durability and performance.

3. Cutting & Shaping: Steel beams and components are cut and shaped using CNC machines to achieve precise dimensions.

4. Welding & Assembly: Components like the bridge, hoist, and trolley are welded and assembled. Skilled welders ensure strong joints and structural integrity.

5. Machining: Precision machining is performed on critical parts to ensure they meet exacting standards for fit and function.

6. Surface Treatment: Components undergo treatments like sandblasting, painting, or powder coating to prevent corrosion and enhance appearance.

7. Electrical Assembly: Electrical systems, including motors, control panels, and wiring, are installed to control the crane’s operations.

8. Final Assembly: All parts are assembled into the final product, ensuring the mechanical and electrical systems are integrated correctly.

*Quality Control:*

1. Material Inspection: Raw materials are inspected for compliance with quality standards before they enter the production line.

2. Precision Checks: During and after machining, dimensions and tolerances are checked using calipers, micrometers, and other precision tools.

3. Weld Quality Inspection: Non-destructive testing methods like ultrasonic testing or radiographic inspections are used to check weld integrity.

4. Load Testing: The crane is subjected to load tests that exceed its rated capacity to ensure it can handle the specified loads safely.

5. Functional Testing: Operational tests are conducted to ensure all mechanical and electrical systems function properly, including the hoist, trolley, and control systems.

6. Final Inspection: A comprehensive inspection is carried out to verify that the assembled crane meets all specified standards and safety regulations.

7. Documentation & Certification: A detailed report documenting all tests and inspections is prepared, and certification is granted if the crane meets all criteria.

8. Customer Acceptance: The final product is reviewed and accepted by the customer, ensuring satisfaction with quality and functionality.

This streamlined yet rigorous approach ensures that each garage overhead crane delivers reliable performance, safety, and long-term durability.

How to use “garage overhead crane”

A garage overhead crane is a versatile tool designed to lift and move heavy objects within a garage or workshop. Here’s a step-by-step guide on how to safely and effectively use it:

1. Preparation

– Inspect the Crane: Ensure that the crane is in good working condition. Check for any signs of wear, damage, or malfunction.

– Clear the Area: Remove any obstructions from the garage floor to allow for safe operation.

– Understand the Load: Know the weight and dimensions of the item you’re lifting to ensure it’s within the crane’s capacity.

2. Setting Up

– Position the Crane: Move the crane directly above the load, aligning the hoist with the center of the heavy object.

– Secure the Load: Attach the appropriate lifting attachment (e.g., sling, hook) to the load, making sure it is secure and balanced.

– Check the Connections: Double-check all connections and ensure the load is properly attached to avoid accidents.

3. Lifting

– Operate the Controls: Use the crane’s control panel to lift the load slowly and smoothly. Typically, this involves pressing buttons or using a remote control.

– Monitor the Lift: Keep an eye on the load as it rises, ensuring it remains stable and balanced.

4. Moving the Load

– Navigate Slowly: Move the crane along its track to the desired location. Do this slowly to maintain control over the load.

– Communicate: If working with others, maintain clear communication to coordinate movements and ensure safety.

5. Lowering the Load

– Position Carefully: Once the load is in place, lower it gently to avoid any sudden drops.

– Dismantle the Setup: Detach the lifting components and store the crane in a safe location.

Safety Tips

– Wear Protective Gear: Always wear safety gloves, helmet, and steel-toed boots.

– Follow Manufacturer Instructions: Adhere to any specific guidelines provided by the crane manufacturer.

– Stay Vigilant: Constantly monitor the surroundings and be prepared to stop the operation if any safety concerns arise.

By following these steps, you can use a garage overhead crane efficiently and safely.

“garage overhead crane” Comparative Analysis

A garage overhead crane, often used in workshops and home garages, plays a crucial role in lifting heavy objects safely and efficiently. This comparative analysis will focus on three prevalent types: manual chain hoist cranes, electric hoist cranes, and pneumatic hoist cranes.

1. Manual Chain Hoist Cranes:

– Advantages: Manual chain hoist cranes are generally the most cost-effective option. They are powered by human effort, making them independent of electricity or air pressure sources. This feature makes them ideal for settings where power supply may be unreliable.

– Disadvantages: These cranes typically have lower lifting capacities and require considerable physical effort, which can be time-consuming and physically taxing for frequent or heavy lifts. They also offer slower operation speeds compared to electric or pneumatic options.

2. Electric Hoist Cranes:

– Advantages: Electric hoist cranes offer a higher lifting capacity and faster operation speed, enabling efficient handling of heavy loads with minimal physical effort. They are suitable for frequent use and can be equipped with various speed settings, remote controls, and safety features.

– Disadvantages: These cranes are more expensive upfront and require a readily available source of electricity. Additionally, they may entail higher maintenance costs due to their complex systems and electrical components.

3. Pneumatic Hoist Cranes:

– Advantages: Pneumatic hoist cranes are powered by compressed air, providing an explosion-proof solution suitable for hazardous environments such as those involving flammable materials. They also offer smooth and precise lifting operations.

– Disadvantages: These cranes require a compressed air system, which can be a significant additional investment. Their reliance on air pressure can also affect performance consistency, especially in environments with fluctuating air supply.

In conclusion, when selecting a garage overhead crane, the choice depends on specific needs such as budget, lifting capacity, frequency of use, and environmental safety requirements. Manual chain hoist cranes are best for occasional use and tight budgets, electric hoist cranes for frequent and heavy-duty lifting, and pneumatic hoist cranes for hazardous environments requiring explosion-proof equipment.

“garage overhead crane” Warranty and Support

When considering the purchase of a garage overhead crane, understanding its warranty and support options is crucial to ensure long-term performance and satisfaction. Typically, reputable manufacturers offer a standard warranty period that covers various components of the crane, such as the hoist, controls, and structural components. This warranty period often ranges from one to five years, depending on the manufacturer and model.

The warranty generally covers defects in materials and workmanship, but it’s important to read the terms and conditions carefully. Some warranties may exclude wear-and-tear parts, misuse, or non-compliance with maintenance schedules. Therefore, regular maintenance and adherence to operational guidelines are essential to keep the warranty valid.

In addition to the warranty, manufacturers usually provide robust customer support services. These services often include technical assistance, troubleshooting, and access to replacement parts. Many companies offer dedicated support lines, email assistance, and even on-site service options to address any issues promptly.

Some manufacturers also provide online resources, such as user manuals, installation guides, and maintenance tips, which can be invaluable for both new and experienced users. Training programs, whether in-person or online, may also be offered to ensure safe and effective operation of the crane.

Extended warranty options might be available for an additional cost, providing peace of mind beyond the standard warranty period. It’s worthwhile to consider if extended coverage aligns with your usage patterns and potential risks.

In summary, when selecting a garage overhead crane, carefully review the warranty details and ensure comprehensive support services are available. This will not only safeguard your investment but also ensure the crane operates efficiently for years to come.

List “garage overhead crane” FAQ

Garage Overhead Crane FAQ

1. What is a garage overhead crane?

A garage overhead crane is a lifting device installed in residential or commercial garages. It’s typically used for lifting heavy objects such as engines, machinery, or other large items that need to be moved efficiently.

2. What types of garage overhead cranes are there?

Common types include single girder cranes, double girder cranes, and jib cranes. Single girder cranes are simpler and often used in smaller spaces, while double girder cranes offer higher lifting capacity. Jib cranes feature a pivoting head for flexible movement.

3. What is the lifting capacity of a garage overhead crane?

Lifting capacities vary widely, ranging from a few hundred pounds to several tons. It’s crucial to choose a crane that meets your specific lifting requirements.

4. How do I install a garage overhead crane?

Installation usually involves mounting the crane to the ceiling or beams of your garage. Due to the complexity and safety implications, it’s often recommended to have a professional handle the installation.

5. What safety features should I look for?

Important safety features include overload protection, emergency stop buttons, and automated limit switches to prevent over-travel of the hook or load.

6. Can a garage overhead crane be customized?

Yes, many manufacturers offer customization options, such as varying lifting capacities, rail lengths, and control mechanisms to better fit your specific needs.

7. What are the power options for these cranes?

They can be manually operated, electrically powered, or even air-powered, depending on the model and your requirements.

8. How do I maintain a garage overhead crane?

Regular maintenance includes checking for wear and tear, lubricating moving parts, and ensuring all safety features are operational. It’s advisable to follow the manufacturer’s maintenance guidelines or hire a professional service.

9. What are the costs involved?

Costs can vary significantly based on the type, capacity, and additional features. They can range from a few hundred to several thousand dollars.

10. Do I need a permit to install a garage overhead crane?

Permit requirements depend on your local regulations. It’s best to consult with local authorities or a professional installer to ensure compliance.

Top 10 FAQ with answer about garage overhead crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQs) about sourcing a garage overhead crane from China, along with concise answers:

1. What is the common lifting capacity for garage overhead cranes?

The typical lifting capacities range from 500 kg to 10 tons, depending on the application.

2. What should I look for in terms of quality standards?

Ensure the crane complies with international standards such as ISO, CE, and ASME. Check for certifications and factory inspection reports.

3. How do I verify the reliability of a Chinese supplier?

Conduct due diligence by checking business licenses, customer reviews, and third-party audits. Platforms like Alibaba offer verified supplier tags.

4. What is the average lead time for manufacturing and shipping?

Production generally takes 4-8 weeks, while shipping can take another 3-6 weeks, depending on your location and shipping method.

5. Can I customize the crane design?

Yes, many manufacturers offer customization options for lifting capacity, span, height, and control systems based on your requirements.

6. What are the payment terms typically required by suppliers?

Common terms include a 30% deposit with the balance payable before shipment. Some suppliers may also accept L/C (Letter of Credit).

7. What kind of warranty and after-sales service is typically offered?

Warranties range from 12 to 24 months. After-sales services may include on-site installation, training, spare parts, and technical support.

8. How do I handle installation and maintenance?

Some suppliers offer installation services or detailed manuals. Regular maintenance is crucial and involves routine inspections, lubrication, and part replacements.

9. What should I know about import duties and taxes?

Import duties vary by country. Consult your local customs office for specific rates and ensure you factor these costs into your overall budget.

10. Is there technical support available for troubleshooting issues?

Reputable suppliers offer technical support via phone, email, or online chat. Some provide remote diagnostics or send technicians on-site if necessary.

These questions and answers should help streamline your sourcing process, ensuring you make an informed decision when purchasing a garage overhead crane from China.