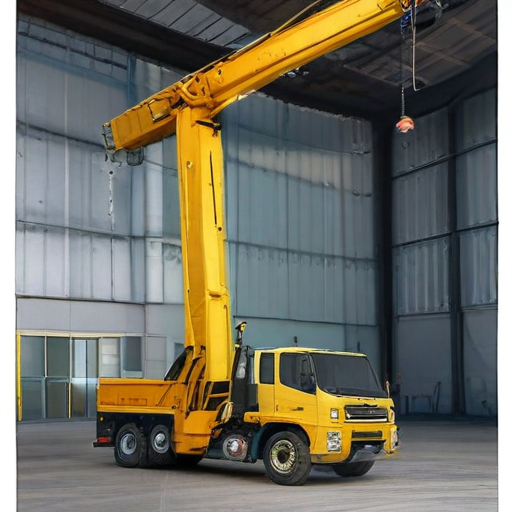

hydraulic truck crane Safety Certifications

Hydraulic truck cranes are powerful machines that require strict safety protocols to ensure they operate effectively and protect both operators and bystanders. Acquiring safety certifications is a critical aspect of deploying these cranes in various industries. Here are some key certifications and standards that are typically adhered to:

1. OSHA Compliance: The Occupational Safety and Health Administration (OSHA) sets forth regulations and guidelines to ensure safe crane operation. OSHA 29 CFR 1926.1400 covers the rules for crane safety in construction.

2. ASME B30 Standards: The American Society of Mechanical Engineers (ASME) provides a suite of B30 standards, including B30.5 for mobile and locomotive cranes, detailing operational practices, equipment maintenance, and safety measures.

3. ANSI/ASSP A10 Standards: The American National Standards Institute (ANSI) and the American Society of Safety Professionals (ASSP) collaborate on A10 standards for construction and demolition operations, which cover safety requirements for equipment like hydraulic truck cranes.

4. CCO Certification (NCCCO): The National Commission for the Certification of Crane Operators (NCCCO) provides certification for crane operators, riggers, and signal persons. This certification ensures that personnel are qualified to operate the crane safely and efficiently.

5. API Standards: The American Petroleum Institute (API) has standards like API RP 2D for offshore cranes, which are also applicable to hydraulic truck cranes in specific industries to ensure safe lifting operations.

6. ISO 9001 & ISO 14001: These International Organization for Standardization (ISO) certifications pertain to quality management systems (QMS) and environmental management systems (EMS), ensuring that the manufacturing and operational processes meet high standards.

Maintaining these certifications not only enhances safety but also fosters a culture of compliance and continual improvement, helping to minimize accidents and downtime. Proper training, regular safety audits, and adherence to these standards play a crucial role in the safe operation of hydraulic truck cranes.

List Reference Technical Parameters of “hydraulic truck crane”

Hydraulic truck cranes are versatile lifting devices that combine a hydraulic system with a truck chassis to provide mobility and lifting capabilities. Here are key technical parameters:

1. Lifting Capacity: Typically ranges from 10 to 1,200 tons, contingent on crane model and configuration.

2. Boom Length: Can extend from 20 to 200 feet, with additional length achievable via jib attachments.

3. Hydraulic System Pressure: Usually operates between 2,500 and 3,500 psi.

4. Outrigger Span: Essential for stability, usually extends between 15 and 30 feet wide.

5. Turning Radius: Varies by model but often lies between 30 to 40 feet, critical for maneuverability.

6. Engine Power: Cranes feature diesel engines with power outputs from 200 to 500 horsepower.

7. Hook Speed: The hoisting speed, typically from 60 to 100 feet per minute, defines lifting efficiency.

8. Load Chart: Specifies lifting capacity at various boom angles and extensions, crucial for safety.

9. Slewing Speed: Rotary motion speed, often between 1.5 and 3 RPM, important for operational fluidity.

10. Transport Dimensions: Includes length, width, and height, affecting road transport logistics.

11. Weight: Total weight ranges from 15 to over 60 tons, impacting axle load and road regulations.

12. Outrigger Load Limits: Indicates the maximum ground pressure, essential for site preparation.

13. Wind Speed Limitation: Maximum operational wind speed, generally around 30 mph, ensures safety during lifts.

14. Hydraulic Fluid Type: Typically high-performance hydraulic oils meeting ISO VG 46 standards.

15. Control Systems: Modern cranes use electronic or digital controls for precision operations and safety monitoring.

Understanding these parameters is crucial for selecting the right hydraulic truck crane for specific applications, ensuring operational efficiency and safety.

List Product features of “hydraulic truck crane”

Hydraulic truck cranes are versatile and powerful pieces of lifting equipment used in construction, manufacturing, and various other industries. Here are their key product features:

1. Load Capacity: They can lift heavy loads, typically ranging from a few tons to several hundred tons, depending on the model.

2. Hydraulic System: Equipped with a robust hydraulic system, these cranes offer smooth and precise control over lifting and lowering operations.

3. Mobility: Mounted on truck chassis, these cranes are easily transportable, allowing for quick relocation between job sites.

4. Telescopic Boom: Many models feature a telescopic boom, providing extended reach and the ability to work at various heights and distances.

5. Stabilizers/Outriggers: These cranes come with deployable stabilizers or outriggers that ensure stability during lifting operations, enhancing safety.

6. 360-Degree Rotation: The crane’s superstructure can typically rotate 360 degrees, offering full range of motion for versatile lifting.

7. Operator Cab: A comfortable, ergonomically designed cab with advanced controls and displays for precision handling and reduced operator fatigue.

8. Safety Features: Includes load moment indicators, anti-two block systems, and overload protection to prevent accidents and ensure safe operation.

9. Attachments and Accessories: Compatibility with various attachments like jibs, winches, and hooks increases operational flexibility.

10. Engine Power: Powered by reliable diesel engines providing the required torque for both crane operation and truck mobility.

11. Ease of Maintenance: Designed for easy access to critical components for regular maintenance, ensuring long-lasting performance.

12. Off-road Capability: Some models feature all-terrain tires and enhanced suspension for navigating rough or uneven surfaces.

13. Compliance: Meets industry standards and regulations, ensuring reliable performance and safety across diverse applications.

14. Advanced Control Systems: May integrate with digital and remote control systems to enhance precision and ease of use.

These features make hydraulic truck cranes indispensable for heavy lifting tasks in various industries, offering a blend of power, mobility, and precision.

List Various Types of “hydraulic truck crane”

Hydraulic truck cranes are essential in various construction and industrial projects due to their mobility and lifting capabilities. Here’s a brief overview of various types:

1. Rough Terrain Cranes: Designed for off-road and rugged surfaces, these cranes have large, heavy-duty tires and are typically smaller. Their hydraulic systems can lift heavy loads in less developed areas.

2. All-Terrain Cranes: Combining the features of rough terrain and truck-mounted cranes, these cranes perform well on both paved roads and rough terrains. They offer unparalleled versatility and mobility.

3. Truck-Mounted Cranes: These cranes are mounted directly on a commercial truck chassis. They are highly mobile and ideal for jobs where frequent moving between sites is required.

4. Boom Truck Cranes: Featuring a crane boom on a standard truck carrier, they are generally lighter and used for less demanding applications. Their versatility makes them suitable for various industries, but they don’t lift as much weight as some other types.

5. Carry Deck Cranes: Compact and with a 360-degree rotating boom, these cranes are used for smaller, indoor or urban lifting tasks. The carry deck allows them to transport materials within the site.

6. Crawler Cranes: While not typically considered a “truck” crane due to their tracks, some hydraulic crawler cranes can be transported on trucks. These cranes offer high lifting capacities and are used for heavy-duty tasks.

7. Telescopic Cranes: Utilizing a boom that extends and retracts, these cranes offer variable reach and lift height, making them suitable for diverse applications from construction to logistics.

8. Truck Loader Cranes (Knuckle Boom Cranes): Mounted on trucks and featuring an articulated arm, these cranes are highly adaptable. They are often used for loading and unloading heavy items directly onto the truck.

Each type of hydraulic truck crane is designed for specific tasks and environments, enhancing efficiency and safety in heavy lifting operations.

List Application of “hydraulic truck crane”

Hydraulic truck cranes are versatile pieces of machinery widely used in various industries due to their ability to lift and move heavy loads efficiently. Here are some key applications:

1. Construction Sites: Hydraulic truck cranes are pivotal in constructing buildings, bridges, and other infrastructure. They lift and position heavy materials like steel beams, concrete blocks, and prefabricated sections with precision.

2. Transport and Logistics: These cranes are used to load and unload heavy cargo from trucks, ships, and trains, facilitating the movement of goods in ports, warehouses, and distribution centers.

3. Utilities and Infrastructure Maintenance: Hydraulic truck cranes assist in installing and maintaining utility lines (electric, water, gas) and support infrastructure work like road repairs and bridge maintenance.

4. Oil and Gas Industry: They are crucial in assembling and maintaining oil rigs and pipelines, as well as in the transportation of heavy equipment across remote locations.

5. Mining Operations: Hydraulic truck cranes play a significant role in lifting and relocating heavy mining machinery and equipment, as well as in constructing mining facilities.

6. Urban Development: In urban environments, these cranes aid in tasks ranging from placing large rooftop units like HVAC systems to removing debris from demolition sites.

7. Event and Entertainment Industries: These cranes help set up stages, lighting, and other heavy equipment for concerts, festivals, and large public gatherings.

8. Disaster Response and Recovery: Following natural disasters, hydraulic truck cranes help clear debris, rescue trapped individuals, and assist in rebuilding efforts by moving large pieces of wreckage.

9. Agriculture: They are used to lift and transport heavy machinery, storage tanks, and other large agricultural equipment within farms.

By efficiently moving heavy loads, hydraulic truck cranes are indispensable across multiple sectors, enhancing productivity and safety in heavy-lifting operations.

List Buyer Types of “hydraulic truck crane”

Buyer types for hydraulic truck cranes vary based on their industry and specific needs. Here are some notable categories:

1. Construction Companies:

– Residential and Commercial Builders: Use hydraulic truck cranes for lifting and positioning heavy materials, such as steel beams, concrete panels, and HVAC units.

– Infrastructure Contractors: Engage in large-scale projects like bridges, highways, and tunnels, requiring robust lifting equipment for materials and equipment.

2. Oil and Gas Industry:

– Exploration and Production Firms: Utilize cranes to maneuver heavy equipment at drilling sites.

– Refineries and Processing Plants: Require cranes for maintenance work and the installation of heavy machinery.

3. Logistics and Transport Firms:

– Freight and Cargo Handlers: Use cranes to load and unload heavy goods from ships, trains, and trucks.

– Port Authorities: Operate cranes to manage container shipping and other heavy lifting operations at docks.

4. Utilities and Infrastructure Maintenance:

– Power and Energy Companies: Use cranes for the installation and maintenance of power lines, wind turbines, and other energy infrastructure.

– Telecommunication Firms: Employ cranes in setting up and maintaining cell towers and communication lines.

5. Mining and Extraction Industries:

– Mining Operators: Utilize cranes to handle equipment and extracted materials at mining sites.

– Aggregate Producers: Need cranes for managing heavy materials like gravel, sand, and minerals.

6. Rental Equipment Companies:

– Fleet Operators: Purchase cranes to rent out to various industries, providing flexible access to heavy lifting equipment.

7. Municipalities and Government Agencies:

– Public Works: Engage cranes for construction, maintenance, and emergency response tasks, including debris removal and infrastructure repair.

8. Specialty Contractors:

– Demolition Experts: Utilize cranes for safe and efficient demolition of large structures.

– Event and Entertainment Companies: Employ cranes for setting up stages, lighting, and other heavy installations for large events.

Each buyer type has specific requirements, influencing the size, capacity, and features of the hydraulic truck cranes they purchase.

List “hydraulic truck crane” Project Types for Different Industries

1. Construction Industry

– Building Construction: Hydraulic truck cranes are crucial for lifting heavy materials such as steel beams, concrete panels, and prefabricated sections to significant heights.

– Infrastructure Projects: They are used in the assembly of bridges, highways, and railways, helping in the placement of large components efficiently.

2. Oil & Gas Industry

– Drilling Sites: Hydraulic truck cranes assist in handling heavy equipment such as drilling rigs, pipes, and other machinery crucial for drilling operations.

– Refineries and Petrochemical Plants: Used for the installation and maintenance of heavy equipment, including reactors, boilers, and piping systems.

3. Utilities Industry

– Power Plants: Employed for routine maintenance and upgrading tasks, including the installation of turbines, transformers, and electrical panels.

– Telecommunications: Used for installing cellular towers and other high-mast communication facilities.

4. Mining Industry

– Ore Extraction: Essential for moving large pieces of mining equipment and transporting heavy loads from mining sites.

– Processing Plants: Used in the assembly, maintenance, and upgrade of crushing, milling, and refining equipment.

5. Manufacturing Industry

– Plant Equipment Installation: Hydraulic truck cranes are used for placing large machinery such as CNC machines, production lines, and conveyor systems.

– Warehouse Logistics: Helpful in reorganizing and setting up large storage systems and heavy-duty shelving units.

6. Entertainment Industry

– Event Setup: Deployed for constructing stages, setting up lighting trusses, and installing large sound systems for concerts and festivals.

– Film Production: Utilized for moving heavy set pieces, rigging, and camera equipment, especially for high-angle shots.

7. Maritime Industry

– Shipbuilding and Repair: Used for the assembly of ship components and heavy equipment, as well as during loading and offloading of cargo.

– Port Operations: Assisting in the loading and unloading of heavy containers and other large cargo items.

Hydraulic truck cranes offer versatile lifting solutions, making them vital across various industrial sectors. Their mobility and lifting capacity enhance operational efficiency and safety in handling heavy loads.

hydraulic truck crane Accessories Upgrades and Custom Manufacturing Options

Hydraulic truck cranes are versatile, mobile lifting machines used in construction, heavy lifting, and industrial tasks. To enhance their performance, various accessories, upgrades, and custom manufacturing options are available.

1. Boom Extensions: Adding extra length to the boom extends the crane’s reach, allowing it to handle tasks at greater heights or distances.

2. Jib Attachments: These provide additional lifting capability and flexibility, ideal for complex job sites requiring diverse ranges of motion.

3. Outriggers: Upgrading to hydraulically extendable outriggers improves stability, especially on uneven terrain, increasing safety and operational efficiency.

4. Counterweights: Custom counterweights can be designed to suit specific tasks, providing added stability and lifting capacity for heavier loads.

5. Winch Systems: High-capacity winches with improved line pull and speed can enhance lifting efficiency and load control.

6. Remote Controls: Wireless remote systems allow operators to control the crane from a safe distance, improving maneuverability and safety.

7. Hydraulic Flow Dividers: These devices distribute hydraulic fluid evenly, enhancing the precision and performance of multiple crane functions simultaneously.

8. Lighting: LED work lights and anti-collision lights increase visibility, making operations safer during dusk, dawn, or nighttime.

9. Specialized Attachments: Custom hooks, grabs, and lifting beams tailored to specific applications can be manufactured to suit unique operational needs.

10. Cab Upgrades: Ergonomic seats, better climate control, and advanced monitoring systems increase operator comfort and efficiency.

By integrating these accessories and upgrades, as well as custom manufacturing options, hydraulic truck cranes can be optimized for specialized projects, enhancing their versatility, safety, and productivity.

List Quality Control and The Manufacturing Process of “hydraulic truck crane”

Quality Control in Hydraulic Truck Crane Manufacturing:

1. Material Inspection: Verify raw materials match required specifications for durability and strength, primarily steel.

2. Component Testing: Test hydraulic systems, electronic components, and engines individually.

3. Precision Manufacturing: Use CNC machines for high-precision parts to ensure perfect fit and function.

4. Assembly Line Checks: Inspect each phase of the assembly process. Components are systematically reviewed for compliance with specified tolerances.

5. Safety Testing: Conduct rigorous tests on lifting mechanisms and load-bearing parts to meet safety standards.

6. Operational Testing: Perform functionality tests to verify that hydraulic systems, outriggers, winches, and booms operate correctly.

7. Non-Destructive Testing (NDT): Implement NDT techniques like ultrasonic or magnetic particle testing to detect internal flaws in critical components.

8. Final Inspection: A comprehensive review of the entire crane, including weight tests, load tests, and stability checks.

9. Certification: Ensure compliance with international standards like ISO, CE, or ASME before dispatch.

Manufacturing Process of Hydraulic Truck Crane:

1. Design and Engineering: Develop detailed 3D models and engineering plans, including simulations to predict performance and identify potential design flaws.

2. Material Procurement: Source high-quality raw materials such as high-strength steel, hydraulic cylinders, electrical systems, and engines.

3. Fabrication: Cut, shape, and weld steel parts for the chassis, boom, outriggers, and other structural components.

4. Machining: Use CNC machining to manufacture precision parts like gear systems and hydraulic pistons.

5. Hydraulic System Assembly: Assemble the hydraulic circuits, including pumps, valves, and cylinders.

6. Component Assembly: Assemble key components—drivetrain, electronics, and control systems—on the chassis.

7. Boom Assembly and Installation: Install telescopic or lattice booms onto the chassis, ensuring correct alignment and functionality.

8. Final Assembly: Integrate all components and systems into the final crane structure.

9. Testing and Calibration: Perform extensive testing and fine-tuning on the assembled crane.

10. Painting and Finishing: Apply corrosion-resistant paint and perform a final cleaning and quality check before shipment.

By adhering to rigorous quality control protocols and a meticulous manufacturing process, hydraulic truck cranes can meet high performance and safety standards.

How to use “hydraulic truck crane”

Using a hydraulic truck crane involves several key steps to ensure safe and efficient operation. Here’s a concise guide to help you:

1. Training and Certification: Ensure that the operator is adequately trained and certified to operate a hydraulic truck crane. Familiarize yourself with the specific crane’s manual.

2. Inspection: Conduct a thorough pre-operation inspection. Check for leaks, fluid levels, tire pressure, and the condition of hydraulic hoses.

3. Site Preparation: Ensure the worksite is stable, level, and free of obstructions. Place outrigger pads if necessary to distribute the load.

4. Setup: Position the truck crane at the designated spot. Deploy the outriggers to stabilize the crane. Make sure the crane is leveled properly using the built-in leveling devices.

5. Securing the Load: Attach the load securely using appropriate rigging techniques. Ensure the load is balanced and within the crane’s rated lifting capacity.

6. Operating Controls: Familiarize yourself with the crane’s controls. The main controls usually include the boom, hoist, and swing functions. Operate these controls smoothly to avoid sudden movements.

7. Lifting: Begin lifting the load slowly. Communicate with ground personnel using standard hand signals or two-way radios. Monitor the load and equipment continuously.

8. Transporting the Load: Move the load to its destination carefully. Avoid swinging or jerky movements. Keep the load as close to the ground as possible during transit.

9. Lowering the Load: Lower the load to the ground or onto the desired platform slowly. Ensure it is stable before releasing the rigging.

10. Shutdown and Storage: After completing the lift, retract the boom and outriggers. Perform a post-operation inspection and address maintenance needs. Store the crane securely.

Safety Note: Always adhere to the manufacturer’s guidelines, OSHA regulations, and site-specific safety protocols. Proper communication and situational awareness are critical for preventing accidents.

“hydraulic truck crane” Comparative Analysis

A hydraulic truck crane is a versatile lifting machine widely used in construction, transportation, and heavy industry for hoisting and moving heavy loads. Key components include a hydraulic system, boom, and chassis. Here’s a comparative analysis of hydraulic truck cranes considering various aspects:

Mobility

Hydraulic Truck Crane: Mounted on a truck chassis, offering high mobility and the ability to travel to different job sites quickly. Their roadworthiness makes them exceptionally versatile for urban and remote locations alike.

Crawler Cranes: While they offer excellent stability and load capacity, crawler cranes lack the mobility of truck cranes due to their tracks. They require considerable time and logistics for transportation.

Set-Up Time

Hydraulic Truck Crane: Fast setup time, often requiring minimal or no assembly. They’re generally ready for operation shortly after arriving at a job site.

All-Terrain Cranes: Comparable in setup ease and speed to hydraulic truck cranes, they combine the advantages of both truck cranes and rough-terrain cranes but at a higher cost.

Lifting Capacity

Hydraulic Truck Crane: Typically, they offer moderate to high lifting capacities, suitable for most construction applications, yet limitations exist compared to crawler cranes.

Crawler Cranes: Superior lifting capacities, often necessary for heavier industrial tasks but require more preparation and site readiness.

Cost

Hydraulic Truck Crane: Tend to be more cost-effective concerning purchase, maintenance, and operation compared to larger, more complex cranes like tower cranes or crawler cranes. This makes them an economical choice for medium-scale operations.

Tower Cranes: Extremely high costs, justified only in large-scale projects where their towering height provides an insurmountable advantage.

Versatility

Hydraulic Truck Crane: High versatility across multiple applications including short-term projects and locations with limited operational space.

Specialized Cranes (e.g., Tower Cranes, Rough Terrain Cranes): These can be superior in specific tasks (height, rough terrain mobility) but lack the overall flexibility.

Conclusion

Hydraulic truck cranes strike a balance between mobility, cost, ease of setup, and versatility. While they may not match the extreme lifting capabilities of crawler cranes or the height advantages of tower cranes, they provide a highly effective solution for a broad range of lifting tasks, making them indispensable for various industries.

“hydraulic truck crane” Warranty and Support

Hydraulic Truck Crane Warranty and Support

When purchasing a hydraulic truck crane, it is crucial to understand the warranty and support services offered to ensure uninterrupted operation and peace of mind. Typically, manufacturers provide a standard warranty covering parts and labor for a specified period, usually between one to two years, depending on the model and brand. This warranty often includes coverage for manufacturing defects and failures under normal use.

In addition to the basic warranty, many manufacturers offer extended warranty options for an additional fee. These extended plans can cover critical components such as the hydraulic system, engine, and chassis for up to five years, providing an extra layer of security for your investment.

Support services are equally important and generally include 24/7 customer service hotlines, online resources, and access to certified technicians. Manufacturers often provide routine maintenance packages and service contracts to keep your crane performing at its best. Onsite support and repair services might also be available, ensuring minimal downtime in case of any issues.

When evaluating warranty and support options, consider the following:

1. Coverage Details: Understand what parts and services are included or excluded.

2. Duration: Know the length of coverage for both the standard and extended warranties.

3. Service Network: Ensure there are authorized service centers and technicians in your region.

4. Response Time: Check how quickly support services can respond to emergencies or breakdowns.

Investing in a hydraulic truck crane with robust warranty and support services ensures long-term operational efficiency and reduces the likelihood of costly downtime. Always read the fine print and consult with the manufacturer to clarify any uncertainties before making a purchase.

List “hydraulic truck crane” FAQ

Hydraulic Truck Crane FAQ

#### 1. What is a hydraulic truck crane?

A hydraulic truck crane is a mobile crane mounted on a truck chassis, utilizing hydraulic power to lift and move heavy loads. It combines mobility with strong lifting capabilities.

#### 2. How does a hydraulic truck crane work?

Hydraulic truck cranes operate using a hydraulic system, where fluid pressure is used to extend and retract pistons within the crane’s boom. This system provides the necessary power to lift heavy loads efficiently.

#### 3. What are the advantages of a hydraulic truck crane?

– Mobility: Easy to transport to various job sites.

– Versatility: Capable of performing a wide range of lifting tasks.

– Efficient Setup: Quick to set up and dismantle.

– High Lifting Capacity: Can lift heavy loads with precision.

#### 4. What are typical applications?

Hydraulic truck cranes are used in construction, infrastructure projects, utility work, and industrial installations. They commonly assist in erecting structures, moving large equipment, and performing maintenance tasks at height.

#### 5. What safety precautions should be taken?

– Proper Training: Operators should be certified and well-trained.

– Regular Maintenance: Ensure the crane is regularly inspected and maintained.

– Load Limits: Never exceed the crane’s rated load capacity.

– Stabilization: Use outriggers to stabilize the crane during lifts.

– Environment: Be aware of weather conditions and ground stability.

#### 6. How to choose the right hydraulic truck crane?

Consider the following factors:

– Load Capacity: Ensure the crane can handle your heaviest loads.

– Boom Length: Select a crane with a boom length suitable for your lifting height requirements.

– Maneuverability: Assess the crane’s ability to navigate your specific job site.

– Engine Power: Adequate power is needed to perform lifts efficiently.

– Added Features: Look for additional features that enhance usability and safety, such as remote controls and sensors.

#### 7. What are the common maintenance tasks?

– Hydraulic Fluid Check: Regularly check and replace hydraulic fluid.

– Inspections: Conduct routine inspections of all moving parts.

– Lubrication: Keep all mechanical parts well-lubricated.

– Repairs: Address any wear and tear or damage immediately to prevent further issues.

Top 10 FAQ with answer about hydraulic truck crane for Buyer Sourcing from China

1. What is a hydraulic truck crane?

A hydraulic truck crane is a type of mobile crane equipped with a hydraulic system for lifting and moving heavy loads. The crane is mounted on a truck chassis, making it easy to transport to various job sites.

2. What are the benefits of sourcing hydraulic truck cranes from China?

China offers competitive pricing, advanced manufacturing technologies, and a wide range of products. Chinese manufacturers often adhere to international quality standards, providing cost-effective and reliable equipment.

3. How can I ensure the quality of a hydraulic truck crane from China?

To ensure quality, check the manufacturer’s certifications (e.g., ISO, CE), request product specifications and testing reports, and consider conducting a factory visit or hiring a third-party inspection service.

4. What is the typical lifting capacity range for hydraulic truck cranes?

The lifting capacity of hydraulic truck cranes typically ranges from 10 to 500 tons. It’s essential to choose a crane that meets your specific operational requirements.

5. What are the key features to look for in a hydraulic truck crane?

Key features include lifting capacity, boom length, hydraulic system type, control mechanisms, ease of maintenance, safety features, and the reliability of the brand.

6. What is the average lead time for manufacturing and delivering a hydraulic truck crane from China?

The average lead time can vary based on the manufacturer’s schedule and order complexity but typically ranges from 30 to 90 days, including production and shipping.

7. Are spare parts and after-sales services readily available for Chinese hydraulic truck cranes?

Reputable Chinese manufacturers usually provide spare parts and after-sales services. Ensure the manufacturer has a global support network or reliable local partners for maintenance and repairs.

8. What are the payment terms generally offered by Chinese manufacturers?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes a combination, like 30% deposit and 70% balance upon shipment.

9. Can Chinese hydraulic truck cranes comply with international safety standards?

Many Chinese hydraulic truck cranes are designed to meet international safety standards. Verify compliance by requesting relevant certificates and documentation from the manufacturer.

10. How do I verify the credibility of a Chinese hydraulic truck crane supplier?

Verify credibility by checking business licenses, looking for certifications and awards, reading customer reviews, and seeking recommendations. Utilizing third-party verification services can also be beneficial.