indoor crane Safety Certifications

Indoor cranes are vital for various industrial applications, but their operation poses significant safety risks. To ensure compliance with safety standards and minimize hazards, various safety certifications govern the use of indoor cranes. Here are some key certifications:

1. OSHA (Occupational Safety and Health Administration): OSHA regulations mandate specific standards for crane operation, including operator qualifications, inspection routines, and maintenance protocols. OSHA 1910.179 is the primary regulation for overhead and gantry cranes.

2. ASME (American Society of Mechanical Engineers): ASME B30 standards cover safety codes for lifting devices. Specifically, ASME B30.2 deals with overhead and gantry cranes, requiring rigorous design, maintenance, and operation protocols.

3. ANSI (American National Standards Institute): ANSI B30 incorporates ASME standards, adding guidelines for the design, operation, inspection, and testing of cranes.

4. CMAA (Crane Manufacturers Association of America): CMAA guidelines focus on the design and construction of cranes, providing best practices to ensure structural integrity and operational safety.

5. ISO (International Organization for Standardization): ISO 9927-1 specifies the conditions for the inspection, maintenance, and operation of cranes, offering a comprehensive international standard.

6. FEM (European Materials Handling Federation): FEM provides guidelines for the safe use of cranes in Europe, emphasizing regular inspections, proper maintenance, and operator training.

7. Certification Bodies: Organizations like NCCCO (National Commission for the Certification of Crane Operators) offer certifications for crane operators, ensuring they have the necessary skills and knowledge to operate safely.

Ensuring compliance with these certifications helps mitigate risks associated with crane operation, enhancing safety for workers and operational efficiency. Regular training, comprehensive inspections, and adherence to these standards are crucial for maintaining a safe working environment.

List Reference Technical Parameters of “indoor crane”

When examining the technical parameters of an indoor crane, several critical elements are universally important for ensuring optimal performance, safety, and suitability for specific applications. Here are the primary technical parameters:

1. Load Capacity:

– Defines the maximum weight the crane can lift, typically ranging from a few hundred kilograms to several tons.

2. Span:

– The horizontal distance between the crane’s runway rails, often varying from a few meters to over 30 meters, depending on the application.

3. Lift Height:

– The maximum vertical distance the hook or lifting device can travel, crucial for adapting to the facility’s ceiling height and specific operational needs.

4. Duty Class:

– Describes the expected operational frequency and load intensity, categorized under FEM, ISO, or CMAA standards (e.g., heavy-duty, medium-duty).

5. Hoist Speed:

– The rate at which the hoist can lift and lower the load, often expressed in meters per minute (m/min), and can be single or variable speed.

6. Lifting Mechanism:

– Includes the type of hoist (electric, manual, or pneumatic), and important characteristics like winding profile and drum capacity.

7. Travel Speed:

– Measurements of the crane’s motion along the runway (bridge travel) and the trolley’s motion across the bridge, also in meters per minute.

8. Control System:

– The type of controls used, which can be pendant push-buttons, remote control, or automated systems.

9. Power Supply:

– Power requirements for both the initial installation and ongoing operation, including voltage and phase specifications.

10. Support Structure:

– The required structural support for safe crane operation, including considerations of runway beams and floor load capacities.

11. Safety Features:

– Incorporates overload protection, emergency stop mechanisms, anti-collision systems, and limit switches.

By focusing on these key parameters, one ensures that the selected indoor crane meets the operational demands, safety requirements, and environmental constraints of its intended application.

List Product features of “indoor crane”

Indoor cranes are essential equipment for material handling, particularly within enclosed spaces like factories, warehouses, and workshops. Below are the primary features of indoor cranes:

1. Compact Design: Tailored for confined spaces, these cranes have a sleek and compact design to maximize functionality without occupying excessive space.

2. High Load Capacity: Despite their compact structure, indoor cranes are engineered to lift heavy loads, typically ranging from a few hundred kilograms to several tons, ensuring they can handle a variety of materials and equipment.

3. Precision Control: Equipped with advanced control systems, indoor cranes offer precise maneuvering capabilities, essential for tasks requiring meticulous placement of objects.

4. Versatile Mounting Options: Indoor cranes can be mounted in several ways, including ceiling-mounted, wall-mounted, or floor-standing, providing flexibility to suit different spatial configurations.

5. Durable Construction: Built with robust materials such as high-strength steel, these cranes are designed to withstand heavy use and harsh working conditions.

6. Safety Features: To ensure operator and workplace safety, indoor cranes come with various safety features, including overload protection, emergency stop functions, and built-in alarms.

7. Smooth & Silent Operation: Incorporation of advanced motor and hoisting technologies allows for smooth and quiet operation, minimizing disruption in the working environment.

8. Adjustable Speed Settings: Many indoor cranes offer variable speed controls, allowing for both quick lifting and delicate positioning of loads.

9. Ergonomic Controls: User-friendly control interfaces, often with wireless or pendant remotes, enable operators to manage the crane efficiently and comfortably.

10. Low Maintenance: Designed with minimal wear-and-tear components, these cranes require low maintenance, reducing downtime and operational costs.

11. Energy Efficiency: Modern indoor cranes emphasize energy efficiency, incorporating features like regenerative braking systems to conserve energy during operations.

12. Modularity: Indoor cranes often feature modular designs, allowing for easy upgrades and customization to meet specific operational requirements.

These features collectively make indoor cranes indispensable tools in various industrial settings, facilitating efficient and safe material handling.

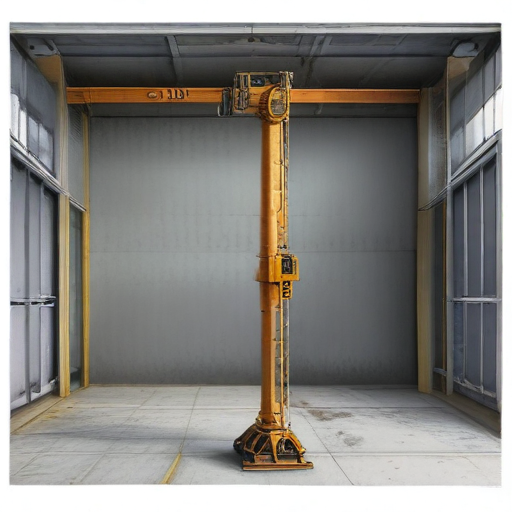

List Various Types of “indoor crane”

Indoor cranes are essential for material handling and lifting within enclosed spaces like factories, workshops, and warehouses. Here are various types of indoor cranes:

1. Overhead Cranes: These cranes are fixed on an overhead rail or beam. They are ideal for heavy lifting and moving loads over large areas.

– Bridge Cranes: These cranes consist of a bridge beam that spans the width of the workspace, supported by end trucks that move along a runway system.

– Gantry Cranes: Similar to bridge cranes but the bridge is supported by legs, moving on ground rails or wheels.

2. Monorail Cranes: These cranes run on a fixed monorail system, commonly used for lifting lighter loads and for specific paths of movement within a facility.

3. Jib Cranes: These feature a horizontal jib or boom that supports a moveable hoist. They can be wall-mounted or floor-mounted, excellent for localized lifting and moving tasks.

– Wall-Mounted Jib Cranes: These are attached to a wall or column, requiring minimal floor space.

– Cantilever Jib Cranes: These extend out from a fixed support, offering great flexibility in load handling.

4. Workstation Cranes: Designed for lighter loads, these cranes use enclosed track systems for ergonomic and efficient lifting.

– Freestanding Workstation Cranes: These are installed on the floor and can be moved if needed.

– Ceiling-Mounted Workstation Cranes: These offer clear floor space as they mount directly to the ceiling.

5. Articulating Cranes: These offer multiple pivot points, allowing for a versatile range of motion. Ideal for areas with obstructions or limited space.

6. Telescoping Cranes: These have boom sections that can extend or retract, providing adjustable reach for various lifting tasks.

Each type of indoor crane is designed for specific applications and space constraints, ensuring efficient and safe material handling in industrial settings.

List Application of “indoor crane”

Indoor cranes, also known as overhead cranes or bridge cranes, are essential equipment in various industries for lifting and moving heavy loads within a confined space. These cranes enhance productivity and ensure safety by minimizing the manual handling of heavy materials. Here are some primary applications of indoor cranes:

1. Manufacturing Plants: Used for moving raw materials to production lines, assembling heavy machinery, and transporting finished goods to storage or shipping areas.

2. Warehouses: Facilitate the efficient movement and organization of large and heavy inventory, ensuring optimal space utilization and faster handling times.

3. Automotive Industry: In automotive manufacturing plants, indoor cranes assist in assembling car parts, such as engines and chassis, and moving completed vehicles through various stages of production.

4. Steel Mills and Foundries: These cranes handle molten metal, heavy steel coils, and other massive metal components, ensuring precise placement and reducing the risk of accidents.

5. Aerospace Industry: Essential for handling large aircraft components such as wings, fuselages, and engines during assembly and maintenance processes.

6. Paper Mills: Used for lifting large rolls of paper and other materials, facilitating smooth production and processing operations.

7. Shipbuilding: Assist in the construction and maintenance of ships by moving large ship modules, engines, and other heavy components within the shipyard.

8. Power Plants: Indoor cranes are crucial for installing and maintaining heavy machinery like turbines and generators, and for handling large quantities of fuel or other materials.

9. Chemical Plants: Used to handle drums, containers, and machinery that may be hazardous or heavy, reducing the manual handling risk.

10. Storage Facilities: Assist in the efficient handling and storage of heavy or bulky goods, improving warehouse management and reducing labor costs.

The versatility and efficiency of indoor cranes make them indispensable tools in any setting where heavy lifting is required. They not only improve operational efficiency but also enhance workplace safety by minimizing the physical strain on workers.

List Buyer Types of “indoor crane”

When it comes to indoor cranes, they are sought after by a variety of buyer types, each with unique requirements based on the specific applications and industry needs. Here are some common buyer types:

1. Manufacturing Plants: These facilities often require indoor cranes for material handling, assembly line support, and moving heavy parts within the production area.

2. Warehouses: To efficiently manage and move inventory, warehouses utilize indoor cranes for stacking, loading, and unloading goods, especially in high-density storage areas.

3. Automotive Industry: Indoor cranes are essential in automotive plants for lifting and assembling heavy vehicle parts, engines, and other components during the manufacturing process.

4. Aerospace Industry: This industry relies on indoor cranes for precision handling of large and delicate aircraft parts, aiding in both manufacturing and maintenance operations.

5. Metal Fabrication Shops: These facilities use indoor cranes to transport heavy metal sheets, beams, and assembled structures, facilitating cutting, welding, and assembly tasks.

6. Power Plants: Indoor cranes in power plants are crucial for handling heavy equipment, turbines, and generators during both installation and maintenance phases.

7. Maintenance and Repair Operations (MRO): In various industries, MRO services require indoor cranes to lift and move heavy machinery or parts for regular servicing and repairs.

8. Construction sites: For indoor construction activities or in environments where larger cranes are impractical, indoor cranes assist in lifting building materials and equipment.

9. Logistics Centers: These centers need indoor cranes to streamline the sorting, storing, and dispatching of goods, enhancing operational efficiency.

10. Chemical and Pharmaceutical Plants: These industries use indoor cranes to transport heavy containers of raw materials and finished products in controlled environments.

11. Research Laboratories: Some labs, especially those dealing with large scientific equipment or testing apparatus, employ indoor cranes for precise material handling.

Overall, the need for indoor cranes spans a wide range of industries requiring efficient, safe, and reliable lifting solutions within confined spaces.

List “indoor crane” Project Types for Different Industries

Certainly! Here are some project types for indoor cranes tailored to different industries:

1. Manufacturing and Assembly:

– Overhead Bridge Cranes: Used for moving materials across large manufacturing floors, assembling components, and positioning heavy machinery.

– Jib Cranes: Ideal for individual workstations for lifting and positioning smaller components.

– Gantry Cranes: Provide flexibility for rearranging equipment setups in manufacturing areas by moving along predefined tracks.

2. Warehousing and Distribution:

– Stacker Cranes: Utilized in automated warehouses for vertical storage and retrieval of items.

– Warehouse Bridge Cranes: Facilitates the movement of goods across the warehouse floor to optimize space and efficiency.

– Monorail Cranes: Transport goods along a fixed path, perfect for streamlined warehouse operations.

3. Automotive Industry:

– Gantry Cranes: Used in assembling large components like car bodies and engines.

– Bridge Cranes: Assist in moving car parts across different sections of the plant.

– Workstation Cranes: Employed for handling parts at specific assembly stations.

4. Aerospace:

– Overhead Cranes: Essential for the precise lifting and positioning of large aerospace components.

– Cleanroom Cranes: Specialized cranes designed to operate in highly controlled environments to prevent contamination.

– Gantry Cranes: Used for the assembly and maintenance of large aircraft parts.

5. Metal Fabrication:

– Magnetic Bridge Cranes: Crucial for handling sheets and coils of metal efficiently.

– Rotating Cranes: Allow for the manipulation of heavy metal parts for welding and cutting operations.

– Gantry Cranes: Facilitate the movement of large metal structures and final products.

6. Food and Beverage:

– Cleanroom Bridge Cranes: Operate in hygienic environments for the processing and packaging of food products.

– Automated Cranes: Improve storage and retrieval systems in large food processing plants.

Indoor cranes are versatile tools tailored to the specific needs of various industries. Their application ranges from lifting and moving heavy materials to ensuring efficiency and safety in production and storage environments.

indoor crane Accessories Upgrades and Custom Manufacturing Options

Indoor crane accessories and upgrades are essential for enhancing efficiency, safety, and versatility. Essential accessories include specialized lifting attachments like magnetic lifters, vacuum lifters, and tongs to handle various materials. End effectors and custom grippers can be tailored to specific loads, improving precision and reducing handling time.

Upgrading to advanced control systems, such as radio remote controls and touch screen interfaces, streamlines operations by allowing operators to control cranes from a safe distance. Integrating anti-collision systems and load monitoring devices augments safety and prevents accidents. In addition, load cells and advanced weighing systems ensure precise measurements, enhancing operational efficiency.

Lighting solutions, such as LED lighting kits, improve visibility in dim environments, while camera systems provide live feed for better load management and safety surveillance. Ergonomic enhancements like padded seats, joysticks, and adjustable control stations improve operator comfort and productivity.

Custom manufacturing options cater to unique operational needs. Tailor crane heights, hoist speeds, and lifting capacities to meet specific requirements. Custom-built overhead, gantry, and jib cranes address particular space constraints and workflow demands. Customization extends to components like wire ropes, motors, and hooks designed for unique applications.

Material choice is another crucial aspect. Opting for corrosion-resistant materials or specialized coatings extends the lifespan of cranes in harsh environments. VFD (Variable Frequency Drives) can be installed to enhance motor efficiency and control, adapting to various load requirements while conserving energy.

In essence, upgrading and customizing indoor cranes with specific accessories and tailored designs drastically improve operational safety, efficiency, and adaptability, making them indispensable assets in various industrial settings.

List Quality Control and The Manufacturing Process of “indoor crane”

Quality Control in Indoor Crane Manufacturing

Quality control (QC) for indoor cranes involves multiple steps to ensure safety, reliability, and performance. Key QC measures include:

1. Component Inspection:

– Material Quality: Check raw materials for compliance with industry standards.

– Dimensions and Tolerances: Use precision instruments to ensure components meet design specifications.

2. Assembly Line Checks:

– Fit and Finish: Inspect sub-assemblies for proper fit, alignment, and finish.

– Torque Verification: Ensure bolts and fasteners are tightened to specified torque values.

3. Functionality Testing:

– Load Testing: Simulate operating conditions to verify load capacity.

– Operational Checks: Test all moving parts, control systems, and safety mechanisms.

4. Final Inspections:

– Visual Inspection: Check for defects, scratches, or inconsistencies in finish.

– Documentation Review: Verify all QC checklists and compliance certificates.

Manufacturing Process of Indoor Cranes

1. Design and Planning:

– CAD Modeling: Create detailed design using Computer-Aided Design (CAD) software.

– Prototyping: Develop prototypes to test design concepts and gather performance data.

2. Material Procurement:

– Raw Materials: Source high-quality steel, cables, motors, and electronics.

– Supplier Evaluation: Select suppliers based on quality, cost, and reliability.

3. Fabrication:

– Cutting and Shaping: Use CNC machines for precise cutting and shaping of metal parts.

– Welding and Assembly: Weld structural components and assemble sub-units.

4. Pre-Assembly Testing:

– Component Testing: Test motors, hydraulics, and electronics before final assembly.

– Sub-Assembly Checks: Inspect and test major sub-assemblies for functionality.

5. Final Assembly:

– Integration: Combine all sub-assemblies into a complete indoor crane.

– Wiring and Plumbing: Complete electrical and hydraulic connections.

6. Quality Assurance:

– Final QC Inspections: Conduct thorough inspections and tests to ensure compliance with standards.

– Certification: Obtain necessary certifications for safety and quality compliance.

7. Shipping and Installation:

– Packaging: Securely pack components for safe transportation.

How to use “indoor crane”

Using an indoor crane involves several crucial steps to ensure safety and efficiency. Below is a concise guide:

1. Preparation

– Inspection: Check the crane for any signs of wear, damage, or malfunction. Ensure all safety devices are operational.

– Load Assessment: Determine the weight and dimensions of the load. Ensure it does not exceed the crane’s capacity.

– Path Clearance: Make sure the area where the crane will operate is clear of obstacles and people.

2. Operation

– Control Familiarity: Understand and familiarize yourself with the crane’s controls, including emergency stop buttons.

– Securing the Load: Properly attach and secure the load using appropriate lifting equipment like slings or hooks.

– Test Lift: Conduct a small test lift to check the balance and stability of the load.

3. Moving the Load

– Smooth Movements: Lift the load slowly and steadily. Avoid sudden starts or stops to prevent swinging.

– Monitoring: Continuously monitor the load, path, and surroundings. Ensure the load remains secure and balanced.

– Communication: Use clear hand signals or a communication system if a team is involved.

4. Setting Down the Load

– Lowering: Gradually lower the load to its designated spot. Ensure it is stable before releasing.

– Unhooking: Carefully detach the lifting equipment from the load.

– Final Check: Inspect the load and crane for any issues that might have arisen during the operation.

5. Post-operation

– Inspection: Perform a post-operation check of the crane for any signs of stress or damage.

– Documentation: Log the details of the operation, including any irregularities or issues.

Safety Precautions

– Training: Only trained and authorized personnel should operate the crane.

– PPE: Use appropriate personal protective equipment (PPE) such as helmets, gloves, and safety shoes.

– Emergency Preparedness: Be aware of emergency procedures and locations of emergency stops.

By following these steps, you can safely and efficiently use an indoor crane for various lifting tasks.

“indoor crane” Comparative Analysis

An indoor crane is a vital piece of equipment in various industries for lifting and moving heavy loads within a confined space. There are several types of indoor cranes, each tailored to specific tasks and environments. Here, we’ll compare three common types: overhead cranes, gantry cranes, and jib cranes.

Overhead Cranes

Overhead cranes, also known as bridge cranes, consist of parallel runways with a traveling bridge spanning the gap. They are ideal for covering large areas and are used extensively in manufacturing and assembly lines. The primary advantage is their ability to lift very heavy loads and provide horizontal movement within the building. They require a substantial initial investment in structural modifications to support the runways but offer high efficiency and safety in operations.

Gantry Cranes

Gantry cranes are similar to overhead cranes but are supported by legs that move on wheels or rails. This flexibility allows them to be easily relocated to different areas within the facility. They are particularly useful in situations where the ceiling structure cannot support an overhead crane. Although not as robust as overhead cranes, they offer a balance between mobility and load capacity, making them suitable for workshops and smaller warehouses.

Jib Cranes

Jib cranes feature a horizontal boom attached to a vertical mast or mounted on a wall. Their reach is limited compared to overhead and gantry cranes, as they typically operate within a fixed radius. Jib cranes are highly effective in localized, repetitive lifting tasks, such as loading and unloading machines or assembly stations. They are easier to install and less expensive than the other types but offer less versatility in terms of load movement and coverage.

Conclusion

Each type of indoor crane has its distinct advantages and trade-offs. Overhead cranes are best for large-scale, heavy-duty applications requiring extensive coverage. Gantry cranes offer a compromise between mobility and capacity, suitable for mid-sized operations. Jib cranes provide an economical solution for specific, repetitive tasks with limited spatial requirements. The choice depends on the specific needs, spatial constraints, and budget of the operation.

“indoor crane” Warranty and Support

When selecting an indoor crane, warranty and support are crucial factors that ensure long-term reliability and performance. Here’s an overview of what to expect:

Warranty

1. Coverage Period: Most manufacturers offer a warranty period ranging between 1 to 3 years, covering defects in materials and workmanship. Some premium models may extend up to 5 years.

2. Components Covered: The warranty typically covers critical components such as the hoist, motor, gearbox, and control system. Wearable parts like ropes, hooks, and brakes may have limited coverage or be excluded altogether.

3. Exclusions: Common exclusions usually involve damage due to misuse, improper maintenance, or unauthorized modifications. Always read the fine print to understand what is not covered.

4. Claim Process: The process usually requires notifying the manufacturer or dealer immediately upon discovering a defect. Proof of purchase and detailed information about the issue are generally required. Some manufacturers offer online portals to streamline the claim process.

Support

1. Technical Assistance: Reliable manufacturers provide around-the-clock technical support via phone, email, or chat. Look for brands that offer dedicated service teams specializing in cranes.

2. On-Site Services: Many manufacturers or authorized dealers offer on-site support for complex issues. This can include installation, routine inspections, and emergency repairs.

3. Spare Parts Availability: Ensure the manufacturer has readily available spare parts to minimize downtime. Some companies offer expedited shipping or maintain local inventories to facilitate quick replacements.

4. Training Programs: Comprehensive operator training can be invaluable. Many companies offer training programs to help users understand operational best practices, which can extend the lifespan of the crane and reduce the likelihood of warranty claims.

5. Maintenance Plans: Opt for manufacturers who offer annual or bi-annual maintenance plans. Regular maintenance not only keeps the crane in optimal condition but also ensures warranty conditions are met.

Investing in a crane with robust warranty and support services ensures peace of mind, operational efficiency, and long-term cost savings.

List “indoor crane” FAQ

Indoor Crane FAQs

#### 1. What is an indoor crane?

An indoor crane is a type of crane specifically designed for use within indoor environments such as warehouses, factories, and workshops. It typically features overhead, gantry, or jib configurations to lift, move, and lower materials.

#### 2. What are the types of indoor cranes?

– Overhead Cranes: Run on tracks installed on the ceiling.

– Gantry Cranes: Feature a similar overhead design but are supported by freestanding legs.

– Jib Cranes: Have a horizontal arm (jib) that supports a hoist fixed to a wall or floor-mounted pillar.

#### 3. What are the common uses of indoor cranes?

Indoor cranes are used for material handling, assembly line moving, warehouse stocking, and heavy equipment maintenance.

#### 4. What capacity do indoor cranes typically have?

Indoor cranes can vary widely in lifting capacity, ranging from a few hundred pounds to several tons, depending on the design and application.

#### 5. What are the installation requirements for an indoor crane?

Installation requirements include sufficient ceiling height, structural support for overhead tracks, and adequate space for crane movement. Some installations may require electrical connections and control systems.

#### 6. What safety measures should be considered?

Important safety measures include regular inspections, proper load handling, trained operators, and adherence to safety regulations and guidelines such as OSHA standards.

#### 7. How is maintenance performed on indoor cranes?

Routine maintenance involves inspecting mechanical components, lubricating moving parts, checking electrical systems, and replacing worn out parts.

#### 8. Can indoor cranes be customized?

Yes, many indoor cranes can be customized to fit specific operational needs, including varying spans, lifting capacities, and specialized attachments.

#### 9. What is the average cost of an indoor crane?

Costs can range from $10,000 to over $100,000 depending on the type, capacity, and customization.

#### 10. Are there any regulatory requirements?

Yes, indoor cranes must comply with national and local regulations regarding safety, installation, and operation which may include standards set by OSHA, ANSI, and other relevant bodies.

Top 10 FAQ with answer about indoor crane for Buyer Sourcing from China

Certainly! Here are the top 10 FAQs about sourcing indoor cranes from China along with concise and informative answers:

1. What types of indoor cranes are available from China?

China manufactures various types of indoor cranes including overhead cranes, gantry cranes, jib cranes, and workstation cranes.

2. How do I assess the quality of indoor cranes from Chinese manufacturers?

Look for ISO 9001 certification, CE marking, and inquire about their quality control processes. Reviews and references from previous clients can also be insightful.

3. Are Chinese indoor cranes compliant with international standards?

Reputable manufacturers comply with international standards like ISO, CE, and ANSI. Always confirm compliance before purchasing.

4. Can Chinese manufacturers customize indoor cranes?

Yes, many manufacturers offer customization based on specific requirements like load capacity, crane span, and operational environment.

5. What is the lead time for ordering an indoor crane from China?

Lead times vary but typically range from 4 to 8 weeks depending on the complexity and customization of the crane.

6. What is the cost comparison between Chinese and other manufacturers?

Chinese-made indoor cranes typically offer competitive pricing but always compare total costs including shipping, installation, and any potential duties.

7. How can I ensure reliable shipping and logistics for my order?

Work with experienced freight forwarders and choose Incoterms that suit your needs best (e.g., FOB, CIF). Confirm packaging standards to avoid damage during transit.

8. What payment terms do Chinese manufacturers usually accept?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes escrow or trade assurance services through platforms like Alibaba.

9. Do Chinese manufacturers offer after-sales service and support?

Many reputable manufacturers offer warranties, spare parts, and after-sales services. Confirm these details before finalizing your purchase.

10. How can I verify the credibility of a Chinese indoor crane supplier?

Visit their facility if possible, review certifications, request client testimonials, or use third-party verification services to ensure their legitimacy.

Sourcing indoor cranes from China can be economical and efficient provided due diligence on quality, compliance, and supplier credibility is conducted.