indoor overhead crane Safety Certifications

Indoor overhead cranes are essential in many industrial operations, but they come with potential hazards. Ensuring safety is paramount, and adhering to appropriate certifications is crucial.

OSHA (Occupational Safety & Health Administration):

OSHA mandates specific safety guidelines for crane operation under 29 CFR 1910.179. Employers must ensure cranes are inspected regularly and operators are trained in safe use.

ASME (American Society of Mechanical Engineers) B30.2:

This standard covers the construction, installation, operation, inspection, and maintenance of overhead and gantry cranes. Compliance with ASME B30.2 ensures that these cranes are operated safely and maintained properly.

ANSI (American National Standards Institute):

ANSI standards, such as ANSI/ASSP B30.2, align closely with ASME requirements, emphasizing operator training, routine inspections, and maintenance checks.

CMAA (Crane Manufacturers Association of America):

CMAA provides specifications and guidelines for the design, manufacturing, installation, and safe operation of overhead cranes. Adherence to CMAA standards ensures high safety and quality in crane systems.

ISO (International Organization for Standardization):

ISO 9927 and ISO 4309 are vital international standards that govern the inspection, maintenance, and safe operation of cranes. These globally recognized standards ensure consistent safety practices.

NCCCO (National Commission for the Certification of Crane Operators):

NCCCO offers certification programs for crane operators, ensuring that they possess the necessary knowledge and skills to operate cranes safely. Certification from NCCCO is often mandatory in many regions.

Local Regulations:

Apart from international and national standards, local regulations may also apply. Compliance with state or regional safety standards can help avoid legal issues and ensure a safer work environment.

In summary, adherence to OSHA, ASME, ANSI, CMAA, ISO, NCCCO, and local regulations is essential for maintaining the safety and reliability of indoor overhead cranes. Regular inspections, proper training, and certification are key components of a robust safety protocol.

List Reference Technical Parameters of “indoor overhead crane”

Certainly! An indoor overhead crane’s technical parameters are critical for ensuring efficient and safe operation in various industrial settings. Below are key reference parameters:

1. Load Capacity:

– Maximum Load: Defines the highest weight the crane can lift (in tons or kilograms).

2. Span:

– Span Length: The horizontal distance between the runway rails, typically measured in meters.

3. Lift Height:

– Hook Lifting Height: The vertical distance the hook can travel (in meters).

4. Travel Speed:

– Trolley (Cross Travel) Speed: Speed at which the trolley moves along the crane beam (in meters per minute).

– Crane (Long Travel) Speed: Speed at which the entire crane moves along the runway (in meters per minute).

– Hoisting Speed: Speed at which the hook raises and lowers (in meters per minute).

5. Control Type:

– Options include pendant control, radio/remote control, or cabin control.

6. Duty Classification:

– Operational Duty Class: Defined by standards such as CMAA, FEM, or ISO. Indicates the frequency of use and average load.

7. Electrical Requirements:

– Power Supply: Voltage and phase requirements (e.g., 380V, 3-phase).

– Control Voltage: Voltage used for the crane’s control circuits.

8. Structural Configuration:

– Single Girder vs. Double Girder: Refers to the number of beams spanning the runway.

– Bridge Crane Type: Specifies whether it’s top-running or under-running.

9. Safety Features:

– Load Limiter: Prevents lifting beyond rated capacity.

– Emergency Stops: Ensures immediate halting of crane operation.

– Limit Switches: Prevents travel beyond the designated path.

10. Environmental Parameters:

– Operating Temperature: The ambient temperature range within which the crane can safely operate.

11. Hook Approach:

– Maximum Hook Approach: The minimum distance from the hook to the end of the crane’s span, both laterally and longitudinally.

12. Regulatory Compliance:

– Standards adherence: Ensures compliance with relevant industry and national safety standards.

These parameters enable optimal selection, use, and maintenance of indoor overhead cranes, ensuring operational efficiency and safety in various industries.

List Product features of “indoor overhead crane”

An indoor overhead crane, also known as a bridge crane, is a critical piece of equipment used in warehouses, manufacturing plants, and other industrial settings. Here are some key product features:

1. Bridge and Trolley System: The overhead crane consists of a bridge that runs on elevated tracks and a trolley that can move horizontally along the bridge. This arrangement enables three-dimensional lifting and transporting.

2. Load Capacity: These cranes are designed to handle heavy loads, often ranging from a few tons to hundreds of tons, depending on the specific model and configuration.

3. High Precision Control: Advanced control systems allow for precise movements and positioning, minimizing the risk of errors and enhancing safety.

4. Variety of Lifting Mechanisms: Equipped with various types of lifts such as wire rope hoists, chain hoists, or vacuum lifts, tailored to different lifting needs.

5. Durability and Robust Construction: Made from high-strength materials to withstand the rigors of industrial use, ensuring long-term reliability and durability.

6. Safety Features: Includes emergency stop buttons, overload protection, anti-sway technology, and limit switches to enhance operational safety.

7. Compact Design: Space-efficient design allows it to be integrated into existing facilities without requiring extensive modifications.

8. Automation and Smart Features: Some models offer automated operation, remote control, and integration with industrial IoT for enhanced productivity and monitoring.

9. Customizable Configurations: Available in single-girder and double-girder designs, as well as various spans and lift heights to suit specific application requirements.

10. Efficient Energy Consumption: Modern cranes are designed to be energy-efficient, reducing operational costs and environmental impact.

11. Smooth and Quiet Operation: Engineered for minimal noise and vibration, contributing to a safer and more comfortable work environment.

12. Ease of Maintenance: Features like accessible components and diagnostic capabilities simplify maintenance, reducing downtime.

These features make indoor overhead cranes indispensable in many industrial applications, enabling efficient, safe, and reliable lifting and material handling.

List Various Types of “indoor overhead crane”

Indoor overhead cranes are essential components in various industries for moving heavy loads efficiently within a building. Here’s a rundown of the various types:

1. Single Girder Overhead Crane:

– Structure: One main girder supported by end trucks.

– Application: Suitable for light to medium loads and smaller spaces.

– Pros: Cost-effective, easier to install.

2. Double Girder Overhead Crane:

– Structure: Two main girders providing additional strength.

– Application: Used for heavier loads and larger spans.

– Pros: Greater lifting capacity and height.

3. Top-Running Overhead Crane:

– Structure: Crane travels on rails mounted on top of runway beams.

– Application: Heavier load bearing capacity.

– Pros: Maximizes vertical space, minimized floor obstruction.

4. Under-Running (Underhung) Overhead Crane:

– Structure: Crane track is supported from the ceiling.

– Application: Suitable for lighter loads and lightweight buildings.

– Pros: Efficient space utilization, allows for multiple cranes on the same runway.

5. Bridge Crane:

– Structure: Bridge girders connected to end trucks running on elevated tracks.

– Application: Typically found in factories and warehouses.

– Pros: Covers large rectangular areas, effective for assembly lines.

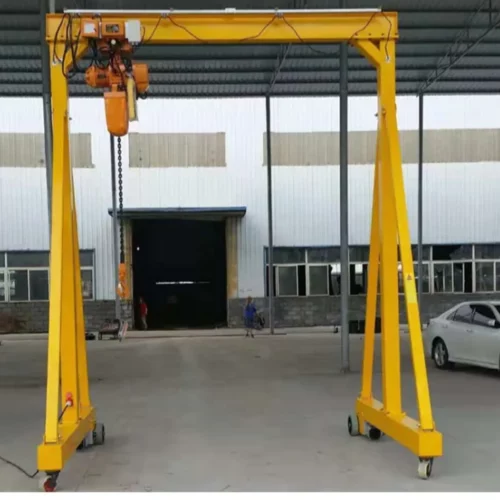

6. Gantry Crane:

– Structure: Supported by legs that move on ground rails.

– Application: Used in environments without adequate overhead support.

– Pros: Can be standardized or customized, portable versions available.

7. Jib Crane:

– Structure: Consists of a boom attached to a vertical mast.

– Application: Ideal for workstations and repetitive tasks.

– Pros: Simple and flexible, cost-effective for small areas.

8. Monorail Crane:

– Structure: Movable hoist runs on a fixed monorail beam.

– Application: Useful for production lines involving repetitive transportation.

– Pros: Efficient for linear paths, easy to install.

Each type caters to different load capacities, space constraints, and application needs, making them versatile tools in material handling operations.

List Application of “indoor overhead crane”

Indoor overhead cranes, also known as bridge cranes, are versatile lifting and material handling devices utilized in various industries. They consist of a trolley and hoist that travels along a horizontal beam, allowing for efficient transportation of heavy loads within a facility. Here are some of their primary applications:

1. Manufacturing Plants: Overhead cranes facilitate the movement of raw materials, components, and finished products, supporting assembly lines and production processes.

2. Warehouse and Storage Facilities: They are used to arrange and retrieve items stored in high and dense shelving, optimizing space and improving inventory management.

3. Steel Industry: Cranes handle heavy steel coils, slabs, and finished products, playing a crucial role in production, machining, and storage operations.

4. Automotive Industry: They assist in lifting and positioning heavy automotive parts and assemblies, streamlining manufacturing and maintenance tasks.

5. Aerospace Sector: Overhead cranes are vital for handling large aircraft components and assemblies, ensuring precision and safety in manufacturing and maintenance.

6. Foundries and Metal Workshops: These cranes manage the movement of molds, castings, and raw materials, enhancing productivity and safety in high-temperature environments.

7. Power Plants: They handle turbines, generators, and other heavy equipment during installation, maintenance, and repair work.

8. Shipbuilding: Overhead cranes lift and transport large ship components, such as hull sections and engines, facilitating efficient assembly.

9. Mining and Minerals Processing: In these industries, cranes are used to handle large equipment and raw materials, aiding in processing and maintenance tasks.

10. Paper Mills: They handle large rolls of paper and other heavy equipment required for the paper manufacturing process.

11. Rail Yards: Cranes manage the loading and unloading of heavy cargo and equipment, ensuring efficient rail transport operations.

In summary, indoor overhead cranes are indispensable across various sectors for their ability to enhance operational efficiency, safety, and productivity in handling heavy and cumbersome loads.

List Buyer Types of “indoor overhead crane”

When it comes to purchasing indoor overhead cranes, several types of buyers exist, each with unique needs and specifications. Here are the primary buyer groups:

1. Manufacturing Plants:

– Automotive: Require cranes for lifting and moving heavy machinery and vehicle parts.

– Aerospace: Utilize cranes for precise handling of delicate aircraft components.

– Metal Fabrication: Need robust cranes for handling large sheets and heavy metal assemblies.

2. Warehousing and Distribution Centers:

– General Warehousing: Use cranes to move large crates and pallets efficiently.

– Cold Storage Facilities: Require cranes that operate in low-temperature environments.

– E-commerce Fulfillment: Need cranes for quick and efficient handling to meet fast-paced demands.

3. Construction Companies:

– Prefabrication Plants: Use overhead cranes for moving large pre-constructed components.

– Material Yards: Require cranes to handle bulky construction materials such as steel beams and cement blocks.

4. Utilities:

– Power Generation: Need cranes for maintenance and assembly of turbines and other heavy equipment.

– Water Treatment Plants: Use cranes for handling large pumps and machinery parts.

5. Mining Operations:

– Processing Plants: Require indoor cranes for material handling in confined spaces.

– Maintenance Facilities: Use cranes for repairing and maintaining large mining equipment.

6. Logistics Companies:

– Port Facilities: Utilize cranes for handling containers and heavy cargo efficiently.

– Railway Depots: Need cranes for loading and unloading heavy freight.

7. Specialized Industries:

– Shipbuilding: Require cranes with high precision and stability for constructing and maintaining ships.

– Paper Mills: Utilize cranes for handling large rolls of paper and heavy machinery.

Understanding these buyer types helps manufacturers tailor their offerings to meet specific industry needs, ensuring optimal performance and operational efficiency.

List “indoor overhead crane” Project Types for Different Industries

Indoor overhead cranes are versatile lifting solutions used across various industries to enhance operational efficiency and safety. Below is a list of project types for different industries that utilize indoor overhead cranes:

1. Manufacturing Industry:

– Assembly Line Support: Transporting heavy components along production lines.

– Automotive Manufacturing: Handling car parts like engines and bodies.

– Aerospace Manufacturing: Moving large aircraft components with precision.

– Metal Fabrication: Lifting heavy metal sheets and products during processing.

2. Warehousing and Distribution:

– Stock Management: Efficiently moving goods within large storage facilities.

– Loading/Unloading: Facilitating the transfer of goods to and from transportation vehicles.

3. Construction Industry:

– Material Handling: Transporting construction materials like steel beams within indoor facilities.

– Prefabrication: Assisting in the assembly of prefabricated building components.

4. Energy Sector:

– Power Plant Maintenance: Handling turbines, generators, and other heavy machinery.

– Oil and Gas: Transporting drilling equipment and maintenance tools.

5. Mining Industry:

– Equipment Maintenance: Lifting heavy mining equipment for repairs.

– Material Handling: Transporting raw materials within processing plants.

6. Shipbuilding and Marine Industry:

– Component Assembly: Moving large ship sections and components during construction.

– Maintenance: Handling marine motors and parts during repairs.

7. Steel and Metal Production:

– Casting and Mold Handling: Transporting heavy molds and freshly cast products.

– Rolling Mill Operations: Moving heavy rolls of metal sheets or coils.

8. Paper and Pulp Industry:

– Roll Handling: Lifting large rolls of paper for processing.

– Maintenance Operations: Transporting heavy equipment for repairs and maintenance.

9. Food and Beverage Industry:

– Ingredient Handling: Transporting large containers of raw materials.

– Packaging Line Support: Moving heavy packaged goods for distribution.

10. Public Sector and Utilities:

– Municipal Services: Handling large equipment and machinery in municipal garages.

– Water Treatment Plants: Moving heavy filtration and pumping equipment.

Indoor overhead cranes offer vital support across these industries by improving material handling capabilities, thereby increasing efficiency and safety in various operations.

indoor overhead crane Accessories Upgrades and Custom Manufacturing Options

Indoor overhead cranes are essential in various industries for material handling, and their performance can be significantly enhanced with appropriate accessories, upgrades, and custom manufacturing options.

Accessories:

1. Remote Controls: Allow operators to control the crane from a safe distance, enhancing efficiency and safety.

2. Lighting Systems: Integrated LED lighting ensures better visibility in low-light environments.

3. Load Cells: Provide precise weight measurements, crucial for accurate load handling and safety.

4. End Trucks: Enable smooth and reliable movement along the crane runway.

5. Below-the-Hook Attachments: Customizable lifting devices such as spreader beams, magnets, and vacuum lifters for tailored load handling.

Upgrades:

1. Automation: Implementing CNC control systems can provide repeatable precision and reduce manual errors.

2. Variable Frequency Drives (VFDs): Enhance motor control for smooth acceleration and deceleration, reducing mechanical stress and energy consumption.

3. Anti-Sway Technology: Minimizes load swing during transit, improving stability and safety.

4. Wireless Monitoring: Real-time data on crane performance and diagnostics for preventative maintenance.

Custom Manufacturing Options:

1. Load Capacity Customization: Tailored designs to accommodate specific weight requirements, enhancing operation efficiency.

2. Special Coatings: For environments with specific needs such as corrosion resistance or spark resistance, like in chemical plants or explosive atmospheres.

3. Adjustable Span and Height: Customizable installations to fit unique warehouse dimensions or production lines.

4. Enhanced Safety Features: Customizable safety features like overload detectors, emergency stop systems, and collision avoidance systems.

5. Specialized Trolleys and Hoists: Tailored lifting mechanisms to meet unique operational requirements, such as high-speed lifting or precise positioning.

In conclusion, the inclusion of targeted accessories, strategic upgrades, and customized manufacturing options can vastly improve the functionality, safety, and efficiency of indoor overhead cranes, meeting the specific needs of diverse industrial applications.

List Quality Control and The Manufacturing Process of “indoor overhead crane”

Quality Control of Indoor Overhead Cranes

1. Material Inspection: Ensure raw materials meet required standards for durability and stress resistance.

2. Welding Quality: Conduct non-destructive testing (NDT) to detect weld defects.

3. Component Verification: Validate dimensions and tolerances of parts like hooks, ropes, and trolleys.

4. Load Testing: Perform static and dynamic load tests to ensure the crane can handle its maximum rated capacity.

5. Functional Testing: Evaluate all mechanical and electrical systems, including limit switches, control panels, and emergency brakes.

6. Surface Treatment: Check for proper painting and anti-corrosion measures.

7. Documentation Review: Verify that all standards, certifications, and user manuals are completed and compliant.

8. Final Inspection: Conduct a thorough final inspection before shipping to ensure all criteria are met.

Manufacturing Process of Indoor Overhead Cranes

1. Design: Engineers design based on load requirements and operational environment, using CAD software.

2. Material Procurement: Source high-quality steel, motors, and electrical components.

3. Cutting and Machining: Use CNC machines to cut and shape steel according to design specifications.

4. Welding and Assembly: Weld major components like bridge girders, hoists, and trolleys; assemble sub-components.

5. Machining of Components: Precision machining for components like wheels and gears to ensure smooth operation.

6. Surface Treatment: Apply primers and protective coatings to prevent corrosion.

7. Electrical Installation: Install motors, control panels, and safety systems including wiring and sensors.

8. Initial Testing: Conduct preliminary testing of assembled units to check for functional defects.

9. Final Assembly: Integrate all components and conduct final assembly.

10. Load Testing: Perform rigorous load tests to verify strength and stability.

11. Quality Inspection: Conduct a final QA inspection to ensure adherence to all standards.

12. Documentation: Prepare technical documents, user manuals, and inspection reports.

13. Packing and Shipping: Properly pack the crane and ship to the customer, ensuring safe transit.

This structured approach ensures the production of high-quality, reliable indoor overhead cranes that meet stringent industrial standards.

How to use “indoor overhead crane”

Using an indoor overhead crane involves several key steps to ensure safety and efficiency. Follow these guidelines:

1. Pre-Operational Checks:

– Inspect the Crane: Check for any visible damage or wear. Ensure that all parts, including hooks, chains, and ropes, are in good condition.

– Test the Controls: Verify that all control buttons and levers are functioning correctly.

– Check Safety Devices: Ensure that limit switches, emergency stops, and other safety mechanisms are operational.

2. Preparing to Lift:

– Clear the Area: Ensure the load path and work area are free of obstacles and personnel.

– Assess the Load: Know the weight of the load and ensure it’s within the crane’s rated capacity.

– Rigging the Load: Use appropriate slings, shackles, and other rigging gear. Ensure they are correctly attached and balanced.

3. Operating the Crane:

– Hoisting the Load: Start lifting gradually. Make sure the load is balanced and securely fastened.

– Moving the Load: Use smooth and slow movements to avoid swinging. Navigate the crane using the overhead tracks or beams.

– Trolley Movement: Move the trolley across the bridge as needed.

– Bridge Movement: Move the bridge along its track to position the load accurately.

– Lowering the Load: Gradually lower the load to its destination, maintaining control at all times.

4. Post-Operational Steps:

– Secure the Crane: Return the crane to its resting position. Disconnect power if required.

– Inspect and Maintain: Perform a post-use inspection. Report any issues or perform necessary maintenance.

5. Safety Protocols:

– Always adhere to standard operating procedures and safety guidelines.

– Wear appropriate personal protective equipment (PPE).

– Communicate clearly with co-workers.

By following these steps, you can effectively and safely use an indoor overhead crane, ensuring efficient material handling in your workspace.

“indoor overhead crane” Comparative Analysis

An indoor overhead crane, often referred to as a bridge crane, is a crucial component in many industrial settings, ranging from manufacturing plants to warehouses. They are designed for lifting and transporting heavy loads efficiently and safely within a contained environment. Here’s a comparative analysis of various types of indoor overhead cranes:

Single-Girder vs. Double-Girder Cranes

Single-Girder Cranes:

– Cost-Effective: Typically less expensive due to simpler construction.

– Space-Saving: Suitable for facilities with height restrictions.

– Lighter Loads: Best for light to moderate loads (up to 20 tons).

– Installation and Maintenance: Easier and less costly to install and maintain.

Double-Girder Cranes:

– Higher Load Capacity: Can lift heavier loads (up to several hundred tons) due to dual girder support.

– Greater Span: Better suited for wider spans and higher lifting heights.

– Diverse Applications: Ideal for more demanding and intensive operations.

– Installation and Maintenance: More complex and expensive to install and maintain, but offers more robust performance.

Overhead Crane Configurations

Top-Running Cranes:

– Capacity and Durability: Typically suited for the heaviest loads and most rigorous applications.

– Installation Flexibility: Can be mounted on top of existing structures, maximizing floor space.

– Cost: Generally higher due to more complex infrastructure.

Under-Running (Underslung) Cranes:

– Space Efficiency: Ideal for facilities with limited headroom.

– Installation: Requires less support structure, which can reduce installation costs.

– Load Capacity: Usually supports lighter loads compared to top-running configurations.

Electric vs. Manual Operation

Electric Overhead Cranes:

– Speed and Efficiency: Faster and more efficient load handling.

– Automation Options: Can incorporate advanced automation and control systems.

– Higher Initial Cost: Higher upfront investment but reduced long-term labor costs.

Manual Overhead Cranes:

– Cost-Effective: Lower initial cost and simpler to operate.

– Limited Capacity and Efficiency: Suitable for limited load capacities and applications requiring minimal operational speed.

Conclusion

“indoor overhead crane” Warranty and Support

When investing in an indoor overhead crane, ensuring comprehensive warranty and support coverage is essential for operational efficiency and longevity of the equipment.

Warranty

Most reputable manufacturers offer warranties that range from one to five years, covering parts and labor. The warranty typically includes:

1. Mechanical Components: Coverage for defects in materials and workmanship pertaining to the hoist, trolley, and bridge mechanisms.

2. Electrical Systems: Protection against failures in the electrical components and controls, ensuring that any malfunctions are promptly addressed.

3. Structural Integrity: Assurance that structural components (beams, girders) will perform under specified conditions without cracking or deformation.

4. Service and Repairs: Depending on the provider, some warranties may cover the cost of on-site repairs, while others may include return-to-base servicing.

Support

High-quality customer support can significantly impact the overall user experience. Key elements include:

1. 24/7 Technical Assistance: Access to knowledgeable support staff around the clock to troubleshoot issues as they arise.

2. Regular Maintenance Plans: Some manufacturers offer routine maintenance packages that include scheduled inspections and servicing to prevent breakdowns.

3. Training Programs: Comprehensive training for your staff on proper usage and maintenance procedures to extend the life of your crane and ensure safety compliance.

4. Spare Parts Availability: Ready access to genuine spare parts with reduced lead times to minimize downtime.

5. Documentation and Resources: Manuals, troubleshooting guides, and instructional videos accessible online or via customer portals.

6. Remote Monitoring Services: Advanced support options may include remote diagnostics and monitoring, allowing technicians to identify and address issues preemptively.

Selecting an overhead crane involves evaluating the warranty and support services to ensure that your investment is safeguarded throughout its operational life, maximizing efficiency and minimizing disruptions.

List “indoor overhead crane” FAQ

Sure, here is a concise FAQ for indoor overhead cranes:

Indoor Overhead Crane FAQ

1. What is an indoor overhead crane?

Indoor overhead cranes, also known as bridge cranes or EOT (Electric Overhead Traveling) cranes, are lifting devices used inside buildings to move heavy loads horizontally and vertically. They typically consist of runways, bridges, and hoists and are controlled from the ground or a cab.

2. What are the primary types of indoor overhead cranes?

– Single-Girder Cranes: Feature one main horizontal beam.

– Double-Girder Cranes: Have two main beams and higher load capacity.

– Gantry Cranes: Operate on floor-mounted rails.

– Jib Cranes: Feature a horizontal beam that rotates around a pivot.

3. What applications are indoor overhead cranes suitable for?

Common applications include manufacturing, warehousing, transportation, and maintenance in sectors such as automotive, aerospace, steel, and paper industries.

4. What are the key benefits of using indoor overhead cranes?

– Efficient material handling

– Increased productivity and safety

– Optimized space utilization

– Reduced labor costs

5. What factors should be considered when selecting an indoor overhead crane?

– Load capacity and weight of materials

– Span and height of the facility

– Frequency and speed of operation

– Environmental conditions (e.g., temperature, humidity)

6. How do you maintain an indoor overhead crane?

Regular inspections, lubrication of moving parts, checking for wear and tear, and ensuring proper alignment are essential. Following the manufacturer’s maintenance schedule is crucial.

7. What safety measures are necessary for operating an indoor overhead crane?

– Proper training for operators

– Regular inspections and maintenance

– Use of safety devices (e.g., limit switches, emergency stops)

– Adherence to safety regulations and standards

8. How is an indoor overhead crane controlled?

They can be controlled via wired pendant controls, wireless remote controls, or from an operator cab, depending on the application and user preference.

9. Are there regulations for using indoor overhead cranes?

Yes, there are industry standards and regulations set by organizations such as OSHA (Occupational Safety and Health Administration) and other local authorities to ensure safe operation.

This brief FAQ covers the essential aspects of indoor overhead cranes, including their types, benefits, applications, and considerations for use and maintenance.

Top 10 FAQ with answer about indoor overhead crane for Buyer Sourcing from China

1. What is an indoor overhead crane?

An indoor overhead crane (also known as a bridge crane) is a type of crane used within buildings to lift, lower, and move heavy loads horizontally. It typically consists of parallel runways with a traveling bridge spanning the gap.

2. What are the common types of indoor overhead cranes?

Common types include single girder, double girder, top running, and under running cranes. The choice depends on load requirements, lift height, and space constraints.

3. How do I determine the right capacity for my needs?

Evaluate the maximum weight you need to lift, factoring in any future requirements. Cranes range from small capacities (1-10 tons) to heavy-duty ones exceeding 100 tons.

4. What are the key specifications to consider?

Key specs include load capacity, span, lifting height, duty cycle, hook approach, and speed. Ensure these are aligned with your operational needs.

5. What standards and certifications should I look for?

Ensure compliance with international standards such as ISO, CE, and specific local regulations. Certification can attest to the crane’s safety and reliability.

6. What are the typical lead times for sourcing from China?

Lead times can vary, often ranging from 4 to 12 weeks depending on customization, order volume, and current production load. Clarify this with your supplier.

7. How are the cranes transported from China?

Cranes are usually shipped in disassembled form, using containers or special transport methods. Ensure your local infrastructure can accommodate the delivery and assembly.

8. What are the costs involved?

Costs include the crane itself, shipping, taxes, custom duties, installation, and any required customs clearance. Always request a detailed quote.

9. What about installation and after-sales support?

Inquire if the supplier offers installation services or partners with local agencies. Check for warranty terms, availability of spare parts, and customer support policies.

10. How do I verify supplier reliability?

Conduct thorough due diligence: check references, visit facilities if possible, review certifications, and understand their experience with international clients. Utilize services like Alibaba’s Trade Assurance or third-party inspection agencies for added security.