industrial jib crane Safety Certifications

Industrial jib cranes, critical for material handling in various sectors, must adhere to safety standards to mitigate risks and ensure operational efficiency. Safety certifications for these cranes typically involve compliance with regulations and standards set forth by recognized organizations and governing bodies.

1. OSHA (Occupational Safety and Health Administration): OSHA sets forth regulations for the safe operation of cranes in the workplace, focusing on preventing accidents and injuries. Compliance with OSHA standards is mandatory in the United States and involves regular inspections and maintenance schedules.

2. ANSI/ASME (American National Standards Institute/American Society of Mechanical Engineers): ASME B30.11 covers the construction, installation, operation, inspection, and maintenance of underhung cranes and monorail systems, including jib cranes. Compliance ensures cranes meet specific safety and performance criteria.

3. CE Marking (Conformité Européenne): For cranes used in the European Economic Area, the CE marking indicates conformity with EU safety, health, and environmental protection standards. This involves rigorous testing and documentation as per the Machinery Directive 2006/42/EC.

4. ISO (International Organization for Standardization): ISO standards like ISO 9001 ensure quality management systems that lead to reliable and safe crane operations. ISO 14001 and ISO 45001 address environmental management and occupational health and safety, respectively.

5. CMAA (Crane Manufacturers Association of America): CMAA specifications offer guidelines for the design, maintenance, and operation of cranes, aligning with best industry practices to enhance safety and performance.

Ensuring that jib cranes are certified according to these standards reduces the risk of operational failures, enhancing safety for operators and longevity for the equipment. Regular training for operators and adherence to maintenance protocols are also crucial components of comprehensive safety management.

List Reference Technical Parameters of “industrial jib crane”

Industrial jib cranes are versatile lifting devices commonly used in various manufacturing and maintenance applications. Here are the key reference technical parameters for industrial jib cranes:

1. Load Capacity (SWL – Safe Working Load):

– Typically ranges from 100 kg to 20,000 kg, depending on the model and application.

2. Span/Radius:

– The horizontal distance from the crane’s pivot point to the end of the boom, typically between 2 to 10 meters.

3. Height Under Boom (HUB):

– The vertical distance from the floor to the underside of the jib boom, typically ranging from 2 to 10 meters.

4. Rotation:

– Degrees of rotation the jib can achieve, typically 180, 270, or 360 degrees, depending on whether it’s a wall-mounted or free-standing model.

5. Boom Length:

– The length of the horizontal arm (boom), typically between 2 to 8 meters.

6. Mounting Type:

– Wall-mounted, floor-mounted (free-standing), ceiling-mounted, or mast type.

7. Boom Construction:

– Usually fabricated from steel or other high-strength materials to ensure durability and load-bearing capability.

8. Motorization:

– Options for manual, electric, or pneumatic operation for vertical lifting and horizontal movement.

9. Lifting Speed:

– The rate at which the crane can lift materials, dependent on the motor, ranging typically from 0.5 to 20 meters per minute.

10. Duty Class:

– Defines the intended frequency and intensity of use, ranging from light (A1) to heavy-duty (A7).

11. Control Systems:

– Options include pendant controls, remote radio controls, or fully automated systems.

12. Safety Features:

– Overload protection, emergency stop buttons, limit switches, and anti-collision systems.

13. Power Supply:

– Generally 220V, 380V, or customized according to specific industrial standards.

14. Installation Requirements:

– Foundation requirements and space considerations for floor-mounted models; wall or ceiling structure strength for mounted variants.

Understanding these key technical parameters aids in selecting the right industrial jib crane for specific operational needs, ensuring efficiency, safety, and performance.

List Product features of “industrial jib crane”

An industrial jib crane is a versatile and efficient piece of lifting equipment commonly used in manufacturing, warehousing, and construction settings. Here are its key product features:

1. Load Capacity: Varies widely, with typical ranges from 250 pounds to several tons, allowing for the handling of different weight categories.

2. Boom Length: The horizontal beam or boom can range from a few feet to over 20 feet, accommodating a variety of spatial requirements and lifting needs.

3. Rotation: Offers either 180-degree or full 360-degree rotation, providing extensive coverage and flexibility in material handling within its radius.

4. Mounting Options: Includes wall-mounted, floor-mounted, and mast-style configurations, allowing for adaptability to different setups and space constraints.

5. Height Adjustment: Many models feature adjustable height settings for more customized and versatile use in various applications.

6. Construction: Built with robust materials like high-strength steel to ensure durability, stability, and long-term operation even in harsh industrial environments.

7. Ease of Operation: Equipped with user-friendly controls, often including manual, electric, or pneumatic options for lifting, lowering, and rotating loads efficiently.

8. Safety Features: Incorporates safety mechanisms such as overload protection, emergency stop buttons, and secure mounting systems to ensure operator safety and equipment reliability.

9. Customizability: Often customizable with various attachments and accessories like hoists, vacuum lifts, and magnets to meet specific operational requirements.

10. Maintenance: Designed for minimal maintenance, with accessible components and often self-lubricating systems to ensure continued, hassle-free use.

11. Mobility: Some models offer wheeled bases or portable mounts for temporary or flexible placement within a facility.

12. Compliance: Meets industry standards and regulations such as OSHA and ANSI, ensuring that the equipment is safe and compliant with workplace safety norms.

Overall, industrial jib cranes are an essential tool for enhancing the efficiency, safety, and versatility of material handling operations in numerous industrial contexts.

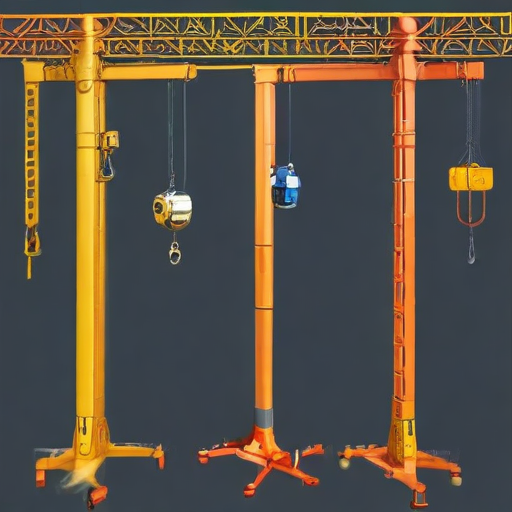

List Various Types of “industrial jib crane”

Industrial jib cranes are versatile lifting solutions widely used in various industries for material handling and positioning. Here are some of the key types of industrial jib cranes:

1. Free-standing Jib Cranes: These are independent structures bolted to the floor, offering 360-degree rotation. They are ideal for spaces without adequate overhead support structures.

2. Wall-mounted Jib Cranes: Installed on a building’s wall or existing columns, these cranes have varying rotation capacity (up to 200 degrees) and save floor space.

3. Mast-type Jib Cranes: Similar to free-standing jib cranes but with additional support from ceiling or floor-mounted structures, providing greater stability and minimal floor space usage.

4. Wall-bracketed Jib Cranes: These cranes are supported by brackets attached to walls or columns, often offering less rotation but ideal for reaching over workstations or machinery.

5. Articulating Jib Cranes: Featuring multiple pivot points, these cranes provide enhanced flexibility, allowing the operator to reach around obstructions and into confined spaces.

6. Workstation Jib Cranes: Typically used for light-duty applications, these cranes are designed for ergonomic and efficient handling of smaller loads, enhancing productivity in workshops and assembly lines.

7. Portable Jib Cranes: Mounted on mobile bases, these cranes can be moved around the facility to provide lifting capabilities where needed, ensuring versatility and ease of repositioning.

8. Foundationless Jib Cranes: These cranes do not require a concrete foundation and can be anchored directly to existing floors, providing cost-effective installation and flexibility in position adjustments.

Choosing the right type of jib crane depends on various factors such as the weight of the loads to be lifted, the required range of motion, available space, and specific application needs. Each type offers unique advantages tailored to different industrial environments and operational requirements.

List Application of “industrial jib crane”

Industrial jib cranes are versatile lifting devices utilized in various settings for handling materials and facilitating workflow. Below are some key applications of industrial jib cranes:

1. Manufacturing Facilities

– Assembly Lines: Jib cranes assist in the assembly of large machinery and equipment by enabling the precise placement of heavy parts.

– Workstations: They streamline tasks such as welding, drilling, and parts fabrication by providing localized lifting and maneuvering capabilities.

2. Warehouses

– Loading and Unloading: Jib cranes expedite the process of loading and unloading goods from trucks and storage shelves.

– Inventory Management: They help in organizing and moving heavy inventory items, reducing manual labor and enhancing safety.

3. Construction Sites

– Material Handling: Essential for lifting and positioning construction materials such as beams, pipes, and rebar.

– Site Preparation: Aid in setting up heavy materials and equipment required for construction activities.

4. Automotive Industry

– Engine Lifting: Used for mounting and dismounting engines and other heavy components from vehicles.

– Parts Handling: Facilitate the movement of bulky vehicle parts within assembly and repair shops.

5. Shipyards and Ports

– Cargo Handling: Jib cranes are employed to load and unload cargo from ships, streamlining dockside operations.

– Ship Maintenance: Assist in repairing and maintaining ships by moving heavy machinery and parts.

6. Mining Operations

– Equipment Maintenance: Used for lifting and positioning heavy mining equipment during maintenance and repairs.

– Material Transport: Facilitate the movement of mined materials and tools, enhancing operational efficiency.

7. Energy Sector

– Wind Turbine Assembly: Jib cranes help in assembling and servicing wind turbines by lifting heavy components like blades and nacelles.

– Power Plants: Essential for maintenance tasks, such as replacing heavy components in turbines and generators.

Conclusion

Industrial jib cranes play a crucial role across multiple sectors by improving efficiency, safety, and productivity in material handling tasks. Their adaptability to various environments makes them indispensable in modern industrial operations.

List Buyer Types of “industrial jib crane”

When considering the buyer types for industrial jib cranes, it’s essential to recognize the diverse range of industries and applications that require these versatile lifting devices. Here are some primary buyer categories:

1. Manufacturing Plants: They utilize jib cranes for lifting and moving materials or products within a specific area, enhancing production efficiency. These can include automotive, aerospace, electronics, and general manufacturing sectors.

2. Warehouses and Distribution Centers: For the efficient handling of goods, loading, and unloading processes, jib cranes provide an effective solution. They are critical in speeding up the movement of heavy items.

3. Construction Companies: In the construction industry, jib cranes are essential for lifting heavy materials and equipment, offering a portable and adaptable lifting solution for various job sites.

4. Marine and Shipyards: These cranes are used for unloading and loading ships, as well as for ship repair and maintenance activities. Their ability to work seamlessly in outdoor environments is a key benefit.

5. Energy Sector: Jib cranes assist in the handling of heavy parts and equipment in power plants, oil refineries, and renewable energy installations like wind farms.

6. Mining and Extraction: These industries rely on jib cranes for the movement of heavy mining equipment and materials, often in challenging environments.

7. Utilities and Municipalities: Public works departments use jib cranes for tasks such as lifting and placing utility poles, sewer covers, and other heavy infrastructure materials.

8. Aerospace and Defense: Precision and reliability are crucial in these sectors, and jib cranes are used for the precise handling of aircraft parts, military equipment, and related maintenance activities.

Buyers in these industries look for jib cranes that offer reliability, durability, and specific features tailored to their operational needs, such as reach, load capacity, and ease of installation. The versatility and efficiency of jib cranes make them indispensable across a wide array of industrial applications.

List “industrial jib crane” Project Types for Different Industries

Certainly! Industrial jib cranes are versatile lifting devices used in various industries to improve efficiency and safety. Here are some common project types for different industries:

Manufacturing

1. Assembly Line Support: Used to lift and position components in car, electronics, and machinery assembly lines.

2. Tool and Die Handling: Assists in the maneuvering of heavy tools and dies.

3. Production Line Maintenance: Facilitates routine maintenance of production equipment.

Warehousing and Logistics

1. Loading and Unloading: Assists in the loading and unloading of goods from trucks and storage racks.

2. Inventory Management: Helps in the organization and retrieval of heavy inventory items.

3. Packaging: Used to lift and transfer bulky items to packaging areas.

Construction

1. Material Handling: Used for lifting and positioning construction materials like steel beams and concrete blocks.

2. On-site Vehicle Loading: Assists in loading construction equipment on trucks.

3. Formwork Positioning: Aids in positioning reusable molds for concrete structures.

Marine and Shipyard

1. Dockside Work: Assists in handling cargo and materials at docks.

2. Ship Assembly: Used in lifting and positioning ship components during assembly.

3. Maintenance and Repair: Facilitates the lifting of heavy machinery and parts for ship repairs.

Energy Sector

1. Wind Turbine Component Handling: Used for lifting wind turbine components during assembly and maintenance.

2. Oil and Gas Field Services: Aids in the handling of heavy pipes and equipment.

3. Power Plant Maintenance: Facilitates the maneuvering and installation of heavy components within power plants.

Aerospace

1. Airplane Assembly: Assists in the assembly of large airplane components.

2. Engine Handling: Facilitates the installation and removal of airplane engines.

3. Maintenance, Repair, and Overhaul (MRO): Used in the repair and maintenance of aircraft components.

Automotive

1. Component Handling: Used for lifting and positioning large auto parts like engines and transmissions.

2. Production Line Use: Assists workers in the assembly of automotive components.

3. Maintenance: Facilitates lifting heavy automotive machinery for servicing.

Each project type utilizes industrial jib cranes to improve operational efficiency, enhance worker safety, and streamline workflows across various sectors.

industrial jib crane Accessories Upgrades and Custom Manufacturing Options

Industrial jib cranes are crucial for material handling in various applications, and they can be customized and upgraded with a range of accessories to enhance their performance, safety, and efficiency. Here are some common accessory options and custom manufacturing upgrades:

1. Hoists and Trolleys:

– Electric Hoists: Enhance lifting speed and control.

– Manual Hoists: Cost-effective for lower frequency use.

– Motorized Trolleys: Improve horizontal load movement.

2. End Stops and Bumpers:

– Rubber End Stops: Prevent trolleys from over-traveling.

– Spring or Hydraulic Bumpers: Absorb impacts and increase crane longevity.

3. Rotational Stops:

– Mechanized Rotational Stops: Limit crane rotation range for safety.

– Manual Rotational Stops: Easy to install and adjust.

4. Power Options:

– Festooning Systems: Organize electrical cables and air hoses.

– Energized Rail Systems: Provide continuous power without dangling wires.

5. Control Systems:

– Remote Controls: Increase operational flexibility and safety.

– Variable Speed Drives: Allow precise control of lifting and travel speeds.

6. Safety Accessories:

– Overload Protection Devices: Prevent crane operations beyond safe limits.

– Anti-Collision Systems: Reduce risk of collisions with other equipment.

– Warning Lights and Alarms: Enhance visibility and alert workers of crane movement.

7. Custom Manufacturing Options:

– Customized Boom Lengths: Tailor the crane reach to specific site requirements.

– Special Coatings and Finishes: Improve durability in harsh environments, such as zinc coatings for corrosion resistance.

– Specialized Mounting Options: Floor-mounted, wall-mounted, or mast-style to fit unique workspace configurations.

8. Lift Assist Devices:

– Magnet Lifters: Efficient for handling ferrous materials.

– Vacuum Lifters: Ideal for non-porous materials like glass and metal sheets.

By incorporating these accessories and custom upgrades, industrial jib cranes can be optimized for specific tasks, enhancing productivity and ensuring a safer workplace.

List Quality Control and The Manufacturing Process of “industrial jib crane”

Quality Control of Industrial Jib Crane

1. Design Verification: Ensure design meets specifications and safety standards.

2. Material Inspection: Verify quality and grade of raw materials.

3. Welding Inspection: Check welds for strength and conformity to standards.

4. Load Testing: Perform load tests to confirm crane can handle maximum rated capacities.

5. Dimensional Accuracy: Measure critical dimensions to ensure compliance with design.

6. Non-Destructive Testing (NDT): Conduct ultrasonic or radiographic inspection for internal flaws.

7. Surface Finish: Ensure proper coating and paint for corrosion resistance.

8. Final Assembly Inspection: Verify correct assembly and operation of all parts.

9. Documentation Audit: Review quality documents and certifications.

10. Compliance Check: Confirm adherence to industry regulations and safety standards.

Manufacturing Process of Industrial Jib Crane

1. Design and Engineering: Development of detailed engineering drawings and specifications using CAD software.

2. Material Procurement: Sourcing high-quality steel and other materials.

3. Cutting and Shaping: Cutting raw materials to required shapes and lengths using CNC machines.

4. Welding and Fabrication: Welding components together to form the main structure; includes both manual and robotic welding.

5. Machining and Assembly: Machining moving parts for precision and assembling them together.

6. Surface Treatment: Applying anti-corrosive coatings, paints, or galvanizing to the fabricated structure.

7. Electrical and Mechanical Integration: Installing electrical wiring, motors, and gears.

8. Quality Inspections: Conducting all stages of quality control including NDT, load testing, and dimensional accuracy checks.

9. Final Assembly: Assembling the crane, ensuring all mechanical and electrical systems are properly integrated.

10. Testing and Commissioning: Performing full operational tests and ensuring compliance with safety standards before commissioning the crane for use.

Careful adherence to quality control procedures throughout the manufacturing process ensures that industrial jib cranes are reliable, safe, and meet the necessary performance criteria.

How to use “industrial jib crane”

An industrial jib crane is a versatile piece of lifting equipment commonly used in manufacturing, warehouses, and construction sites. Here’s a concise guide on how to use it effectively and safely:

1. Pre-Use Inspection:

– Visual Check: Inspect the crane for any signs of damage or wear, especially on the jib arm, base, and hoist.

– Weight Capacity: Verify that the load does not exceed the jib crane’s weight capacity.

2. Setting Up:

– Positioning: Ensure the crane is securely mounted to the wall, floor, or pillar.

– Clear Area: Make sure the area around the crane is clear of obstructions.

3. Operating the Crane:

– Hoist Attachment: Securely attach the load to the hoist using appropriate slings or lifting devices.

– Lifting: Gradually lift the load using the hoist control, keeping it balanced and stable.

– Swinging the Arm: Gently swing the jib arm to position the load above the desired location.

– Lowering: Carefully lower the load to the ground or onto a platform, making sure it is stable before detaching.

4. Safety Considerations:

– No Overloading: Never exceed the crane’s maximum load capacity.

– Balanced Loads: Ensure the load is balanced and secure to prevent swinging or dropping.

– Clear Path: Keep the path of the load clear of personnel and obstacles.

– Emergency Stop: Be aware of the emergency stop button or mechanism on the control system.

– Training: Only trained and authorized personnel should operate the crane.

5. Maintenance:

– Regular Checks: Perform routine maintenance checks and lubrication as per the manufacturer’s guidelines.

– Report Issues: Immediately report any malfunctions or safety concerns.

By following these steps, you can ensure efficient and safe operation while minimizing risks associated with industrial jib cranes.

“industrial jib crane” Comparative Analysis

An industrial jib crane is an essential piece of lifting equipment in various sectors, including manufacturing, warehousing, and construction. This type of crane is characterized by a horizontal arm (jib) that supports a hoist and is either fixed or capable of rotating. Jib cranes are classified primarily into two types: wall-mounted and floor-mounted (free-standing). Below is a comparative analysis of these types:

Wall-Mounted Jib Cranes:

– Advantages:

– Space-Saving: Attach directly to a wall or other vertical supports, conserving valuable floor space.

– Cost-Efficient: Generally less expensive due to fewer materials and simpler installation.

– Installation: Less intrusive, requiring no foundation work.

– Disadvantages:

– Limited Swing: Typically offer a swing range up to 180 degrees, which may limit their utility in certain scenarios.

– Structural Dependence: Heavily reliant on the strength and stability of the supporting wall.

Free-Standing Jib Cranes:

– Advantages:

– Versatile Rotation: Capable of 360-degree rotation, providing a broader operational range.

– Independent Support: Standalone structure, making them suitable for open spaces where wall support isn’t available.

– Greater Load Capacity: Generally, can support heavier loads compared to wall-mounted versions.

– Disadvantages:

– Space Usage: Occupies floor space and may require a significant area for installation and operation.

– Higher Cost: More expensive due to the need for a robust foundation and additional materials.

– Complex Installation: Requires more intricate and costly installation procedures.

Summarized Comparison:

– Space Efficiency: Wall-mounted cranes are more space-efficient but limited in rotation and load capacity. In contrast, free-standing cranes offer higher operational flexibility but occupy more floor space.

– Cost Considerations: Wall-mounted cranes are typically more cost-effective but come with limitations on load capacity. Free-standing cranes, while more expensive, provide greater versatility and strength.

In conclusion, the selection between wall-mounted and free-standing jib cranes should be guided by specific operational requirements, space availability, load demands, and budget constraints. Each type offers distinct advantages and limitations, making them suitable for different industrial environments.

“industrial jib crane” Warranty and Support

When considering the purchase of an industrial jib crane, it’s crucial to understand the warranty and support options available to ensure a seamless and reliable operation. Most reputable manufacturers provide a comprehensive warranty that generally covers defects in materials and workmanship for a period ranging from one to five years. It’s advisable to confirm the specific terms, as these can vary widely. This warranty often includes the repair or replacement of defective parts but usually excludes normal wear and tear, misuse, or improper installation.

In addition to the warranty, robust customer support is a critical factor. Most manufacturers offer a range of support services including technical assistance, troubleshooting, and maintenance guidance. Support can be accessed through various channels such as phone, email, or online chat, ensuring quick and effective resolution of any issues.

Some manufacturers also have service agreements or extended warranty plans which can be purchased separately. These can cover preventive maintenance, emergency service, and even periodic inspections to ensure the jib crane remains in optimal working condition. It’s beneficial to inquire about the availability and cost of these services upfront.

Training is another vital aspect often provided by suppliers. Comprehensive training sessions for operators and maintenance staff can significantly enhance the longevity and efficiency of the jib crane.

Lastly, look for companies that offer a strong parts availability network. Quick access to genuine parts can minimize downtime and extend the life of your equipment.

In essence, a good warranty combined with strong support services and training ensures that your investment in an industrial jib crane is protected and remains productive throughout its lifespan.

List “industrial jib crane” FAQ

Certainly! Here are some frequently asked questions (FAQ) about industrial jib cranes:

1. What is an industrial jib crane?

– An industrial jib crane is a type of crane with a horizontal jib or boom that supports a movable hoist. It is typically mounted on a wall or floor and is used to lift and transport materials within a specific area.

2. Where are jib cranes commonly used?

– Jib cranes are commonly used in manufacturing facilities, warehouses, assembly lines, and docks where lifting and moving heavy objects is required within a limited work area.

3. What are the key components of a jib crane?

– The key components include the mast (or column), the jib arm, the hoist and trolley, and the base or mounting structure.

4. What are the different types of jib cranes?

– The main types include free-standing jib cranes, wall-mounted jib cranes, wall-traveling jib cranes, and mast-type jib cranes.

5. How much weight can a jib crane lift?

– The lifting capacity of jib cranes ranges from small models that handle a few hundred pounds to industrial types that can lift several tons, depending on design and specifications.

6. How far can a jib crane reach?

– The reach, or span, of a jib crane typically ranges from 5 to 20 feet, although custom models can offer longer reaches.

7. What considerations are important when selecting a jib crane?

– Key considerations include weight capacity, boom length, rotation angle, power requirements, and mounting options. Additionally, the working environment and specific job requirements should be assessed.

8. Can jib cranes rotate a full 360 degrees?

– Free-standing and mast-type jib cranes can often rotate 360 degrees, while wall-mounted systems typically have a 180 to 200-degree rotation, depending on design.

9. Are jib cranes easy to install?

– Installation complexity varies by type. Wall-mounted and floor-mounted cranes require secure mounting structures and may need professional installation to ensure safety and stability.

10. What maintenance is required for jib cranes?

– Regular inspections, lubrication of moving parts, checking for wear and tear, and ensuring the structural integrity are essential maintenance tasks.

11. Are there any safety guidelines for operating jib cranes?

– Yes, operators should be trained, follow load limits, inspect equipment before use, avoid side loading, and comply with OSHA and other regulatory standards.

This succinct FAQ provides a quick overview of industrial jib cranes, ensuring key points are addressed within the word limit.

Top 10 FAQ with answer about industrial jib crane for Buyer Sourcing from China

1. What is an industrial jib crane?

An industrial jib crane is a type of lifting device used to move heavy loads within a small radius. It typically consists of a horizontal boom attached to a vertical mast or wall, providing efficient lifting and rotating movements.

2. What capacities do jib cranes from China offer?

Chinese manufacturers typically offer jib cranes with lifting capacities ranging from 0.5 tons to 20 tons. Custom capacities can often be requested based on specific needs.

3. What types of jib cranes are available?

Common types include freestanding, wall-mounted, and mast-style jib cranes. Each type is suited to different installation environments and operational requirements.

4. What are the key features to look for?

Important features include load capacity, boom length, rotation range (manual or motorized), installation type, and material quality. Additionally, compliance with international safety standards is crucial.

5. What materials are typically used in manufacturing?

High-quality steel is the primary material used in the construction of jib cranes, ensuring durability and strength. Some models may also incorporate aluminum for lighter applications.

6. How long is the delivery time?

Delivery times can vary but generally range from 20 to 60 days depending on the complexity of the crane and the manufacturer’s current order backlog. Always confirm with the supplier.

7. Can these cranes be customized?

Yes, many Chinese manufacturers offer customization options including boom length, rotation range, and load capacity to better match specific operational needs.

8. What is the typical warranty period?

The standard warranty period for industrial jib cranes from China is usually 12 to 24 months. Extended warranties may be available for an additional cost.

9. How do I ensure the quality of the crane?

Request detailed product specifications, quality certifications (such as ISO), and customer references. Pre-shipment inspections and third-party quality assurance services can also be valuable.

10. What are the shipping terms and costs?

Shipping terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) are commonly used. Shipping costs will depend on the crane’s size, weight, and destination. Be sure to discuss and confirm these terms with the supplier.

By addressing these frequently asked questions, buyers can make informed decisions when sourcing industrial jib cranes from China.