jib crane 2 ton Safety Certifications

To ensure the safe operation of a 2-ton jib crane, it’s essential to adhere to specific safety certifications and guidelines. Here are some critical safety certifications and regulations to consider:

1. OSHA (Occupational Safety and Health Administration): OSHA 29 CFR 1910.179 covers overhead and gantry cranes, which include jib cranes. Ensuring compliance with OSHA standards involves regular inspections, proper training for operators, and implementing safety protocols.

2. ASME (American Society of Mechanical Engineers): ASME B30.2 and ASME B30.16 provide safety standards for overhead and underhung cranes, including jib cranes. These standards address construction, installation, operation, and maintenance to ensure safe use.

3. ANSI (American National Standards Institute): ANSI B30.20 provides additional guidelines for below-the-hook lifting devices often used with jib cranes, addressing their design, inspection, and use.

4. CMAA (Crane Manufacturers Association of America): CMAA Specification No. 74 outlines performance standards for cranes, including design, manufacturing, and testing procedures to ensure durability and safety.

5. ISO (International Organization for Standardization): ISO 9927-1 and ISO 4309 cover the inspection, maintenance, and discard criteria for cranes and lifting appliances, ensuring globally recognized safety benchmarks.

6. Frequent Inspections: Regular checks are imperative to look for wear and tear, especially on critical components such as the hoist, jib arm, and the base.

7. Load Testing: Conduct load tests periodically as per ANSI and ASME guidelines to ensure that the jib crane can safely lift its rated capacity.

8. Training: Operators must be thoroughly trained and certified in safe lifting practices, understanding the crane’s operation, load limits, and emergency procedures.

By adhering to these standards and practices, you ensure a safe working environment, minimize the risk of accidents, and comply with mandatory safety regulations for operating a 2-ton jib crane.

List Reference Technical Parameters of “jib crane 2 ton”

A jib crane with a 2-ton capacity (equivalent to 2000 kg) has various technical parameters that are essential for its selection, installation, and operation. These parameters ensure that the crane meets the necessary safety standards and performance requirements for lifting and moving loads. Here is a list of the reference technical parameters:

1. Capacity: 2 tons (2000 kg).

2. Jib Length (Span): The distance from the supporting structure to the end of the jib arm, typically ranging between 2-6 meters but can vary based on design.

3. Height Under Boom: The vertical distance from the floor to the underside of the jib arm, which usually varies from 2 to 10 meters.

4. Boom Rotation: Can range from 180 degrees to 360 degrees, depending on whether it is wall-mounted or floor-mounted.

5. Type of Mounting:

– Wall-Mounted: Affixed to a wall or building column.

– Floor-Mounted (Free-Standing): Bolted to a concrete foundation.

– Mast-Style (Foundationless): Requires no foundation and supports itself.

6. Working Environment: Indoor or outdoor use, which affects material and coating, such as powder-coating for indoor use or galvanized/painted for outdoor use.

7. Hoist Type:

– Manual Chain Hoist: Operated by hand.

– Electric Chain Hoist: Powered by electricity.

– Wire Rope Hoist: Allows for smooth and fast lifting.

8. Power Supply: Typically 3-phase, 230V, 380V, or 460V, dependent on the hoist type.

9. Travelling Speed: For electric hoists, travel speed varies, commonly between 0.5 to 10 meters per minute.

10. Control System:

– Pendant Control: Hand-operated control.

– Wireless Remote: Remote-operated control.

11. Safety Features: Overload protection, emergency stop, limit switches, etc.

12. Material: High-strength steel or aluminum for the jib and structural components.

13. Design Standards: Compliance with relevant standards (e.g., ASME, OSHA, CE) for safety and performance.

Each parameter plays a critical role in the performance and suitability of the jib crane for specific applications.

List Product features of “jib crane 2 ton”

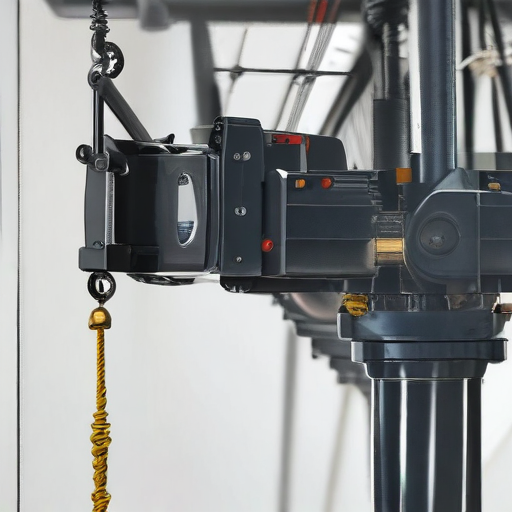

A jib crane is an essential piece of equipment in many industrial and manufacturing environments, offering versatile and reliable lifting solutions. Here are some key product features of a 2-ton jib crane:

1. Load Capacity:

– Designed to lift and handle loads up to 2 tons (4,000 lbs).

2. Arm Length:

– Typically features a jib arm that can range from 10 to 20 feet, with variations possible depending on specific models.

3. Rotation:

– Offers 180° to 360° rotation, depending on whether it’s a wall-mounted or freestanding model.

4. Construction Material:

– Often constructed from high-grade steel, providing durability and strength.

5. Mounting Options:

– Available in both wall-mounted and freestanding pedestal models, catering to various spatial and operational needs.

6. Hoist Mechanism:

– Equipped with either manual, electric, or pneumatic hoists, depending on the required application.

7. Ease of Use:

– User-friendly controls, ensuring safe and efficient operation with minimum training.

8. Adjustable Boom:

– Some models feature an adjustable boom for added flexibility in lifting operations.

9. Safety Features:

– Incorporates safety mechanisms such as overload protection, emergency stop buttons, and sometimes integrated limit switches to prevent damage.

10. Versatile Applications:

– Suitable for diverse industries including automotive, aerospace, warehousing, and general manufacturing.

11. Installation:

– Typically designed for straightforward installation, with minimal disruption to ongoing operations.

12. Maintenance:

– Built for durability with components that are easy to access for routine maintenance and inspections.

13. Customization:

– Many manufacturers offer customization options to meet specific lifting requirements or spatial constraints.

14. Compliance:

– Conforms to industry standards and safety regulations (e.g., ASME, OSHA).

15. Accessories:

– Compatible with various accessories like trolleys, hooks, and spreader beams to enhance functionality.

These features collectively make the 2-ton jib crane a reliable and effective solution for heavy lifting and material handling tasks in numerous industrial settings.

List Various Types of “jib crane 2 ton”

A “jib crane 2 ton” is a versatile lifting device designed to handle relatively light loads with a capacity of up to 2 tons. Below are various types of 2-ton jib cranes:

1. Freestanding Jib Crane: Offers flexibility in location since it can be installed anywhere on the plant floor. It usually comes with a large base plate secured to a concrete foundation.

2. Wall-Mounted Jib Crane: This type is mounted directly onto a wall or existing vertical structure, saving floor space. It’s ideal for areas with height restrictions.

3. Mast-Type Jib Crane: These are supported at the floor and top ceiling without requiring a foundational base, providing a middle ground between freestanding and wall-mounted options.

4. Articulating Jib Crane: Features an arm with one or more pivot points, allowing for a wider range of motion and the ability to maneuver around obstacles.

5. Cantilever Jib Crane: This type has its boom mounted either to a vertical column or a wall and extends outwards, providing considerable reach and height.

6. Wall Bracket Jib Crane: Similar to wall-mounted types but uses wall brackets for additional support, allowing for greater load capacity and reach.

7. Overbraced Jib Crane: The boom is supported on top, reducing deflection and increasing stability. Suitable for heavier and more frequent use.

8. Underbraced Jib Crane: Has a support brace below the boom, often used when overhead obstructions exist, limiting installation height.

Each type offers unique advantages making them suitable for different applications and environments. When selecting a jib crane, considerations such as floor space, operational flexibility, and the nature of the load and workspace are essential.

List Application of “jib crane 2 ton”

Jib cranes, particularly those with a 2-ton lifting capacity, are versatile and widely used in various industries to facilitate the lifting and maneuvering of heavy loads. Here are some common applications:

1. Manufacturing Plants: Jib cranes assist in the assembly process by moving heavy components between workstations. They are instrumental in lifting machinery parts, aiding in both fabrication and assembly.

2. Warehousing and Distribution: In warehouses, jib cranes help in loading and unloading materials from trucks, organizing inventory, and placing heavy items onto storage racks. This streamlines operations and improves efficiency.

3. Marine and Shipyards: Jib cranes handle heavy components such as boat engines, propellers, and other large equipment used in shipbuilding and maintenance tasks. They are essential for effective loading and unloading at docks.

4. Automotive Industry: Within the automotive industry, jib cranes are used to lift engines, car bodies, and heavy auto parts. This aids in the manufacturing and maintenance processes, ensuring safe and efficient handling of heavy components.

5. Construction Sites: On construction sites, jib cranes are deployed to lift construction materials, tools, and equipment to various heights and locations. They are vital for managing construction tasks in confined spaces.

6. Machining and Tool Rooms: In machine shops, jib cranes help in lifting and positioning heavy machine parts and tools. They contribute to precision and safety in machining operations, reducing manual handling risks.

7. Foundries and Metal Works: Jib cranes facilitate the movement of heavy molds, castings, and metal rods, playing a significant role in the foundry operations. They improve workflow efficiency and reduce manual labor.

8. Aerospace Industry: Jib cranes assist in handling delicate and heavy aerospace components. They ensure precise movement and placement of parts during the assembly and maintenance of aircraft.

9. Small Workshops and Garages: In smaller settings, jib cranes are utilized for lifting engines, transmissions, and other heavy tools, enhancing work safety and reducing manual strain.

Jib cranes with a 2-ton capacity provide essential support across many industries, enhancing productivity, safety, and operational efficiency by enabling effective handling of heavy loads.

List Buyer Types of “jib crane 2 ton”

When it comes to purchasing a 2-ton jib crane, buyers generally fall into several distinct categories based on their specific needs and applications. Below is a succinct overview of the primary buyer types for a 2-ton jib crane:

1. Industrial Manufacturers:

– Description: These buyers typically operate in sectors like automotive, aerospace, machinery, and manufacturing.

– Needs: They require efficient material handling solutions to improve productivity and safety in their operations.

2. Warehousing and Logistics Companies:

– Description: Companies involved in storage, distribution, and transportation of goods.

– Needs: These buyers need jib cranes for loading and unloading trucks, positioning materials, and other handling tasks within their warehouses.

3. Construction Companies:

– Description: Firms engaged in building infrastructure, commercial buildings, and other significant projects.

– Needs: Heavy lifting machinery like jib cranes is crucial for moving construction materials and equipment on site.

4. Marine and Shipyard Operators:

– Description: Businesses that build, repair, and maintain ships and other marine vessels.

– Needs: Jib cranes are essential for handling heavy loads such as engines, components, and other ship parts.

5. Utility and Infrastructure Companies:

– Description: Organizations involved in utilities like water, electricity, and telecommunications.

– Needs: These companies may use jib cranes for the installation and maintenance of utility poles, cables, and other heavy infrastructure components.

6. Maintenance and Repair Shops:

– Description: Workshops that specialize in the repair and maintenance of large equipment and machinery.

– Needs: A jib crane can facilitate the lifting and positioning of heavy parts and machinery during repairs and maintenance tasks.

7. Individual Contractors:

– Description: Independent contractors or small businesses specializing in heavy lifting jobs or specific sectors requiring such equipment.

– Needs: They invest in jib cranes to improve efficiency and expand their service offerings.

Each of these buyer types has distinct needs that a 2-ton jib crane can fulfill, making it a versatile piece of equipment across various industries.

List “jib crane 2 ton” Project Types for Different Industries

Jib cranes, particularly those with a 2-ton lifting capacity, are versatile tools used across various industries for their efficiency in material handling. Here are some project types in different industries where 2-ton jib cranes play a crucial role:

1. Manufacturing Industry:

– Assembly Lines: Used to lift and position heavy components.

– Machine Maintenance: Facilitates the removal and installation of large machine parts.

– Material Handling: Transports raw materials and finished products within the facility.

2. Construction Industry:

– Building Sites: Lifts heavy construction materials like steel beams and concrete blocks to appropriate heights.

– Plant Setup: Assists in the installation of heavy equipment and machinery during plant construction or renovation.

3. Warehousing and Logistics:

– Loading and Unloading: Helps in efficiently moving heavy goods from trucks to storage areas.

– Inventory Management: Assists in organizing and stacking bulky items in warehouses.

4. Automotive Industry:

– Vehicle Assembly: Supports the installation of heavy components such as engines and transmissions.

– Repair and Maintenance: Lifts cars, parts, or machinery for repair tasks or regular maintenance.

5. Marine Industry:

– Shipbuilding: Facilitates the handling of large components like engines, propellers, and other heavy parts.

– Port Operations: Assists in loading and unloading cargo from ships.

6. Mining Industry:

– Equipment Maintenance: Used in the maintenance and repair of heavy mining equipment.

– Material Handling: Carries out tasks such as moving ore bags and other heavy mining materials.

7. Energy Sector:

– Wind Turbine Maintenance: Assists in lifting and installing turbine components.

– Oil and Gas: Helps in the assembly, maintenance, and repair of drilling equipment and machinery.

Each of these applications maximizes the potential of a 2-ton jib crane, improving operational efficiency and safety across diverse industries.

jib crane 2 ton Accessories Upgrades and Custom Manufacturing Options

A jib crane is a versatile piece of lifting equipment used across various industries. For a 2-ton jib crane, several accessories, upgrades, and custom manufacturing options can enhance its performance, safety, and usability.

Accessories:

1. Electric Hoists: These provide efficient and effortless lifting, replacing manual operation.

2. Motorized Rotation Mechanisms: Facilitate easier and smoother crane movement.

3. Variable Frequency Drives (VFDs): Allow for controlled and variable lifting speeds.

4. Remote Controls: Offer safe and convenient operation from a distance.

5. End Stops and Bumpers: Prevent overtravel and collisions, enhancing safety.

6. Festoon Systems: Organize and protect electrical cables or pneumatic lines.

Upgrades:

1. Increased Span and Height: Customized to meet specific operational needs.

2. Enhanced Corrosion Resistance: Ideal for harsh environments, using materials like stainless steel or specialized coatings.

3. Load Indicators and Monitoring Systems: Real-time tracking of load weight and crane performance.

4. Enhanced Ergonomics: Adjustable handles and controls to make operation more comfortable.

5. Safety Upgrades: Advanced limit switches and emergency stop mechanisms.

Custom Manufacturing Options:

1. Tailored Boom Lengths: Specific to the workspace, ensuring optimal reach.

2. Foundation-Free Systems: For facilities where installing a foundation isn’t feasible.

3. Custom Paint and Finish: To match corporate colors or meet safety standards.

4. Special Load Attachments: Custom hooks, clamps, or lifting devices for unique loads.

5. 360° Rotation: Full-circle rotation capabilities for maximum flexibility in confined spaces.

6. Environmental Customization: Design modifications for extreme temperatures or cleanroom specifications.

These enhancements ensure that a 2-ton jib crane operates efficiently and safely, meeting the specific demands of different environments and applications.

List Quality Control and The Manufacturing Process of “jib crane 2 ton”

Quality Control of Jib Crane 2 Ton

1. Material Inspection:

– Ensure raw materials meet ASTM standards.

– Conduct tensile strength, hardness, and chemical composition tests.

2. Welding Quality:

– Verify weld joints through visual inspection and NDT methods (Ultrasonic, X-ray).

– Certify welders and maintain welding logs.

3. Machining Accuracy:

– Inspect machined parts with precision instruments (micrometers, calipers).

– Maintain tight tolerances as specified in design documents.

4. Load Testing:

– Conduct static and dynamic load tests at 125% of rated capacity (2.5 tons).

– Verify stability, deformation, and mechanical integrity.

5. Paint and Coating:

– Inspect surface preparation and coating thickness.

– Ensure compliance with anti-corrosion standards.

6. Assembly Inspection:

– Verify alignment and fit of components.

– Ensure operational checks like rotation, lift, and travel mechanisms.

7. Documentation and Certification:

– Maintain records of all inspections, tests, and certifications.

– Provide customers with quality assurance documents and manuals.

Manufacturing Process of Jib Crane 2 Ton

1. Design and Engineering:

– Develop CAD models and engineering drawings.

– Perform finite element analysis (FEA) for stress and load distribution.

2. Material Procurement:

– Source high-quality steel, motors, and components from certified suppliers.

– Ensure materials meet design specifications.

3. Cutting and Shaping:

– Use CNC machines, plasma cutters, or laser cutters for precision.

– Prepare beams, columns, and baseplates to required dimensions.

4. Welding and Fabrication:

– Assemble components using MIG/TIG welding techniques.

– Create sub-assemblies such as the boom, base, and mounting brackets.

5. Machining Operations:

– Perform drilling, tapping, and milling on sub-assemblies.

– Ensure critical dimensions and tolerances are maintained.

6. Surface Preparation:

– Clean, sandblast, and prepare surfaces.

– Apply primer and topcoat as per anti-corrosion standards.

7. Assembly:

– Assemble major components including the jib arm, hoist, and trolley.

– Integrate electrical and mechanical systems.

8. Testing and Inspection:

– Perform load and functional tests.

– Inspect for alignment, rotation, and lifting capabilities.

How to use “jib crane 2 ton”

A jib crane is a versatile piece of lifting equipment commonly used in industrial settings. Here’s a step-by-step guide on how to operate a 2-ton jib crane:

1. Inspection: Before using the crane, perform a thorough inspection. Check for any signs of wear, damage, or malfunction in the crane’s structure, hoist, and controls.

2. Load Assessment: Determine the weight of the load to ensure it does not exceed the 2-ton capacity of the crane.

3. Clear the Area: Ensure the work area is clear of obstructions and personnel who are not involved in the lifting operation.

4. Secure the Load: Attach the load securely using appropriate lifting slings or chains. Ensure the load is balanced to prevent swaying or tipping.

5. Hoist Controls: Familiarize yourself with the crane’s controls. Most jib cranes have a simple control panel for lifting, lowering, and horizontal movement.

6. Lifting the Load: Gradually lift the load a few inches to test stability. Ensure it is securely attached and balanced before lifting it to the desired height.

7. Moving the Load: Use the jib crane’s arm to move the load horizontally to the desired location. Move slowly to maintain control and ensure safety.

8. Lowering the Load: Once in position, carefully lower the load into place. Double-check that the area beneath the load is clear.

9. Detaching the Load: Once the load is safely lowered, detach the lifting slings or chains.

10. After Use: After completing the lift, return the crane to its starting position and perform a quick inspection to ensure there are no new signs of wear or damage.

11. Documentation: Record the operation details, including any issues encountered and maintenance performed, for future reference.

Safety first! Always follow the manufacturer’s guidelines and consult the user manual specific to your jib crane model.

“jib crane 2 ton” Comparative Analysis

When evaluating 2-ton jib cranes, several key factors should be considered, including type, range of motion, materials, ease of installation, and cost. Here’s a comparative analysis of three popular choices: Freestanding, Wall-mounted, and Mast-style jib cranes.

Freestanding Jib Cranes

Pros:

– Versatility: Freestanding jib cranes offer a full 360-degree rotation, providing maximum flexibility in materials handling.

– Capacity: They can handle heavy loads efficiently up to 2 tons.

– Flexible Installation: Can be installed virtually anywhere, as they do not depend on existing structures.

Cons:

– Complex Installation: Requires a reinforced foundation, which can increase installation time and costs.

– Space Requirements: Occupies floor space which might be a drawback in crowded workspaces.

Wall-mounted Jib Cranes

Pros:

– Space-saving: Since they are mounted on the wall or an existing column, they save valuable floor space.

– Affordable Installation: Installation tends to be easier and cheaper than freestanding models, as no dedicated foundation is needed.

– Efficiency: Ideal for localized workstations, offering up to 180 degrees of rotation.

Cons:

– Limited Range: Restricted to semi-circular or limited area coverage due to mounting constraints.

– Structural Dependency: Requires a robust wall or structural column for mounting, which might not be available in all facilities.

Mast-style Jib Cranes

Pros:

– Cost-effective: Typically less expensive than freestanding models while offering similar functionalities.

– Compact Design: Takes less space than freestanding cranes, requiring only a small concrete floor foundation.

– Stability: Often more stable than wall-mounted versions, with nearly 360-degree coverage.

Cons:

– Moderate Installation: More complex than wall-mounted but less so than freestanding versions.

– Range of Motion: Slightly less flexible in comparison to freestanding cranes due to reliance on supporting structures.

Conclusion

The choice between freestanding, wall-mounted, and mast-style jib cranes depends on the specific requirements of your application. Freestanding cranes offer maximum flexibility but at a higher cost and space requirement. Wall-mounted cranes are ideal for confined spaces and localized tasks but offer limited range. Mast-style jib cranes present a balanced option, providing good reach and stability without substantial floor space consumption.

“jib crane 2 ton” Warranty and Support

When purchasing a 2-ton jib crane, it is essential to consider warranty and support to ensure long-term functionality and reliability. Most reputable manufacturers provide a standard warranty covering a period ranging from 1 to 5 years, depending on the brand and model. This warranty typically covers defects in materials and workmanship. However, it’s crucial to read the fine print; some warranties exclude regular wear and tear, misuse, or improper installation.

Support services are equally important and often include technical assistance, spare parts availability, and routine maintenance guidelines. Manufacturers usually offer customer support through multiple channels such as phone, email, and live chat. Some companies provide on-site support and training to ensure proper installation and safe operation. Additionally, many manufacturers offer service packages that include regular inspections and preventative maintenance to extend the equipment’s lifespan.

Extended warranties and service contracts are often available for an additional cost. These can be particularly beneficial in minimizing downtime and unforeseen expenses. Ensure the manufacturer or supplier has a robust support network, preferably with local service centers or authorized dealers who can provide prompt assistance.

Customer reviews can be a valuable resource for gauging the effectiveness of a manufacturer’s warranty and support services. Look for reviews that highlight quick response times and effective problem resolution.

In summary, before purchasing a 2-ton jib crane, thoroughly investigate the warranty terms and available support services. A strong warranty and reliable customer support can provide peace of mind and ensure that your jib crane remains operational and efficient for years to come.

List “jib crane 2 ton” FAQ

Jib Crane 2 Ton: Frequently Asked Questions (FAQs)

1. What is a jib crane?

A jib crane is a type of crane featuring a horizontal arm (jib or boom) that supports a movable hoist, fixed on a wall or a floor-mounted pillar. It is used to lift, lower, and move heavy loads.

2. What are the typical applications of a 2-ton jib crane?

It is commonly used in manufacturing, warehouses, workshops, and construction sites to handle materials, load and unload heavy parts, and position machinery.

3. How is a jib crane mounted?

Jib cranes can be floor-mounted (pillar or free-standing), wall-mounted, or column-mounted. The choice depends on the installation environment and load requirements.

4. What is the maximum load a 2-ton jib crane can carry?

As the name suggests, it can carry a maximum load of 2 tons (4,000 pounds). It’s crucial not to exceed this limit to ensure safety and longevity.

5. What factors should I consider when selecting a jib crane?

Consider the load capacity, height and span of the jib arm, rotation needed (typically 180 to 360 degrees), installation location, and type of mounting.

6. What is the typical rotation angle of a jib crane?

Jib cranes can usually rotate up to 180, 270, or even full 360 degrees, depending on the design and mounting.

7. How much space is needed for installing a 2-ton jib crane?

The space requirement depends on the crane’s dimensions, including boom length and height. Ensure sufficient clearance for full rotation and operation.

8. What are the maintenance requirements?

Regular inspection and maintenance include checking bolts, wear on the hoist, lubrication of moving parts, and ensuring structural integrity.

9. Are there any safety guidelines?

Always follow the manufacturer’s guidelines, conduct regular safety inspections, ensure operator training, and use appropriate personal protective equipment (PPE).

10. Can a jib crane be customized?

Yes, many manufacturers offer customization options to meet specific operational requirements, including different boom lengths, heights, and rotation capacities.

By understanding these FAQs, operators and buyers can make informed decisions regarding the purchase, installation, and maintenance of a 2-ton jib crane.

Top 10 FAQ with answer about jib crane 2 ton for Buyer Sourcing from China

Top 10 FAQ About Sourcing a 2-Ton Jib Crane from China

1. What is a jib crane and how is it used?

A jib crane is designed with a rotating horizontal arm for lifting and moving materials within a confined workspace. It’s ideal for workshops, warehouses, and production lines.

2. What makes a 2-ton jib crane suitable for my needs?

A 2-ton lifting capacity is suitable for handling moderate loads typically encountered in manufacturing, assembly, and repair facilities. Evaluate your maximum lifting needs to ensure this capacity suffices.

3. Are Chinese manufacturers reliable for sourcing jib cranes?

Yes, many Chinese manufacturers offer high-quality jib cranes at competitive prices. Research and select reputable suppliers with positive customer reviews and compliance with international standards.

4. What standards should the jib crane comply with?

Ensure that the crane complies with international safety and quality standards such as ISO, CE, or ANSI. This guarantees safety and reliability in operation.

5. How do I verify the quality of a jib crane from a Chinese supplier?

Request product certifications, conduct factory audits (if possible), and ask for references from previous clients. Some suppliers may also provide video demonstrations or third-party inspection services.

6. What are the options for installation and maintenance?

Installation options include self-assembly with provided manuals or professional installation services by the supplier. For maintenance, check if the supplier offers after-sales services or spare parts supply.

7. What is the average lead time for delivery?

Lead times can vary depending on the supplier’s production schedules and shipping logistics. Typically, expect a lead time of 4-8 weeks from order confirmation to delivery.

8. What are the shipping considerations when importing from China?

Consider shipping methods (sea or air), customs duties, and port handling charges. Work with freight forwarders for smoother logistics and compliance with import regulations.

9. How is the payment process typically handled?

Common payment terms include T/T (telegraphic transfer), L/C (letter of credit), and sometimes escrow services. Typically, suppliers request a deposit before production with the balance paid before shipment.

10. What if I encounter issues after purchase?

Check the supplier’s warranty and support policies. Good suppliers offer after-sales support, including maintenance guidance and parts replacement. Ensure clear communication channels for timely resolution of any issues.

These FAQs should help you navigate the process of sourcing a 2-ton jib crane from China, ensuring you make an informed purchasing decision.