jib crane floor mounted Safety Certifications

Floor-mounted jib cranes are essential lifting devices used in various industries, including manufacturing, warehousing, and construction. Ensuring the safety and reliability of these cranes is paramount, and achieving relevant safety certifications is a crucial part of this process. Key safety certifications and standards for floor-mounted jib cranes include:

1. OSHA (Occupational Safety and Health Administration):

– OSHA sets forth regulations aimed at minimizing workplace hazards. For jib cranes, compliance with OSHA standards, particularly those outlined in OSHA 1910.179 (Overhead and Gantry Cranes), is essential.

2. ANSI/ASME (American National Standards Institute / American Society of Mechanical Engineers):

– ASME B30.11 specifically addresses monorails and underhung cranes, including jib cranes. It provides detailed safety requirements regarding construction, installation, operation, inspection, and maintenance.

3. FEM (Fédération Européenne de la Manutention):

– European-based, FEM standards offer guidelines on the safe design, operation, and maintenance of lifting equipment. These standards are particularly relevant for cranes used within Europe.

4. ISO (International Organization for Standardization):

– ISO 9001 certification ensures that the manufacturer adheres to strict quality management systems. For jib cranes, ISO 4301-5:1991 details classifications for cranes and lifting appliances.

5. CE (Conformité Européenne) Marking:

– For cranes used in the European Economic Area, the CE mark is mandatory, indicating compliance with European safety, health, and environmental protection standards.

Obtaining these certifications involves rigorous testing and inspection to ensure that the jib crane meets all necessary safety and performance criteria. Regular inspections, compliance with maintenance schedules, and employee training are equally critical to maintaining the crane’s safety throughout its lifecycle. Employing certified jib cranes not only enhances workplace safety but also boosts operational efficiency and reliability.

List Reference Technical Parameters of “jib crane floor mounted”

Sure! Here are the reference technical parameters for a floor-mounted jib crane:

1. Load Capacity:

– Ranging from 0.5 tons to 5 tons, depending on the model and design.

2. Jib Arm Length (Span):

– Typically between 2 meters to 7 meters.

3. Height Under Boom:

– Standard heights range from 2 meters to 5 meters.

4. Slewing Range:

– Can be 180°, 270°, or 360°; depends on the design and installation environment.

5. Slewing Mechanism:

– Manual or motorized, depending on the model and operational requirements.

6. Rotation Speed:

– For motorized slewing, rotation speeds usually vary from 0.5 to 2 RPM.

7. Hoist Type:

– Options for electric wire rope hoists, chain hoists, or manual hoists.

8. Power Supply:

– Standard power supply is 220V/240V single-phase or 380V/415V three-phase, 50/60 Hz.

9. Hoisting Speed:

– Variable speeds based on the hoist type, typically from 5 meters/min to 20 meters/min.

10. Traveling Speed:

– If equipped with an electric trolley, speeds range from 10 to 20 meters/min.

11. Column Height:

– Adjusted based on the specific application, could range from 3 meters to 10 meters.

12. Base Plate Dimensions:

– Varies with the crane size but generally measured in terms of length, width, and thickness sufficing structural stability.

13. Foundation Requirements:

– Requires a concrete foundation, often specified by the manufacturer for adequate support.

14. Control Mechanism:

– Push-button pendant, radio remote control, or control panels, ensuring ergonomic operation.

15. Safety Features:

– Including overload protection, emergency stop, limit switches, and emergency braking.

16. Material and Coating:

– Typically made from high-grade steel with anti-corrosive coatings or finishes for durability.

These parameters could vary based on specific manufacturer designs and customer requirements. It’s essential to consult technical datasheets or specialists for precise specifications tailored to your application’s needs.

List Product features of “jib crane floor mounted”

A floor-mounted jib crane is an essential piece of equipment for various industrial and construction applications. Here are some key features:

1. 360-Degree Rotation: Offers full radial coverage, allowing for maximum flexibility and reach within the work area.

2. Robust Construction: Made from high-quality steel or durable materials, ensuring longevity and reliability under heavy-duty use.

3. Adjustable Boom: Some models offer adjustable boom lengths and heights, providing versatility for different tasks and spatial constraints.

4. High Load Capacity: Can handle a wide range of weights, typically from a few hundred pounds to several tons, depending on the model.

5. Easy Installation: Designed for straightforward installation, either bolted to a concrete floor or mounted on a foundation for stability.

6. Safety Features: Includes safety stops, overload protection, and optional galvanization for resistance to corrosion and harsh environments.

7. Versatile Mounting Options: Available in various configurations, including wall-mounted and mast-mounted, to suit diverse application needs.

8. Manual or Motorized Operation: Some models offer manual operation for simple tasks, while others are motorized for more efficient and effortless lifting.

9. Height Adjustability: Certain models allow for height adjustments to accommodate different operational requirements and improve accessibility.

10. Compact Design: Efficient use of space, ideal for crowded or limited floor spaces.

11. Ease of Maintenance: Simplified design for easy maintenance and reduced downtime, with accessible components for quick repairs.

12. Customization Options: Available with various attachments, like hooks, lifting magnets, or vacuum lifters, to suit specific lifting needs.

13. Enhanced Mobility: Some models include swivel features or telescoping booms to extend the operational range without moving the base.

14. Compliance with Standards: Meets industry standards and safety regulations to ensure safe and reliable operation.

List Application of “jib crane floor mounted”

A jib crane floor mounted boasts a variety of applications across multiple industries owing to its versatility and effectiveness in material handling. Here are some key applications:

1. Manufacturing: Used to hoist and maneuver heavy components on assembly lines, enhancing efficiency in production processes.

2. Warehousing and Distribution: Facilitates the movement and stacking of bulky items, improving storage logistics and inventory management.

3. Construction Sites: Assists in lifting and placing construction materials like steel beams, concrete blocks, and other heavy items at specific points on the site.

4. Maintenance and Repair Workshops: Supports technicians by lifting engines, gearboxes, and other heavy machinery parts during repair and maintenance tasks.

5. Marine Industry: Employed in shipyards for loading and unloading cargo, and for installing components such as engines and equipment onboard vessels.

6. Automotive Industry: Crucial in car manufacturing plants for tasks such as the installation of engines, car bodies, and other heavy components.

7. Energy Sector: Utilized in power plants and renewable energy facilities for handling heavy equipment, such as turbines, generators, and solar panels.

8. Mining: Plays a role in moving heavy mining equipment and ores, facilitating smoother and safer operations.

9. Railways: Helps in the assembly, maintenance, and repair of train components, including engines and bogies.

10. Chemical and Pharmaceutical: Assists in handling large reactors, mixing drums, and other heavy equipment, ensuring safety and precision in positioning.

11. Food and Beverage: Used for lifting heavy raw material containers and placing food processing machinery.

The floor-mounted design ensures stability and can handle significant weights, offering a safe and controlled lifting mechanism suitable for repetitive and precise tasks. Whether in industrial environments or maintenance facilities, a jib crane floor mounted significantly enhances operational efficiency and safety.

List Various Types of “jib crane floor mounted”

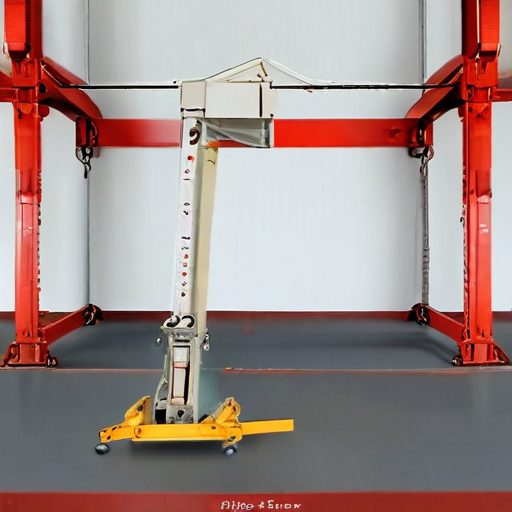

A floor-mounted jib crane is a versatile lifting device commonly used in manufacturing, warehousing, and construction settings. Here’s a brief overview of various types of floor-mounted jib cranes:

1. Free-Standing Jib Crane

– Description: Self-supporting and bolted to the floor using a base plate and anchor bolts.

– Capacity: Typically ranges from 1 to 10 tons.

– Benefits: Offers a full 360-degree rotation and is highly adaptable to different work areas.

2. Mast Type Jib Crane

– Description: Uses both the floor and an overhead support structure for installation.

– Capacity: Generally up to 10 tons.

– Benefits: Provides 360-degree rotation with less floor space footprint compared to a free-standing crane.

3. Articulating Jib Crane

– Description: Features two swivel arms, allowing for more flexible positioning and precise load placement.

– Capacity: Varies but usually falls in the same range as other jib cranes.

– Benefits: Excellent for navigating around corners or obstacles and reaching into confined spaces.

4. Wall-Mounted Jib Crane with a Floor Base

– Description: Typically mounted on a pillar or column, using the floor for additional support.

– Capacity: Up to 5 tons.

– Benefits: Saves floor space by utilizing existing structural columns but still provides robust lifting solutions.

5. Foundationless Jib Crane

– Description: Designed to be bolted directly to an existing, reinforced concrete floor without the need for a separate foundation.

– Capacity: Limited to lighter loads, generally up to 1 ton.

– Benefits: Easier to install and relocate, making it suitable for flexible or temporary setups.

6. Portable Jib Crane

– Description: Mounted on a mobile base that can be moved around a workspace.

– Capacity: Generally lower, often up to 1 ton.

– Benefits: Offers mobility and flexibility for different tasks and locations within a facility.

Each type of floor-mounted jib crane has its own set of advantages, suitability for specific tasks, and load capacities, allowing for customized solutions to a variety of material handling needs.

jib crane floor mounted Accessories Upgrades and Custom Manufacturing Options

Jib cranes are versatile lifting solutions commonly used in various industries for their efficiency and flexibility. Floor-mounted jib cranes can be customized and accessorized to suit specific operational needs. Here are some key accessories, upgrades, and custom manufacturing options:

1. Hoists and Trolleys: Upgrading your jib crane with electric or manual hoists enhances lifting efficiency. Motorized trolleys can provide smooth, effortless movement along the jib arm.

2. Rotation Stops: These allow for controlled movement by limiting the jib crane’s rotation, enhancing safety, and preventing over-rotation.

3. Variable Speed Controls: Adding variable speed drives for hoists and trolleys can provide precise control over lifting and positioning tasks.

4. Extended Reach and Height: Custom manufacturing can increase the jib arm’s length or height to cover larger work areas and accommodate different building heights.

5. Boom Extensions and Articulating Arms: These enhance reach and flexibility, allowing the crane to navigate obstacles and perform complex movements.

6. Alignment Rails: Installing alignment rails ensures the trolley moves in a straight path, reducing wear and tear on components.

7. Anti-Collision Devices: These ensure the crane operates safely in environments where multiple cranes or other equipment are in use, avoiding accidents and damage.

8. Weather-Proofing and Coatings: For outdoor applications, protective coatings against rust and extreme weather conditions are crucial. Options include galvanization and specialized paints.

9. Remote Controls: Enhancing operator safety and convenience, wireless remote controls allow the crane to be operated from a safe distance.

10. Load Indicators and Safety Alarms: Real-time load monitoring systems and safety alarms can prevent overloading and enhance operational safety.

11. Lighting and Sound Signals: These improve visibility and communication, crucial in noisy or dimly lit environments.

By leveraging these accessories, upgrades, and custom manufacturing options, a floor-mounted jib crane can be tailored to meet precise operational requirements, thereby maximizing efficiency, safety, and productivity.

List Quality Control and The Manufacturing Process of “jib crane floor mounted”

Quality Control of Jib Crane Floor Mounted:

1. Material Inspection: Inspect raw materials for quality and compliance with specifications before production.

2. In-process Monitoring: Continuously monitor production processes to ensure adherence to design standards.

3. Non-Destructive Testing (NDT): Employ NDT methods like ultrasonic, radiographic, or magnetic particle testing to check for internal flaws without damaging the crane.

4. Welding Quality: Inspect welded joints using visual, ultrasonic, and radiographic techniques to ensure strength and durability.

5. Dimensional Accuracy: Check dimensional accuracy using precision measuring tools to ensure components fit correctly.

6. Load Testing: Perform load tests to ensure the crane can handle specified loads safely and effectively.

7. Assembly Inspection: Verify the correct assembly of all components and ensure proper alignment.

8. Paint and Coating Inspection: Examine paint and protective coatings for uniformity, thickness, and adherence to corrosion-resistance standards.

9. Final Inspection: Conduct a comprehensive final inspection covering all aspects of the crane before shipping.

10. Documentation and Records: Maintain detailed records of inspections and tests for traceability and compliance.

Manufacturing Process of Jib Crane Floor Mounted:

1. Design and Engineering: Develop detailed designs and specifications tailored to customer requirements and industry standards.

2. Material Procurement: Source high-quality materials, including steel beams, bolts, and electrical components.

3. Cutting and Fabrication: Cut and shape raw materials using CNC machines, laser cutters, and other precision tools.

4. Welding: Weld components together following engineering specifications and safety standards.

5. Machining: Machine parts to specified tolerances to ensure smooth assembly and operation.

6. Assembly: Assemble the primary structure, including the vertical mast and horizontal jib arm, and attach mechanical components like bearings and brakes.

7. Surface Treatment: Apply anti-corrosive coatings and paint to protect against environmental factors.

8. Electrical Wiring: Install electrical components and wiring for the hoist, control panel, and other accessories.

9. Sub-assembly Testing: Test each sub-assembly, such as the hoist and rotary mechanism, for proper function.

10. Final Assembly and Testing: Integrate all components and perform rigorous final testing, including load and safety checks.

11. Packaging and Shipping: Securely pack and label the finished crane for transportation to the installation site.

How to use “jib crane floor mounted”

A floor-mounted jib crane is a versatile piece of lifting equipment often used in workshops, manufacturing units, and warehouses. Here’s a concise guide on how to use it safely and effectively:

1. Inspection:

– Before Each Use: Check the crane for any visible damage, wear, or malfunction, especially the mount, boom, and hoist.

– Load Limits: Ensure the weight of the load doesn’t exceed the crane’s maximum capacity.

2. Preparation:

– Clear Area: Make sure the area around the crane is free from obstructions.

– Secure Load: Attach the load securely using appropriate slings or lifting attachments. Verify the load’s balance.

3. Operation:

– Position the Boom: Manually or electrically move the boom to align directly above the load.

– Lift:

– Use the hoist control to lift the load slowly and steadily.

– Ensure the load is stable and secure before moving it.

– Swing the Boom: Carefully rotate the boom to the desired location. Utilize any rotation controls or manually position it.

– Lower the Load: Once in position, gently lower the load using the hoist control.

4. Safety Precautions:

– Remain Alert: Always remain attentive. Never leave a suspended load unattended.

– Avoid Overhead Movement: Do not move loads over people to prevent accidents.

– Communication: Ensure clear communication among team members to avoid mishaps.

5. After Use:

– Power Off: Turn off the crane and secure it in a safe position.

– Inspection: Conduct a post-operation inspection to check for any issues that need addressing.

By following these steps, you can ensure the safe and efficient operation of a floor-mounted jib crane.

“jib crane floor mounted” Comparative Analysis

Comparative Analysis of Floor Mounted Jib Cranes

1. Design & Structure:

Floor mounted jib cranes are robust and versatile lifting devices anchored directly to concrete slabs or base plates. This design provides maximal stability and allows high load capacities. They generally support 180-degree to 360-degree boom rotation, enhancing operational flexibility.

2. Load Capacity:

Jib cranes’ load capacity ranges typically from 0.5 to 10 tons. However, higher capacity models do exist for specialized applications. The pivotal factor is ensuring the supporting floor structure can bear the combined weight of the crane and potential maximum load.

3. Space Utilization:

These cranes excel in maximizing workspace efficiency. Unlike overhead cranes, they do not require extensive headroom or structural modifications. They are ideal for workstations or areas with lower ceilings, providing targeted lifting capabilities without interrupting overall floor plans significantly.

4. Installation & Maintenance:

Floor mount installations are relatively straightforward but necessitate precise alignment and robust anchoring. Maintenance is minimal compared to other crane types, focusing mainly on lubrication and periodic inspection of bolts and joints for wear and stability.

5. Mobility & Reach:

Floor mounted jib cranes offer varying boom lengths, typically up to 20 feet. Advanced models provide manual or motorized rotation and trolley travel, enhancing reach and ease of use for operators. Their fixed base, though potentially limiting geographic mobility, ensures consistent and predictable performance within their radius.

6. Cost Efficiency:

These cranes offer an economical lifting solution relative to other crane types, given their lower initial investment and operating costs. Customizable options allow industries to balance cost with specific functional demands, ensuring tailored efficiency.

7. Applications:

Widely used in manufacturing, assembly lines, warehouses, and maintenance shops, their adaptable nature suits diverse industries from automotive to aerospace. Their capability to handle repetitive, localized lifting tasks makes them invaluable in improving workflow and operational productivity.

In summary, floor mounted jib cranes combine structural integrity, operational flexibility, and cost efficiency, making them a pragmatic choice for many industrial environments requiring localized lifting solutions.

“jib crane floor mounted” Warranty and Support

When choosing a jib crane floor mounted, it is essential to consider the warranty and support services offered by the manufacturer. Reliable manufacturers typically provide comprehensive warranties, ensuring that the equipment is protected against defects in materials and workmanship for a specified period. A standard warranty duration may range from one to five years, depending on the manufacturer and model.

Warranty coverage usually includes repair or replacement of defective parts, but it’s crucial to read the warranty terms carefully to understand any limitations or exclusions, such as wear and tear, misuse, or incorrect installation. Some manufacturers might also offer extended warranty options for added peace of mind.

Support services are equally important. Look for companies that provide robust customer support including technical assistance, installation guidance, and maintenance services. Reputable manufacturers often have dedicated support teams ready to help with troubleshooting, spare parts availability, and regular inspections to ensure optimal performance and safety.

Additionally, choosing a manufacturer with a strong network of service providers can be beneficial. This ensures timely and efficient service, minimizing downtime and maintaining operational productivity.

In summary, when investing in a floor mounted jib crane, prioritize manufacturers offering a solid warranty and comprehensive support services. This not only protects your investment but also ensures sustained performance and longevity of the equipment.

List “jib crane floor mounted” FAQ

Jib Crane Floor Mounted FAQ

1. What is a floor-mounted jib crane?

– A floor-mounted jib crane is a type of crane fixed to the floor, designed for lifting and moving materials within a specific radius. It consists of a vertical mast and a horizontal jib arm that can rotate, usually up to 360 degrees.

2. What are the common applications?

– Floor-mounted jib cranes are commonly used in manufacturing, assembly lines, warehouses, and workshops for lifting and moving heavy loads with ease and precision.

3. What is the load capacity?

– Load capacities vary widely, typically ranging from 250 pounds to several tons, depending on the model and design specifications.

4. What are the standard rotation options?

– Most floor-mounted jib cranes offer either 180-degree, 270-degree, or full 360-degree rotation capabilities.

5. What are the height and reach options?

– Height and reach options vary. Standard models may offer heights up to 20 feet and horizontal reach (span) up to 16 feet. Customizable options may also be available to meet specific needs.

6. What power options are available?

– Jib cranes can be operated manually or powered. Electric hoists are commonly used for powered systems, which can include variable speed controls and remote operations.

7. What are the installation requirements?

– Installation typically requires a reinforced concrete floor with sufficient thickness and integrity to anchor the crane securely. Professional installation is recommended to ensure safety and compliance with relevant regulations.

8. What are the safety features?

– Safety features may include load limiters, emergency stop buttons, anti-sway systems, and secure anchoring systems. Regular maintenance and inspections are critical for safe operation.

9. What maintenance is required?

– Regular maintenance includes inspecting the jib arm, mast, hoist, and mounting bolts for wear and tear. Lubrication of moving parts and load testing are also essential.

10. Can it be customized?

– Yes, many manufacturers offer customizable options for height, reach, load capacity, and rotation to meet specific operational requirements.

These FAQs aim to provide a basic understanding of floor-mounted jib cranes, their applications, features, and maintenance needs.

Top 10 FAQ with answer about jib crane floor mounted for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing floor-mounted jib cranes from China, along with concise answers:

1. What is a floor-mounted jib crane?

– A floor-mounted jib crane is a type of crane with a rotating jib arm fixed on a vertical mast anchored to the floor, providing versatile lifting solutions in factories and workshops.

2. What are the advantages of using a floor-mounted jib crane?

– Advantages include flexibility, space efficiency, ease of installation, and the ability to handle heavy loads with precision.

3. What is the typical load capacity and span for floor-mounted jib cranes?

– Load capacities range from 0.5 to 15 tons, with spans typically ranging from 2 to 6 meters.

4. What should I consider when sourcing from China?

– Consider supplier reputation, quality certifications (ISO, CE), customization options, lead time, and post-sales support.

5. How do I verify the quality of the jib crane?

– Request quality certifications, conduct factory audits, ask for third-party inspection reports, and check customer testimonials.

6. What is the average lead time for a jib crane order from China?

– Lead times generally range from 4 to 8 weeks, depending on customization and order volume.

7. How is shipping and installation managed?

– Suppliers usually assist with shipping logistics. Installation manuals are provided, and some suppliers offer installation services or remote assistance.

8. Are spare parts and maintenance services available?

– Reputable suppliers offer spare parts and maintenance services. Confirm availability and delivery timelines during order negotiation.

9. What kind of warranties do Chinese suppliers typically offer?

– Warranties range from 12 to 24 months. Ensure warranty terms cover critical components like the motor, gearbox, and electrical systems.

10. How do I handle payment and ensure transaction security?

– Use secure payment methods like L/C (Letter of Credit) or T/T (Telegraphic Transfer). Platforms like Alibaba provide trade assurance services for added security.

By addressing these key points, you can make informed decisions when sourcing floor-mounted jib cranes from China.