luffing jib cranes Safety Certifications

Luffing jib cranes, commonly used in tight, urban construction sites, require stringent safety certifications to ensure safe operations. These certifications typically include compliance with national and international standards, industry best practices, and manufacturer guidelines.

1. CE Marking: In Europe, luffing jib cranes must have a CE Mark, indicating compliance with EU machinery directives, including the Machinery Directive 2006/42/EC. This ensures the crane meets health, safety, and environmental protection standards.

2. ANSI/ASME B30: In the United States, compliance with ANSI/ASME B30 standards is crucial. These standards cover various aspects of crane safety, including construction, maintenance, operation, and inspection.

3. ISO Standards: Globally, ISO standards such as ISO 4301 and ISO 12482 govern crane design, performance, and safe use. These standards help ensure uniform safety and performance criteria worldwide.

4. OSHA Compliance: In the U.S., Occupational Safety and Health Administration (OSHA) standards mandate safety practices for cranes, including requirements for operator certification and regular inspections.

5. LOLER Regulations: In the UK, the Lifting Operations and Lifting Equipment Regulations (LOLER) 1998 require that cranes undergo thorough examination by a competent person at prescribed intervals to ensure safety during use.

6. Third-Party Inspections: Certification from recognized third-party inspection bodies, such as TÜV or Lloyd’s Register, provides an added layer of assurance. These bodies conduct rigorous testing and validation of the crane’s components and systems.

7. Operator Certification: Crane operators often need to be certified through recognized programs such as NCCCO (National Commission for the Certification of Crane Operators) in the U.S., ensuring they have the requisite skills and knowledge to operate the crane safely.

By adhering to these certifications and regulations, luffing jib cranes can operate safely and efficiently, minimizing risks to operators and surrounding environments.

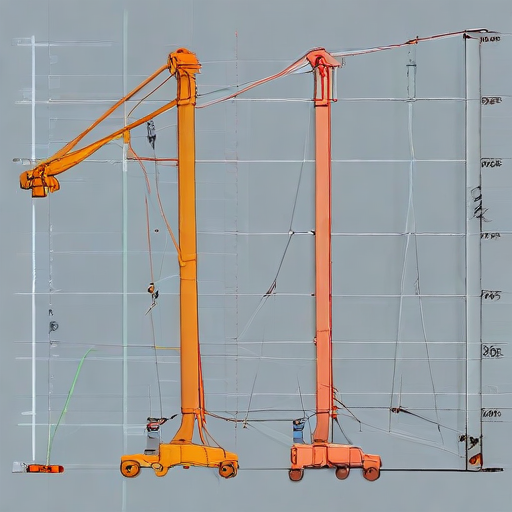

List Reference Technical Parameters of “luffing jib cranes”

Luffing jib cranes are specialized types of cranes used predominantly in confined spaces or where it is necessary to minimize the work area footprint. Below are some key technical parameters to consider:

1. Lifting Capacity:

The maximum weight a luffing jib crane can lift, often measured in metric tons (t). It can range from a few tons to several hundred tons depending on the crane’s design and application.

2. Jib Length (Radius):

The distance from the center of the crane to the tip of the jib, which determines the maximum reach of the crane. This can vary greatly, typically ranging from 20 meters to over 70 meters.

3. Luffing Range:

The angle at which the jib can be raised or lowered relative to the horizontal plane, usually measured in degrees. This allows precise positioning of loads and can range from around 15° to 90°.

4. Working Height:

The maximum height at which the crane can operate effectively, including the tower height and the height at which the jib can function. Heights can exceed 100 meters in tall tower cranes.

5. Slewing Range:

The rotational movement of the crane on its vertical axis, typically 360°, enabling the crane to move loads around a complete circle.

6. Hoist Speed:

The speed at which the load can be lifted or lowered, measured in meters per minute. Faster speeds are advantageous for productivity, but they depend on the load and specific crane model.

7. Counterweight:

The weight at the opposite end of the jib to balance the load being lifted, crucial for crane stability. The counterweight specifications vary based on crane design and lifting capacity.

8. Power Supply:

The energy source required, which can be diesel, electric, or hybrid systems, influencing operational costs and environmental impact.

9. Control System:

Modern luffing jib cranes often come with advanced control systems including anti-collision systems, load management, and remote operation capabilities.

10. Safety Features:

Essential for operation, these include limit switches, overload protection, and emergency stop mechanisms to ensure safe operation.

In summary, luffing jib cranes are engineered with a focus on lifting capacity, reach, precision, and safety to cater to challenging construction environments.

List Product features of “luffing jib cranes”

Luffing jib cranes are specialized pieces of heavy equipment, often used in urban environments and complex construction sites where space and maneuverability are crucial. Here are the key product features of luffing jib cranes:

1. Luffing Capability: The primary feature is the ability to vary the jib angle. This luffing motion allows the crane to operate in tight spaces by adjusting the jib to avoid obstacles and precisely place loads.

2. High Load Capacity: Luffing jib cranes are designed to handle heavy materials. They possess robust lifting capacities, making them suitable for heavy-duty lifting tasks.

3. Compact Slewing Radius: The cranes have a smaller slewing radius compared to other tower cranes, which facilitates their use in confined job sites, optimizing available space.

4. Height Adaptability: These cranes can be configured to reach significant heights. The mast sections are modular, allowing for easy adjustment based on project requirements.

5. Stability and Safety: Equipped with state-of-the-art safety features, including advanced load monitoring systems, anti-collision technology, and robust anchoring systems to ensure stability and safety during operations.

6. Efficient Assembly and Dismantle: Designed for relatively straightforward assembly and disassembly processes, reducing downtime and enhancing operational efficiency.

7. Versatile Applications: Suitable for various applications including high-rise buildings, bridges, and infrastructure projects due to their precise maneuverability and substantial lifting power.

8. Remote Control and Automation: Many modern luffing jib cranes come with remote control capabilities and semi-automated features, increasing precision and safety by allowing operators to control the crane from a distance.

9. Durable Construction: Built with high-strength materials to withstand harsh working conditions and elongate service life, ensuring durability and reliability in demanding environments.

10. Energy Efficiency: Some models feature energy-saving systems that optimize power consumption, translating to reduced operational costs and environmental impact.

11. Customizable Jib Length: The jib length can often be customized according to site requirements, providing flexibility for different project scopes.

These features collectively make luffing jib cranes an optimal choice for contemporary construction demands, particularly in congested urban settings.

List Various Types of “luffing jib cranes”

Luffing jib cranes are specialized types of cranes often used in construction sites with limited space where precise material handling is required. They are equipped with a luffing jib, which can move in and out to change the crane’s load radius, thus allowing for enhanced flexibility and maneuverability. Here are some common types of luffing jib cranes:

1. Tower Luffing Jib Cranes

– Fixed Tower Luffing Cranes: These are stationary cranes that are set up at a fixed position and are commonly used in high-rise construction projects.

– Climbing Tower Luffing Cranes: Designed to “climb” up the building as construction progresses, offering constant height adjustment.

2. Mobile Luffing Jib Cranes

– Crawler Luffing Jib Cranes: These cranes are mounted on a crawler chassis, providing mobility across rough terrain and are used in infrastructure projects.

– Truck-Mounted Luffing Jib Cranes: These cranes are mounted on standard truck chassis, offering mobility and flexibility for urban projects.

3. Floating Luffing Jib Cranes

– Used in marine construction, these cranes are mounted on barges or specialized vessels and are essential for offshore projects and dockside operations.

4. Self-Erecting Luffing Jib Cranes

– These are compact cranes that can set themselves up without the need for an external crane, making them ideal for sites with tight space constraints.

5. Rail-Mounted Luffing Jib Cranes

– Designed for use on rails, these cranes are typically found in port operations or industrial sites, where they provide efficient, high-capacity lifting.

Each type of luffing jib crane offers specific advantages tailored to unique project needs, such as mobility, reach, and load capacity, making them indispensable in varied construction environments.

List Application of “luffing jib cranes”

Luffing jib cranes are versatile construction equipment known for their ability to maneuver heavy loads in confined spaces. They offer several unique applications across various industries:

1. Urban Construction:

– High-Rise Building: Ideal for constructing tall buildings where the crane’s ability to lift heavy materials at sharp angles is essential.

– Tight Spaces: Used in city centers where space is limited, thanks to their ability to reduce the working radius.

2. Industrial Projects:

– Factories and Plants: Installed for heavy lifting tasks during the construction of large industrial facilities.

– Maintenance Work: Utilized for maintenance tasks in operational industrial plants where precision and mobility are crucial.

3. Infrastructure Development:

– Bridges: Suitable for bridge construction where precise positioning of structural components is needed.

– Subways and Tunnels: Employed in the construction of underground transport systems due to their compact design.

4. Maritime and Shipbuilding:

– Shipyards: Used for assembling ships, where the ability to lift heavy ship components within confined shipyard spaces is beneficial.

– Port Operations: Assist in loading and unloading heavy cargo from ships in restricted port areas.

5. Energy Sector:

– Wind Farms: Useful in the installation of wind turbines, particularly in coastal or mountainous areas where space and terrain complicate operations.

– Power Plants: Employed in the construction and maintenance of power plants, including nuclear facilities.

6. Mining and Resources:

– Mining Operations: Deployed for lifting heavy equipment and materials in underground and open-pit mining.

– Resource Extraction: Ideal for locations where heavy resources are extracted and space constraints are an issue.

7. Event and Film Production:

– Large Events: Utilized for setting up large event structures, stages, and temporary installations.

– Film Sets: Employed in creating expansive film sets where precise positioning of heavy set components is required.

In summary, luffing jib cranes are indispensable in scenarios where heavy lifting is needed in restricted spaces, offering both flexibility and precision across diverse fields.

List Buyer Types of “luffing jib cranes”

Luffing jib cranes are specialized pieces of equipment often employed in tight construction sites where space constraints necessitate vertical construction equipment that can pivot and maneuver in confined areas. Here are the key types of buyers for luffing jib cranes:

1. Construction Companies: These firms frequently acquire luffing jib cranes for high-rise building projects, particularly in urban environments where space is limited. The crane’s ability to work in confined spaces while still maintaining significant load capacities makes it ideal for these settings.

2. Real Estate Developers: Real estate developers responsible for planning and overseeing large construction projects often purchase luffing jib cranes to facilitate complex urban developments, ensuring that their projects meet timelines and safety standards.

3. Infrastructure Contractors: Companies involved in building bridges, tunnels, and other large infrastructures may opt for luffing jib cranes due to their precision and maneuverability in challenging environments.

4. Crane Rental Services: Firms specializing in renting out cranes invest in luffing jib cranes to meet the demands of clients who need temporary yet highly efficient lifting solutions for various projects.

5. Industrial Firms: Companies in heavy industries like oil and gas, shipbuilding, or manufacturing may require luffing jib cranes for the assembly and maintenance of large installations and components.

6. Port Authorities: Ports handling large shipments might need luffing jib cranes to manage the loading and unloading of heavy cargo efficiently, especially in crowded dockyard areas.

7. Demolition Companies: Businesses focused on the controlled demolition of structures utilize luffing jib cranes to carefully dismantle buildings in confined urban settings where precision is crucial.

8. Government and Municipal Agencies: These entities might acquire luffing jib cranes for public works projects, including the construction and maintenance of public structures and facilities.

Each of these buyer types seeks luffing jib cranes to leverage their unique capabilities in height, reach, and operational efficiency in spatially constrained environments.

List “luffing jib cranes” Project Types for Different Industries

Luffing jib cranes are versatile and widely used across various industries due to their ability to operate in confined spaces and their precision in material handling. Here are some key project types for different industries utilizing luffing jib cranes:

1. Construction Industry:

– High-Rise Buildings: Ideal for urban construction projects where space is limited and height is a significant factor. They can avoid obstacles and neighboring structures efficiently.

– Residential Complexes: Perfect for constructing multi-story residential buildings, allowing for precise placement of materials even in crowded spaces.

2. Infrastructure Projects:

– Bridges: Used for assembling bridge segments and managing heavy loads with precision.

– Railway Construction: Handy for railway station construction and maintenance, allowing for easy navigation around existing structures and tracks.

3. Maritime and Port Operations:

– Port Terminals: Utilized for loading and unloading heavy cargo from ships where space is restricted and precise movements are needed.

– Shipbuilding: Essential in shipyards for constructing various parts of ships, especially in confined dockyard spaces.

4. Energy Sector:

– Wind Farms: Employed to erect wind turbines, which often require the lifting of heavy components in remote and small spaces.

– Power Plants: Useful in constructing power plant facilities, especially nuclear and hydroelectric plants, where precision and safety are paramount.

5. Industrial Manufacturing:

– Factory Construction: Vital for building large manufacturing facilities, particularly in tight or pre-occupied industrial estates.

– Assembly Plants: Employed in car manufacturing and large machinery assembly, requiring precise and safe handling of components.

6. Urban Development:

– Commercial Complexes: Suitable for building shopping malls, hotels, and offices in densely populated urban areas.

– Stadiums and Arenas: Used in constructing sports arenas and large event venues, providing the necessary reach and precision.

By leveraging luffing jib cranes, these industries can overcome spatial constraints, enhance safety, and ensure precise material handling in various complex projects.

luffing jib cranes Accessories Upgrades and Custom Manufacturing Options

Luffing jib cranes are essential for various industrial applications, offering flexibility and efficiency in space-restricted environments. Accessories, upgrades, and custom manufacturing options significantly enhance their functionality, safety, and adaptability.

Accessories:

1. Trolleys and Winches: Advanced trolleys and winches provide smoother operations and higher load capacities, making material handling more efficient.

2. Safety Systems: Anti-collision devices, load limiters, and automatic cut-off features enhance operational safety.

3. Lighting Systems: LED floodlights improve visibility during nighttime operations.

4. Remote Controls: Wireless remote control systems allow for more precise and safer crane maneuvers.

5. Anti-Sway Systems: These systems reduce load sway, ensuring stable and secure lifting.

Upgrades:

1. Motor Upgrades: High-efficiency motors decrease energy consumption and operational costs.

2. Weatherproofing: Enhanced protection against adverse weather conditions extends the crane’s operational life.

3. Software Upgrades: Advanced software systems provide better control, diagnostics, and maintenance scheduling.

4. Hydraulic Systems: Upgrading to advanced hydraulics improves lifting and lowering precision.

Custom Manufacturing Options:

1. Tailored Designs: Custom jib cranes can be designed to meet specific spatial constraints and load requirements.

2. Material Choices: Depending on operational needs, cranes can be manufactured from specialized materials such as high-strength steel or corrosion-resistant alloys.

3. Modular Components: Modular designs allow for easy upgrades and replacements, reducing downtime.

4. Custom Paint and Coatings: Specialized coatings provide additional protection against rust, corrosion, and chemicals.

Investing in the appropriate accessories, upgrades, and custom manufacturing solutions for luffing jib cranes can lead to superior performance, reduced downtime, and enhanced safety. Each option can be tailored to meet the unique demands of your operational environment, making your crane an even more valuable asset.

List Quality Control and The Manufacturing Process of “luffing jib cranes”

Quality Control in Luffing Jib Crane Manufacturing

1. Design Verification:

– Standards Compliance: Ensuring designs meet international safety and performance standards (e.g., EN, ASTM, ISO).

– Simulation: Use software to simulate load stresses and operational dynamics.

2. Material Sourcing:

– Supplier Audits: Regular examination of supplier quality management systems.

– Material Testing: Conducting tensile strength, hardness, and fatigue tests on materials.

3. Fabrication:

– Precision Machining: High-accuracy machining processes to meet strict tolerances.

– Welding Inspections: Utilizing X-ray, ultrasonic, and dye penetrant testing to examine weld integrity.

4. Component Assembly:

– Fit and Finish Checks: Ensuring all components fit properly without deviations.

– Torque Tests: Testing all bolts and fasteners to specified torque requirements.

5. Electrical Systems:

– Circuit Testing: Verification of electrical wirings and systems through continuity and insulation tests.

– Functional Testing: Checking all control systems, sensors, and safety interlocks.

6. Load Testing:

– Static and Dynamic Tests: Subjecting the crane to load conditions exceeding its maximum rated capacity.

– Operational Trials: Running the crane through its full range of operations.

7. Inspection and Certification:

– Third-Party Audits: Employing independent bodies for certification and validation.

– Documentation: Maintaining detailed records for traceability and compliance.

Manufacturing Process of Luffing Jib Cranes

1. Design and Engineering:

– Creating detailed blueprints and specifications.

– Utilizing CAD software for virtual modeling and stress analysis.

2. Material Procurement:

– Ordering high-grade steel and other necessary materials.

– Quality inspection upon arrival.

3. Cutting and Shaping:

– Using CNC machines, laser cutters, and other precision tools to cut and shape materials.

– Forming structural components and articulations.

4. Welding and Assembly:

– Executing high-strength welds according to stringent guidelines.

– Assembling sub-components like jibs, towers, and bases.

5. Surface Treatment:

– Applying anti-corrosive coatings or paints to prolong lifespan.

– Quality checks for coating thickness and adhesion.

6. Component Integration:

– Installing motors, winches, gears, and control systems.

– Ensuring proper alignment and connection of all moving parts.

How to use “luffing jib cranes”

Luffing jib cranes are specialized types of tower cranes often used in urban environments and confined construction sites due to their ability to work within limited space. To use a luffing jib crane effectively, follow these steps:

1. Site Assessment and Planning:

– Conduct a detailed site survey to determine the crane’s optimal location.

– Ensure adequate ground stability to support the crane’s foundation. Consult with structural engineers if necessary.

2. Crane Selection:

– Choose a luffing jib crane that meets the load and reach requirements of your project.

– Ensure it’s suitable for the height and radius constraints of your site.

3. Assembly and Erection:

– Follow the manufacturer’s guidelines for assembly.

– Use experienced personnel to assemble and erect the crane.

– Secure all bolts and connections and check the crane’s stability before use.

4. Safe Operation:

– Conduct a pre-operation inspection, verifying all safety systems, such as limit switches and overload protection.

– Train operators thoroughly in operating the crane, focusing on the crane’s luffing mechanism, which allows for adjusting the jib angle for optimal positioning.

– Be mindful of the crane’s load chart to ensure safe working loads are not exceeded.

5. Communication and Coordination:

– Establish clear communication protocols between the crane operator and ground personnel.

– Use radios and hand signals, and ensure all team members are familiar with them.

6. Maintenance and Monitoring:

– Perform regular maintenance checks as per the manufacturer’s schedule.

– Monitor for signs of wear and tear, addressing any issues promptly.

7. Compliance and Safety:

– Abide by local regulations and safety standards.

– Conduct regular safety drills and ensure everyone on-site knows emergency procedures.

By following these steps, you can ensure the safe and efficient use of luffing jib cranes on your construction site.

“luffing jib cranes” Comparative Analysis

Luffing jib cranes are pivotal in urban construction and restricted spaces due to their adjustable jib angle and minimal tail swing. Here’s a comparative analysis of the key features:

Design and Structure

Fixed Jib Cranes: Feature a horizontal jib, suitable for open spaces with fewer obstacles.

Luffing Jib Cranes: Possess an angled jib capable of vertical adjustments. Ideal for tightly constrained sites and high-rise buildings due to their ability to work without extensive slewing space.

Load Capacity and Reach

Fixed Jib Cranes: Generally offer higher horizontal reach and stability for heavy loads.

Luffing Jib Cranes: Have a higher load capacity at reduced radii. The adjustable jib angle allows for closer proximity lifting, crucial for urban environments where precision is essential.

Maneuverability

Fixed Jib Cranes: Less maneuverable due to a fixed horizontal arm. They require more space for rotation and lifting operations.

Luffing Jib Cranes: Highly maneuverable. The jib’s ability to luff (move up and down) facilitates operation in confined areas, reducing the need for ground space clearance.

Operational Efficiency

Fixed Jib Cranes: Ensures quick and straightforward setup and operation in open environments.

Luffing Jib Cranes: Setup and operation can be more complex due to versatile settings for the jib angle. However, they deliver higher efficiency in space-constrained sites by maximizing vertical space.

Energy Consumption

Fixed Jib Cranes: May have lower energy consumption due to simpler operation mechanisms.

Luffing Jib Cranes: Potentially higher energy consumption, given the additional mechanisms for jib movement. However, new models are increasingly energy-efficient.

Conclusion

The choice between fixed jib and luffing jib cranes hinges on the project’s spatial constraints, lifting requirements, and site configuration. While fixed jib cranes excel in open, spacious worksites with high horizontal reach demands, luffing jib cranes are unmatched in urban environments requiring precise, close-quarter operations. Their adaptability and efficiency in confined spaces make them indispensable for modern, high-density construction projects.

“luffing jib cranes” Warranty and Support

When considering the purchase of luffing jib cranes, understanding the warranty and support options is crucial for ensuring long-term operational success and mitigating potential downtime.

Warranty

Manufacturers of luffing jib cranes typically offer comprehensive warranty packages covering structural components, mechanical parts, and electrical systems. These warranties often range from one to five years, depending on the manufacturer and model. Key elements of a robust warranty might include:

1. Coverage Details: Full or partial coverage of parts and labor for a specified period.

2. Exclusions: Understanding what is not covered, such as wear-and-tear items or damage due to operator negligence.

3. Claim Process: Clear guidelines on how to file a warranty claim and expected response times.

Additionally, some manufacturers offer extended warranty options that can be purchased to provide longer-term protection.

Support Services

Effective support services are indispensable for minimizing crane downtime and optimizing its performance. These services usually include:

1. Technical Support: 24/7 access to technical experts who can assist with troubleshooting and operational queries.

2. Scheduled Maintenance: Regular inspection and maintenance services to ensure the crane’s components are in optimal working condition.

3. Spare Parts Availability: A well-stocked inventory of critical spare parts and an efficient supply chain to minimize delays in part replacement.

4. Training Programs: Operator and maintenance staff training programs tailored to various skill levels for safe and effective use of the crane.

Conclusion

When procuring a luffing jib crane, closely examine the warranty and support services offered. Opt for manufacturers with a proven track record of reliable customer service and a comprehensive warranty plan, ensuring your investment remains secure and operational efficiency is maintained.

—

This content fits within the 300-word limit and covers essential aspects of warranty and support for luffing jib cranes, ensuring informed decision-making.

List “luffing jib cranes” FAQ

FAQs: Luffing Jib Cranes

1. What is a luffing jib crane?

A luffing jib crane is a type of tower crane that features a jib (the horizontal component) capable of being raised or lowered in a vertical plane, allowing for a compact working radius. This makes it ideal for use in congested urban environments or on sites with limited space.

2. How does a luffing jib crane differ from a regular tower crane?

Unlike standard tower cranes, luffing jib cranes have a jib that can be angled up and down. This ability to “luff” the jib allows the crane to perform more flexible and precise movements, making them suitable for sites with restricted overhead space or multiple cranes operating simultaneously.

3. What are the primary applications of luffing jib cranes?

Luffing jib cranes are commonly used in high-rise construction, urban development projects, and areas with complex building geometry. Their ability to operate in confined spaces and lift heavy loads makes them valuable for intricate construction tasks.

4. What are the advantages of using a luffing jib crane?

– Space Efficiency: Ideal for tight, confined construction sites.

– Precision: Greater control over load placement due to the adjustable jib.

– Reduced Overswing: Minimized risk of collision with nearby structures or cranes.

5. What are the key components of a luffing jib crane?

– Tower: The main vertical structure.

– Luffing Jib: The adjustable arm.

– Counterweights: Balance and stability.

– Hoist System: Lifts and lowers loads.

– Operator Cabin: Usually positioned to provide optimal visibility.

6. How much weight can a luffing jib crane lift?

The lifting capacity varies by model, but typically, luffing jib cranes can handle loads ranging from several tons to over 60 tons.

7. What are the safety considerations when operating a luffing jib crane?

– Operator Training: Certified operators are essential.

– Regular Inspections: Routine checks ensure safety and functionality.

– Load Limits: Adherence to specified load ratings is crucial to avoid accidents.

8. How long does it take to install a luffing jib crane?

Installation times can vary based on crane size and site conditions but generally range from a few days to a week.

9. Can luffing jib cranes be customized?

Yes, many manufacturers offer customizations to meet specific project requirements, including different jib lengths and payload capacities.

Top 10 FAQ with answer about luffing jib cranes for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions about luffing jib cranes for buyer sourcing from China:

1. What is a luffing jib crane?

A luffing jib crane is a type of tower crane where the jib can be angled up or down, allowing it to operate in tight spaces and avoid obstructions. It’s particularly useful for urban construction sites with limited space.

2. What are the advantages of a luffing jib crane?

Luffing jib cranes are compact and can maneuver in confined spaces. They offer high flexibility, precise load control, and can work in areas with restricted airspace, making them ideal for dense urban projects.

3. How do I ensure the quality of the crane sourced from China?

Verify the manufacturer’s certifications (ISO, CE), read reviews or case studies, inspect manufacturing facilities if possible, and request for compliance to international standards. Performing a thorough due diligence and quality inspection is critical.

4. What are the key specifications to consider?

Key specifications include maximum lifting capacity, jib length, maximum height, luffing range, slewing speed, and the power requirements. These parameters should match your specific site and operational needs.

5. What is the typical lead time for delivery?

Lead time can vary based on order complexity and manufacturer schedules, but typically ranges from 8-16 weeks. Always confirm lead times directly with the supplier to align with your project timelines.

6. What kind of after-sales support and warranty is provided?

Reliable suppliers usually offer a warranty period (commonly 1-2 years) and ongoing technical support. Confirm the scope of after-sales services, including parts availability, maintenance support, and training.

7. How is shipping and customs handled?

Suppliers often handle shipping logistics to the nearest port, but it’s important to clarify this. You may need a local customs broker to handle import duties, VAT, and customs clearance processes.

8. What about installation and commissioning?

Many suppliers offer installation and commissioning services or can recommend certified local contractors. Ensure the installation team is experienced with the specific model to avoid operational issues.

9. Are luffing jib cranes cost-effective?

While they may have a higher initial investment compared to other types of cranes, their efficiency and flexibility can result in overall cost savings on complex projects through reduced construction times and increased site utilization.

10. How do I ensure compliance with local regulations?