mini gantry crane Safety Certifications

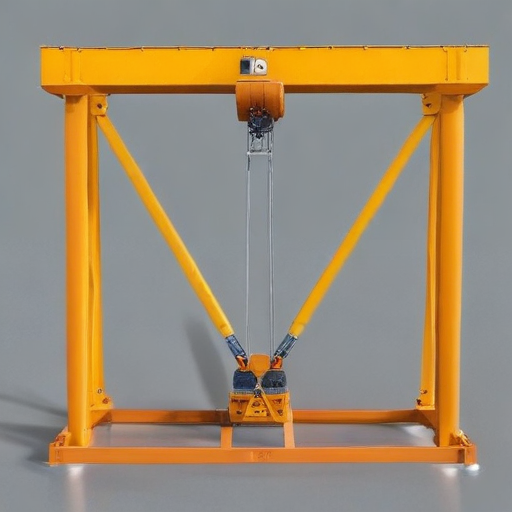

A mini gantry crane is a versatile piece of equipment used for lifting and moving heavy loads, often in industrial, construction, and warehouse settings. Ensuring its safety involves obtaining several key certifications and adhering to relevant safety standards.

1. OSHA Compliance (Occupational Safety and Health Administration): Cranes used in the workplace must comply with OSHA standards. These regulations cover inspection, maintenance, operation, and operator training.

2. ANSI/ASME B30 Standards: The American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) provide guidelines for various types of cranes under the B30 series. B30.16, for example, covers overhead and gantry cranes. This standard addresses design, inspection, maintenance, and operation practices to ensure safety.

3. CE Marking (European Conformity): For cranes used within the European Economic Area, the CE marking is crucial. It indicates conformity with health, safety, and environmental protection standards as per the relevant EU Directives.

4. ISO Standards: The International Organization for Standardization (ISO) provides international safety standards. ISO 9001 (for quality management systems) and ISO 14001 (for environmental management) are often relevant. ISO 4309 specifies the care and usage of wire ropes used in cranes, which is crucial for safety.

5. NRTL Certification (Nationally Recognized Testing Laboratory): Products must often be tested and certified by an NRTL accredited by OSHA. Examples include UL (Underwriters Laboratories) and CSA (Canadian Standards Association).

Regular inspections and maintenance, along with operator training and adherence to manufacturer guidelines, are also paramount for the safe operation of mini gantry cranes. Compliance with these standards and certifications helps mitigate risks, ensuring the safety of personnel and the longevity of equipment.

List Reference Technical Parameters of “mini gantry crane”

A mini gantry crane is a compact, versatile lifting device used for light to moderate lifting applications. Below are its reference technical parameters:

1. Capacity: Typically ranges from 0.25 to 5 tons, suitable for handling smaller loads.

2. Span Width: Varies according to the model, generally from 2 to 7 meters. This is the distance between the two sides of the crane structure.

3. Lifting Height: Commonly ranges from 2 to 6 meters, dependent on the specific application and model.

4. Frame Material: Often constructed from high-strength steel or aluminum for a balance of durability and lightweight properties.

5. Lift Speed: Usually between 0.5 to 10 meters per minute, adjustable based on the model and lifting mechanism.

6. Power Supply: Can vary; typically electric (single-phase or three-phase), but manual options are also available.

7. Wheel Type: May include polyurethane, rubber, or steel wheels, either fixed or swivel, often fitted with locking mechanisms for stability.

8. Mobility Features: Designed for ease of movement, often featuring casters or wheels enabling relocation within a workspace.

9. Environmental Tolerance: Depending on the design, some can operate in extreme temperatures, high humidity, or corrosive environments.

10. Safety Features: Generally includes overload protection, emergency stop functions, and sometimes anti-sway technology.

11. Assembly: Quick and straightforward, with many models being bolt-together designs.

12. Customization: Options may include adjustable height, span, and custom wheel configurations to suit specific needs.

13. Control Method: Can range from simple pendant controls to wireless radio remote controls for more advanced models.

14. Compliance: Should meet relevant safety and quality standards, such as ISO, ANSI, or CE certifications.

These parameters ensure that mini gantry cranes are adaptable to various industrial, commercial, and maintenance applications, providing a critical balance between operational efficiency and safety.

List Product features of “mini gantry crane”

A mini gantry crane is a versatile lifting device used for multiple applications in various industries. Below are the key product features of a mini gantry crane:

1. Compact Design: The smaller size makes it ideal for confined spaces and easy to maneuver in tight areas.

2. Adjustable Height: Many models offer adjustable height capabilities to accommodate different lifting requirements.

3. Mobility: Equipped with casters or wheels, mini gantry cranes are easy to move around the workspace.

4. Load Capacity: Despite their size, mini gantry cranes can lift considerable weights, typically ranging from 500 kg to several tons, depending on the model.

5. Durable Construction: Made from high-quality materials like steel or aluminum, ensuring long-term use and reliability.

6. Quick Assembly and Disassembly: Designed for easy setup, making it convenient for jobs that require frequent relocation and temporary use.

7. Versatile Applications: Suitable for a variety of tasks such as lifting engines, machinery, or heavy equipment in workshops, warehouses, and construction sites.

8. Safety Features: Includes safety mechanisms such as brakes on wheels, overload protection, and secure latching systems to ensure safe operation.

9. Customizability: Available in various configurations and specifications to meet specific job requirements.

10. Cost-Effective: Offers a budget-friendly alternative to fixed overhead cranes, providing flexibility without excessive investment.

11. Ease of Use: User-friendly controls and ergonomic design offer simple operation, often requiring minimal training.

12. Power Options: Available in manual, electric, or even battery-operated versions to suit different operational needs.

These features make mini gantry cranes an efficient, adaptable, and economical solution for material handling and lifting tasks.

List Application of “mini gantry crane”

A mini gantry crane is a versatile, portable lifting device with numerous applications across various industries. Here are some notable uses:

1. Warehousing and Storage:

– Inventory Handling: Efficiently moves heavy items, aiding in organizing and retrieving inventory.

– Loading/Unloading: Facilitates the transfer of materials from trucks to storage areas.

2. Manufacturing Facilities:

– Assembly Line Assistance: Moves parts between assembly stations, boosting efficiency.

– Maintenance: Supports lifting and installing heavy machines or components during repairs.

3. Construction Sites:

– Material Transportation: Transfers construction materials within confined spaces.

– Installation Work: Assists in installing smaller structural elements like beams and pipes.

4. Automotive Workshops:

– Engine Removal/Installation: Simplifies lifting and positioning of heavy engines.

– Component Handling: Eases the maneuvering of large components such as axles and transmissions.

5. Research and Development Labs:

– Prototype Testing: Facilitates the handling of prototypes and testing equipment.

– Material Handling: Moves heavy laboratory apparatus or experimental setups.

6. Maritime and Shipping:

– Dockside Operations: Assists in loading and unloading small boats, equipment, or cargo.

– Ship Maintenance: Supports in handling heavy parts for maintenance and repairs.

7. Retail and Supermarkets:

– Stock Management: Assists in organizing and moving heavy stock items in the backroom or on the floor.

– Display Setup: Aids in setting up heavy promotional displays and shelving.

8. Small to Medium-sized Enterprises (SMEs):

– Versatile Lifting: Enhances operational efficiency in businesses handling bulky or heavy items.

– Space Utilization: Ideal for operations within limited spaces due to its compact design and mobility.

By integrating mini gantry cranes into these applications, businesses can improve safety, efficiency, and productivity, making them an invaluable asset in handling and moving heavy loads.

List Various Types of “mini gantry crane”

Mini gantry cranes are versatile, portable lifting devices commonly used for light to moderate loads in various industries. Here are various types of mini gantry cranes:

1. Adjustable Height Mini Gantry Cranes:

– Feature adjustable height settings to accommodate different applications, making them flexible for various lifting needs.

2. Fixed Height Mini Gantry Cranes:

– Have a non-adjustable height. They are typically more stable and easier to set up due to their simplicity.

3. Portable Mini Gantry Cranes:

– Designed with wheels or casters, allowing them to be easily moved around a workspace for on-the-go lifting tasks.

4. Aluminum Mini Gantry Cranes:

– Lightweight yet durable, these cranes are made from aluminum, making them easier to transport and set up compared to their steel counterparts.

5. Steel Mini Gantry Cranes:

– Built from sturdy steel, these cranes are more robust and are ideal for slightly heavier loads and more demanding environments.

6. A-Frame Mini Gantry Cranes:

– Characterized by their A-frame design, these cranes offer excellent stability and are often used in workshops and small manufacturing facilities.

7. Workstation Mini Gantry Cranes:

– Specifically designed to assist with tasks in confined spaces such as production lines, offering precision lifting capabilities.

8. Height Adjustable and Span Adjustable Mini Gantry Cranes:

– Offer both height and span adjustments to provide maximum flexibility for various tasks and load sizes.

9. Motorized Mini Gantry Cranes:

– Equipped with motorized systems for lifting and moving loads, reducing manual labor and increasing efficiency.

10. Telescoping Mini Gantry Cranes:

– Feature telescopic legs for easy height adjustment, ideal for areas with limited headroom.

Each type has its own unique set of features catering to different tasks, making mini gantry cranes highly adaptable tools for numerous applications ranging from warehouses and workshops to construction sites and maintenance tasks.

mini gantry crane Accessories Upgrades and Custom Manufacturing Options

Mini gantry cranes are versatile lifting systems commonly used in workshops, warehouses, and construction sites. Optimizing their functionality involves several accessories, upgrades, and custom manufacturing options tailored to specific operational needs.

Accessories:

1. Hoists and Trolleys: Electric or manual hoists can be fitted along with adjustable trolleys for smooth horizontal movement.

2. End Stops: To prevent the trolley from sliding off the beam, end stops can be added.

3. Cables and Chains: Heavy-duty lifting cables and chains ensure secure and reliable lifting operations.

Upgrades:

1. Motorization: Adding motorized propulsion to the gantry crane enables easy movement along tracks.

2. Control Systems: Remote control or automated systems provide precision and enhance safety.

3. Height Adjustability: Telescoping legs allow for varied height adjustments, increasing versatility.

4. Material Upgrades: Opt for corrosion-resistant materials like stainless steel or aluminum for improved durability in harsh environments.

Custom Manufacturing Options:

1. Capacity Modifications: Tailor the lifting capacity to meet specific weight requirements.

2. Dimensions: Customizable height, width, and length to fit unique spatial constraints.

3. Portability Features: Adding wheels or casters for easy relocation within a job site.

4. Hybrid Designs: Combine elements such as fixed and adjustable legs for enhanced functionality.

Whether it’s adding sophisticated control systems or opting for durable materials, these enhancements can significantly expand the mini gantry crane’s operational efficiency and lifespan. Custom manufacturing ensures that the crane precisely meets the unique needs of various industries, ensuring safety and optimizing workflow.

List Quality Control and The Manufacturing Process of “mini gantry crane”

Quality Control and Manufacturing Process of Mini Gantry Cranes

#### Manufacturing Process

1. Design and Engineering:

– Concept Development: Engineers gather requirements and develop the initial design using CAD software.

– Material Selection: Choosing high-strength steels and alloys to ensure durability and safety.

2. Material Procurement:

– Sourcing: Acquire raw materials and components like steel beams, casters, bolts, and motors from verified suppliers.

3. Fabrication:

– Cutting and Shaping: Steel beams are cut, shaped, and drilled to specifications using CNC machines.

– Welding and Assembly: Components are welded together and primary assembly is performed to create the crane frame.

4. Surface Treatment:

– Cleaning: The frame undergoes shot blasting or acid cleaning to remove impurities.

– Coating: Application of anti-corrosive coatings and painting to protect against environmental factors.

5. Mechanical and Electrical Integration:

– Mounting Casters: Wheels are installed for mobility.

– Motor Installation: If powered, electrical motors and drives are installed and wired.

6. Final Assembly and Inspection:

– Assembling: Complete assembly of the crane with load testing mechanisms.

– Calibration: Ensuring all moving parts operate smoothly and adhere to design specifications.

#### Quality Control

1. Incoming Inspection:

– Material Testing: Inspect and test raw materials for compliance with specifications.

– Component Verification: Ensure all components meet design and safety standards.

2. In-Process Inspection:

– Dimensional Checks: Monitor dimensions after cutting and shaping to ensure precision.

– Welding Inspections: Perform non-destructive testing to check weld integrity.

3. Post-Assembly Testing:

– Load Testing: Perform static and dynamic tests to ensure the crane can handle the specified loads.

– Operational Testing: Verify the functionality of mechanical and electrical components.

4. Final Inspection:

– Visual Inspection: Check for any defects in paint, coatings, and overall assembly.

– Documentation Review: Ensure all quality records and compliance documents are up to date.

5. Certification and Compliance:

– Standards Adherence: Ensure the product complies with international standards like ISO, ASME, or CE.

– Customer-Specific Inspection: Perform additional tests as per customer requirements.

How to use “mini gantry crane”

A mini gantry crane is a versatile lifting device ideal for light to medium lifting tasks. Here’s a guide on how to use it effectively:

Pre-Use Inspection:

1. Check for Damage: Inspect the crane for visible damage, wear, or corrosion.

2. Verify Capacity: Ensure the load does not exceed the crane’s rated capacity.

3. Inspect Wheels: Ensure all wheels are in good condition and can rotate freely.

4. Test the Hoist: Operate the hoist without a load to ensure it functions smoothly.

Setup:

1. Position the Crane: Move the crane to the desired location. Ensure the surface is flat and stable.

2. Lock the Wheels: Engage the wheel locks to prevent movement during lifting.

3. Adjust Height: If your crane is height-adjustable, set it to the required height and securely lock it in place.

Lifting the Load:

1. Attach Sling/Hook: Securely attach the sling or hook to the load. Ensure it is balanced to prevent tipping.

2. Lift Slowly: Gradually lift the load using the hoist. Check for stability and make sure the load is secure.

3. Move the Load: Unlock the wheels and carefully move the crane to the desired location. Always push, never pull, to reduce tipping risk.

4. Lower the Load: Once in position, relock the wheels and slowly lower the load to the ground or onto a surface.

Post-Use:

1. Disconnect Load: Remove the sling or hook from the load.

2. Store Safely: Move the crane to a safe, designated storage area.

3. Maintenance: Perform any necessary maintenance, such as lubricating moving parts and cleaning.

Safety Tips:

– Always follow the manufacturer’s guidelines and load limits.

– Do not leave suspended loads unattended.

– Use personal protective equipment (PPE) as required.

By following these steps, you can effectively and safely use a mini gantry crane for your lifting needs.

“mini gantry crane” Comparative Analysis

A mini gantry crane is a compact, versatile lifting device often used in workshops, warehouses, and small industrial settings. This crane typically features a lightweight, portable design, which contrasts significantly with larger gantry cranes employed in heavy-duty applications such as shipyards and large manufacturing plants.

Mobility and Portability:

Mini gantry cranes excel in mobility and ease of transport. Their smaller size allows them to be easily moved and assembled by a single person or a small team, often without the need for special tools or equipment. Larger gantry cranes, on the other hand, are generally fixed installations or require significant logistical support for movement.

Lifting Capacity:

While mini gantry cranes can lift several hundred kilograms up to a few tons, they fall short when compared to the heavy lifting capabilities of standard gantry cranes, which can handle loads from several tons to hundreds of tons. This limitation makes mini gantry cranes suitable for less demanding lifting tasks.

Cost Efficiency:

Mini gantry cranes are more affordable, both in terms of initial purchase and ongoing maintenance costs. Larger gantry cranes involve a higher capital investment and incur more substantial maintenance expenses due to their complex structures and higher operational demands.

Versatility:

Mini gantry cranes offer greater versatility for small-scale operations. They can be easily adjusted to fit different workspaces and can be used for a variety of tasks, from lifting equipment to positioning heavy tools. Larger gantry cranes are specialized for specific heavy-duty tasks and are less adaptable to changing operational needs.

Safety:

Both mini and larger gantry cranes are designed with safety features. However, mini gantry cranes generally have simpler, more user-friendly safety mechanisms suited for low-capacity tasks. Larger cranes incorporate advanced safety systems to handle the increased risk associated with their higher lifting capacities.

In summary, mini gantry cranes provide a cost-effective, portable, and versatile lifting solution for light to moderate lifting needs, whereas larger gantry cranes deliver substantial lifting power for heavy-duty industrial applications at a higher operational cost and lower flexibility.

“mini gantry crane” Warranty and Support

Warranty and Support for Mini Gantry Crane

When you invest in a mini gantry crane, ensuring robust warranty and support services is crucial to maximize your equipment’s lifespan and performance. Manufacturers typically offer a warranty period ranging from 1 to 3 years, covering defects in materials and workmanship. This warranty generally includes the crane’s frame, mechanical components, and essential parts like the lifting hoist and trolley.

It’s important to thoroughly read the warranty terms to understand what is covered and any potential exclusions. For instance, warranties might exclude components subject to normal wear and tear, such as cables and hooks, or damage resulting from misuse, overloading, or improper maintenance.

Support services are equally vital. Premier manufacturers provide comprehensive customer support, including 24/7 technical assistance, online resources for troubleshooting, and access to spare parts. Look for suppliers who offer on-site training and maintenance services to ensure your staff can safely operate and maintain the crane.

Additionally, some suppliers offer extended warranty and service contracts for added peace of mind. These packages might include scheduled maintenance, priority service, and discounts on replacement parts, which can be invaluable in minimizing downtime and repair costs.

To sum up, when purchasing a mini gantry crane, prioritize manufacturers that offer a clear, comprehensive warranty and robust support services. This ensures that your investment is protected and that you have immediate access to expert advice and repairs when needed. Always keep documentation of your warranty and support agreements readily available to streamline any future claims or service requests.

List “mini gantry crane” FAQ

Mini Gantry Crane FAQ

1. What is a Mini Gantry Crane?

– A mini gantry crane is a smaller, portable lifting device used to move or lift heavy items in workshops, garages, or small manufacturing units. They typically have a simple, sturdy structure and can be moved around easily.

2. What are the common applications?

– They are commonly used in automotive workshops, warehouses, small factories, and construction sites for tasks like lifting engines, heavy machinery, and other weighty objects.

3. What capacity do Mini Gantry Cranes have?

– These cranes typically have a lifting capacity ranging from a few hundred kilograms to several tons, depending on the model and manufacturer.

4. How are they powered?

– Mini gantry cranes can be manual, electric, or pneumatic. Manual models use hand-operated mechanisms, while electric and pneumatic models have motorized systems for easier and faster operation.

5. Are they adjustable?

– Many mini gantry cranes feature adjustable heights and spans, allowing for versatile use across different tasks and environments.

6. What materials are they made from?

– They are usually made from high-strength steel or aluminum, offering a balance between durability and portability.

7. Are they easy to assemble and disassemble?

– Yes, one of the key advantages of mini gantry cranes is their ease of assembly and disassembly, making them highly portable and convenient for various locations.

8. What safety features do they have?

– Common safety features include overload protection, emergency stop buttons, and locking casters to prevent unwanted movement.

9. How much do they cost?

– Prices can vary widely based on capacity, brand, and additional features, but mini gantry cranes generally range from a few hundred to several thousand dollars.

10. Do they require maintenance?

– Regular maintenance such as lubrication, inspection of moving parts, and checking for wear and tear is necessary to ensure longevity and safe operation.

11. Can they be customized?

– Many manufacturers offer customization options to meet specific requirements, including different sizes, capacities, and additional features.

These FAQs provide a quick overview of mini gantry cranes, covering their applications, features, and general usage guidelines.

Top 10 FAQ with answer about mini gantry crane for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions (FAQs) about sourcing mini gantry cranes from China, along with concise answers:

1. What is a mini gantry crane?

– A mini gantry crane is a small, lightweight crane designed for lifting tasks in confined spaces, often used in workshops, warehouses, and small manufacturing units.

2. What are the load capacities available?

– Load capacities for mini gantry cranes typically range from 0.5 tons to 10 tons, depending on the design and specifications of the model.

3. What materials are used in construction?

– Most mini gantry cranes are made of high-quality steel or aluminum, ensuring a balance between durability and mobility.

4. How to ensure the quality of a mini gantry crane from China?

– Verify certifications such as ISO, CE, and SGS. Request quality assurance documentation, perform inspections, and consider third-party quality checks.

5. What are the standard sizes and dimensions?

– Standard sizes vary, but typical frame heights range from 2 to 5 meters, with adjustable beam lengths to accommodate different workspaces.

6. Can the crane be customized?

– Yes, many manufacturers offer customization options in terms of dimensions, load capacities, and additional features like height adjustability.

7. What is the typical lead time for production and delivery?

– Lead time can range from 30 to 60 days, depending on the complexity of the order and current demand.

8. What kind of warranty and after-sales service is provided?

– Warranties typically cover one to two years. After-sales services often include technical support, spare parts availability, and maintenance guidelines.

9. How do shipping and import processes work?

– Shipping can be done via sea or air freight. It’s essential to be aware of customs tariffs, import duties, and necessary documentation for smooth importation.

10. What is the approximate cost?

– Prices can vary widely based on specifications, but a standard mini gantry crane might range from $1,000 to $10,000. Obtain multiple quotes and compare.

These answers provide a foundational understanding for anyone considering purchasing a mini gantry crane from China.