mobile gantry crane Safety Certifications

A mobile gantry crane is a versatile piece of equipment used for lifting and moving heavy loads in various industries such as construction, manufacturing, and shipping. Ensuring the safety and reliability of these cranes requires adherence to specific safety certifications and standards. Below are key certifications and standards relevant to mobile gantry cranes:

1. OSHA (Occupational Safety and Health Administration):

– OSHA sets the standard for workplace safety in the United States.

– Compliance with OSHA regulations (29 CFR 1910.179) is mandatory for operating cranes safely to prevent accidents and ensure worker safety.

2. ASME (American Society of Mechanical Engineers):

– ASME B30.17 covers “Overhead and Gantry Cranes (Top Running Bridge, Single or Multiple Girder, Top Running Trolley Hoist)” and sets design, maintenance, and operation standards.

– Following ASME guidelines ensures proper crane function and minimizes risks during lifting operations.

3. ANSI (American National Standards Institute):

– ANSI standards, such as ANSI/ASSP A10.42, pertain to “Rigging Qualifications and Responsibilities.”

– These standards promote safety by defining the roles and responsibilities of personnel operating and maintaining gantry cranes.

4. CMAA (Crane Manufacturers Association of America):

– CMAA Specification 74 provides guidelines for the design, installation, and maintenance of overhead traveling cranes, positioning it as critical for mobile gantry cranes.

– Adherence to CMAA standards helps maintain structural integrity and operational safety.

5. CE Marking (Conformité Européene):

– Mobile gantry cranes in Europe must comply with the Machinery Directive 2006/42/EC to obtain CE marking.

– This ensures the crane meets essential health and safety requirements before being sold or used in the European Economic Area (EEA).

6. ISO (International Organization for Standardization):

– ISO 9927 provides guidelines on the inspection, usage, and maintenance of cranes.

– Implementing ISO standards ensures a global benchmark for safety, enhancing operational consistency worldwide.

These certifications and standards collectively ensure that mobile gantry cranes are designed, operated, and maintained in a manner that prioritizes safety and efficiency. Regular audits, inspections, and adherence to these regulations are crucial in mitigating risks and protecting workers in various lifting operations.

List Reference Technical Parameters of “mobile gantry crane”

A mobile gantry crane is a versatile lifting device widely used in various industries. To understand its capabilities and limitations, it is essential to consider several key technical parameters:

1. Load Capacity: This refers to the maximum weight the crane can lift, typically ranging from a few hundred kilograms to several tons.

2. Span: The horizontal distance between the two legs of the crane, which determines the width of the area the crane can cover. Span lengths can vary significantly, often between 3 meters and 30 meters.

3. Lifting Height: The maximum elevation the crane’s hook can reach from the ground, commonly between 2 meters and 12 meters.

4. Overall Height: The total height of the crane from the ground to the highest point, which can impact its usability in spaces with height restrictions.

5. Wheel Configuration: The type and number of wheels, which affect mobility and stability. Options include pneumatic tires, polyurethane wheels, or steel casters.

6. Travel Speed: The rate at which the crane can move horizontally, which influences operational efficiency. Speeds can range from a few meters per minute to several meters per second.

7. Lifting Speed: The speed at which the load can be raised or lowered, impacting cycle times. Typical speeds range from a few centimeters to several meters per minute.

8. Power Source: The energy supply for the crane’s operations, which can be electric, diesel, or manual, affecting its flexibility and environmental impact.

9. Control System: Methods for operating the crane, such as wireless remote controls, wired pendant controls, or manual controls.

10. Construction Material: The materials used to build the crane, typically high-strength steel or aluminum, affecting weight, durability, and maintenance.

11. Safety Features: Include overload protection, emergency stop buttons, and anti-drop devices ensuring safe operation.

These parameters collectively determine the mobile gantry crane’s suitability for specific applications, influencing factors like portability, ease of use, and operational efficiency.

List Product features of “mobile gantry crane”

Certainly! Here are the key product features of a mobile gantry crane:

1. Portability: Designed to be easily moved and transported to different locations, offering flexibility in various workspaces.

2. Adjustable Height and Span: Allows customization to accommodate different lifting requirements and workspace constraints.

3. Capacity Range: Typically supports lifting capacities from a few hundred kilograms to several tons, depending on the specific model.

4. Robust Construction: Built using high-strength materials like steel or aluminum, ensuring durability and long-term usage.

5. Ease of Assembly: Often features a modular design that allows for quick and straightforward assembly and disassembly, aiding in ease of use and transport.

6. Versatile Applications: Suitable for a variety of settings, including manufacturing plants, construction sites, workshops, and warehouses.

7. Manual or Powered Operation: Offers options for manual operation via hand chain hoists or powered operation using electric hoists for more efficient lifting.

8. Swiveling Wheels/Casters: Equipped with locking casters that provide mobility and secure positioning once in place.

9. Safety Features: Includes mechanisms like overload protection, durable brakes, and safety latches to ensure safe operations.

10. Customization Options: Typically available with customized options for specific needs, such as different lifting capacities, sizes, and additional accessories.

11. Weather-resistant Coatings: Often treated with coatings that make them resistant to corrosion and other environmental factors, suitable for both indoor and outdoor use.

12. Cost-effective: provides a cost-effective lifting solution without the need for permanent installation, reducing overall investment in infrastructure.

13. Ease of Maintenance: Designed for minimal maintenance requirements, ensuring uninterrupted productivity.

These features collectively make mobile gantry cranes an essential tool for many industries requiring versatile and reliable lifting solutions.

List Various Types of “mobile gantry crane”

Certainly! Here are various types of mobile gantry cranes commonly used in industries:

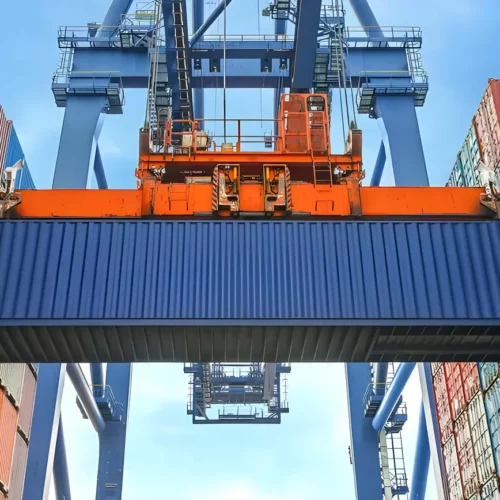

1. Rubber-Tired Gantry Crane (RTG):

– Used primarily in container terminals.

– Moves on rubber tires, allowing flexibility and mobility across different terrains.

– Ideal for stacking and managing large container yards.

2. Rail-Mounted Gantry Crane (RMG):

– Operates on fixed rails.

– Commonly used in intermodal and container terminals.

– Suitable for handling heavy loads and large-scale lifting tasks.

3. Portable Gantry Crane:

– Lightweight and easy to assemble or disassemble.

– Often used for small-scale tasks in workshops.

– Ideal for maintenance jobs and locations with space constraints.

4. Adjustable Height Gantry Crane:

– Features adjustable height settings.

– Provides flexibility in accommodating different lifting heights.

– Useful in varied applications from workshops to outdoor sites.

5. Workshop Gantry Crane:

– Designed for use in workshop environments.

– Typically smaller in size.

– Suitable for handling machinery and equipment within workshop settings.

6. Engine Hoist Gantry Crane:

– Specifically intended for lifting and moving engines.

– Commonly used in automotive repair shops.

– Easily maneuverable and often features adjustable heights.

7. Aluminum Gantry Crane:

– Made from aluminum, making it lightweight.

– Corrosion-resistant, suitable for indoor and outdoor use.

– Often used in light to medium lifting tasks.

8. Overhead Gantry Crane:

– Utilizes an overhead beam for lifting.

– Can be either fixed or mobile.

– Suitable for high-capacity lifting and precise load positioning.

9. Heavy-Duty Gantry Crane:

– Built for handling very heavy loads.

– Suitable for industrial use, shipping, and large construction projects.

– Often has higher load capacities and sturdier construction.

Each type serves different industries and lifting needs, offering versatility and efficiency across a wide range of applications.

List Application of “mobile gantry crane”

Mobile gantry cranes are versatile lifting solutions used in various industries and applications due to their mobility, adaptability, and capability to handle different weights and sizes. Here are some key applications:

1. Construction Sites: Mobile gantry cranes are employed to lift and move heavy construction materials such as steel beams, concrete blocks, and machinery. Their mobility allows them to navigate around job sites efficiently.

2. Warehousing and Logistics: In warehouses, they facilitate the loading and unloading of heavy goods, streamline inventory management, and increase efficiency by moving items across different storage areas.

3. Manufacturing: They assist in assembling large products, moving heavy components between workstations, and positioning materials accurately. They are essential in industries like automotive, aerospace, and shipbuilding.

4. Workshops and Repair Facilities: Used for lifting engines, vehicle bodies, and other heavy parts, they make repairs and maintenance operations more manageable and safer.

5. Ports and Harbors: Mobile gantry cranes handle the loading and unloading of containers, cargo, and equipment from ships, significantly speeding up port operations.

6. Aviation: In hangars, they move aircraft parts, engines, and other heavy equipment necessary for maintenance and assembly.

7. Railway Maintenance: They lift and position rails, sleepers, and track equipment, aiding in the construction and maintenance of railway infrastructure.

8. Mining and Oil industries: Mobile gantry cranes are utilized to lift and transport heavy mining equipment and machinery, improving operational efficiency and safety.

9. Event Setup and Management: For large events, they handle the setup and takedown of stages, lighting rigs, sound equipment, and other heavy components.

10. Art Installations and Restoration: They assist in moving large sculptures, art pieces, and restoration equipment, providing precise placement and ensuring the safety of valuable items.

These applications highlight the significance of mobile gantry cranes across multiple sectors, enhancing operational efficiency, safety, and productivity.

List Buyer Types of “mobile gantry crane”

Mobile gantry cranes are versatile lifting solutions that can be used across various industries for numerous applications. The buyer types for mobile gantry cranes include:

1. Construction Companies:

These companies use mobile gantry cranes to lift and move heavy construction materials, machinery, and equipment on job sites. The cranes’ mobility allows them to navigate through diverse and often uneven terrains.

2. Manufacturing Plants:

In manufacturing settings, mobile gantry cranes handle the transportation of heavy components, machinery, and assemblies within the production area. They help improve workflow efficiency and safety in manufacturing processes.

3. Warehousing and Logistics Firms:

Warehouses and logistics centers use mobile gantry cranes to load and unload cargo, manage inventories, and facilitate the transfer of goods onto and off from trucks or other transport vehicles. Their ability to handle heavy loads enhances operational efficiency.

4. Marine and Shipyards:

Mobile gantry cranes are crucial in marine environments for lifting and placing large components, ship parts, or even entire smaller vessels. Their mobility is particularly beneficial for operations that require frequent adjustment.

5. Automotive Industry:

Car manufacturers and repair shops use these cranes to move engines, chassis, and other large automobile components. The cranes’ precision and strength make them ideal for handling heavy parts safely.

6. Aerospace Sector:

Aerospace companies use mobile gantry cranes for assembling aircraft parts, lifting engines, and transporting large aerospace components. They help maintain precision and safety in handling high-value items.

7. Railroad Maintenance and Construction Companies:

In the railroad industry, mobile gantry cranes facilitate the installation and maintenance of tracks, lifting of railcars, and handling of large track components. Flexibility and strength are key benefits here.

8. Power and Energy Sector:

Companies in this sector utilize mobile gantry cranes for handling heavy equipment, transformers, and other components necessary for power plants, wind energy farms, and other energy infrastructure projects.

Each of these buyer types values mobile gantry cranes for their lifting capabilities, mobility, and adaptability to various work environments, optimizing operational efficiency and safety.

List “mobile gantry crane” Project Types for Different Industries

Mobile gantry cranes are versatile lifting solutions used across various industries. Each industry may utilize these cranes for different specific project types depending on their unique requirements.

1. Construction Industry

– Building Construction: Used for lifting heavy materials like steel beams, concrete blocks, and other construction materials.

– Bridge Construction: Essential for placing precast segments and lifting heavy components.

2. Manufacturing Industry

– Assembly Line: Facilitates the movement of large components along the production line.

– Maintenance Tasks: Useful for lifting and maneuvering heavy machinery during repairs.

3. Shipping and Logistics

– Container Handling: Employed for loading and unloading heavy shipping containers to and from transport vehicles.

– Warehouse Applications: Used in warehouses for moving large and heavy palleted goods.

4. Automotive Industry

– Engine Assembly: Assists in the precise lifting and positioning of heavy engine components during the assembly.

– Vehicle Maintenance: Used in garages and workshops for lifting vehicles for repairs and maintenance.

5. Aerospace Industry

– Aircraft Assembly: Used for lifting large aircraft components during assembly.

– Hanger Operations: Helps in the maintenance tasks by lifting and moving jet engines and other aerospace components.

6. Oil and Gas Industry

– Rig Construction: Specialized cranes for assembling large sections of oil rigs.

– Field Maintenance: Useful for lifting and placing heavy equipment needed for field operations.

7. Wind Energy

– Turbine Installation: Used to lift and position heavy components such as turbine blades and nacelles during installation.

8. Mining Industry

– Equipment Relocation: Employed for moving heavy mining machinery and equipment inside mines.

– Shaft Construction: Used for lifting and placing reinforcement materials during shaft construction.

Mobile gantry cranes are crucial in any industry requiring the frequent lifting and movement of heavy loads, providing a flexible, cost-effective solution to enhance productivity and safety.

mobile gantry crane Accessories Upgrades and Custom Manufacturing Options

Mobile gantry cranes are versatile lifting solutions used in various industries. To enhance their functionality, a range of accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Electric Hoists: Electrically powered hoists can improve lifting efficiency compared to manual ones.

2. Chain and Wire Rope Hoists: Suitable for different load capacities and lifting speeds.

3. Remote Controls: Wireless operation for improved safety and convenience.

4. Catenary Systems: For managing electrical and data cables, ensuring a clutter-free workspace.

5. Custom Wheels and Casters: Options like polyurethane, pneumatic, or steel wheels to suit different floor conditions and environments.

6. Spreader Bars and Lifting Beams: Enhance the lifting capability by evenly distributing the load.

7. Height Adjustment Kits: Allow for easy modifications in crane height to suit different applications.

Upgrades:

1. Motorized Travel: Automate the movement of the gantry crane across the workspace for improved operational efficiency.

2. Load Cells: For accurate weight measurement and monitoring, enhancing safety.

3. Anti-Sway Technology: Reduces the pendulum effect, ensuring stable and precise load positioning.

4. Enhanced Safety Features: Integrate features like emergency stops and overload protection.

Custom Manufacturing:

1. Tailored Dimensions: Custom sizes to fit specific operational spaces, ensuring optimal use of the crane.

2. Material Choices: Options include aluminum for lightweight mobility or stainless steel for corrosive environments.

3. Special Coatings: Anti-corrosive and weatherproof coatings for outdoor use or harsh environments.

4. Integrated Systems: Seamless integration with existing production lines and automated systems.

Customizing a mobile gantry crane with these accessories and upgrades can significantly extend its capabilities, making it a more efficient and safer lifting solution tailored to specific needs.

List Quality Control and The Manufacturing Process of “mobile gantry crane”

Quality Control and Manufacturing Process of Mobile Gantry Crane

#### Manufacturing Process

1. Design and Engineering:

– _Requirement Analysis_: Define operational needs, load capacities, and environmental conditions.

– _Technical Drawings_: Create detailed blueprints and CAD models.

– _Material Selection_: Choose high-strength steels and other robust materials.

2. Material Procurement:

– _Vendor Selection_: Source raw materials from certified suppliers.

– _Inspection_: Rigorous checking to ensure material quality (e.g., tensile strength, corrosion resistance).

3. Fabrication:

– _Cutting & Shaping_: Use CNC machines, lasers, and plasma cutters for precision.

– _Welding_: Employ MIG/TIG welding for strength and durability.

– _Machining_: Precision milling and drilling for component accuracy.

4. Assembly:

– _Pre-assembly_: Sub-assemblies like beams, legs, and trolleys are put together.

– _Final Assembly_: Integrating sub-assemblies into the final crane structure.

5. Finishing:

– _Surface Treatment_: Sandblasting, priming, and painting for rust prevention.

– _Assembly of Final Components_: Install electrical systems, hydraulic units, and safety features.

#### Quality Control

1. Incoming Material Inspection:

– _Chemical and Physical Testing_: Verify material composition and mechanical properties.

– _Dimensional Checks_: Ensure conformance to design specifications.

2. In-process Inspection:

– _Welding Inspections_: Ultrasonic or X-ray techniques to check joint integrity.

– _Dimensional Accuracy_: Regular checks using calipers, micrometers, and 3D scanners.

3. Final Inspection:

– _Load Testing_: Verify structural integrity by applying test loads.

– _Functional Testing_: Ensure mobility, lifting capabilities, and safety features.

– _Compliance Checks_: Confirm adherence to OSHA, ISO, and other relevant standards.

4. Documentation and Reporting:

– _Quality Records_: Maintain detailed logs of inspections, tests, and certifications.

– _Non-conformance Handling_: Address defects through corrective actions.

5. Customer Inspection and Approval:

– _Pre-shipment Review_: Allow customer inspections and third-party audits if required.

– _Training & Manuals_: Provide operational guidelines and safety manuals.

By adhering to these stringent quality control measures and a meticulously planned manufacturing process, the reliability and safety of mobile gantry cranes can be assured.

How to use “mobile gantry crane”

A mobile gantry crane is a versatile lifting device used for handling materials in various settings, from warehouses to construction sites. Here’s a concise guide on using it effectively:

Steps to Use a Mobile Gantry Crane:

1. Inspection:

– Visual Check: Inspect the crane for any visible damage or wear.

– Load Test: Ensure the crane’s load capacity matches the intended weight of the materials to be lifted.

2. Setup:

– Positioning: Place the gantry crane on a flat, stable surface.

– Wheels/Tracks: If the crane is on wheels, lock them in place. If on tracks, ensure they are aligned.

3. Safety Measures:

– PPE: Wear appropriate personal protective equipment (helmet, gloves, safety shoes).

– Clear Area: Ensure the surrounding area is clear of obstructions and personnel.

4. Operation:

– Attach Load: Use proper rigging techniques to attach the load securely to the crane’s hook.

– Lift Operation: Slowly operate the crane to lift the load, keeping it as close to the ground as possible.

– Movement: Move the crane slowly to its destination. For wheeled models, unlock wheels and manually push or utilize motorized assistance. For track-mounted models, use the control system.

5. Placing the Load:

– Lowering: Carefully lower the load to the ground or onto the desired platform.

– Detachment: Once stable, detach the rigging equipment from the load.

6. Shutdown:

– Turn Off Controls: Ensure the control system is turned off.

– Lock Wheels/Tracks: Secure the crane by locking wheels or placing stops on tracks.

Tips:

– Always follow the manufacturer’s guidelines.

– Regularly maintain and inspect the crane.

– Ensure operators are trained and certified.

Using a mobile gantry crane efficiently improves productivity while maintaining safety standards.

“mobile gantry crane” Comparative Analysis

Mobile gantry cranes are versatile lifting solutions widely used across various industries for their flexibility, ease of movement, and operational efficiency. Here’s a comparative analysis highlighting key aspects:

1. Design and Mobility:

– A-frame gantry cranes: Characterized by adjustable height and a-frame design providing stability and ease of use. Best for smaller, portable applications.

– Rubber Tired Gantry (RTG) Cranes: Ideal for outdoor use, particularly in container yards. They have rubber tires that allow easy maneuverability across different terrains.

– Rail Mounted Gantry (RMG) Cranes: Typically used in intermodal and container terminals. They move on fixed rails, offering high loading capacities but restricted to their tracks.

2. Capacity and Load Range:

– A-frame Cranes: Generally support loads from small to moderate capacities (up to 10 tons).

– RTG and RMG Cranes: These can handle significantly larger loads (from 20 tons to over 100 tons), making them suitable for heavy-duty applications.

3. Operational Range:

– A-frame Cranes: Limited operational range but can be relocated easily, ideal for workshops and smaller spaces.

– RTG Cranes: Offer flexibility within a wide operating area without the need for tracks but may have limitations due to tire wear and ground conditions.

– RMG Cranes: Provide high precision and quick operations over long distances, though confined to the installed rail system.

4. Cost and Maintenance:

– A-frame Cranes: Cost-effective with minimal maintenance, ideal for budget-conscious operations.

– RTG Cranes: Higher initial investment and ongoing maintenance costs due to their complex systems and mobility features.

– RMG Cranes: Expensive installation and maintenance but lower long-term operational costs due to their efficiency and minimal wear on non-mobile parts.

5. Application Suitability:

– A-frame Cranes: Perfect for workshops, garages, and light manufacturing.

– RTG Cranes: Best suited for logistics, shipping yards, and large outdoor storage areas.

– RMG Cranes: Optimal for heavy-duty operations in rail yards and large-scale container terminals.

In summary, the choice of mobile gantry crane hinges on specific operational needs, load requirements, and budget constraints, with each type offering distinct advantages tailored to particular contexts.

“mobile gantry crane” Warranty and Support

When considering the purchase of a mobile gantry crane, understanding the warranty and support services available is crucial for long-term reliability and peace of mind.

Warranty:

Most reputable manufacturers offer a limited warranty, typically covering one to two years from the date of purchase. The warranty often includes coverage for defects in materials and workmanship, ensuring that any faults arising from these issues will be rectified, either through repair or replacement, at no additional cost. It’s important to read the warranty terms thoroughly, as exclusions may apply for parts subjected to normal wear and tear, misuse, or unauthorized modifications. Some manufacturers might also offer extended warranty plans for an additional fee, providing prolonged protection against potential defects.

Support:

Reliable technical support is essential for maintaining the optimal performance of your mobile gantry crane. Manufacturers usually provide several layers of support, including:

1. Technical Assistance: Access to expert technical advice via phone, email, or online chat. This support is invaluable for troubleshooting and resolving operational issues swiftly.

2. Maintenance Services: Regular maintenance checks can be scheduled to ensure your crane operates efficiently and safely. Some companies offer comprehensive maintenance plans that include routine inspections, lubrication, adjustment of components, and more.

3. Spare Parts Availability: Prompt access to genuine spare parts minimizes downtime. Manufacturers often maintain a stock of critical parts and offer expedited shipping services.

4. Training Programs: Operator and safety training sessions are often available to ensure your team is knowledgeable about the correct usage and safety protocols.

5. Online Resources: Most manufacturers provide well-documented manuals, FAQs, and video tutorials through their websites, empowering users to find solutions independently.

In summary, a robust warranty coupled with comprehensive support services can significantly enhance the reliability and longevity of your mobile gantry crane, ensuring seamless, safe, and productive operations.

List “mobile gantry crane” FAQ

Frequently Asked Questions: Mobile Gantry Crane

1. What is a mobile gantry crane?

A mobile gantry crane is a versatile lifting device equipped with wheels, allowing it to move freely and lift heavy loads within various settings such as workshops, warehouses, and construction sites.

2. What are the key advantages of a mobile gantry crane?

Key benefits include portability, adaptability to different job sites, ease of assembly and disassembly, and the ability to handle heavy loads efficiently without the need for permanent installations.

3. What weight capacities are available?

Mobile gantry cranes come in various weight capacities, typically ranging from 500 kg to over 20 tons, depending on the model and manufacturer.

4. How do you operate a mobile gantry crane?

Operations involve positioning the crane over the load, using manual or powered hoists to lift the item, and moving it to the desired location. Safety protocols must always be followed.

5. Can mobile gantry cranes be used outdoors?

Yes, certain models are designed for outdoor use and come with weather-resistant materials and tires suitable for rugged terrain.

6. What are the main components of a mobile gantry crane?

The main components include the frame (usually made of steel or aluminum), beams, legs with wheels or casters, and a hoist mechanism (manual or powered).

7. How do I choose the right mobile gantry crane?

Consider load capacity, height, width, material, mobility requirements, and environmental conditions. Consulting with a crane specialist can help identify the best model for your needs.

8. Are there any safety considerations?

Yes, ensure regular inspections, adhere to weight limits, use proper lifting techniques, and conduct operator training. Always follow the manufacturer’s guidelines and safety regulations.

9. How much maintenance do mobile gantry cranes require?

Routine maintenance includes checking structural integrity, wheel conditions, hoist operation, and all fastenings. Regular servicing ensures longevity and safety.

10. Can mobile gantry cranes be customized?

Many manufacturers offer customization options, such as adjustable heights, widths, and additional safety features to suit specific applications.

For more detailed information, refer to the manufacturer’s manual or seek advice from industry experts.

Top 10 FAQ with answer about mobile gantry crane for Buyer Sourcing from China

Certainly! Here’s a concise list of the top 10 frequently asked questions about mobile gantry cranes, specifically for buyers sourcing from China:

1. What is a mobile gantry crane?

– A mobile gantry crane is a versatile lifting device on wheels that supports a movable bridge for lifting and transporting heavy loads. It offers flexibility and can be used indoors or outdoors.

2. What are the primary applications of a mobile gantry crane?

– These cranes are commonly used in manufacturing facilities, warehouses, construction sites, shipyards, and for maintenance tasks due to their mobility and adaptability.

3. What capacities and sizes are available?

– Mobile gantry cranes come in various load capacities ranging from a few hundred kilograms to several tons. Custom sizes can be tailored to meet specific requirements.

4. What materials are used in the construction of these cranes?

– They are generally made from robust materials such as high-grade steel or aluminum to ensure durability and strength while minimizing weight.

5. What are the shipping options for purchasing from China?

– Buyers can opt for sea freight, air freight, or express courier services. Sea freight is often the most cost-effective for large or heavy items.

6. How do I ensure the quality of the cranes?

– Always request quality assurance documents, adherences to international standards, and possibly conduct inspections through third-party services or factory visits.

7. What is the typical lead time for delivery?

– Lead times can vary; however, it typically ranges from 4 to 8 weeks depending on the crane’s specifications and order complexity.

8. Are there any import duties or taxes?

– Import duties and taxes depend on your country’s regulations. Check local trade laws or consult with a customs broker for precise information.

9. What kind of after-sales support is available?

– Chinese manufacturers often provide after-sales support including parts replacement, maintenance services, and technical assistance. Confirm these details before purchase.

10. Can the cranes be customized?

– Yes, most suppliers offer customization based on capacity, size, power source (manual or electric), and specific functional requirements to match your needs.

These answers should provide a good starting point for any buyer looking to source mobile gantry cranes from China.