overhead crane for sale Safety Certifications

When purchasing an overhead crane, it’s crucial to ensure that it meets all necessary safety certifications to maintain a safe working environment. Here are some common safety certifications to look for:

1. OSHA Compliance: In the U.S., cranes must adhere to Occupational Safety and Health Administration (OSHA) standards, specifically OSHA 29 CFR 1910.179, which outlines general safety standards for overhead and gantry cranes.

2. ASME Standards: The American Society of Mechanical Engineers (ASME) has set forth guidelines in ASME B30.2 for overhead and gantry cranes, focusing on safety requirements for design, maintenance, and testing.

3. ANSI Standards: The American National Standards Institute (ANSI) has additional standards, such as ANSI/ASSP A1264.1, which addresses safety requirements for workplace walking/working surfaces, including those affected by overhead crane operations.

4. ISO Certification: The International Organization for Standardization (ISO) provides global standards like ISO 9927 for the inspection, maintenance, and safe operation of cranes.

5. CE Marking: In Europe, overhead cranes must meet the requirements of the Machinery Directive 2006/42/EC and boast CE marking, indicating conformity with health, safety, and environmental protection standards.

6. FEM Standards: The European Federation of Materials Handling (FEM) provides guidelines and classifications for crane design and safety, ensuring mechanical and structural integrity.

7. CSA Standards: In Canada, the Canadian Standards Association (CSA) provides standards like CSA B167-16 for overhead travelling cranes, ensuring compliant design and safe use.

When shopping for an overhead crane, always verify that these certifications are up-to-date and applicable to the model you consider. Adherence to these standards reduces the risk of accidents and ensures the crane’s optimal performance and lifespan.

List Reference Technical Parameters of “overhead crane for sale”

When evaluating an “overhead crane for sale,” several technical parameters are critical to ensure optimal performance and suitability for specific applications. Below are the primary parameters to consider:

1. Load Capacity: The maximum weight the crane can handle, typically ranging from a few tons to several hundred tons based on industrial needs.

2. Span: The horizontal distance between the crane’s runway rails, impacting the area where the crane can operate. It should be tailored to the building’s width.

3. Lift Height: The maximum height the crane can lift the load, which should match the vertical clearance required for your operations.

4. Crane Speed: Includes hoisting speed (vertical lifting/lowering), trolley speed (movement across the bridge), and bridge speed (movement along the runway). These speeds affect efficiency and cycle times.

5. Duty Cycle: Defined by classifications like A1 to A8 or FEM classes, it determines how frequently and for how long the crane can operate without declining performance.

6. Power Supply: Voltage and phase requirements for the crane’s electric drive system, ensuring compatibility with the facility’s power setup.

7. Control System: Can range from manual pendant controls to advanced wireless remote controls, impacting operational flexibility and safety.

8. Runway: Structural rails supporting crane movement, requiring specifications for beam type and mounting details.

9. Hoist Type: Specifies whether the crane uses a wire rope or chain hoist, which affects load capacity, speed, and maintenance needs.

10. Brake System: Essential for safety, the braking system should ensure smooth operation and quick response during emergency stops.

11. Safety Features: Overload protection, anti-collision systems, limit switches, and emergency shut-down mechanisms enhance operational safety.

12. Environmental Conditions: Consideration of temperature ranges, corrosive environments, and potential hazards to ensure the crane’s durability and longevity.

13. Regulatory Compliance: Adherence to industry standards and regulations (e.g., OSHA, ANSI, ISO) ensures safety and quality during operation.

These parameters collectively determine the operational efficiency, safety, and suitability of an overhead crane for specific applications, ensuring a well-informed purchase decision.

List Product features of “overhead crane for sale”

Product Features of Overhead Crane for Sale

1. Load Capacity: Ranging from several tons to hundreds of tons, tailored to meet various industrial needs.

2. Bridge Type: Available in single or double girder configurations to suit specific structural and load-bearing requirements.

3. Span and Lift Height: Customizable span and lift height options to match facility dimensions and operational needs.

4. Control Options: Multiple control methods including pendant control, remote control, and cabin control for enhanced operational flexibility.

5. Hoist Mechanism: High-quality electric or manual hoists designed for smooth and efficient lifting and lowering operations.

6. Travelling Mechanism: Equipped with robust wheels and rails for smooth horizontal movement of the crane along the runway.

7. Safety Features: Integrated with safety systems such as overload protection, emergency stop buttons, and limit switches to ensure safe operation.

8. Durable Construction: Made from high-grade steel and corrosion-resistant materials to ensure longevity under heavy-duty applications.

9. Precision and Accuracy: Advanced motion control systems for precise positioning and load handling.

10. Energy Efficiency: Designed with energy-efficient motors and drives to reduce power consumption.

11. Ease of Maintenance: Modular design enabling easy access to components for quick and hassle-free maintenance and repairs.

12. Customizability: Configurable with a variety of attachments and accessories to suit specific lifting tasks.

13. Environmental Adaptability: Suitable for both indoor and outdoor installations, with weatherproof options available.

14. Smooth Operation: Anti-sway technology and variable speed controls for smooth and stable load handling.

15. Compliance and Certification: Meets international safety and quality standards, certified by relevant authorities for industrial equipment.

This concise overview highlights the fundamental features and benefits of an overhead crane for sale, designed to boost productivity and safety in various industrial settings.

List Various Types of “overhead crane for sale”

Certainly! Here are various types of overhead cranes available for sale:

1. Single Girder Overhead Crane:

– Features one main girder and is suitable for light to moderate lifting tasks. Ideal for smaller warehouses and workshops.

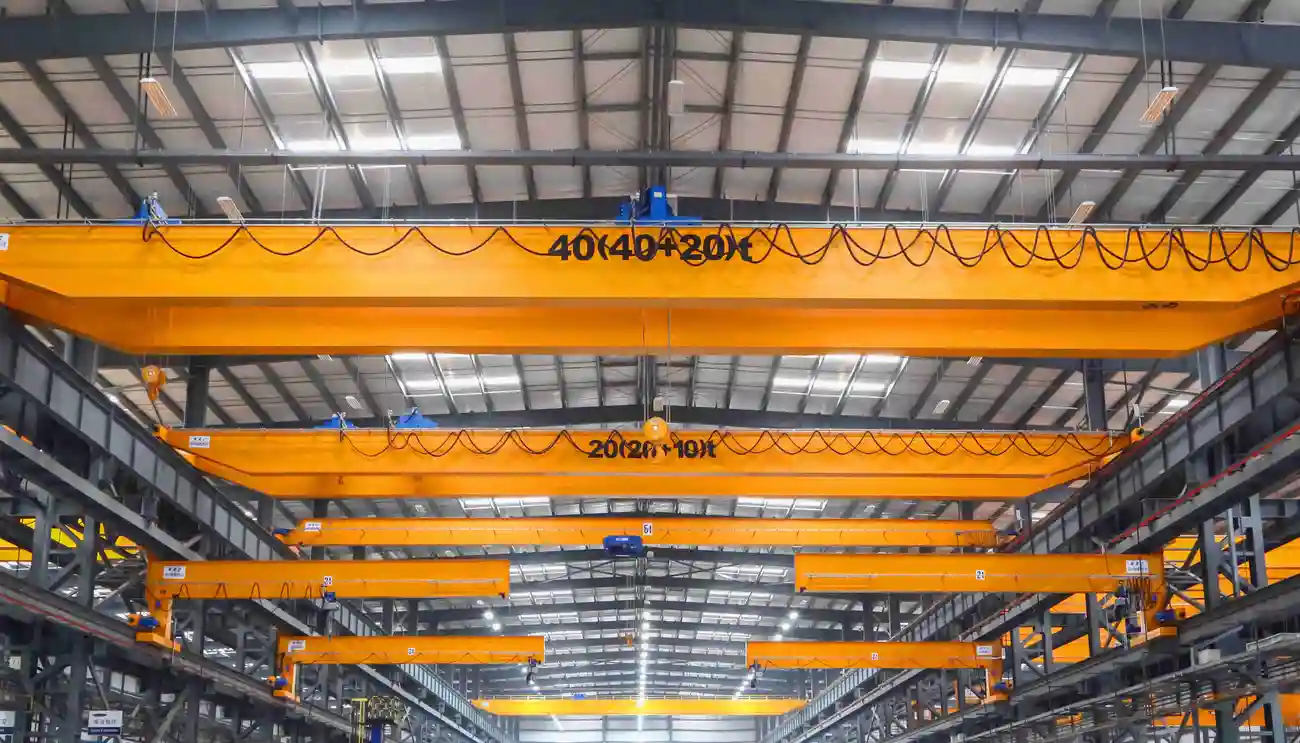

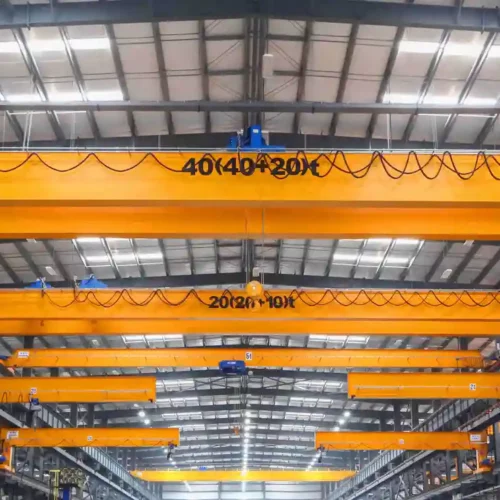

2. Double Girder Overhead Crane:

– Incorporates two main girders, providing greater load capacity and durability. Perfect for heavy-duty lifting in large industrial applications.

3. Top Running Overhead Crane:

– Operates on rails fixed to the top of the runway beams. Suitable for maximizing vertical lifting space and handling higher capacities.

4. Under Running (Underslung) Overhead Crane:

– Runs on the bottom flange of the runway beams, maximizing floor space. Used in facilities with limited headroom.

5. Gantry Crane:

– Has legs which can travel on rails at ground level. Ideal for loading and unloading in open spaces and shipyards.

6. Semi-Gantry Crane:

– Combines the features of a standard gantry crane and an overhead crane. One side runs on a raised runway, while the other side runs on rails on the floor.

7. Monorail Crane:

– Features a single rail system for the trolley to travel and is ideal for point-to-point material handling within a restricted path.

8. Process Crane:

– Tailor-made and designed for a specific process such as steel manufacturing or paper milling, ensuring enhanced efficiency and safety.

9. Explosion Proof Crane:

– Built with special materials and components to safely operate in hazardous environments with explosive gases or dust.

10. Jib Crane:

– Has a horizontal arm (jib) that supports a movable hoist, perfect for lifting tasks within a workstation or on production lines.

Selecting the right type of overhead crane depends on factors including load capacity, lifting height, span, duty cycle, and specific application requirements.

List Application of “overhead crane for sale”

Overhead cranes, available for sale, offer versatile and powerful solutions for various industrial applications. Common sectors that utilize overhead cranes include:

1. Manufacturing: Overhead cranes efficiently maneuver large components in assembly lines, streamlining the production process in industries such as automotive, aerospace, and heavy machinery.

2. Warehousing and Distribution: They optimize storage by maximizing vertical space, facilitating the handling of heavy pallets, containers, and large items, thus improving operational efficiency.

3. Construction: Essential for moving heavy building materials and equipment, overhead cranes support tasks such as lifting steel beams, concrete panels, and other heavy infrastructure materials safely.

4. Shipping and Logistics: Ports and rail yards employ overhead cranes to swiftly load and unload cargo, enhancing turnaround times and operational throughput while handling containers and bulk materials.

5. Steel and Metal Fabrication: Overhead cranes handle the transport of raw materials, heavy plates, and fabricated parts, ensuring precise placement and minimizing the risk of material damage.

6. Mining: In mining operations, overhead cranes assist in lifting and transporting heavy mining equipment, facilitating the movement of ore and maintenance of critical machinery.

7. Energy Sector: In power plants and renewable energy installations, overhead cranes play a crucial role in installing and maintaining heavy equipment like turbines and generators.

8. Automotive Maintenance: Overhead cranes streamline engine removals, vehicle assembly, and handling of oversized parts, particularly in large scale and commercial automotive workshops.

9. Paper Mills: Vital for handling large rolls of paper through different stages of production and packaging, ensuring seamless and efficient workflows.

10. Chemical and Petrochemical Industries: Overhead cranes handle large reactions vessels, storage tanks, and other heavy components required in the processing plants.

Overall, the versatility and strength of overhead cranes make them indispensable across various industries, ensuring safe, efficient, and precise handling of heavy loads.

List Buyer Types of “overhead crane for sale”

When considering buyers for “overhead cranes for sale,” it’s crucial to recognize the diverse range of industries and applications that necessitate the use of these powerful lifting solutions. Here are the primary buyer types:

1. Manufacturing Plants: These facilities employ overhead cranes to handle heavy machinery, move raw materials, and transfer finished products during various stages of production. Common applications include automotive manufacturing, aerospace, and heavy equipment production.

2. Warehouses and Distribution Centers: Overhead cranes are essential for moving large, bulky goods efficiently across vast storage areas. These buyers seek to enhance their logistical operations and reduce downtime in order fulfillment processes.

3. Construction Companies: Large cranes are indispensable in construction sites for lifting heavy building materials like steel beams, concrete panels, and prefabricated components. They are crucial for high-rise building projects and infrastructure developments.

4. Steel and Metal Industries: Foundries and metal fabrication plants often require overhead cranes to manage the heavy loads of raw metal, semi-finished products, and final goods. These industries rely on the precision and strength of cranes to handle ingots, rolls, and massive metal sheets.

5. Shipyards and Ports: The maritime industry uses overhead cranes to load and unload cargo from ships, manage shipping containers, and facilitate shipbuilding and repair operations.

6. Energy Sector: Power plants, especially those involved in renewable energy like wind turbines and hydroelectric dams, as well as traditional coal and nuclear power plants, need cranes for maintenance and installation of heavy equipment.

7. Mining Operations: Underground and surface mining operations use overhead cranes for maintaining heavy equipment, transporting mined materials, and assisting in general operations within the mine sites.

8. Railway Maintenance: Companies involved in railway logistics utilize overhead cranes for handling heavy rail components, assembling train cars, and performing maintenance tasks.

By understanding the specific needs of these varied buyer types, sellers can tailor their marketing and support services to address the unique challenges and requirements faced by each of these sectors.

List “overhead crane for sale” Project Types for Different Industries

Overhead cranes, essential for material handling across various industries, come in numerous types tailored to specific needs. Here are some of the project types and the industries they serve:

1. Single Girder Overhead Cranes:

– Manufacturing: Efficient for moderate lifting, ideal for warehouses, and assembly lines.

– Textile Industry: Suitable for moving lighter loads of fabric and equipment.

2. Double Girder Overhead Cranes:

– Heavy Industry: Perfect for steel mills, automotive, and machinery manufacturing, handling heavier loads and larger spans.

– Construction: Employed for large-scale projects involving heavy lifting and moving of construction materials.

3. Gantry Cranes:

– Shipbuilding: Crucial for lifting ship components, suitable for outdoor use and heavy load capacities.

– Rail Yards: Used for loading and unloading containers from trains.

4. Jib Cranes:

– Warehousing: Excellent for repetitive tasks, ideal for loading and unloading trucks within a smaller radius.

– Workshops: Used for material handling within confined spaces.

5. Explosion-proof Cranes:

– Chemical Industry: Designed with safety features to operate in hazardous environments where flammable gases or vapors may be present.

– Oil and Gas: Essential for lifting and moving in potentially explosive atmospheres.

6. Magnetic Overhead Cranes:

– Steel Production: Optimal for handling metal sheets, plates, and scrap metals efficiently.

– Recycling Plants: Useful for sorting and moving ferrous materials.

7. Clean Room Overhead Cranes:

– Pharmaceutical: Designed to lift in sterile environments.

– Electronics: Ideal for handling delicate, contamination-sensitive components.

8. Automated Overhead Cranes:

– Logistics: Enhances efficiency in automated warehouses.

– Automotive Assembly: Integrates with automated production lines for precision handling and assembly.

Each type of overhead crane is uniquely suited to specific industrial requirements, improving productivity, safety, and efficiency in material handling operations.

overhead crane for sale Accessories Upgrades and Custom Manufacturing Options

Searching for an overhead crane for sale? Brighten your purchase with our extensive range of accessories, upgrades, and custom manufacturing options designed to maximize your investment.

Accessories:

1. Load Indicators: Improve safety with precise weight measurements.

2. Radio Remote Controls: Enhance operational efficiency and ease.

3. Anti-Collision Systems: Minimize accidents and downtime.

4. Motorized Rotation Hooks: Simplify complex lifts.

5. Load Limiting Devices: Protect from overloading and enhance safety.

Upgrades:

1. Variable Frequency Drives (VFDs): Achieve smoother starts, stops, and variable speeds to enhance performance and reduce wear.

2. Smart Features: Integrate IoT capabilities for real-time monitoring and predictive maintenance.

3. LED Lighting: Improved visibility, energy efficiency, and reduced maintenance costs.

4. Advanced Hoisting: Upgrade to higher capacity hoists for greater capability.

5. Enhanced Motors: Choose energy-efficient motors for better performance and lower operational costs.

Custom Manufacturing Options:

1. Tailored Design: Customized crane configurations to meet your specific spatial and load requirements.

2. Material Choices: Opt for heavier gauge steel or specialized coatings for extreme environments.

3. Specialized Trolleys and Beams: Adjust to complex operational needs and space constraints.

4. Extended Lifting Heights: Modified design to achieve greater lifting heights for particular applications.

5. Precision Control Systems: Advanced control systems for specialized lifting applications and precision movements.

Our commitment to providing tailored solutions ensures your overhead crane not only meets but exceeds your operational requirements. Explore how your crane can be enhanced with these accessories, upgrades, and custom manufacturing options to improve safety, efficiency, and overall performance. For specific needs, consult with our technical experts to craft the perfect overhead crane solution.

List Quality Control and The Manufacturing Process of “overhead crane for sale”

Quality Control and The Manufacturing Process of Overhead Cranes for Sale

Manufacturing Process:

1. Design and Engineering:

– Requirement Analysis: Understanding client specifications.

– CAD Modeling: Creating detailed design models.

– Compliance Check: Ensuring designs meet industry standards such as ISO, ASME, etc.

2. Material Sourcing:

– Material Selection: High-strength steel and other durable materials.

– Supplier Verification: Ensuring materials are from certified vendors.

3. Fabrication:

– Cutting: Using CNC machines to cut steel components to precise dimensions.

– Welding: Employing automated welding systems for consistency and strength.

– Machining: Precision machining for components like gears and bearings.

4. Assembly:

– Main Frame Assembly: Assembling the primary structure.

– Component Integration: Installing motors, winches, cables, and control systems.

– Electrical Wiring: Setting up control panels, sensors, and safety systems.

5. Painting and Finishing:

– Surface Treatment: Sandblasting and anti-corrosion coating.

– Painting: Applying durable, weather-resistant paint.

Quality Control:

1. Incoming Material Inspection:

– Verification: Checking raw materials for compliance with specific standards.

– Testing: Chemical and mechanical testing of materials.

2. In-Process Inspections:

– Dimensional Checks: Ensuring components meet specified tolerances.

– Weld Inspections: Visual and NDT (Non-Destructive Testing) methods like ultrasonic or radiography.

3. Assembly Verification:

– Alignment Checks: Ensuring proper alignment of all components.

– Functional Testing: Running operational tests to verify movement, lifting capacity, and control systems.

4. Final Testing and Certification:

– Load Testing: Testing cranes under specified load conditions.

– Safety Certification: Confirming compliance with safety and operational standards.

5. Documentation:

– Quality Records: Maintaining detailed records of inspections and tests.

– User Manuals and Certifications: Providing comprehensive documentation for end-users.

By meticulously following these steps, manufacturers ensure that each overhead crane meets rigorous quality standards, resulting in safe, reliable, and durable products for their clients.

How to use “overhead crane for sale”

Looking to expand your industrial capabilities? An overhead crane for sale could be your perfect solution. These cranes are essential for various operations, from manufacturing plants to construction sites, offering you improved efficiency and safety when lifting and transporting heavy loads.

Start by understanding your specific needs. Identify the type of overhead crane suitable for your tasks—single girder, double girder, or Ceiling Cranes are some options. Consider the weight capacity, span, and lifting height essential for your work environment.

Next, research reputable suppliers. Look for companies specializing in industrial equipment to ensure high-quality cranes and after-sales support. Check customer reviews and testimonials to gauge the reliability of the seller.

When selecting a crane, ensure it meets industry standards and safety regulations. Look for features like anti-sway technology, load limit indicators, and emergency stop functions.

Once you’ve made your choice, arrange for professional installation. Proper setup is crucial for safe and efficient operation. Make sure that your staff receives adequate training in operating the crane and is familiar with safety protocols.

Lastly, establish a maintenance routine. Regular inspections and servicing can extend the lifespan of your crane and ensure it operates smoothly. Consult the manufacturer’s guidelines for maintenance schedules and requirements.

In summary, buying an overhead crane involves careful planning and research. Identify your needs, choose a reputable supplier, ensure compliance with safety standards, arrange professional installation, and commit to regular maintenance. With the right approach, an overhead crane can significantly enhance your operational productivity and safety.

“overhead crane for sale” Comparative Analysis

When considering an overhead crane for sale, several key factors must be analyzed to make an informed decision. Here’s a comparative analysis of the main aspects to consider:

1. Types of Overhead Cranes

• Bridge Cranes: Versatile and commonly used for manufacturing and maintenance. Available in single or double girder configurations.

• Gantry Cranes: Ideal for outdoor applications or when installing a permanent runway structure indoors isn’t feasible. Portable and adjustable options are available.

• Jib Cranes: Suited for smaller workspaces with localized lifting needs.

2. Capacity Requirements

The weight of the loads you plan to lift is critical. Overhead cranes come in various capacities, typically ranging from 1 ton to 400 tons. Selecting a crane that can handle your maximum load with room for growth is advisable.

3. Span and Lift Height

Crane span (distance between runway rails) and lift height (distance the hook can travel) are essential. Ensure the selected crane fits within your facility’s spatial constraints and meets operational needs.

4. Operating Environment

Environmental factors such as temperature, humidity, and exposure to corrosive elements must be considered. Special coatings and materials may be needed for harsh environments.

5. Control Systems

• Manual: Cost-effective but less efficient for frequent, heavy lifting.

• Semi-Automated: Offers a balance between control and automation.

• Fully Automated: Ideal for repetitive tasks, enhancing productivity and safety but at a higher cost.

6. Safety Features

Look for advanced safety features like anti-collision systems, overload protection, and emergency stop mechanisms to ensure worker safety and prevent equipment damage.

7. Cost

Initial purchase price varies widely based on type, capacity, and features. Additionally, factor in installation, maintenance, and training costs.

8. Brand and Warranty

Reputable brands often offer superior quality, better after-sales support, and comprehensive warranties, which can reduce long-term costs and downtime.

Summary

Selecting the right overhead crane involves balancing several factors: type, capacity, spatial requirements, environmental suitability, control system, safety features, cost, brand reputation, and warranty. Thoroughly evaluating these aspects will ensure you choose a crane that meets your operational needs while maximizing safety and efficiency.

“overhead crane for sale” Warranty and Support

When considering an overhead crane for sale, it’s crucial to evaluate the warranty and support options provided by the manufacturer or dealer. A robust warranty and support system ensure peace of mind and longevity for your investment. Typically, overhead cranes come with a manufacturer’s warranty that can range from one year to several years, depending on the make and model. This warranty usually covers defects in materials and workmanship, providing free repair or replacement of defective parts within the stipulated period.

Support is equally essential. Reputable sellers often offer comprehensive support services, including technical assistance, regular maintenance, and emergency repair services. Technical assistance can involve on-site installation guidance, troubleshooting, and real-time support through various channels like phone, email, or live chat. Regular maintenance services might include periodic inspections, parts replacement, and software updates to keep the crane in optimal working condition.

Before making a purchase, ensure to read the warranty terms and conditions thoroughly. Check for any limitations or exclusions, such as those related to improper use or lack of maintenance. Additionally, inquire about the availability of extended warranties or support packages that can further safeguard your equipment.

Investing in an overhead crane is a significant decision, so prioritizing a seller offering strong warranty and support services will enhance reliability, performance, and safety, ensuring your operations run smoothly and efficiently.

List “overhead crane for sale” FAQ

Overhead Crane for Sale FAQ

1. What types of overhead cranes are available?

– There are various types, including single girder, double girder, gantry, and jib cranes. Each type is suited for different lifting capacities and applications.

2. What should I consider when choosing an overhead crane?

– Consider the crane’s lifting capacity, span, lifting height, duty cycle, and the specific requirements of your application.

3. How much does an overhead crane cost?

– The cost varies widely depending on type, capacity, and specifications. It can range from a few thousand to several hundred thousand dollars.

4. Are used overhead cranes available?

– Yes, many suppliers offer refurbished or used overhead cranes, which can be a cost-effective option.

5. Can a crane be customized?

– Many manufacturers offer customization to meet specific needs, including modifications to lifting capacity, control systems, and additional features.

6. What is involved in the installation process?

– Installation typically involves site preparation, assembly, and testing. Professional installation ensures safety and compliance with regulatory standards.

7. What kind of maintenance is required?

– Regular inspections, lubrication, and part replacements are essential for the longevity and safe operation of the crane.

8. Are there any safety guidelines to follow?

– Operators must follow OSHA guidelines, maintenance schedules, and proper training to ensure safe usage.

9. How long is the warranty for an overhead crane?

– Most manufacturers offer a warranty that ranges from 1 to 3 years, depending on the model and terms.

10. Where can I find a reliable supplier?

– Research reputable manufacturers and suppliers with good reviews, industry certifications, and a proven track record of support.

11. What are the delivery times?

– Delivery times vary based on customization and manufacturing schedules but typically range from a few weeks to several months.

12. Can financing options be available?

– Many suppliers provide financing plans or leasing options to help manage the investment.

These frequently asked questions should help guide you through the process of purchasing an overhead crane, ensuring you make an informed decision.

Top 10 FAQ with answer about overhead crane for sale for Buyer Sourcing from China

Certainly! Here are the top 10 FAQs with answers about sourcing overhead cranes from China, tailored for prospective buyers:

1. What types of overhead cranes are available?

Chinese manufacturers offer a wide range of overhead cranes, including single and double girder, top-running, under-running, and specialized options like explosion-proof or magnetic overhead cranes.

2. How do I ensure the crane meets my requirements?

Provide detailed specifications, including lifting capacity, span, height of lift, speed, and any special operational environments. Reputable manufacturers can customize solutions to meet your needs.

3. What are the key quality standards to check?

Ensure the manufacturer complies with international standards like ISO, CE, or ANSI. Look for certifications and verify adherence to these standards for quality assurance.

4. What is the typical lead time for production and delivery?

Lead times vary but generally range from 30 to 90 days depending on the complexity and customization of the crane. Always confirm lead times with the manufacturer before placing an order.

5. How do I manage shipping logistics?

Many manufacturers offer assistance with shipping logistics, including FOB (Free On Board) or CIF (Cost, Insurance, and Freight) terms. It’s advisable to engage with a trusted freight forwarder for smooth logistics.

6. Are there after-sales services and warranties?

Most reputable manufacturers offer warranties ranging from 1 to 2 years and provide after-sales services including installation guidance, maintenance support, and spare parts availability.

7. How can I verify the reliability of the manufacturer?

Conduct due diligence by checking references, reviewing past projects, reading customer reviews, and possibly visiting the manufacturer’s facility. Using platforms like Alibaba or Made-in-China with verified supplier statuses can also help.

8. What are the payment terms?

Common payment terms are T/T (Telegraphic Transfer), L/C (Letter of Credit), or a combination of both. Typically, a down payment is required with the balance paid before shipment.

9. What documentation is required for import?

Essential documents include the commercial invoice, packing list, bill of lading, certificate of origin, and any specific certificates required by your country’s regulations. Your freight forwarder can guide you on this.

10. How do I handle installation and training?

Most manufacturers can provide manuals, video guides, or send a technician to assist with installation and training. Ensure these services are clarified and included in the contract if required.

By addressing these FAQs, buyers can make informed decisions and streamline the process of sourcing overhead cranes from China.