overhead electric winch Safety Certifications

When operating or purchasing an overhead electric winch, it’s essential to ensure it complies with various safety certifications to guarantee reliable performance and protect operators.

1. OSHA (Occupational Safety and Health Administration): OSHA sets the standard for workplace safety in the United States. Overhead electric winches should comply with OSHA standards to minimize workplace hazards.

2. ASME (American Society of Mechanical Engineers): ASME B30.7 specifics for winches standard outlines the safety guidelines to be followed in manufacturing and operating winches. Compliance ensures that the winch meets rigorous safety requirements.

3. ANSI (American National Standards Institute): ANSI standards such as ANSI/ASSP B30.2-2020 address safety while managing lifting devices like overhead winches. ANSI certification shows that the winch meets essential safety and performance benchmarks.

4. CE (Conformité Européenne): For winches used in the European Economic Area, CE marking is essential. This indicates compliance with the relevant European directives, including safety, health, and environmental protection standards.

5. ISO (International Organization for Standardization): ISO standards such as ISO 9001 for quality management systems and ISO 13849 for safety of machinery provide a framework ensuring the winch is manufactured to high-quality and safety standards.

6. CSA (Canadian Standards Association): CSA certification is relevant for equipment in Canada. It ensures that the electric winch complies with Canadian electrical safety standards.

7. UL (Underwriters Laboratories): UL certification indicates that the electric components of the winch meet stringent safety requirements for the United States and Canada.

By ensuring that your overhead electric winch complies with these certifications, you help safeguard the environment and the operators, reinforcing a commitment to safety and reliability in material handling operations. Always verify that the winch’s documentation includes up-to-date certifications to maintain compliance and operational integrity.

List Reference Technical Parameters of “overhead electric winch”

Certainly! Here are the key technical parameters for an overhead electric winch:

1. Load Capacity: The maximum weight the winch can lift, typically ranging from 500 kg to several tons, depending on the model.

2. Lifting Height: The maximum height to which the winch can lift a load, which can vary widely from a few meters to over 30 meters.

3. Lifting Speed: The speed at which the winch can lift a load, often specified in meters per minute (m/min). Adjustable speed options may be available.

4. Motor Power: The power of the electric motor driving the winch, measured in kilowatts (kW) or horsepower (HP). Typically, this ranges from 0.5 kW to several kW.

5. Voltage: The operating voltage of the winch, often in the range of 220V-240V for single-phase and 380V-415V for three-phase systems.

6. Frequency: The electrical frequency, usually 50 Hz or 60 Hz, matching the electric supply standards of the region.

7. Control System: Types of controls available, such as pendant buttons, remote control, or integrated control panels for precise operation.

8. Rope Type and Length: The type and length of the hoisting rope or cable, including its diameter and material, which may affect the lifting process.

9. Drum Capacity: The length of rope that can be wound onto the winch drum, affecting the overall height or distance achievable for lifting.

10. Braking System: The type of braking system used for load holding, which can include mechanical, electrical, or dual braking systems for added safety.

11. Duty Cycle: The operational rating indicating how often the winch can be used within a given period (e.g., S2-30 minutes).

12. Protection Class: The IP rating for dust and water resistance, often IP54 or higher for industrial use.

13. Dimensions and Weight: The physical size and weight of the winch, crucial for installation and mounting requirements.

14. Safety Features: Integrated safety features like overload protection, emergency stop buttons, limit switches, and thermal protection for the motor.

These parameters help in selecting the appropriate overhead electric winch for specific lifting requirements and operating conditions.

List Product features of “overhead electric winch”

Certainly! Here are the primary product features of an overhead electric winch:

1. Load Capacity: The overhead electric winch is capable of lifting and moving loads ranging from a few hundred pounds to several tons, depending on the model.

2. Motor Power: Equipped with a powerful electric motor, typically ranging from 1 HP to several HP, ensuring reliable performance and efficient load handling.

3. Durable Construction: Features a robust design with high-quality materials such as steel or aluminum, providing longevity and resistance to wear and tear.

4. Lifting Height: Offers significant lifting heights, with some models capable of raising loads up to 50 feet or more.

5. Control System: Often includes a wired or wireless remote control, allowing safe and convenient operation from a distance.

6. Speed Variation: Some models come with variable speed control settings, enabling precise management of lifting and lowering speeds.

7. Safety Mechanisms: Incorporates safety features such as automatic brake systems, overload protection, and emergency stop buttons to enhance operational safety.

8. Cable Length and Type: Outfitted with durable, high-tensile steel cables or synthetic ropes of varying lengths to accommodate different lifting requirements.

9. Easy Installation: Designed for straightforward installation, often with mounting brackets or fixtures that fit standard overhead frameworks.

10. Versatility: Suitable for a variety of applications including industrial, construction, warehousing, and automotive contexts.

11. Maintenance & Serviceability: Engineered for easy maintenance with accessible components, and often accompanied by comprehensive service manuals or customer support.

12. Energy Efficiency: Some models are designed to be energy-efficient, reducing operational costs over time.

13. Weather Resistance: Many units are built to withstand harsh environmental conditions, featuring weather-resistant casings and components.

14. Compact Design: Despite their strength, many winches have a compact form factor, making them suitable for use in restricted spaces.

Overall, an overhead electric winch provides a powerful, reliable, and versatile solution for lifting and moving heavy loads in various industrial and commercial settings.

List Application of “overhead electric winch”

An overhead electric winch is a versatile and powerful lifting and lowering device used across various industries and applications. Here are some of its primary applications:

1. Industrial Manufacturing: Employed for lifting heavy machinery components, materials, and products during assembly and production processes.

2. Warehouse Operations: Facilitates the movement of large and heavy cargo within warehouse spaces, improving material handling and storage efficiency.

3. Construction Sites: Utilized to lift construction materials, tools, and equipment to different heights, significantly reducing manual labor and speeding up the construction process.

4. Marine and Dockyards: Used for loading and unloading heavy cargo, equipment, and supplies from ships and boats, ensuring quick and safe maritime operations.

5. Automotive Workshops: Assists in lifting vehicles or heavy engine parts during repairs and maintenance, enhancing safety and productivity in auto garages.

6. Mining Operations: Essential for hoisting minerals, ore, and machinery in and out of mining shafts, providing crucial support for both underground and surface mining activities.

7. Theatrical Productions: Employed to move heavy stage props, backdrops, and lighting rigs, ensuring smooth set changes and improving performance aesthetics.

8. Agricultural Sector: Used to lift heavy farming equipment, bales of hay, and other agricultural materials, improving efficiency and safety on farms.

9. Energy Sector: Applied in the installation and maintenance of wind turbines, transmission towers, and other energy infrastructure, allowing for high-elevation tasks.

10. Rescue Operations: Leveraged by emergency services for lifting and rescuing individuals from difficult-to-reach places, enhancing the efficacy of rescue missions.

11. Aerospace Industry: Used for assembling and maintaining aircraft components, ensuring precise and efficient handling of delicate and heavy parts.

In essence, an overhead electric winch is an indispensable tool in environments that require reliable lifting, positioning, and securing of heavy loads, significantly enhancing operational efficiency and safety standards across multiple sectors.

List Various Types of “overhead electric winch”

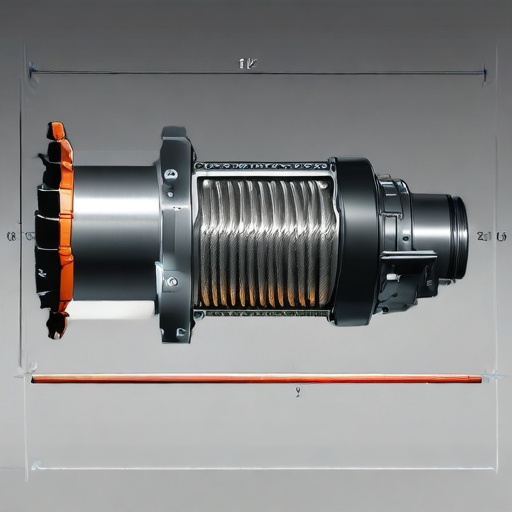

Overhead electric winches are versatile devices used for lifting, pulling, and positioning loads in various industrial settings. They operate with electric motors and can be mounted on overhead beams, gantries, or cranes. Here are some common types:

1. Electric Chain Hoist Winches:

– Uses a chain to lift loads.

– Ideal for precision lifting due to their smaller incremental movement.

– Suitable for lighter to moderately heavy loads.

2. Electric Wire Rope Hoist Winches:

– Utilizes a wire rope, allowing for higher load capacity.

– More durable and longer lifting distances.

– Used in heavy-duty industrial applications and construction sites.

3. Trolley-Mounted Winches:

– Mounted on trolleys that move along a beam or track.

– Provide horizontal movement, enhancing flexibility.

– Ideal for assembly lines and production floors.

4. Jib Crane Winches:

– Attached to jib cranes that have rotating arms.

– Perfect for lifting materials in a semi-circular area.

– Frequently used in workshops and warehouses.

5. Gantry Crane Winches:

– Mounted on gantry cranes with adjustable spans.

– Suitable for outdoor settings and heavy-duty tasks.

– Common in shipyards, rail yards, and construction sites.

6. Monorail Winches:

– Operate on a fixed monorail system.

– Suitable for continuous movement along a straight path.

– Often used in assembly lines and manufacturing plants.

7. Stationary Winches:

– Fixed in one location.

– Provides lifting or pulling in a specific area.

– Used in applications like loading docks and warehouses.

Each type offers distinct advantages depending on load capacity, operational environment, and specific application needs.

overhead electric winch Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing your overhead electric winch can significantly enhance its performance, safety, and versatility. Here are some popular accessories, upgrades, and custom manufacturing options to consider:

Accessories:

1. Remote Controls: Wireless or wired remote controls can provide better operational flexibility and safety, allowing the operator to control the winch from a safe distance.

2. Snatch Blocks: These pulley systems can double the pulling power of your winch and allow for more complex rigging configurations.

3. Synthetic Ropes: Nowadays, synthetic ropes are a lighter and safer alternative to traditional steel cables, reducing the risk of injuries.

4. Fairleads: Install roller or hawse fairleads to guide the rope smoothly and minimize friction.

5. Brake Systems: Adding an automatic brake system can enhance safety, preventing accidental load drops.

6. Load Indicators: These sensors provide real-time data on the load, helping to prevent overloading and potential equipment failure.

Upgrades:

1. Motor Upgrades: Enhance the power and efficiency of your winch by opting for a higher horsepower motor.

2. Speed Control: Variable speed controls allow for more precise operation and can be crucial for delicate tasks.

3. Enhanced Gear Systems: Advanced gearing can increase efficiency and reduce wear and tear over time.

4. Safety Features: Integrate advanced safety features like emergency stop buttons, overload protection, and thermal cut-offs.

Custom Manufacturing Options:

1. Tailor-Made Mounting Plates: Custom mounting solutions can ensure a perfect fit for your specific application and enhance stability.

2. Special Coatings and Materials: Opt for rust-resistant coatings, marine-grade materials, or heavy-duty construction for specific environments.

3. Custom Drum Sizes: Adapt the drum size to fit specific lengths and diameters of ropes or cables based on your operational needs.

4. Integration with Other Equipment: Design your winch to integrate seamlessly with your existing machinery and systems, such as cranes or conveyor belts.

Customizing and upgrading your overhead electric winch can not only prolong its lifespan but also improve efficiency and safety, ultimately making your operations more effective and reliable.

List Quality Control and The Manufacturing Process of “overhead electric winch”

Quality Control for Overhead Electric Winch:

1. Material Inspection:

– Verify quality and specifications of raw materials.

– Ensure compliance with industry standards.

2. Component Testing:

– Check electrical components such as motors and switches.

– Use non-destructive testing for metal components to identify defects.

3. Dimensional Accuracy:

– Measure parts to ensure they meet design specifications.

– Use precision tools like calipers and micrometers.

4. Load Testing:

– Conduct load tests to ensure winch can handle specified capacities.

– Perform cycle testing to assess durability under repeated use.

5. Safety Inspection:

– Verify that safety features, such as limit switches and emergency brakes, are functional.

– Conduct electrical safety tests to prevent malfunctions.

6. Final Assembly Inspection:

– Inspect the assembled winch to ensure all components are properly integrated.

– Perform operational tests to check smooth functioning.

—

Manufacturing Process of Overhead Electric Winch:

1. Design and Engineering:

– Develop detailed mechanical and electrical designs.

– Create prototypes to validate design concepts.

2. Material Selection:

– Source high-quality steel, electrical motors, and cables.

– Ensure materials meet strength and durability requirements.

3. Fabrication:

– Cut and shape steel components using CNC machines and welding.

– Fabricate motor housing and winch drum with precise specifications.

4. Machining:

– Use lathes and milling machines to achieve required tolerances.

– Drill mounting holes and machine gear teeth.

5. Electronics Assembly:

– Assemble control circuitry, motor, and wiring.

– Test electrical components before integrating them into the winch.

6. Assembly:

– Assemble frame, motor, and drum.

– Install control system, safety mechanisms, and cover.

7. Testing:

– Perform dimensional inspections and functionality tests.

– Conduct load and safety testing in simulated real-world conditions.

8. Finishing:

– Apply protective coatings to prevent corrosion.

– Final quality check before packaging.

9. Packaging and Shipping:

– Package winches securely to prevent damage during transport.

– Ship to customers with detailed manuals and safety instructions.

This streamlined process ensures that overhead electric winches are both reliable and safe for industrial use.

How to use “overhead electric winch”

Using an overhead electric winch involves several steps to ensure safe and efficient operation. Here’s a concise guide:

Preparation:

1. Read the Manual:

Before operation, thoroughly read the manufacturer’s manual to understand the specific features and safety instructions of your winch model.

2. Inspect the Winch:

Check for any visible damages or wear on the winch, cable, and hook. Ensure all components are in good working condition.

3. Secure the Area:

Clear the surrounding area of any obstacles and personnel that might interfere with the winching process.

Operation:

1. Power On:

Connect the winch to a suitable power source as specified in the manual. Ensure the power supply is stable and matches the winch’s requirements.

2. Position the Hook:

Lower the hook to the load using the control switch, keeping a steady hand to avoid sudden movements.

3. Attach the Load:

Securely attach the hook to the load using proper slings or chains. Ensure the load is balanced and positioned directly beneath the winch.

4. Lift the Load:

Gradually lift the load by operating the control switch. Monitor the load and winch constantly to prevent overloading and ensure smooth operation.

Safety Tips:

– Do not exceed the winch’s rated capacity.

– Keep hands and body parts clear of the winch and load during operation.

– Do not leave the winch unattended while it is in use.

– Regularly inspect the winch and maintain it according to the manufacturer’s guidelines.

Conclusion:

Using an overhead electric winch requires careful preparation, attentive operation, and adherence to safety guidelines. Always follow the specific instructions provided by the manufacturer to ensure safe and effective use.

“overhead electric winch” Comparative Analysis

An overhead electric winch is a powerful and versatile tool used in various industries for lifting and moving heavy loads. Comparing several aspects of different overhead electric winches reveals crucial insights into their performance and suitability for specific applications.

1. Capacity and Power:

– Winches vary significantly in their lifting capacities, typically ranging from a few hundred kilograms to several tons.

– Higher capacity winches often require more powerful motors and better structural integrity.

– For instance, a 1-ton winch might have a motor rated at 2 HP, while a 5-ton winch could demand a 10 HP motor.

2. Speed and Efficiency:

– Lifting speed is a critical factor; higher-speed winches increase efficiency but often at the cost of precision.

– Winch speeds can vary from around 3 meters per minute to over 20 meters per minute.

– Applications requiring fine control, such as assembly lines, benefit from adjustable speed settings.

3. Design and Build Quality:

– The materials used in winch construction, such as steel or aluminum, affect durability and weight.

– Heavy-duty winches typically feature robust designs to withstand harsh environments like construction sites.

– Corrosion-resistant models are essential for outdoor or marine use.

4. Control Systems:

– Modern winches come with advanced control systems, including remote control and automated safety features.

– Remote-controlled winches enhance operational flexibility and safety by allowing operators to stand clear of the load.

– Excessive load sensors, emergency stop functions, and automatic braking systems are vital safety features.

5. Maintenance and Longevity:

– Maintenance requirements can differ significantly between models.

– Winches with sealed bearings and lubrication-free gear systems reduce maintenance time and costs.

– Regular inspections and proper maintenance extend the lifespan of a winch, making some models more cost-effective in the long run.

In summary, selecting the right overhead electric winch involves balancing capacity, speed, build quality, control systems, and maintenance needs based on the specific requirements of the application.

“overhead electric winch” Warranty and Support

Warranty and Support for Overhead Electric Winches

#### Warranty

Our overhead electric winches come with a comprehensive 3-year limited warranty. This warranty covers any manufacturing defects in materials or workmanship under normal use during the warranty period. If a defect arises and a valid claim is received within the warranty period, we will either (1) repair the defect at no charge, using new or refurbished replacement parts, or (2) replace the product with a new or refurbished unit.

#### Terms and Exclusions

The warranty does not cover:

– Damage due to misuse, abuse, or improper maintenance.

– Wear and tear from regular usage.

– Any unauthorized alterations or repairs.

– Damage resulting from natural disasters.

To make a warranty claim, please retain your proof of purchase and contact our customer service team.

#### Support

We pride ourselves on providing exceptional customer support to ensure your overhead electric winch operates optimally. Our support team is available via phone, email, and live chat.

##### Support Services Include:

– Installation Guidance: Detailed manuals and video tutorials to assist you in proper installation.

– Technical Support: Expert advice and troubleshooting assistance to resolve any operational issues.

– Maintenance Tips: Regular maintenance guidelines to extend the lifespan of your winch.

We also offer an extensive online knowledge base, including FAQs, user manuals, and troubleshooting guides. For more complex issues, our certified technicians are available for on-site service appointments.

##### Contact Us

– Phone: 1-800-123-4567 (Mon-Fri, 9 AM – 5 PM PST)

– Email: [email protected]

– Live Chat: Available on our website

Your satisfaction is our priority. We are committed to providing the best support to ensure your overhead electric winch performs reliably for years to come.

List “overhead electric winch” FAQ

Overhead Electric Winch FAQ

1. What is an Overhead Electric Winch?

An overhead electric winch is a mechanical device used for lifting and lowering heavy loads. It consists of a motor, drum, and cable, mounted on a fixed frame. The electric motor powers the drum to spool the cable, lifting or lowering the load attached to it.

2. How do I choose the right winch capacity?

Select a winch with a capacity exceeding the maximum weight you intend to lift. It’s recommended to have a safety margin; typically, the winch’s capacity should be 1.5 times the maximum load.

3. What is the voltage requirement for an electric winch?

Most electric winches run on 110/120V or 220/240V, depending on the region and power supply available. Ensure your power source aligns with the winch’s voltage specifications.

4. Can I use an overhead electric winch outdoors?

Yes, but it must be rated for outdoor use. Look for winches with weather-resistant housing and components to ensure durability under varying weather conditions.

5. What maintenance is required?

Regularly inspect the winch for wear and tear. Lubricate moving parts, check the cable for fraying, and ensure electrical connections remain secure. Routine maintenance can prolong the winch’s lifespan.

6. Are overhead electric winches safe?

Yes, when used correctly. They often come with safety features like automatic brakes and thermal overload protection. Always follow the manufacturer’s guidelines and never exceed the rated capacity.

7. What is the difference between a winch and a hoist?

A winch pulls loads horizontally, while a hoist lifts loads vertically. Overhead electric winches often perform both functions but are primarily designed for lifting.

8. Can I install the winch myself?

It’s possible if you follow the manufacturer’s instructions precisely and have a secure mounting setup. However, professional installation is recommended to ensure safety and proper function.

9. What are the typical applications?

Overhead electric winches are used in various settings, including construction, manufacturing, and warehouses, for lifting heavy machinery, materials, and equipment.

10. What are the advantages of an electric winch?

Electric winches are efficient, require less manual effort, offer precise control, and can be operated remotely in many cases.

Top 10 FAQ with answer about overhead electric winch for Buyer Sourcing from China

Certainly! Here’s a concise FAQ guide for buyers sourcing overhead electric winches from China:

1. What is an overhead electric winch?

An overhead electric winch is a motorized device used to lift, lower, and pull heavy loads. It’s commonly used in industrial settings, construction sites, and warehouses.

2. What are the key specifications to consider?

Key specifications include load capacity, lifting speed, motor power, cable length and diameter, and voltage requirements. Ensure these meet your operational needs.

3. What standards and certifications should I look for?

Look for CE, ISO, and potentially UL certifications. These indicate that the winch meets international standards for safety and quality.

4. How do I verify the reliability of a Chinese supplier?

Check supplier ratings on Alibaba, Global Sources, or Made-in-China. Request references, ask for certificates of authenticity, and consider third-party inspections.

5. What are the typical lead times for delivery?

Lead times can vary based on the supplier and order size, but generally, expect 30-45 days for custom orders and about 15-20 days for stock items.

6. Are there customs duties and taxes involved?

Yes, importing winches can incur customs duties and taxes. These vary by country, so consult with a local customs broker for accurate rates.

7. What is the typical warranty period?

Most reputable suppliers offer a one to two-year warranty that covers manufacturing defects. Always check the specifics of the warranty.

8. Can I get spare parts and after-sale service?

Reliable suppliers usually provide spare parts and after-sale service. Confirm the availability and lead times for these parts beforehand.

9. Are there options for customization?

Yes, many suppliers offer customization for specific needs such as load capacity, cable length, and motor type. Share your requirements early in the negotiation process.

10. What are the payment terms typically required?

Common payment terms include a 30% deposit with the balance paid before shipping, or via Letter of Credit (L/C). Negotiate terms that protect your investment.

By addressing these FAQs, buyers can make more informed decisions when sourcing overhead electric winches from China.