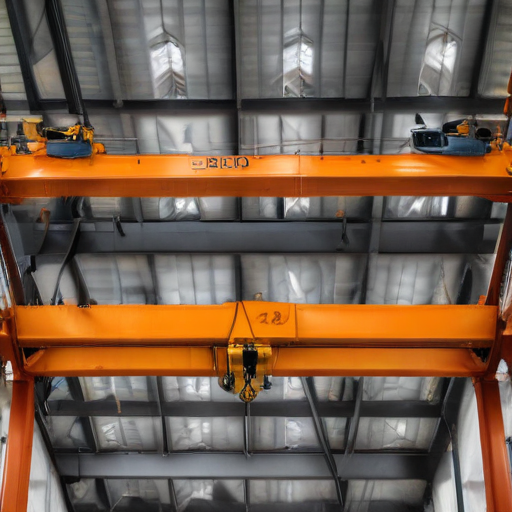

overhead shop crane Safety Certifications

Overhead shop cranes play a crucial role in material handling within industrial settings, and ensuring their safety is paramount. Various certifications and standards exist to maintain safety and operational integrity:

1. OSHA Regulations: The Occupational Safety and Health Administration (OSHA) sets forth several regulations under 29 CFR 1910.179, which outlines the safety requirements for overhead and gantry cranes. Compliance with OSHA regulations ensures safe working conditions.

2. ASME B30.2: The American Society of Mechanical Engineers (ASME) provides specific guidelines through its B30.2 standard, detailing the construction, installation, operation, inspection, and maintenance of overhead and gantry cranes. Adhering to ASME standards signifies a commitment to high safety and operational criteria.

3. CMAA Standards: The Crane Manufacturers Association of America (CMAA) offers comprehensive specifications with its CMAA 70 and CMAA 74 guidelines, applicable to multiple crane types. These standards are influential in promoting safety design and performance criteria.

4. ANSI/ASME: The ANSI/ASME B30 standards address various aspects of crane operation including responsibility, maintenance, safety features, and inspection protocols. These standards ensure cranes are designed and used in a safe, consistent manner.

5. ISO Certification: Many companies seek ISO 9001 Certification for Quality Management Systems to emphasize their adherence to quality and safety.

6. Periodic Inspections and Maintenance: Routine inspections and continuous maintenance are crucial for safety. Regular inspections are often mandated by both regulatory bodies and manufacturer guidelines, ensuring ongoing operational safety.

7. Training and Certification: Operator training and certification are essential. Certifications such as those from the National Commission for the Certification of Crane Operators (NCCCO) ensure crane operators are proficient.

Adherence to these certifications and standards ensures that overhead shop cranes operate safely and efficiently, thereby minimizing risks and enhancing productivity. Regular updates and reviews of these regulations and standards are vital for maintaining a safe working environment.

List Reference Technical Parameters of “overhead shop crane”

An overhead shop crane, commonly used in industrial and manufacturing settings, has several essential technical parameters:

1. Load Capacity:

– Indicates the maximum weight the crane can safely lift, ranging from a few hundred kilograms to several hundred tons.

2. Span:

– The horizontal distance covered by the crane, reflecting the width of the area it can service. Typical spans range from 10 to 40 meters.

3. Lift Height:

– The vertical distance the hook can travel, from the ground level to the maximum height. This can range from a few meters to over 30 meters.

4. Duty Cycle / Class:

– Defines the frequency and intensity of crane usage, often categorized by standards like FEM (ISO Class).

5. Speed:

– Hoisting Speed: Rate at which the load can be lifted or lowered, typically from 0.5 to 10 meters per minute.

– Trolley Speed: The sideways movement of the hoist along the bridge, generally between 20 to 40 meters per minute.

– Bridge Speed: The travel speed of the entire crane along the runway beams, usually 40 to 100 meters per minute.

6. Power Supply:

– Specifications for electrical power, including voltage (usually 230V to 480V), phase (typically three-phase), and frequency (50Hz or 60Hz).

7. Control Systems:

– Includes remote control, pendant control, or cabin control and often features PLC (Programmable Logic Controller) for automation.

8. Safety Features:

– Emergency stop buttons, overload protection, limit switches, anti-collision systems, and brake systems to ensure safe operation.

9. Materials and Construction:

– Structural components, usually made from high-strength steel to ensure durability and stability.

10. Environmental Adaptability:

– Designed to operate in various environments, including indoors, outdoors, high temperatures, or corrosive settings.

11. Maintenance Requirements:

– Regular inspections and specific maintenance procedures to ensure longevity and reliable operation.

12. Compliance Standards:

– Adherence to regional and international standards such as OSHA, ANSI, and ISO for safety and performance.

Understanding these parameters is crucial for selecting the right overhead shop crane for specific industrial applications.

List Product features of “overhead shop crane”

An overhead shop crane, commonly used in industrial and manufacturing settings, offers several key features designed to enhance efficiency, safety, and versatility. Here’s a succinct list of some primary features:

1. High Load Capacity: Capable of lifting substantial weights, often ranging from 1 ton to several dozens of tons, depending on the specific model and configuration.

2. Wide Span: Able to cover large working areas thanks to their extensive bridge span, facilitating material handling across significant distances.

3. Adjustable Height: Offers variable height settings to accommodate different lifting needs and to optimize vertical space utilization.

4. Electric Hoists: Equipped with robust electric hoists for smooth, efficient, and precise lifting operations. Many models come with dual-speed controls.

5. Remote Control Operation: Many cranes include wireless remote controls, ensuring safer operation by allowing the operator to control the crane from a distance.

6. Durable Construction: Built with high-strength steel or other robust materials to withstand heavy-duty use and harsh industrial environments.

7. Automated Systems: Some advanced models feature automated controls and programmable logic controllers (PLCs) for improved precision and efficiency.

8. Safety Mechanisms: Incorporates safety features such as overload protection, emergency stop buttons, and anti-sway technology to prevent accidents and equipment damage.

9. Variable Travel Speeds: Allows for adjustable travel speeds to match the specific requirements of the task, enhancing operational versatility.

10. Easy Maintenance: Designed for straightforward maintenance with accessible components and diagnostic features to minimize downtime.

11. Compact Design: Space-efficient designs that optimize workspace without compromising on lifting capability.

12. Customization Options: Available with various customization options including different hoist types, lifting capacities, spans, and additional safety features.

13. Environmental Adaptability: Suitable for indoor and outdoor use, with weatherproof and corrosion-resistant variants available for harsher environments.

These features collectively make overhead shop cranes indispensable in environments where heavy lifting and precise movement of materials are critical.

List Various Types of “overhead shop crane”

Overhead shop cranes are essential tools in various industries for lifting and moving heavy loads efficiently. They come in several types, each suited to specific tasks and environments:

1. Bridge Cranes: Featuring a horizontal bridge beam that travels along two runways, these cranes can span large workspaces and handle heavy loads. Subtypes include:

– Single Girder: Ideal for light to moderate loads.

– Double Girder: Suitable for heavy lifting and larger spans.

2. Gantry Cranes: Supported by legs that move on wheels or tracks, these cranes are versatile and can be used both indoors and outdoors. Variations include:

– Full Gantry Crane: Spans the entire workspace, often used in shipyards and construction sites.

– Semi-Gantry Crane: One side is supported by legs, while the other side runs on a track attached to a wall or structure.

3. Jib Cranes: Consist of a horizontal arm (jib) fixed to a vertical mast or a building wall. Ideal for smaller workstations, they allow easy rotation and movement within a specific radius.

4. Monorail Cranes: Utilize a single runway beam, usually in a straight or curved track, and are perfect for production lines or assembly areas where loads need to move along a predetermined path.

5. Workstation Cranes: Designed for lighter loads and repetitive tasks, these cranes often feature ergonomic designs to improve worker efficiency and safety.

6. Top Running Cranes: The bridge and hoist run on top of the runway beams, allowing for maximum hook height and lifting capacity. Common in heavy industries like steel manufacturing.

7. Under Running (Underslung) Cranes: The bridge runs on the bottom flange of the runway beams. These cranes are suitable for spaces with limited headroom.

Each type of overhead shop crane offers unique advantages, making them indispensable in various industrial applications for enhancing productivity and safety.

List Application of “overhead shop crane”

Overhead shop cranes are versatile lifting devices commonly used in various industries for material handling. Their ability to move heavy loads effortlessly across different directions (up/down, left/right, forward/backward) makes them invaluable in numerous applications. Below are key applications of overhead shop cranes:

1. Manufacturing Industries: Utilize cranes to transport raw materials, components, and finished products. This enhances workflow efficiency and safety by reducing manual handling.

2. Warehousing and Distribution Centers: Cranes streamline the movement of bulky goods, optimizing space utilization and improving inventory management.

3. Automotive Industry: Used in assembly lines for handling heavy car parts, engines, and even entire vehicles, facilitating precise placement during manufacturing processes.

4. Steel and Metal Production: Essential for moving large steel beams, sheets, and coils within production facilities, aiding in processes like forging, casting, and machining.

5. Shipbuilding: Assist in lifting and positioning massive ship components and modules, expediting the construction and repair processes.

6. Paper and Pulp Industry: Overhead cranes handle large rolls of paper and heavy machinery used in paper production, enhancing operational efficiency.

7. Aerospace: Precision lifting of aircraft components, engines, and assemblies is crucial to maintaining strict production and safety standards.

8. Power Plants: Facilitate the movement of heavy and bulky equipment, including turbines and generators, necessary for maintenance and installation tasks.

9. Construction Sites: Particularly indoors, such as in prefabricated building sections or large infrastructure projects, where they assist in positioning large components.

10. Mining: Used for the safe and efficient handling of heavy machinery and extracted materials within mining facilities.

11. Maintenance Facilities: Essential for repairing heavy equipment and machinery, allowing technicians to lift and maneuver parts for maintenance tasks easily.

By enhancing material handling efficiency, improving safety, and reducing labor costs, overhead shop cranes significantly contribute to the productivity and smooth operation of various industrial and commercial sectors.

List Buyer Types of “overhead shop crane”

Buyer types for overhead shop cranes can be categorized based on their specific needs and industry applications. Here are the primary buyer types:

1. Manufacturing Industries: These include automotive, aerospace, metal fabrication, and heavy machinery manufacturers. Overhead cranes are pivotal for moving heavy components and finished products efficiently within the production facility.

2. Warehousing and Distribution Centers: These facilities use overhead cranes to manage heavy palletized goods and streamline the loading and unloading processes. Cranes help optimize storage space and improve material handling capabilities.

3. Construction Companies: Overhead cranes are critical for handling large materials like steel beams, concrete blocks, and other building supplies. They help enhance safety and efficiency on construction sites.

4. Shipbuilding and Marine Industries: Shipyards use overhead cranes to move large ship components, engines, and other heavy materials. These cranes are integral to the assembly and repair of ships.

5. Utilities and Energy Sectors: These sectors, including power plants and renewable energy facilities, require overhead cranes for the maintenance and installation of large equipment like turbines, generators, and transformers.

6. Maintenance Workshops: Various industries operate workshops that require overhead cranes for the repair and maintenance of heavy equipment and machinery. These can include railways, manufacturing plants, and mining operations.

7. Metal Service Centers: Facilities that process and distribute metal products need overhead cranes to handle large metal sheets, coils, and bars efficiently.

8. Recycling and Scrap Yards: These businesses use overhead cranes to handle and sort heavy scrap metal and other recyclable materials, facilitating efficient processing.

9. Aerospace Maintenance and Repair Operations (MROs): These specialized workshops use overhead cranes to move large aircraft components and engines during inspection, maintenance, and repair activities.

Each buyer type has unique requirements based on the nature of their operations, making overhead shop cranes indispensable for enhancing productivity and ensuring safety in material handling tasks.

List “overhead shop crane” Project Types for Different Industries

Overhead shop cranes are essential in various industries for efficient material handling. Here’s a brief overview of their types across different sectors:

1. Automotive Industry:

– Single Girder Overhead Cranes: Used for engine assembly and parts transfer.

– Jib Cranes: Ideal for workstations to lift smaller components.

2. Manufacturing:

– Double Girder Overhead Cranes: Heavy-duty, suitable for large-scale assembly lines.

– Workstation Cranes: Flexible and used for repetitive lifting tasks.

3. Aerospace:

– Gantry Cranes: Mobile cranes for large part assembly.

– Monorail Systems: For precision placement of aviation components.

4. Construction:

– Bridge Cranes: Used for moving construction materials across large sites.

– Telescoping Cranes: Adaptable for lifting materials at varied heights.

5. Steel Industry:

– Ladle Cranes: For transporting molten metal.

– Foundry Cranes: Designed for the harsh environments of steel plants.

6. Warehousing and Logistics:

– Top Running Cranes: For high capacity lifting and long span coverage.

– Under Running Cranes: Suitable for maximized vertical space usage.

7. Power Generation:

– Turbine Cranes: Precision positioning of turbine components.

– Hydroelectric Station Cranes: Handling generators and other heavy equipment.

8. Shipbuilding:

– Goliath Cranes: Massive capacity for ship hull assembly.

– Deck Cranes: Handling large components on ship decks.

These overhead crane types are tailored for specific needs, ensuring safe and efficient operations across diverse industrial applications.

overhead shop crane Accessories Upgrades and Custom Manufacturing Options

Overhead shop cranes are crucial for material handling in various industrial settings. To enhance their functionality and efficiency, a range of accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. Remote Controls: For improved safety and convenience, wireless remote controls allow operators to manage crane operations from a distance.

2. Hoist Units: Choose from electric, manual, or pneumatic hoist units for lifting and lowering loads effectively.

3. Load Indicators: These devices provide real-time weight measurements to prevent overloading and ensure safe handling.

4. End Trucks and Gear Reducers: Enhance crane mobility and precision with durable end trucks and high-quality gear reducers.

5. Lifting Magnets and Vacuum Lifters: Ideal for handling ferrous materials and non-ferrous items, respectively.

Upgrades:

1. Variable Frequency Drives (VFDs): VFDs offer smooth acceleration and deceleration, reducing mechanical stress and prolonging crane life.

2. Anti-Sway Technology: Improve load control and minimize swinging for enhanced operational safety and precision.

3. Enhanced Safety Features: Upgrade with anti-collision systems, overload protection, and emergency stop functions for better risk management.

4. Automated Positioning Systems: Increase efficiency by programming cranes to move to pre-set positions automatically.

Custom Manufacturing Options:

1. Tailored Dimensions: Cranes can be custom-built to fit specific space constraints and operational requirements.

2. Specialized End Effectors: Customize end effectors to handle unique loads or specific processes.

3. Material Choices: Opt for different materials, such as stainless steel for corrosive environments or aluminum for lightweight applications.

4. Environmental Adaptations: Design cranes to withstand extreme temperatures, moisture, or other environmental factors.

With these accessories, upgrades, and custom options, overhead shop cranes can be optimized to meet specific operational needs, enhancing productivity and safety in any industrial setting.

List Quality Control and The Manufacturing Process of “overhead shop crane”

Quality Control of Overhead Shop Cranes

1. Design Verification:

– Ensure crane design meets industry standards (e.g., ASME, OSHA).

– Simulation software for load testing and stress analysis.

2. Material Inspection:

– Verify material certifications for structural integrity.

– Conduct chemical and mechanical property tests.

3. Fabrication Quality:

– Weld inspections using NDT techniques like ultrasonic or radiography.

– Checking dimensions and tolerances through precision instruments.

4. Load Testing:

– Perform static and dynamic load tests to confirm performance.

– Safety factor verification by testing beyond specified limits.

5. Component Testing:

– Inspect hoists, trolleys, and motors for operational reliability.

– Electrical component testing for voltage/current specs.

6. Final Assembly Inspection:

– Visual and functional inspection of the assembled crane.

– Ensure alignment and structural stability.

7. Documentation:

– Maintain quality records for traceability.

– Compliance certificates provided with the final product.

Manufacturing Process of Overhead Shop Cranes

1. Design and Planning:

– Conceptual and detailed design.

– Project planning, including materials and manpower.

2. Material Procurement:

– Source high-grade steel and components.

– Quality checks on incoming materials.

3. Cutting and Shaping:

– Use CNC machines to cut steel to specifications.

– Shaping and forming structural components.

4. Welding and Assembly:

– Welding of parts to form the main structure.

– Inspection of welds for quality and integrity.

5. Machining:

– Precision machining of components.

– Ensuring perfect fits for movable parts like hoists and trolleys.

6. Surface Treatment:

– Sandblasting and painting to prevent corrosion.

– Coating to enhance durability.

7. Component Integration:

– Installation of motors, hoists, and control systems.

– Electrical wiring and functional testing.

8. Testing:

– Rigorous operational and safety testing.

– Performance validation against load capacities.

9. Final Inspection and Shipping:

– Comprehensive final inspection.

– Packaging and shipment to the customer with required documentation.

By adhering to strict quality control protocols and a robust manufacturing process, overhead shop cranes are ensured to be safe, efficient, and reliable.

How to use “overhead shop crane”

An overhead shop crane is a lifting device used to move heavy objects within a workspace. Here’s a concise guide on how to use it safely and effectively:

1. Inspection:

– Visual Check: Inspect the crane for any visible damage or wear, including the hoist, cables, and hooks.

– Operational Test: Conduct a test run without a load to ensure all controls and movements are functioning correctly.

2. Preparation:

– Load Assessment: Verify the weight of the load and ensure it does not exceed the crane’s capacity.

– Rigging: Secure the load with appropriate slings, hooks, or chains. Ensure balancing and no risk of shifting.

3. Operation:

– Control Familiarization: Understand the crane’s controls. Most have buttons or a pendant with directional arrows.

– Lifting the Load: Slowly lift the load a few inches to check stability. Adjust rigging if the load is unbalanced.

– Moving the Load: Use smooth and controlled movements. Avoid jerky motions or sudden stops.

– Lowering the Load: Position the load accurately and lower it slowly to its final position.

4. Post-Operation:

– Unload Properly: Ensure the load is stable and secure before disconnecting rigging.

– Inspect Equipment: After use, re-inspect the crane for any signs of damage or wear.

– Shutdown Procedure: Turn off the crane and store control devices safely.

5. Safety Tips:

– Clear Area: Ensure the area beneath the load is free of people and obstructions.

– Communication: Use clear signals or a spotter to guide movements.

– Training: Ensure all operators are trained and understand the crane’s operation and safety procedures.

By following these steps, you can safely and efficiently use an overhead shop crane to move heavy items within your workspace.

“overhead shop crane” Comparative Analysis

Comparative Analysis of Overhead Shop Cranes

Overhead shop cranes, fundamental in industrial environments for material handling, can be classified primarily into three types: Bridge Cranes, Gantry Cranes, and Jib Cranes. Each type presents unique features suitable for different applications.

Bridge Cranes are typically used in large manufacturing spaces, providing extensive coverage. They consist of parallel runways with a traveling bridge spanning the gap. These cranes offer high weight capacity and precise control over load positioning, making them ideal for heavy-duty tasks. However, they require significant installation effort and structural support.

Gantry Cranes offer versatility as they are supported by freestanding legs moving on wheels or along a track system. These cranes are split into full and semi-gantry types. Gantry cranes are advantageous due to their mobility, enabling usage in various locations within a facility or outdoors. They are often more cost-effective than bridge cranes but may possess lower load capacities and need ample floor space for maneuvering.

Jib Cranes are anchored to a wall or floor-mounted pillar and feature a jib arm that can swing in an arc. Jib cranes are suitable for localized lifting tasks within a small radius and are highly space-efficient. They provide smooth rotational movement and are easy to maintain. However, they are limited in both reach and capacity compared to bridge and gantry cranes.

Conclusion: Selection among overhead shop cranes depends on application demands:

– Bridge Cranes excel in heavy-duty, extensive area coverage.

– Gantry Cranes are favored for their mobility and cost-efficiency.

– Jib Cranes are ideal for localized, smaller-scale tasks.

Considerations include installation space, load requirements, and operational flexibility. Each type offers distinct advantages, making it critical to align the crane type with specific industrial needs.

“overhead shop crane” Warranty and Support

Warranty and Support for Overhead Shop Crane

When investing in an overhead shop crane, understanding the warranty and support structure is crucial for ensuring long-term operational efficiency and peace of mind.

Warranty Coverage:

Most reputable manufacturers offer a comprehensive warranty that typically covers a period ranging from one to five years, depending on the model and components. This often includes:

1. Structural Warranty: Covers defects in materials and workmanship related to the crane’s main components, such as the bridge, trolley, and hoist.

2. Mechanical and Electrical Components Warranty: Protects against failures in motors, brakes, and control systems, ensuring that repair or replacement costs are minimized.

3. Limited Wear Warranty: Some manufacturers offer coverage for normal wear and tear on specific parts, although this is often limited to the first year.

What the Warranty Does Not Cover:

Standard exclusions typically include damages due to:

– Improper installation or maintenance

– Overloading or misuse of the crane

– Unauthorized modifications

– Natural wear on consumables like cables and pads

Support Services:

High-quality support services can significantly extend the life of your overhead shop crane and ensure minimal downtime. These services often include:

1. Customer Support: Responsive helplines or chat services that offer immediate assistance for troubleshooting and operational advice.

2. Maintenance Packages: Scheduled maintenance programs can be purchased to ensure that the crane is always in optimal working condition.

3. On-Site Service: Some manufacturers offer on-site technical support to address complex issues that cannot be resolved remotely.

4. Training Programs: Comprehensive training for operators and maintenance staff to ensure safe and efficient use of the equipment.

In summary, a robust warranty and support framework not only protects your investment but also ensures that your overhead shop crane operates seamlessly, enhancing productivity and safety in your workspace. Always review the specific terms and conditions of the warranty and support services before making a purchase to ensure they meet your operational needs.

List “overhead shop crane” FAQ

Certainly! Here are some frequently asked questions (FAQs) about overhead shop cranes:

1. What is an overhead shop crane?

An overhead shop crane is a mechanical lifting device used in industrial settings to move heavy loads horizontally and vertically. It typically consists of a hoist attached to a trolley that travels along a fixed beam or bridge.

2. What are the types of overhead shop cranes?

The primary types include:

– Single Girder Cranes: Have one main girder and are suitable for lighter loads.

– Double Girder Cranes: Feature two girders for increased load capacity.

– Gantry Cranes: Supported by freestanding legs, suitable for outdoor applications.

– Jib Cranes: Have a rotating arm for localized lifting.

3. How is the capacity of an overhead crane determined?

The capacity is determined by the design and is usually stated in terms of maximum load weight (e.g., 5 tons). It is crucial to never exceed the rated capacity to ensure safe operation.

4. What safety features should an overhead shop crane have?

Important safety features include:

– Overload protection

– Emergency stop functions

– Limit switches to prevent over-travel

– Regular inspection and maintenance

5. How often should an overhead crane be inspected?

The frequency of inspections depends on usage but generally includes:

– Daily Visual Inspections: Check for any obvious issues.

– Monthly Detailed Inspections: Examine the condition of the crane’s components.

– Annual Comprehensive Inspections: Thorough examination by a certified professional.

6. What are common applications for overhead shop cranes?

They are used in various industries, including manufacturing, automotive, warehousing, and construction, for tasks such as moving heavy machinery, assembly line support, and loading/unloading freight.

7. How do I choose the right crane for my shop?

Consider factors such as load capacity, span, lifting height, duty cycle, and specific application requirements. Consulting with a crane specialist can help ensure you select the appropriate equipment.

8. Can an overhead crane be customized?

Yes, overhead cranes can be tailored to meet specific requirements, including custom spans, specialized hoisting mechanisms, and additional safety features.

Top 10 FAQ with answer about overhead shop crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing overhead shop cranes from China:

1. What types of overhead shop cranes are available?

– China manufacturers offer various types such as single-girder, double-girder, and gantry cranes, each suited for different weight capacities and operational requirements.

2. How do I ensure the quality of the crane?

– Ensure the manufacturer is ISO certified and request third-party inspection reports. You might also want to visit the factory or get references from previous clients.

3. What is the lead time for delivery?

– Typical lead times range from 30 to 60 days, depending on customization and manufacturing capacity.

4. What do I need to customize?

– You can customize load capacity, span, lifting height, and operational speed. Communicate your specific needs clearly with the manufacturer.

5. What is the cost structure?

– The cost generally includes the crane itself, freight, customs duties, and installation. Obtain a detailed quotation to avoid hidden costs.

6. Are spare parts readily available?

– Confirm with the supplier that spare parts are readily available and inquire about the lead time for obtaining them.

7. What after-sales support is provided?

– Good manufacturers offer warranties, often ranging from 1 to 2 years, and some provide on-site technical support and training.

8. How do I handle shipping and customs clearance?

– Chinese manufacturers usually handle FOB (Free on Board) terms. Hiring a reliable freight forwarder can facilitate shipping and customs clearance.

9. What standards do these cranes adhere to?

– Ensure the cranes comply with international standards like ISO, CE, or ASME. Check for compliance with specific safety and operational standards.

10. What kind of maintenance is required?

– Regular maintenance includes checking for wear and tear, lubrication, and ensuring electrical components are functional. Manufacturers typically provide a manual detailing maintenance procedures.

These FAQs cover essential information and can help buyers make informed decisions when sourcing overhead shop cranes from China.