overhead trolley crane Safety Certifications

Overhead trolley cranes are essential in various industrial settings for heavy lifting and material handling. Ensuring their safe operation requires adherence to several safety certifications and standards.

1. OSHA Compliance: The Occupational Safety and Health Administration (OSHA) sets national standards for crane safety in the United States. OSHA 1910.179 and 1926 Subpart CC specify requirements for crane inspections, maintenance, and operator training.

2. ASME B30 Standards: The American Society of Mechanical Engineers (ASME) B30 series cover safety for various types of cranes. Specifically, ASME B30.2 pertains to overhead and gantry cranes, providing guidelines for design, construction, installation, inspection, and operation.

3. CMAA Specifications: The Crane Manufacturers Association of America (CMAA) provides detailed specifications for overhead cranes through CMAA Specification No. 70 and 74, covering single and double girder cranes. These guidelines emphasize manufacturing quality and safety.

4. ISO Standards: International Organization for Standardization (ISO) offers global standards like ISO 4301, related to classification and ISO 9927 for inspection, maintenance, and safe use of cranes.

5. Inspection and Certification: Regular inspections are critical. Third-party certifications by accredited bodies ensure adherence to applicable safety standards. Potential checks include load testing, structural integrity assessments, and functional testing of safety features.

6. Operator Training and Certification: Crane operators should be certified through recognized programs like those from the National Commission for the Certification of Crane Operators (NCCCO) or relevant local authorities to ensure they have the necessary skills and knowledge for safe operations.

7. Documentation and Record Keeping: Maintaining comprehensive records of inspections, maintenance, and operator training ensures compliance and can aid in identifying potential safety issues before accidents occur.

Adherence to these certifications and standards is crucial for ensuring the safe operation of overhead trolley cranes, protecting both operators and equipment.

List Reference Technical Parameters of “overhead trolley crane”

An overhead trolley crane is a versatile lifting device used in various industries for material handling. Below are some key technical parameters to consider:

1. Load Capacity: Maximum weight the crane can lift, typically ranging from a few tons to several hundred tons.

2. Span: The horizontal distance between the end trucks or legs of the crane, which defines the width of the lifting area.

3. Height of Lift: The vertical distance the hook can travel, which determines the maximum lifting height available.

4. Hoist Speed: Rate at which the hoist can raise or lower the load, generally measured in meters per minute (m/min) or feet per minute (ft/min).

5. Trolley Speed: Speed at which the trolley moves along the crane bridge, also measured in m/min or ft/min.

6. Bridge Speed: Rate at which the entire crane moves along its runway system.

7. Duty Cycle: A measure of the crane’s operational capabilities, categorized by factors such as load intensity and frequency of use. Common classifications include A1 to A8, with higher numbers indicating more demanding applications.

8. Control System: Includes either manual, pendant, radio remote, or automated control mechanisms for maneuvering the crane.

9. Electrical Requirements: Voltage, phase, and frequency specifications needed for crane operation.

10. Structural Requirements: Materials and design standards for the crane’s bridge, trolley, and supporting framework to ensure stability and safety.

11. Operating Environment: Conditions like indoor/outdoor usage, temperature ranges, and exposure to elements such as dust, moisture, or chemicals.

12. Safety Features: Incorporates overload protection, emergency stop mechanisms, anti-collision systems, and fail-safe brakes.

13. Compliance Standards: Adherence to regional and international standards such as ASME, OSHA, and FEM guidelines.

These parameters must be tailored to specific applications to ensure optimal performance and safety.

List Product features of “overhead trolley crane”

An overhead trolley crane is a versatile and essential piece of material handling equipment used in various industrial settings. Here are some key product features:

1. Load Capacity: Overhead trolley cranes come with varying load capacities, typically ranging from a few tons to several hundred tons, to accommodate different industrial needs.

2. Span and Lift Height: These cranes offer a wide range of span widths and lift heights, adaptable to specific facility dimensions and height requirements.

3. Construction Material: Typically made from high-quality steel, ensuring robustness, durability, and long lifecycle.

4. Control Systems: Available with multiple control options such as pendant controls, radio remote controls, and operator cabins, providing flexibility in operation.

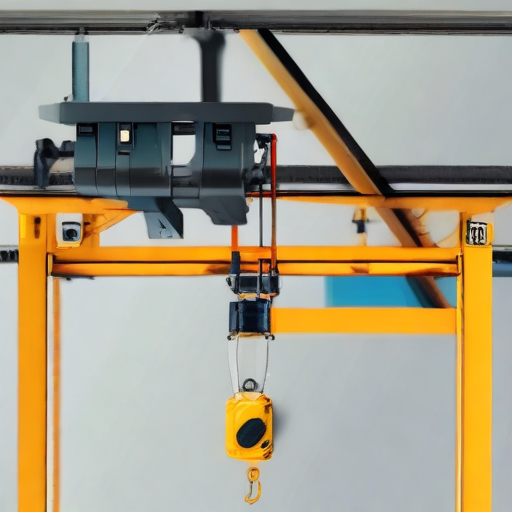

5. Hoist Mechanism: Equipped with a reliable hoist mechanism that includes electric wire rope or chain hoists for lifting and lowering loads efficiently.

6. Travel Mechanism: Features a trolley system that can glide smoothly along the crane’s bridge, supported by geared motors for horizontal movement.

7. Safety Features: Integrated with various safety mechanisms like emergency stop buttons, overload limiters, anti-collision devices, and fail-safe brakes.

8. Variable Speeds: Offers variable speed options for the hoisting, cross-travel, and long-travel motions, providing precise control and efficiency.

9. Maintenance Friendly: Designed with easy access to components for quick maintenance and minimal downtime.

10. Customization: Can be customized with additional features like anti-sway technology, specialized grabbing attachments, or explosion-proof designs for specific applications.

11. Installation and Ergonomics: Ergonomically designed for ease of installation and operation, reducing strain on operators and enhancing productivity.

12. Compliance and Standards: Built to comply with international standards and regulations, ensuring safety and reliability.

13. Energy Efficient: Incorporates energy-efficient motors and drives to reduce operational costs and environmental impact.

These features make overhead trolley cranes indispensable for industries such as manufacturing, warehousing, shipping, and construction, providing an optimal solution for lifting and transporting heavy loads.

List Various Types of “overhead trolley crane”

Overhead trolley cranes are essential for material handling in various industries. These cranes are distinguished by their ability to move loads along a horizontal bridge, which is supported by vertical columns or runways, typically installed on the ceiling. Here are several types of overhead trolley cranes:

1. Single Girder Overhead Cranes:

– Feature one main bridge girder.

– Suitable for lighter loads.

– Simpler and more cost-effective.

– Typically used in small manufacturing facilities and workshops.

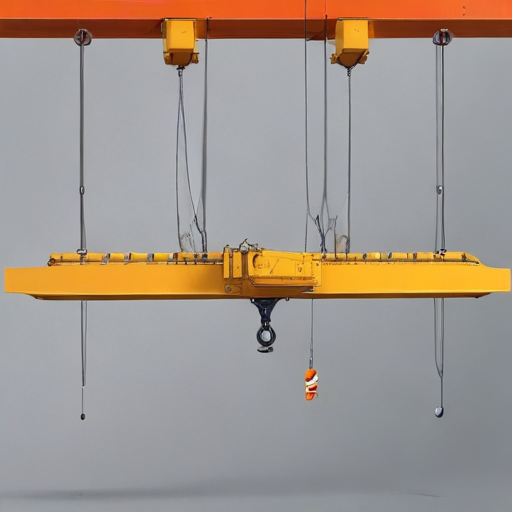

2. Double Girder Overhead Cranes:

– Include two main bridge girders.

– Ideal for handling heavier loads.

– Offer greater hook height and span.

– Common in larger industrial applications like steel mills and heavy manufacturing.

3. Top Running Overhead Cranes:

– Bridge girder moves along the top of the runway beams.

– Suitable for very high load capacities.

– Requires a higher ceiling for installation.

– Widely used in heavy industrial environments.

4. Under Running (Underslung) Overhead Cranes:

– Bridge girder runs on the bottom flange of the runway beams.

– Suitable for lighter loads and lower ceilings.

– Provides better space utilization.

– Often used in smaller workshops and assembly lines.

5. Gantry Cranes:

– Similar to overhead cranes, but supported by freestanding legs.

– Can be used indoors or outdoors.

– Flexible installation as they do not require runway beams.

– Used in shipyards, rail yards, and large-scale construction sites.

6. Bridge Cranes:

– Spanning across the width of the workspace.

– Move the trolley along the bridge for precise placement.

– Can be either single or double girder.

– Common in both light and heavy manufacturing environments.

7. Monorail Cranes:

– Utilize a single runway beam (monorail).

– Trolley moves along a fixed path.

– Best for simple and repetitive workflows.

– Often found in automated production lines and assembly processes.

Each type offers distinct advantages tailored to specific operational needs, ensuring efficient load handling and material transportation within facilities.

List Application of “overhead trolley crane”

An overhead trolley crane boasts versatility across numerous industries due to its ability to move heavy loads with precision and efficiency. Here are some of its key applications:

1. Manufacturing: Facilitates the assembly line production by transporting raw materials and finished products between workstations.

2. Warehousing: Assists in the seamless storage, retrieval, and management of large or heavy inventory items, enhancing logistics and workflow.

3. Steel Mills: Manages the handling and movement of bulky steel components, such as coils, slabs, and bars, improving safety and productivity.

4. Automotive Industry: Plays a critical role in handling heavy car parts and assemblies on production lines, allowing for greater automation and efficiency.

5. Construction: Used on construction sites to lift and position heavy materials such as steel beams, pre-fabricated structures, and construction equipment.

6. Shipbuilding: Essential for transporting massive ship components and assemblies, aiding in the construction and repair of vessels.

7. Aerospace: Handles large aircraft components like wings, engines, and fuselages during assembly, maintenance, and repair.

8. Mining: Assists in the transportation of mined materials and heavy mining equipment within the mining site.

9. Paper Mills: Manages large rolls of paper through the production and finishing processes, ensuring efficient workflow.

10. Power Plants: Services include the installation, maintenance, and replacement of heavy machinery, turbines, and generators.

The overhead trolley crane is integral to operations where the precise handling of heavy loads is required, reducing manual labor, enhancing safety, and increasing operational efficiency across a wide range of industries.

List Buyer Types of “overhead trolley crane”

When exploring the market for overhead trolley cranes, several buyer types emerge, each with specific needs and applications. Below are the primary buyer types:

1. Manufacturing Plants: These facilities often require overhead trolley cranes for moving heavy materials and components within production areas, handling assembly lines, and loading/unloading goods.

2. Warehouses and Distribution Centers: In these environments, overhead cranes are essential for managing large inventories, stacking goods, and optimizing space by moving items to high or hard-to-reach shelves.

3. Construction Companies: Cranes are critical for lifting and placing heavy building materials, aiding in the construction of infrastructure projects, and ensuring smooth operations on construction sites.

4. Metal Fabrication Shops: These shops utilize overhead trolley cranes for carrying metal sheets, pipes, and fabricated components. They facilitate welding, cutting, and assembly processes by providing precise positioning and movement of heavy materials.

5. Logistics and Shipping Firms: These buyers need cranes for handling containers, cargo, and heavy packages at ports, rail yards, and other transportation hubs, ensuring efficient loading and unloading.

6. Automotive Industry: Overhead cranes in auto manufacturing plants help in the assembly of vehicles, moving parts such as engines and large components between different stages of the production line.

7. Aerospace Industry: Precision and the ability to handle large, delicate parts make overhead trolley cranes indispensable in the aerospace sector for moving aircraft components and assemblies.

8. Steel Mills and Foundries: Heavy lifting capabilities are crucial in these industries for moving raw materials, molten metal, and finished products within the facility.

9. Power Plants: Maintenance activities in power generation plants often require the heavy lifting and precise placement of large equipment and machinery, facilitated by overhead cranes.

10. Research and Development Centers: Laboratories and R&D bodies may need specialized cranes for manipulating experimental apparatus, heavy machinery, or large prototypes.

Each type of buyer evaluates factors such as load capacity, span, lift height, duty cycle, and specific operational needs when selecting an overhead trolley crane.

List “overhead trolley crane” Project Types for Different Industries

Overhead trolley cranes, often referred to as overhead bridge cranes, are versatile lifting devices used across various industries to enhance efficiency, safety, and productivity. Here’s a brief overview of the project types for different industries:

1. Manufacturing:

– Assembly Lines: Facilitates movement and precise placement of components along the production line.

– Heavy Equipment Manufacturing: Assists in handling large, heavy components such as engines, frames, and other machinery parts.

2. Warehousing and Logistics:

– Material Handling: Efficient in transporting goods and materials across large warehouse spaces.

– Inventory Management: Helps in quick and safe retrieval of items from high storage areas, optimizing space utilization.

3. Construction:

– Precast Concrete Component Handling: Used for lifting and positioning precast concrete components.

– Steel Fabrication: Essential for handling steel beams and other heavy construction materials safely.

4. Automotive:

– Assembly Plants: Plays a crucial role in the handling, assembly, and transport of vehicle parts.

– Maintenance Bays: Facilitates lifting engines, transmissions, and other heavy components for repair and maintenance.

5. Aerospace:

– Aircraft Assembly: Critical in manipulating large aircraft components like fuselages, wings, and engines.

– Maintenance Hangars: Used for the periodic maintenance and component replacement of aircraft.

6. Shipping and Ports:

– Cargo Handling: Efficient in loading and unloading heavy cargo from ships.

– Container Movement: Assists in the stacking and retrieval of shipping containers.

7. Mining:

– Material Extraction: Aids in lifting heavy loads of extracted materials.

– Equipment Maintenance: Essential for maintaining and repairing heavy mining equipment.

8. Energy (Oil, Gas, and Wind):

– Turbine Assembly: Used in assembling wind turbines or other heavy energy-generating components.

– Oil Rig Maintenance: Facilitates the lifting of heavy equipment and parts for maintenance on offshore and onshore rigs.

overhead trolley crane Accessories Upgrades and Custom Manufacturing Options

Overhead trolley cranes are versatile and essential for various industrial applications, and their functionality can be significantly enhanced through a range of accessories, upgrades, and custom manufacturing options.

Accessories:

1. Lifting Attachments: Enhance versatility with magnets, grabs, spreader beams, and lifting beams suitable for different loads.

2. Remote Controls: Improve operator safety and precision with wireless remote control systems.

3. End Trucks: Optimize movement with durable wheel assemblies for smooth operation.

4. Hoists: Upgrade with electric or pneumatic hoists to accommodate different load capacities.

5. Safety Features: Integrate anti-collision systems, overload sensors, and emergency stop mechanisms for enhanced safety.

Upgrades:

1. Automation Systems: Integrate PLCs and automation software to streamline operations and increase efficiency.

2. Variable Frequency Drives (VFDs): Improve speed control and energy efficiency of the crane.

3. LED Lighting: Install energy-efficient lighting to improve visibility in the workspace.

4. Noise Reduction: Implement noise-canceling systems and quiet-running gears to reduce operational noise.

5. Maintenance-Free Components: Upgrade to self-lubricating bearings and other low-maintenance parts to reduce downtime.

Custom Manufacturing Options:

1. Tailored Dimensions: Design cranes with custom spans, heights, and capacities to fit specific workspace requirements.

2. Material Choices: Use specialized materials such as stainless steel or corrosion-resistant metals for extreme environments.

3. Specialized Trolley Designs: Create custom trolleys for unique lifting needs or to handle unconventional load shapes.

4. Weatherproofing: Add protective coatings and enclosures for outdoor or harsh environment applications.

5. Integrated Solutions: Develop turnkey systems that integrate the crane with existing workflows and facilities.

By leveraging these accessories, upgrades, and customized manufacturing options, businesses can significantly enhance the efficiency, safety, and adaptability of their overhead trolley cranes to meet specific operational demands.

List Quality Control and The Manufacturing Process of “overhead trolley crane”

Quality Control and Manufacturing Process of Overhead Trolley Crane

Manufacturing Process:

1. Design and Engineering:

– Requirements analysis

– CAD modeling and simulation

– Stress and load testing using software

2. Material Selection:

– High-strength steel for durability

– Electrical components for the control system

– Selection of motors, cables, and safety components

3. Fabrication:

– Cutting of steel using laser or plasma cutters

– Welding of structural components

– Machining for precision parts (e.g., gears)

4. Assembly:

– Combining of sub-assemblies (e.g. trolley, bridge)

– Installation of motors and control systems

– Integration of components (e.g., hoists, trolleys)

5. Surface Treatment:

– Sandblasting for surface cleaning

– Painting or powder coating for corrosion resistance

6. Control System Programming:

– Configuration of control software

– Installation of control panels and wiring

7. Testing:

– Load testing at various capacities

– Operational testing for mechanical and electrical functions

– Safety feature validation

Quality Control:

1. Material Inspection:

– Verification of material certificates

– Mechanical and chemical property testing

2. Fabrication Quality Checks:

– Weld inspections (e.g., visual, ultrasonic testing)

– Dimensional accuracy checks

3. Pre-assembly Inspection:

– Verification of component specifications

– Non-destructive testing (NDT) for critical parts

4. In-Process Inspection:

– Monitoring of assembly processes

– Torque checks on fasteners

5. Final Inspection:

– Comprehensive load and operational tests

– Verification of electrical systems

6. Documentation and Compliance:

– Record keeping of inspections and tests

– Ensuring adherence to industry standards and regulations (e.g., ISO, OSHA)

7. Customer Acceptance:

– Final inspection in presence of the customer or third-party

– Customer feedback integration

This streamlined process and rigorous quality control ensure the overhead trolley crane meets performance, safety, and reliability standards.

How to use “overhead trolley crane”

Using an overhead trolley crane involves several key steps to ensure safe and efficient operation. Here’s a concise guide:

Preparation

1. Inspection: Before use, inspect the crane for any visible damage or wear, ensuring all components are in proper working condition.

2. Environment Check: Ensure the area around the crane is clear of obstructions and personnel not involved in the operation.

3. Load Assessment: Verify the weight of the load to ensure it does not exceed the crane’s capacity.

Operation

1. Positioning: Use the controls to move the trolley to a position directly above the load. Most overhead trolley cranes have remote or pendant controls for this purpose.

2. Hoisting the Load:

– Attach the hook or other lifting devices to the load securely.

– Slowly lift the load a few inches off the ground to check for balance.

– If the load is balanced, continue raising it to the desired height.

3. Moving the Load:

– Once the load is lifted, use the controls to move the trolley along the overhead track to the target location.

– Move the load slowly and steadily to prevent swinging.

4. Lowering the Load:

– Once the load is in position, slowly lower it to the ground.

– Ensure that the area is clear and the load is positioned correctly before fully lowering it.

Post-Operation

1. Secure the Crane: After the task is complete, move the empty trolley to a parking position.

2. Power Down: Turn off the crane and secure it per manufacturer guidelines.

3. Documentation: Note any issues or maintenance needs in a logbook.

Safety Tips

– Always wear appropriate personal protective equipment (PPE).

– Never exceed the crane’s load limit.

– Communicate clearly with team members using signals or radio.

By following these steps, you can safely and efficiently operate an overhead trolley crane.

“overhead trolley crane” Comparative Analysis

An overhead trolley crane, often called an overhead bridge crane, is a vital piece of industrial equipment used for material handling in warehouses, factories, and large indoor facilities. It consists of parallel runways with a traveling bridge spanning the gap. The lifting mechanism, or hoist, travels along the bridge, enabling it to move loads horizontally and vertically.

##### Comparative Analysis

Design and Structure:

Compared to gantry cranes, which feature a similar basic mechanism, overhead trolley cranes are permanently mounted on building structures, making them more stable and capable of handling heavier loads. Gantry cranes, however, are more versatile and can be moved to different locations within a facility.

Capacity and Range:

Overhead trolley cranes usually have higher weight capacities and greater spans than jib cranes, which are typically used for lighter loads and have a limited radial reach. The overhead crane’s ability to traverse across the entire length and breadth of a facility provides it with a comprehensive range of operation.

Cost and Installation:

While initial installation costs for overhead trolley cranes can be high due to the need for structural support, their maintenance costs are generally lower compared to mobile cranes, which require regular inspections and servicing due to their mobile nature.

Operational Efficiency:

In terms of operational efficiency, overhead trolley cranes excel, particularly in environments requiring repetitive, high-volume movements. They are faster and more precise compared to forklifts, which are limited by aisle space and maneuverability.

Safety:

Regarding safety, overhead trolley cranes offer an advantage by reducing floor-level obstructions and minimizing the risk of accidents. In contrast, mobile lifting equipment like forklifts and mobile cranes pose a higher risk of collisions and tipping over.

In summary, overhead trolley cranes are superior in handling heavy materials, offering higher efficiency for industrial applications that require large-scale, repetitive movements with minimal floor disruption. However, they come at a higher initial cost and are more permanent installations compared to other material handling options like gantry cranes or forklifts.

“overhead trolley crane” Warranty and Support

Warranty and Support for Overhead Trolley Cranes

Warranty:

Our overhead trolley cranes come with a comprehensive warranty to ensure peace of mind and reliability. Each crane is covered for a period of one year from the date of purchase. This warranty includes coverage for any defects in materials or workmanship under normal use. Should any issues arise, we commit to repairing or replacing defective parts at no additional cost, ensuring minimal disruption to your operations.

Support:

We pride ourselves on offering exemplary support for our overhead trolley crane systems. Our dedicated customer service team is available to assist you with any concerns or questions. Here’s how we support our customers:

1. 24/7 Customer Service: Reach out to our expert team via phone, email, or live chat for immediate assistance.

2. On-Site Support: Our technicians are available for on-site inspections, maintenance, and repairs to ensure your crane operates efficiently.

3. Preventative Maintenance Programs: Enroll in our maintenance programs to extend the lifespan of your crane, avoid unexpected downtimes, and ensure compliance with safety regulations.

4. Training and Documentation: We offer comprehensive training programs and detailed manuals to help your team operate the crane safely and effectively.

5. Spare Parts Availability: We maintain a robust inventory of spare parts to facilitate quick replacements, minimizing downtime.

Steps for Warranty and Support Claims:

1. Contact Us: Initiate your claim by contacting our support team with details of the issue.

2. Assessment: Our technical team will evaluate the problem, potentially requiring photos or on-site inspection.

3. Resolution: Based on the assessment, we will either repair or replace the defective part or component.

By choosing our overhead trolley cranes, you are investing in quality, reliability, and unparalleled support.

List “overhead trolley crane” FAQ

Overhead Trolley Crane FAQs

1. What is an overhead trolley crane?

An overhead trolley crane is a type of crane where a trolley (hoisting mechanism) runs on rails or tracks installed on the crane’s bridge, enabling horizontal movement of heavy loads. Commonly used in industrial settings for transporting materials within a given area.

2. What are the main types of overhead trolley cranes?

– Single Girder Cranes: Featuring one main bridge girder, ideal for light to moderate lifting.

– Double Girder Cranes: Having two main bridge girders, suited for heavy-duty lifting tasks.

– Top Running Cranes: The trolley runs on tracks mounted on top of the crane bridge.

– Under Running Cranes: The trolley runs on the bottom flange of the bridge beams.

3. What industries commonly use overhead trolley cranes?

Overhead trolley cranes are widely used in manufacturing, warehousing, metal production, automotive, aerospace, and shipbuilding industries. They facilitate efficient movement and positioning of heavy materials.

4. What weight capacities are available for overhead trolley cranes?

These cranes can handle a wide range of weights, from a few tons to several hundred tons, depending on the design and configuration. Specific capacities should match the operational needs.

5. How do you maintain an overhead trolley crane?

Regular inspections and preventive maintenance are crucial. This includes checking electrical components, testing safety mechanisms, lubricating moving parts, tightening fasteners, and ensuring the integrity of the rails and structure.

6. What safety measures should be followed?

– Regular training for operators.

– Routine inspections and maintenance.

– Adherence to load capacity limits.

– Use of appropriate personal protective equipment (PPE).

– Implementation of emergency shut-off protocols.

7. Can overhead trolley cranes be customized?

Yes, they can be tailored to specific operational requirements, including varying span lengths, lifting heights, speeds, and control systems. Customization ensures optimal performance for specific tasks.

8. What are the advantages of using an overhead trolley crane?

– Efficient material handling.

– Reduced labor costs and improved safety.

– Improved space utilization in warehouses.

– Adaptability to various operational needs.

By addressing the above FAQs, you’ll have a foundational understanding of overhead trolley cranes, their functionalities, maintenance, and safety considerations.

Top 10 FAQ with answer about overhead trolley crane for Buyer Sourcing from China

1. What is an overhead trolley crane?

An overhead trolley crane consists of a hoist trolley running on rails or beams fixed above the working area, capable of lifting and moving heavy loads horizontally and vertically.

2. Why source overhead trolley cranes from China?

China is known for its cost-effective manufacturing, advanced production technologies, and a wide range of suppliers offering customizable options that meet international standards and rigorous quality checks.

3. What are the key specifications to consider?

Buyers should consider lifting capacity, span, lifting height, duty cycle, control options, and the type of environment (indoor/outdoor) where the crane will be operated.

4. How do I ensure quality when sourcing from China?

Use reputable suppliers with certifications like ISO, conduct factory audits, ask for quality control reports, request product samples, and check customer testimonials or reviews.

5. What are the common certifications for Chinese manufacturers?

Look for ISO 9001, CE, SGS, and CCC certifications, which ensure adherence to international quality and safety standards.

6. What is the typical lead time for manufacturing and shipping?

Generally, the production lead time ranges from 30 to 60 days depending on customization requirements, with additional shipping time varying based on destination and shipping method.

7. Are there custom design options available?

Yes, Chinese manufacturers often offer extensive customization to cater to specific operational needs, including specialized hoists, control systems, and structural modifications.

8. What about after-sales services and support?

Reputable suppliers provide after-sales services including installation assistance, training, regular maintenance, spare parts supply, and a warranty period.

9. How is shipping managed and what are the costs?

Shipping can be arranged via sea freight for bulky items, and costs depend on the destination, volume, and weight. Suppliers typically assist with logistics and export documentation.

10. What payment terms are commonly accepted?

Common payment terms include a 30% deposit upon order confirmation and the 70% balance before shipment. Payment methods often include T/T (Telegraphic Transfer), L/C (Letter of Credit), or Western Union.

By addressing these key questions, you can effectively source reliable and efficient overhead trolley cranes from China, ensuring operational productivity and safety.