port container crane Safety Certifications

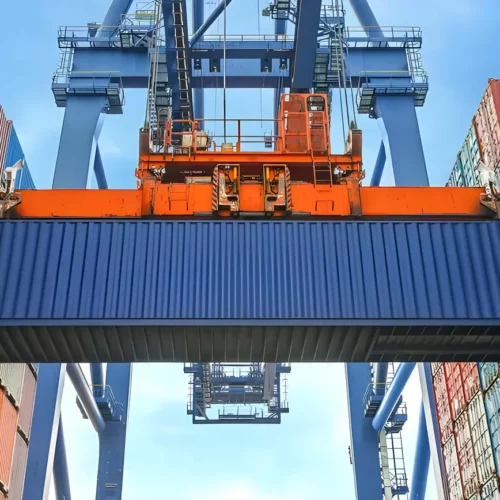

Port container cranes are essential for the efficient handling of cargo in maritime terminals, but their massive size and operational complexity make them subjects of stringent safety regulations. Ensuring the safe operation of port container cranes involves adhering to several international and national safety certifications and standards.

1. ISO 9001: This certification ensures that the company operating the cranes has a quality management system in place, which includes safety protocols.

2. ISO 45001: A globally recognized standard for Occupational Health and Safety Management Systems (OHSMS), ISO 45001 helps organizations control risks, reduce workplace hazards, and improve employee safety.

3. EN 13852-1: This European standard specifies the safety requirements for the design, inspection, maintenance, and operation of offshore cranes, including port container cranes.

4. FEM 1.001: Issued by the European Materials Handling Federation, this standard outlines general guidelines for the safe design and use of lifting equipment.

5. OSHA Compliance: In the United States, cranes must comply with regulations set by the Occupational Safety and Health Administration (OSHA), which includes standards for crane operation, inspections, and training.

6. Maritime Labour Convention (MLC) 2006: This includes provisions to ensure the safety and health of workers at sea, indirectly affecting port crane operations by setting guidelines for safer working conditions.

7. IEC 61508: This standard focuses on the functional safety of electrical, electronic, and programmable electronic safety-related systems, critical for the electronically controlled systems of modern cranes.

8. ASME B30: The American Society of Mechanical Engineers (ASME) provides safety standards specific to cranes and lifting devices, including operational guidelines and maintenance procedures.

Adhering to these certifications ensures not only regulatory compliance but also the safety and well-being of crane operators and other port personnel, minimizing risks associated with crane operations.

List Reference Technical Parameters of “port container crane”

Port container cranes, also known as ship-to-shore (STS) cranes, are indispensable in modern container terminals for loading and unloading container ships. Here are the key technical parameters to consider:

1. Lifting Capacity: This refers to the maximum weight a crane can lift, typically ranging from 40 to 100 tons, depending on the crane size and design.

2. Lifting Height: This is the maximum height the crane can lift a container, generally between 30 to 50 meters above the quay level.

3. Outreach: The horizontal distance from the crane’s vertical axis to the outermost point it can reach over the water. In modern cranes, this can stretch from 40 to 70 meters to accommodate larger ships.

4. Backreach: The distance a crane can reach inland from its vertical axis, usually between 10 to 20 meters, to transfer containers to and from the quay.

5. Span: The horizontal distance between the rails on which the crane moves along the quay, typically ranging from 15 to 35 meters.

6. Hoist Speed: The rate at which the lifting mechanism can lift or lower a container, generally between 70 to 180 meters per minute empty and 45 to 90 meters per minute under load.

7. Trolley Speed: The speed at which the crane’s trolley, which holds the lifting mechanism, moves horizontally along the boom. This speed ranges from 150 to 300 meters per minute.

8. Gantry Speed: The rate at which the entire crane structure moves along the quay, usually between 20 to 45 meters per minute.

9. Operational Height: The overall height of the crane, important for clearing tall ship structures, typically from 50 to 120 meters.

10. Electrification and Power Supply: STS cranes are generally electrified and require substantial power, often using 3-phase AC with voltage between 3 to 20 kV and power ratings up to several megawatts.

11. Automation and Control Systems: Advanced STS cranes may include semi-automated or fully automated control systems, improving efficiency and safety.

These parameters help determine the crane’s capability to handle different sizes and types of container ships efficiently and safely.

List Product features of “port container crane”

A port container crane, also known as a ship-to-shore (STS) crane, is a crucial piece of equipment used in ports and harbors for loading and unloading containers from ships. Below are the key features of a port container crane:

1. High Lifting Capacity: These cranes are designed to lift heavy containers, often with capacities exceeding 60 metric tons, allowing for the efficient handling of fully loaded containers.

2. Extended Reach: With booms extending up to 60 meters or more, port container cranes can reach across large vessels, accommodating multiple rows of containers on ships of various sizes.

3. Precision Control: Advanced control systems provide precise movements, ensuring containers can be moved with accuracy, reducing the risk of damage to cargo.

4. Trolley Mechanism: Equipped with trolleys that traverse the length of the boom, the crane ensures swift transport of containers from ship to quay.

5. Anti-sway Technology: Modern cranes utilize anti-sway technology to minimize container swinging during lifting operations, enhancing safety and efficiency.

6. Automated Systems: Some models feature automated systems for improved operational efficiency, including automatic positioning and container tracking.

7. Operator Cabins: Ergonomically designed cabins provide operators with clear visibility, often including climate control and advanced diagnostics for enhanced operator comfort and productivity.

8. Safety Features: Equipped with multiple safety systems, including overload protection, emergency stop mechanisms, and collision-avoidance technology, these cranes prioritize operational safety.

9. Energy Efficiency: Many cranes incorporate energy-saving features like regenerative braking and energy recuperation systems, reducing overall power consumption.

10. Durable Construction: Built to withstand harsh maritime environments, these cranes use corrosion-resistant materials and coatings, ensuring longevity and reliable performance.

11. Maintenance Access: Designed for ease of maintenance, with accessible components and integrated diagnostic systems, minimizing downtime.

12. Customizability: Can be tailored to specific port requirements, including variations in height, reach, and lifting capacity, to meet diverse operational needs.

Overall, port container cranes are integral to modern port operations, facilitating the smooth flow of global trade through their sophisticated design and advanced technological features.

List Various Types of “port container crane”

Port container cranes play a vital role in modern shipping and logistics by loading and unloading containers from vessels efficiently. Here are various types of port container cranes:

1. Ship-to-Shore (STS) Cranes:

– Panamax STS Cranes: Designed to handle ships that can pass through the Panama Canal, typically with container capacities up to about 13 rows across.

– Post-Panamax STS Cranes: For vessels too large for the Panama Canal, handling around 18 rows across.

– Super-Post-Panamax STS Cranes: These cranes accommodate the largest ships, with capacities of over 22 rows across.

2. Rubber-Tired Gantry (RTG) Cranes:

– These mobile cranes operate on rubber tires, making them flexible for moving around the container yard. They are essential for stacking and organizing containers.

3. Rail-Mounted Gantry (RMG) Cranes:

– Fixed on rails, these cranes are highly efficient for operations in container yards, particularly where high stacking and long-distance travel across the yard are needed.

4. Straddle Carriers:

– These vehicles lift containers by straddling them, transporting them over short distances within the terminal. They are versatile and often used for moving containers to and from storage areas.

5. Reach Stackers:

– These are forklift-like machines used for handling containers in small to medium-sized terminals. They have a telescopic boom to lift and move containers over short distances.

6. Floating Cranes:

– Mounted on barges or ships, these cranes are used in ports with limited infrastructure or for heavy lifting tasks that shore-based cranes cannot manage.

Each type of port container crane plays a specific role in ensuring the smooth handling of containers in various terminal operations, catering to different sizes of vessels, yard configurations, and logistical needs.

List Application of “port container crane”

Port container cranes, also known as ship-to-shore cranes, are essential pieces of equipment used in maritime logistics and container handling at port terminals. Here are some key applications:

1. Loading and Unloading Containers: These cranes transfer containers between ships and the port terminal, facilitating efficient cargo handling.

2. Stacking and Storage: They organize containers in storage yards, stacking them systematically to optimize space utilization and accessibility.

3. Intermodal Transfer: Port cranes handle transfer of containers between different transport modes (ship, rail, truck), ensuring seamless logistics and supply chain operations.

4. Transshipment Operations: Used in transshipment hubs, cranes transfer containers from larger mother ships to smaller feeder vessels, supporting global trade routes.

5. Cargo Inspection: Cranes are often equipped with technology to scan and inspect cargo, aiding in security and customs checks.

6. Specialized Handling: Some cranes are designed to handle odd-sized or heavy cargo, ensuring diverse container types can be efficiently managed.

7. Automated Operations: Modern port cranes incorporate automation and remote control technologies, increasing precision, safety, and operational efficiency.

8. Environmental Management: Electric or hybrid cranes reduce carbon emissions, contributing to sustainable port operations.

9. Capacity Management: By optimizing crane usage, ports can handle increased cargo volume without proportional increases in labor or operational costs.

10. Disaster Relief and Humanitarian Aid: In emergency situations, cranes expedite the unloading of relief supplies, helping in timely disaster response.

These applications demonstrate the pivotal role of port container cranes in facilitating global trade, enhancing operational efficiency, and supporting robust supply chain management.

List Buyer Types of “port container crane”

When discussing the buyer types of port container cranes, it’s essential to focus on various stakeholders involved in port and logistics operations. Here are key buyer types of port container cranes:

1. Port Authorities: These are government or semi-government entities responsible for managing port operations. Port authorities invest in container cranes to ensure efficient cargo handling and increase port throughput. They focus on enhancing their port’s competitiveness and operational efficiency.

2. Terminal Operators: These can be independent companies or subsidiaries of larger port authorities that manage specific terminals within a port. Terminal operators purchase container cranes to optimize container loading and unloading processes, thereby improving turnaround times and service quality for shipping lines.

3. Shipping Lines: Some major shipping lines may invest in container cranes, especially if they operate their dedicated terminals. By owning the equipment, they aim to reduce dependency on third-party terminal operators and ensure timely and efficient services as part of their integrated logistics solutions.

4. Logistics and Shipping Companies: Integrated logistics providers and shipping companies that offer end-to-end supply chain solutions may also invest in container cranes. This allows them to control and streamline their logistics operations, guaranteeing efficiency and reducing costs for their clients.

5. Industrial and Special Economic Zones: These zones, often developed to boost industrial growth and exports, require efficient port infrastructure. Hence, their management bodies may invest in container cranes to attract businesses by ensuring smooth and efficient logistics support.

6. Private Investors and Developers: There is a growing trend of private investment in port infrastructure. Private investors and developers may acquire container cranes as part of their investments in developing new port facilities or upgrading existing ones to enhance capacity and performance.

7. Government Agencies: National or regional government agencies may purchase container cranes as part of broader economic development initiatives aimed at improving trade infrastructure and boosting economic growth.

These buyer types ensure that port container cranes are efficiently utilized to improve overall port performance, streamline logistics, and enhance global trade efficiency.

List “port container crane” Project Types for Different Industries

Port container cranes, essential for loading and unloading shipping containers, are integral to various industries. Here are some primary project types associated with different industries:

1. Maritime Shipping:

– Ship-to-Shore Cranes: Used for loading/unloading containers from vessels at port terminals.

– Rail-Mounted Gantry Cranes (RMG): Employed for stacking and transferring containers within terminal rail yards.

2. Logistics and Warehousing:

– Rubber-Tired Gantry Cranes (RTG): Commonly used in container yards to move containers between storage stacks and trucks.

– Automated Stacking Cranes (ASC): Designed for high-efficiency automated container handling within warehousing and distribution centers.

3. Manufacturing:

– Straddle Carriers: Employed for direct transfer of containers between various stages of production and shipping areas.

– Reach Stackers: Used within manufacturing facilities to handle heavy components and finished products stored in containers.

4. Energy:

– Heavy Lift Cranes: Utilized for moving large containerized parts for power plants, wind turbines, and other energy projects.

– Floating Cranes: Used in offshore energy projects for transferring containers laden with equipment to support oil and gas platforms or wind farms.

5. Construction:

– Mobile Harbor Cranes: Deployed at construction sites near waterways for flexible container handling.

– Crawler Cranes: Utilized for transporting building materials in containers across large construction sites.

6. Automotive:

– Automated Guided Vehicles (AGV): Employed for efficient and autonomous container transport within automotive plants.

7. Agriculture:

– Forklift Trucks: Used for managing smaller containerized loads within agricultural facilities.

– Telescopic Handlers: Employed for container handling in farm environments, particularly for bulk goods.

Port container crane projects cater to the specialized needs of different industries, facilitating efficient and effective handling and transportation logistics across diverse sectors.

port container crane Accessories Upgrades and Custom Manufacturing Options

Port container cranes are critical assets in modern maritime logistics, and their efficiency can be significantly enhanced with accessories, upgrades, and custom manufacturing options tailored to specific operational needs. Among the most popular accessories are spreaders, which can be customized for handling different container sizes and types, including twin-lift, tandem, and rotating spreaders. Anti-sway systems are another valuable upgrade, stabilizing loads to reduce cycle times and increase safety during operations.

Advanced automation and control systems can also be integrated, such as remote control operation, which enhances efficiency by reducing the need for on-site operators. Energy-efficient drives and regenerative braking systems help in lowering operational costs and minimizing environmental impact.

Custom manufacturing allows for the adaptation of cranes to unique operational needs. This could include variable span and height adjustments, custom hoisting capacities, and specialized grab attachments for handling bulk materials or non-containerized cargo. Structural reinforcements and corrosion-resistant coatings are additional custom options that extend the crane’s lifecycle in harsh maritime environments.

Telemetry and real-time data analytics systems are increasingly being adopted to provide operators with actionable insights into crane performance, predictive maintenance, and fault diagnostics. Upgrading the crane’s software can also offer more precise control, better alignment with port operations management systems, and enhanced data security.

Incorporating these upgrades and custom features not only boosts the efficiency and versatility of port container cranes but also enhances their longevity, safety, and operational effectiveness. Investing in these enhancements can lead to substantial long-term savings and higher throughput, ultimately making port operations more competitive and responsive to the demands of global trade.

List Quality Control and The Manufacturing Process of “port container crane”

Quality Control of Port Container Cranes

1. Material Inspection: Ensure all raw materials meet industry standards. Metals and components undergo chemical analysis and mechanical tests for authenticity and reliability.

2. Welding Quality: Use non-destructive tests like ultrasonic or radiographic inspection to check weld quality, ensuring structural integrity.

3. Dimensional Accuracy: Precise measurements and alignment of parts using advanced tools such as laser trackers guarantee dimensional accuracy.

4. Load Testing: Cranes are subject to load tests to verify their lifting capacity and stability. Simulated loads may exceed operational ranges to ensure safety margins.

5. Electrical Systems: Inspect wiring, control systems, and automation components for functionality and safety compliance.

6. Paint and Coating: Surface coatings are checked for adherence, thickness, and resilience against corrosion and environmental conditions.

7. Functional Testing: Conduct comprehensive testing, including operational speed, movement, and responsiveness checks, to ensure performance standards.

Manufacturing Process of Port Container Cranes

1. Design and Engineering: Begin with extensive design and engineering using CAD software. Perform simulations for stress and load analysis.

2. Material Procurement: Source high-quality materials like high-tensile steel, electronic components, and hydraulic systems.

3. Fabrication: Cut, shape, and weld steel components. Ensure structural elements meet design specifications through rigorous testing.

4. Assembly: Pre-assemble major components such as the crane’s boom, trolley, and girder. Use precision alignment tools for accurate assembly.

5. Electrical and Hydraulic Installation: Integrate electrical systems, including PLCs, sensors, and motors. Install hydraulic systems for operations like lifting and moving.

6. Quality Control: Conduct a series of inspections and tests, including load testing, functional testing, and safety checks.

7. Surface Treatment: Apply anti-corrosion coatings and paint for durability against harsh marine environments.

8. Final Assembly and Testing: Complete the final assembly of all components and conduct a series of functional tests to ensure the crane meets all operational and safety standards.

9. Transportation: Disassemble (if necessary) for transportation and ship the crane to the port for installation and commissioning.

10. Installation: Install the crane at the port, followed by final calibration and testing to ensure proper functionality.

Through meticulous quality control and a well-structured manufacturing process, port container cranes are built to meet stringent performance and safety standards.

How to use “port container crane”

Operating a port container crane involves several key steps, performed by trained professionals to ensure safety and efficiency. Here’s a streamlined process:

1. Pre-Operation Check:

– Inspection: Conduct a thorough inspection of the crane to check for any mechanical or electrical issues. Ensure all safety systems are functioning.

– Documentation: Review work orders, cargo details, and any specific instructions or constraints.

2. Cabin Setup:

– Climb into the Operator’s Cabin: Access the elevated cabin using ladders or elevators.

– Adjust Controls: Familiarize yourself with the crane controls, including joysticks, pedals, and monitors.

3. Positioning the Crane:

– Move Gantry: Use the gantry controls to position the crane directly over the container stack.

– Trolley Movement: Adjust the trolley to align with the container, using both lateral and longitudinal movements.

4. Engage Spreaders:

– Lower Spreaders: Extend the spreader beam and position it over the container.

– Locking Mechanism: Engage the spreader’s twist locks to secure the container. Visual and digital indicators will confirm a secure lock.

5. Lifting the Container:

– Vertical Lift: Smoothly lift the container vertically to clear other containers or obstacles.

– Monitor Load: Constantly monitor load indicators and cameras to ensure stability.

6. Transport and Position:

– Trolley Travel: Move the trolley along the gantry to transport the container to the designated area.

– Gantry Movement: Adjust the crane’s position as needed during the transfer process.

7. Lowering the Container:

– Align and Descend: Carefully lower the container into its designated spot, ensuring alignment with stacking or truck positioning points.

– Release Locks: Disengage the twist locks and raise the spreader beam.

8. Post-Operation Procedures:

– Final Checks: Conduct a post-operation inspection to ensure no damage or issues occurred.

– Documentation: Complete necessary logs and reports detailing the operation.

Safety Note: Always adhere to safety protocols, wear protective gear, and stay updated with training sessions and certifications.

“port container crane” Comparative Analysis

Port container cranes, essential for efficient cargo handling, vary by type and functionality. The three primary types are Ship-to-Shore (STS), Rubber-Tired Gantry (RTG), and Rail-Mounted Gantry (RMG) cranes. This comparative analysis highlights their distinct attributes.

Ship-to-Shore (STS) Cranes:

– Usage: Primarily for loading and unloading containers between ships and the dock.

– Advantages: High reach and lift capacity, direct ship interface.

– Disadvantages: High capital and maintenance costs, fixed position limits flexibility.

– Best suited for: Large seaports with frequent, high-volume container traffic.

Rubber-Tired Gantry (RTG) Cranes:

– Usage: Handles container movement within storage yards.

– Advantages: Mobility due to rubber tires, moderate lifting capacity, relatively lower costs.

– Disadvantages: Potentially less stable than RMG cranes, higher operational costs due to fuel and maintenance needs.

– Best suited for: Medium to large ports needing flexibility in container stacking and yard arrangement.

Rail-Mounted Gantry (RMG) Cranes:

– Usage: Also used in container yards with fixed rail tracks.

– Advantages: Higher stability and lifting capacity, efficient for long-term high-density stacking.

– Disadvantages: Limited mobility, higher upfront infrastructure costs.

– Best suited for: Ports with established rail infrastructures and consistent long-term storage operations.

Conclusion

STS cranes excel in ship-to-dock transitions, ideal for large ports with significant marine traffic. RTGs offer flexible yard operations, suitable for varying container movements and mid-sized ports. RMGs provide stable, efficient long-term stacking for ports with dedicated rail setups. Choice depends on specific port needs, balancing cost, capacity, and operational flexibility.

“port container crane” Warranty and Support

Port Container Crane Warranty and Support

The warranty for port container cranes typically covers a specified period, during which the manufacturer guarantees the repair or replacement of components due to defects in materials or workmanship. Standard warranty durations vary but commonly range from 1 to 5 years. Extended warranties may be available upon request, providing additional peace of mind beyond the standard period.

During the warranty period, the manufacturer is responsible for providing genuine parts and performing necessary repairs at no extra cost. It’s essential to adhere to the maintenance schedule and usage guidelines stipulated in the user manual to ensure the warranty remains valid. Any modifications, unauthorized repairs, or misuse can void the warranty.

Support Services

Support services for port container cranes encompass preventive maintenance, technical assistance, and emergency repair services. Manufacturers typically offer comprehensive support packages, including:

1. Preventive Maintenance: Regular inspections, lubrication, and adjustments to ensure optimal performance and extend the crane’s lifespan. Preventive maintenance minimizes the risk of unexpected downtime and costly repairs.

2. Technical Assistance: Access to experienced technicians who can provide troubleshooting advice, remote diagnostics, and on-site support. Technicians can assist with software updates, operational training, and optimization tips to enhance crane efficiency.

3. Emergency Repairs: Rapid response teams available 24/7 to address any unforeseen issues promptly. This service focuses on minimizing operational disruptions and returning the crane to service as quickly as possible.

4. Spare Parts Availability: Guaranteed availability of critical components and parts, either through a centralized inventory or a local distribution network, to ensure minimal downtime.

5. Training Programs: Comprehensive training for operators and maintenance staff to ensure safe and efficient crane operation. Training programs cover routine maintenance, safety protocols, and emergency procedures.

In summary, robust warranty and support services for port container cranes are essential to maintaining operational efficiency, ensuring safety, and maximizing the equipment’s operational lifespan.

List “port container crane” FAQ

Port Container Crane FAQ

#### 1. What is a port container crane?

Port container cranes, also known as container handling gantry cranes, are large industrial machines used at shipping ports to load and unload intermodal containers from ships.

#### 2. What are the main types of port container cranes?

The two primary types are:

– Ship-to-Shore (STS) Cranes: These cranes are used to move containers between the ship and the dock.

– Rubber-Tired Gantry (RTG) Cranes: These cranes handle containers within the terminal’s container yard, moving them to and from storage stacks.

#### 3. How do port container cranes operate?

Port container cranes use a combination of hoisting mechanisms, trolleys, and booms. The hoisting mechanism lifts containers, the trolley moves them horizontally across the boom, and the boom structure moves containers over the ship or onto the dock.

#### 4. What is the maximum lifting capacity of a port container crane?

This varies by model and manufacturer, but modern STS cranes can typically handle up to 80-100 tons.

#### 5. What is the average range of a boom on a port container crane?

Booms can extend from 50 to 70 meters, depending on the crane design and the size of the ships it services.

#### 6. How are port container cranes powered?

They are generally powered by electricity, which can be supplied through fixed electrical connections or through diesel-electric generators.

#### 7. What safety features are included in port container cranes?

Safety features include anti-collision systems, load sensors, emergency stop mechanisms, operator cabins with all-around visibility, and automated systems to reduce human error.

#### 8. How do operators control port container cranes?

Operators control cranes from a cabin located on the crane, typically using joysticks and computer systems to maneuver the crane and handle containers.

#### 9. What are the maintenance requirements for port container cranes?

Routine maintenance includes inspection and lubrication of mechanical parts, electrical system checks, software updates, and regular safety audits.

#### 10. How do port container cranes contribute to port efficiency?

They significantly reduce loading and unloading times, enable the rapid transfer of containers, and support high-frequency shipping schedules, thereby enhancing overall port throughput.

These FAQs provide a basic understanding of port container cranes, their types, operations, and significance in modern shipping logistics.

Top 10 FAQ with answer about port container crane for Buyer Sourcing from China

Certainly! Here’s a concise FAQ for buyers sourcing port container cranes from China:

1. What Types of Port Container Cranes Are Available?

– The main types are Ship-to-Shore (STS) cranes, Rubber-Tyred Gantry (RTG) cranes, and Rail-Mounted Gantry (RMG) cranes. Each serves specific operational needs and environments.

2. What Factors Should Be Considered When Choosing a Crane?

– Consider load capacity, lift height, span, speed, environmental conditions, and compatibility with existing infrastructure.

3. How Do I Verify the Quality of Cranes from China?

– Look for ISO certifications, past performance records, third-party inspection reports, and customer reviews. Visiting the factory can provide additional assurance.

4. What Is the Typical Lead Time for Delivery?

– Lead times can range from 4 to 12 months, depending on the crane’s specifications and manufacturing complexity.

5. Can I Customize the Crane to Meet Specific Requirements?

– Yes, most manufacturers offer customization options for dimensions, control systems, and load capacities, tailored to meet your needs.

6. What Are the Payment Terms Usually Offered?

– Common terms include a 30% upfront deposit, with the remaining 70% payable upon shipping, after inspection. Letters of credit (LC) are also widely accepted.

7. How Is Shipment and Delivery Handled?

– Most manufacturers handle packaging, shipping, and logistics. Cranes are usually shipped disassembled in containers or as bulk cargo, then reassembled on-site.

8. What Kind of After-Sales Support Is Provided?

– Typical support includes installation, commissioning, training, spare parts, and maintenance services. Some manufacturers offer remote technical support and on-site repairs.

9. What Warranty Is Provided?

– Warranties usually range from 1 to 2 years, covering manufacturing defects. Extended warranties and service agreements may be available.

10. Are There Specific Import Regulations or Certifications Required?

– Compliance with international standards like IEC, CSA, and local port authority regulations are necessary. Ensure the manufacturer can provide all required documentation for customs clearance.

These FAQs should assist in making an informed decision when sourcing port container cranes from China.