portal crane Safety Certifications

Portal cranes, widely used in industrial and maritime settings, require rigorous safety standards and certifications to ensure safe operations. Here’s an overview of some primary safety certifications and standards relevant to portal cranes:

1. OSHA (Occupational Safety and Health Administration):

– 29 CFR 1910.179: This regulation covers overhead and gantry cranes, emphasizing inspection, maintenance, and operation requirements.

– 29 CFR 1926.550: This refers to cranes and derricks in construction, stipulating extended safety measures.

2. ANSI (American National Standards Institute):

– ANSI/ASME B30.2: Focuses on overhead and gantry cranes, detailing requirements for construction, installation, operation, inspection, and testing.

3. CMAA (Crane Manufacturers Association of America):

– CMAA Specification No. 70 (Top Running Bridge & Gantry Type Multiple Girder Cranes): Provides guidelines for the design and construction of cranes, ensuring they meet safety and performance standards.

4. FEM (European Materials Handling Federation):

– FEM 1.001: This is a European standard offering rules for the design of portal and gantry cranes, focusing on durability and safety-related aspects.

5. ISO (International Organization for Standardization):

– ISO 9927: Specifies the requirements for the inspection, maintenance, and operation of cranes to assure safety in international contexts.

6. EN (European Standards):

– EN 14439: Addresses the safety requirements for tower cranes which can be applicable to portal cranes used in construction.

7. Lifting Equipment Engineers Association (LEEA):

– LEEA Code of Practice: Offers guidelines on the design, assembly, maintenance, and operation of lifting equipment, including portal cranes.

Obtaining these certifications involves regular inspections, maintenance regimes, operator training, and adherence to prescribed operational protocols. Compliance ensures not only the protection of workers but also the optimization of crane performance and longevity.

List Reference Technical Parameters of “portal crane”

Portal cranes, commonly used in maritime and industrial applications, are crucial for loading, unloading, and transporting heavy materials. Here are some key technical parameters:

1. Lifting Capacity:

– Defines the maximum weight the crane can lift.

– Typically ranges from 5 to 200 tons based on crane design and application.

2. Span:

– The horizontal distance between the supports of the crane.

– Varies generally between 5 meters to 35 meters.

3. Lifting Height:

– Maximum vertical distance the hook can travel from the crane’s lowest point to the highest point.

– Ranges from 10 to 50 meters.

4. Outreach:

– The horizontal reach of the crane from the center of the rotation.

– Can extend up to 50 meters.

5. Slewing Angle:

– The angle at which the crane can rotate horizontally.

– Full rotation (360 degrees) is common, though some models may have limited rotation.

6. Travel Speed:

– Speed at which the crane moves along its rails, usually measured in meters per minute.

– Generally ranges from 20 to 100 meters per minute.

7. Hoisting Speed:

– The speed at which the crane can lift or lower a load.

– Varies from 5 to 30 meters per minute, depending on the load weight and crane model.

8. Power Supply:

– The type and voltage of electrical power required.

– Typically uses 380V/50Hz or 440V/60Hz depending on regional standards.

9. Control System:

– May include remote control, cabin control, or both.

– Advanced models may incorporate automated or semi-automated systems.

10. Wind Resistance:

– Ability to withstand wind speeds for operational safety.

– Often rated for winds up to 20 m/s (operational) and 50 m/s (survival mode).

11. Structural Material:

– Generally made of high-strength steel to ensure durability and load-bearing capacity.

12. Safety Features:

– Includes overload protection, emergency stop systems, and anti-collision devices.

These parameters help define the operational scope and limitations of portal cranes, ensuring their effectiveness in various heavy-duty applications.

List Product features of “portal crane”

Portal cranes, also known as gantry cranes, are vital in industries such as shipping, construction, and manufacturing due to their versatility and efficiency. Here are some key features of portal cranes:

1. Heavy Lifting Capacity: Designed to lift substantial weights, ranging from several tons to hundreds of tons, facilitating the movement of heavy materials and equipment.

2. Wide Span Coverage: They offer extensive coverage, spanning wide areas without the need for additional supporting structures, making them ideal for large storage yards and shipyards.

3. Mobility: Equipped with wheels or tracks, portal cranes can be moved along railways or open yards, providing flexibility in positioning and coverage.

4. Variable Height Adjustment: The adjustable height feature enables them to accommodate various lifting and operational needs, allowing for efficiency in different projects.

5. Precision Handling: Advanced control systems allow for precise maneuvering of loads, reducing the risk of damage and enhancing safety.

6. Robust Construction: Built with high-strength materials like steel, portal cranes are designed to withstand harsh environmental conditions and heavy usage.

7. Automated Systems: Many modern portal cranes come with automated features such as remote control operations, anti-sway technology, automated load positioning, and emergency stop systems for enhanced safety and efficiency.

8. Multi-directional Movement: They support movements in multiple directions (up, down, left, right, forward, and backward), offering comprehensive operational flexibility.

9. Hook and Grab Mechanisms: Equipped with a variety of attachments such as hooks, grabs, and magnets to handle different types of loads, from containers to bulk materials.

10. Safety Features: Includes features like overload protection, wind sensors, collision avoidance systems, and fail-safe brakes to ensure the safety of operations.

11. Versatility: Can be used in various applications including shipbuilding, rail yards, container handling, and construction, and can handle diverse types of loads.

12. Energy Efficiency: Some modern portal cranes are designed with energy-efficient motors and regenerative braking systems to reduce power consumption and operational costs.

These features make portal cranes indispensable for heavy-duty lifting and material handling in various industrial sectors.

List Various Types of “portal crane”

Portal cranes, also known as gantry cranes, come in various types, each designed for specific applications and operational environments. Below are some common types:

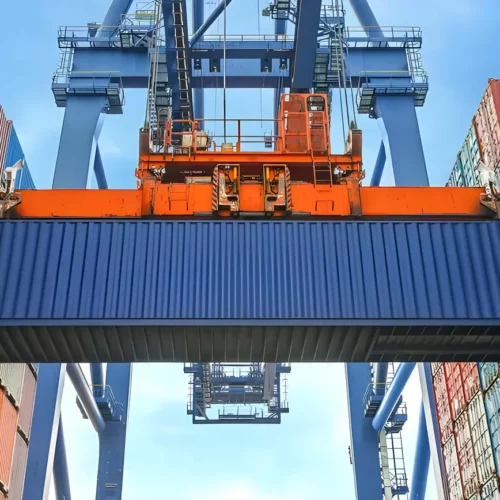

1. Full-Gantry Crane: This type features two legs that run on a fixed rail or track. It typically spans large distances and is used in shipyards, container yards, and large assembly areas.

2. Semi-Gantry Crane: With only one leg running on a rail or track, the other side is attached to a wall or a building. This design is ideal for spaces where full-gantry cranes cannot be accommodated.

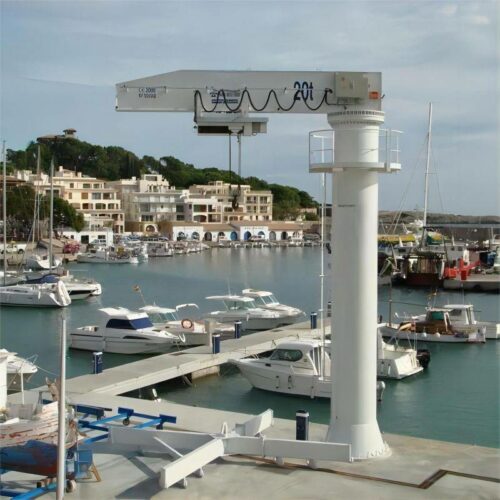

3. Portable Gantry Crane: A smaller, movable version usually on wheels, making it easy to relocate and use as needed. It’s ideal for light lifting tasks in workshops or garages.

4. Adjustable Gantry Crane: This type can vary in height and span, providing flexibility for different lifting needs. It’s particularly useful in environments where load sizes and requirements frequently change.

5. Waste Handling Gantry Crane: Specially designed for handling waste and scrap materials, often featuring additional attachments like grabs or magnets to manage assorted waste efficiently.

6. Rail-Mounted Gantry Crane (RMG): These cranes are rail-mounted for heavy lifting tasks, commonly used in shipping yards to move containers.

7. Rubber-Tired Gantry Crane (RTG): Equipped with rubber tires for mobility, these cranes are typically used in container terminals to organize and stack containers.

8. Workstation Gantry Crane: Designed for specific workstation setups, providing localized lifting capability. They are generally found in manufacturing and assembly operations.

9. Container Gantry Crane: Also known as ship-to-shore cranes, these are massive cranes used to load and unload container ships efficiently.

10. Cantilever Gantry Crane: Features a single or double cantilever extending beyond the cantilever beams, often used for loading operations that need the crane to extend beyond its legs.

Each type of portal crane is designed to meet specific operational needs, enhancing efficiency and safety for diverse lifting applications.

List Application of “portal crane”

Portal cranes, also known as gantry cranes, are crucial for various industrial and logistical applications due to their robust construction and versatility. Here are some key applications:

1. Shipping and Ports:

– Loading and Unloading Cargo: These cranes handle heavy cargo from ships to docks and vice versa.

– Container Handling: Specialized for moving shipping containers efficiently.

2. Rail Yards:

– Freight Handling: Used for lifting and placing large freight containers onto rail cars.

– Maintenance: Assists in the maintenance and assembly of rail cars and tracks.

3. Industrial and Manufacturing Plants:

– Heavy Machining: Moves large parts or machinery around the workshop.

– Production Line: Assists in the assembly and movement of heavy equipment.

4. Construction Sites:

– Material Handling: Lifts and positions heavy building materials like steel beams, precast concrete, and equipment.

– Modular Construction: Facilitates the assembly of large modular sections.

5. Warehousing and Storage:

– Inventory Management: Transfers bulky items to storage spaces and retrieves them as needed.

– Automated Systems: Integrated with automated storage systems for efficiency.

6. Steel and Metal Industries:

– Handling Raw Materials: Moves heavy raw materials like logs, steel coils, and metal sheets.

– Finished Products: Manages the transportation of finished heavy-duty products.

7. Power Plants:

– Equipment Installation: Helps in the installation and maintenance of large turbines, generators, and other equipment.

– Nuclear Facilities: Ensures safe handling of heavy nuclear reactors and associated components.

8. Shipbuilding and Repair:

– Construction: Assists in the assembly of ship parts and modules.

– Repair and Maintenance: Facilitates heavy lifting necessary for ship repairs.

Portal cranes are essential in any industry that requires the movement of heavy loads, combining power and precision to enhance efficiency and safety.

List Buyer Types of “portal crane”

Portal cranes (also known as gantry cranes) serve a variety of industries and purposes due to their versatile design and capacity. Here are the primary buyer types for portal cranes:

1. Construction Companies: Utilized for transporting heavy materials on site, often used in large infrastructure projects like bridges, highways, and skyscrapers.

2. Manufacturing and Assembly Plants: Essential for moving large components or assemblies, especially in industries such as automotive, aerospace, and heavy machinery production.

3. Shipyards and Ports: Integral for loading and unloading shipping containers, handling large vessel components, and general cargo operations.

4. Warehousing and Distribution Centers: Assist in moving large goods or containers within storage facilities, optimizing space utilization and operational efficiency.

5. Mining and Resource Extraction Firms: Used for lifting and transporting mined materials, machinery, and other heavy equipment.

6. Railway Yards: Employed in loading and unloading railway cars, often handling bulky goods like coal, timber, and containers.

7. Energy Sector: Crucial in power plants, wind farms, and oil rigs for installing heavy components such as turbines, transformers, and drilling equipment.

8. Infrastructure Maintenance and Utility Companies: Utilized for maintenance tasks involving large-scale infrastructure such as bridges, dams, and pipelines.

Each of these buyer types relies on the robust lifting capacity, versatility, and efficiency that portal cranes offer to streamline their operations and boost productivity.

List “portal crane” Project Types for Different Industries

Portal cranes, also known as gantry cranes, are versatile lifting devices used in various industries for handling heavy loads. Here’s a breakdown of common project types where different industries employ portal cranes:

1. Shipping and Port Operations:

– *Container Handling:* Moving containers between ships, storage areas, and trucks.

– *Bulk Material Handling:* Loading and unloading bulk commodities like coal, grain, and ore.

– *Maintenance:* Lifting heavy machinery and equipment for repairs and maintenance.

2. Construction:

– *Building Infrastructure:* Lifting steel beams, concrete blocks, and other construction materials.

– *Bridge Construction:* Installing large components, such as girders and segments.

– *Tunnel Construction:* Transporting muck cars, segments for lining, and heavy machinery.

3. Manufacturing:

– *Assembly Line Operations:* Handling parts and assemblies in automobile and aircraft manufacturing.

– *Fabrication:* Moving heavy materials like sheets of metal, large components, and finished products.

– *Maintenance and Repairs:* Accessing and lifting heavy machinery for routine checks and fixes.

4. Steel and Metal Industry:

– *Material Handling:* Transporting raw materials, semi-finished, and finished steel products.

– *Storage Management:* Organizing large metal coils, sheets, and profiles in storage areas.

5. Railway and Transit:

– *Track Maintenance:* Lifting track sections, rail cars, and maintenance equipment.

– *Depot Operations:* Handling heavy components like bogies, wheels, and engines.

6. Power Generation:

– *Nuclear Plants:* Installing and maintaining reactors, steam generators, and other critical components.

– *Hydro Power:* Moving turbines, generator parts, and conducting maintenance.

– *Wind Energy:* Assembling and maintaining wind turbines and components.

7. Mining:

– *Material Transfer:* Handling extracted minerals and ores.

– *Equipment Management:* Moving heavy mining equipment for maintenance and relocation.

8. Automotive:

– *Vehicle Assembly:* Handling car bodies, engines, and other heavy components during manufacturing.

– *Logistics:* Transporting pallets, containers, and large parts within factories.

Portal cranes are crucial across industries for their ability to lift and move heavy loads efficiently, enhancing productivity and safety.

portal crane Accessories Upgrades and Custom Manufacturing Options

Portal cranes, integral to various industries such as shipping and manufacturing, offer a range of accessories, upgrades, and custom manufacturing options to meet specific operational needs.

Accessories:

1. Spreader Beams: These essential tools facilitate the handling of large, uneven loads, ensuring stability and safety.

2. Hooks and Lifting Gear: Diverse hooks, from standard to specialized, adapt cranes to a multitude of lifting requirements.

3. Remote Controls: Enhance operator safety and efficiency with wireless remote control systems, allowing for precise maneuverability.

4. Lighting Systems: Integrated lights improve visibility during night operations or in poorly lit environments, ensuring safe and accurate lifting.

Upgrades:

1. Automated Systems: Incorporating automation can enhance operational efficiency by reducing manual intervention and increasing precision.

2. Load Monitoring Systems: These systems provide real-time data on load weights and distribution, preventing overloads and enhancing safety.

3. Energy Efficient Drives: Upgrading to modern, energy-efficient motors and drives reduces power consumption and operational costs.

4. Advanced Safety Features: Adding anti-sway technology, collision avoidance systems, and emergency stop features can significantly boost operational safety.

Custom Manufacturing Options:

1. Tailored Dimensions and Capacities: Custom crane designs to suit specific spatial restrictions or load capacities not available in standard models.

2. Specialized Grabbing Devices: Custom-engineered grabbing apparatuses for handling unique materials, such as bulk goods or oversized items.

3. Environmental Adaptations: Cranes adapted for extreme environments, be it high-temperature furnaces, corrosive chemical plants, or outdoor marine conditions.

4. Integration with Existing Systems: Seamless incorporation with existing infrastructure, including software and mechanical systems, to ensure cohesive operations.

By opting for tailored accessories, innovative upgrades, and custom manufacturing solutions, businesses can significantly enhance the functionality, efficiency, and safety of their portal crane operations.

List Quality Control and The Manufacturing Process of “portal crane”

Quality Control:

1. Material Verification: Ensure that raw materials meet required standards through certificates and testing.

2. Dimensional Inspection: Measure components to confirm adherence to design specifications.

3. Welding Quality: Inspect welds using various NDT (Non-Destructive Testing) methods like ultrasonic and radiographic testing.

4. Load Testing: Perform static and dynamic load tests to verify load-bearing capacity.

5. Surface Treatment: Check for proper application of corrosion-resistant coatings and paint.

6. Component Testing: Test individual components like motors, ropes, and electrical systems.

7. Assembly Inspection: Confirm that assembly aligns with engineering drawings.

8. Functionality Testing: Conduct operational tests to ensure smooth movements and functionality.

9. Compliance Check: Ensure the crane meets industry standards and regulations.

10. Documentation Review: Maintain thorough records of inspections, tests, and certifications.

Manufacturing Process:

1. Design and Engineering: Create detailed designs and blueprints using CAD software. Perform simulations to predict performance and identify potential issues.

2. Material Sourcing: Procure high-quality steel and other materials, ensuring compliance with specifications.

3. Cutting and Shaping: Cut steel plates and shapes to required dimensions using CNC machines and plasma cutters.

4. Welding and Assembly: Assemble main structural components. Utilize robotic and manual welding to connect parts securely.

5. Machining: Machine parts for precision fitting in areas such as joints and housings.

6. Surface Preparation: Clean and prepare surfaces for painting or coating to prevent corrosion.

7. Painting and Coating: Apply protective coatings and paints in controlled environments to ensure durability.

8. Electrical and Mechanical Installation: Install motors, electrical systems, ropes, and other mechanical parts.

9. System Integration: Integrate all systems and perform wiring and coupling of various components.

10. Testing and Calibration: Conduct comprehensive testing of the assembled crane, including load tests and functional verification.

11. Final Inspection: Perform a final quality assurance inspection to ensure all aspects meet specified criteria.

12. Shipping and Installation: Disassemble if required and ship to the installation site. Final setup and installation are often performed by specialized teams.

These steps ensure that portal cranes are reliable, safe, and meet all operational requirements.

How to use “portal crane”

A portal crane, also known as a gantry crane, is a type of overhead lifting device used in various industrial applications, such as shipyards, warehouses, and construction sites. Here’s a concise guide on how to use a portal crane safely and efficiently:

1. Inspect the Crane:

– Before operation, thoroughly inspect the crane for any visible defects or damage.

– Check for proper functioning of all mechanical and electrical components.

2. Understand Controls:

– Familiarize yourself with the crane’s control panel, which typically includes joystick controls, switches, and emergency stop buttons.

– Ensure you know how to operate each control element.

3. Load Preparation:

– Ensure the load is within the crane’s weight capacity limits.

– Secure the load using appropriate lifting gear such as chains, slings, or hooks.

4. Safety Checks:

– Verify that the load is balanced and securely fastened.

– Make sure the area around the crane and the path of the load are clear of obstructions and personnel.

5. Operation:

– Start by lifting the load slowly and steadily to ensure stability.

– Use the joystick to maneuver the load horizontally, taking care to avoid sudden movements.

– Continuously monitor the load and crane for any signs of instability.

6. Positioning the Load:

– Once the load reaches the desired location, lower it slowly and carefully.

– Ensure the load is safely set down and detached from the lifting gear.

7. Shutdown Procedures:

– After completing the lift, return the crane to its standby position.

– Turn off the crane control panel and perform a final inspection.

Safety Tip: Always wear appropriate personal protective equipment (PPE) and follow local regulations. Ensure only trained and certified operators handle the crane.

By adhering to these steps, you can use a portal crane efficiently while maintaining a high standard of safety.

“portal crane” Comparative Analysis

Portal cranes, also known as gantry cranes, serve pivotal roles in various industries, especially in construction, shipyards, and logistics. Their distinct design features a horizontal bridge supported by vertical legs moving on a set of rails. This analysis delves into their advantages and limitations in comparison to other types of cranes such as tower cranes and mobile cranes.

Advantages:

1. High Load Capacity:

Portal cranes can handle massive loads, often exceeding the capabilities of mobile cranes. This makes them ideal for shipbuilding and heavy industrial tasks.

2. Span and Coverage:

They cover large areas both horizontally and vertically, providing extensive coverage without the need to relocate equipment, in contrast to tower cranes that might need strategic placement or multiple units for similar coverage.

3. Stability:

Their structure provides excellent stability, reducing the risk of accidents when lifting heavy loads. Mobile cranes, although versatile, can sometimes face stability issues, especially on uneven terrains.

4. Operational Flexibility:

Portal cranes can operate in various weather conditions and environments, offering greater reliability for long-term projects compared to mobile cranes, which might be limited by adverse weather.

Limitations:

1. Mobility:

While portal cranes offer great coverage, their fixed path is a limitation compared to the mobility of mobile cranes, which can be easily transported to different sites. Tower cranes, usually fixed, also share this limitation but are more flexible in height adjustments.

2. Cost:

The initial setup cost for portal cranes is significantly higher than for mobile cranes due to infrastructure requirements like rails and robust foundations.

3. Space Requirement:

They require substantial space for installation, making them unsuitable for congested urban sites where tower cranes excel due to their smaller footprint.

4. Complex Installation:

Installation and dismantling of portal cranes are more complex and time-consuming than for mobile cranes, affecting project timelines.

In conclusion, while portal cranes excel in load capacity, stability, and extensive coverage, their lack of mobility, higher costs, and complex installation process can be limiting factors. They are best suited for large-scale, long-term industrial projects where space and cost considerations align with their benefits.

“portal crane” Warranty and Support

Warranty and Support for Portal Crane

Our portal cranes come with a comprehensive warranty and support package designed to ensure the highest level of performance, safety, and customer satisfaction. For a detailed understanding of what’s included, please read below:

Warranty Terms:

1. Standard Warranty Period: Each portal crane is covered by a two-year limited warranty from the date of installation or thirty months from the date of shipment, whichever comes first.

2. Included Coverage:

– Parts: All essential parts such as motors, gears, and control systems are under warranty.

– Labor: Professional labor for repair or replacement of parts found to be defective is included.

– Transport: Transportation costs for parts requiring replacement within the warranty period.

3. Exclusions:

– Damage due to misuse, neglect, or unauthorized modifications.

– Normal wear and tear (e.g., scratches, abrasions).

– Components not originally supplied by the manufacturer.

4. Claim Procedure:

– Contact our customer service team with your serial number and purchase date.

– Provide a detailed description of the issue, supported by photos if needed.

– We will guide you through the claim process, ensuring swift resolution.

Support Services:

1. Technical Support:

– 24/7 Hotline: Access to our dedicated support line for immediate assistance.

– Online Support: Comprehensive resources including FAQs, manuals, and troubleshooting guides available on our website.

2. On-Site Assistance:

– Installation and Setup: Expert technicians available for installation and system optimization.

– Maintenance Programs: Customizable preventive maintenance packages to suit specific operational needs.

3. Training and Documentation:

– Operator Training: Extensive training sessions for operators and maintenance personnel.

– Documentation: Access to electronic and printed manuals for operational and service procedures.

With our robust warranty and support framework, you can invest in our portal cranes with confidence, knowing that expert assistance is just a call or click away.

List “portal crane” FAQ

Portal Crane FAQs

1. What is a portal crane?

A portal crane, also known as a gantry crane, is a type of crane that consists of a hoist mounted on a beam or bridge, which is supported by two or more legs. These legs can move along tracks or rails, providing both horizontal and vertical lifting capabilities.

2. What are the common uses of portal cranes?

Portal cranes are commonly used in shipyards, warehouses, construction sites, and factories. They are ideal for lifting heavy equipment, moving large containers, and handling bulky materials in outdoor or indoor settings.

3. How is a portal crane powered?

Portal cranes can be powered by electricity, hydraulics, or even diesel engines. The choice of power depends on the specific requirements of the operation, including load capacity, lifting height, and maneuverability.

4. What is the load capacity of a typical portal crane?

The load capacity of portal cranes varies widely depending on their size and design. They can range from a few tons to several hundred tons. It’s essential to consult the manufacturer’s specifications to determine the exact capacity of a particular crane.

5. What safety features are included in portal cranes?

Modern portal cranes come with a variety of safety features, including overload protection, emergency stop functions, limit switches, anti-collision systems, and load moment indicators. These features are designed to ensure safe and efficient operation.

6. How are portal cranes maintained?

Regular maintenance is crucial for the safe operation of portal cranes. This maintenance includes routine inspections, lubrication of moving parts, checking electrical systems, and replacing worn-out components. Adhering to a maintenance schedule as recommended by the manufacturer can prevent breakdowns and extend the crane’s lifespan.

7. Can portal cranes be customized?

Yes, portal cranes can be customized to meet specific operational needs. Customizations may include modifications in height, span, load capacity, and additional features like automation and remote control.

8. What should be considered when choosing a portal crane?

When selecting a portal crane, consider factors such as load capacity, lifting height, span, power source, safety features, and the specific requirements of your operation. It’s also advisable to consult with a professional to ensure that the selected crane meets all industry standards and regulations.

Top 10 FAQ with answer about portal crane for Buyer Sourcing from China

Certainly! Below are the top 10 frequently asked questions (FAQs) about sourcing portal cranes from China, along with their concise answers:

1. What is a Portal Crane?

A portal crane, also known as a gantry crane, is a type of crane that is supported by a pair of support legs, which can move on rails embedded in the ground. It’s widely used for lifting and transporting heavy loads.

2. Why Source Portal Cranes from China?

China offers cost-effective manufacturing, advanced technology, and diverse options. Chinese manufacturers also often have experienced in exporting these machines worldwide.

3. Which Portals Crane Manufacturers are Reliable in China?

Reliable manufacturers include:

– ZPMC (Shanghai Zhenhua Heavy Industries Co., Ltd.)

– SANY Group

– XCMG Group

4. What Should I Look for in a Supplier?

Check for:

– ISO certifications

– CE Marking

– Customer reviews and testimonials

– Experience in exporting

– Technical support and after-sales service

5. How Do I Ensure Quality?

Conduct a factory audit, request samples, and ask for detailed specifications. Employ third-party inspection services like SGS or Bureau Veritas.

6. What is the Typical Lead Time?

Lead times can vary, but typically it’s between 2-6 months depending on the complexity and customization of the crane.

7. Are Spare Parts Readily Available?

Most reputable manufacturers provide a full range of spare parts, and it’s advisable to confirm this before purchase.

8. What About Shipping and Logistics?

Ensure your supplier handles export formalities and opt for a reputable freight forwarder. Shipping times vary depending on the destination but generally take 20-60 days.

9. How Do I Handle After-Sales Service and Maintenance?

Choose suppliers that offer comprehensive after-sales support, including troubleshooting, maintenance training, and remote assistance.

10. What Payment Terms are Common?

Typical terms include a 30% deposit before production and 70% before shipping. L/C (Letter of Credit) and T/T (Telegraphic Transfer) are commonly used.

By understanding these key aspects, you can make an informed decision when sourcing portal cranes from China.