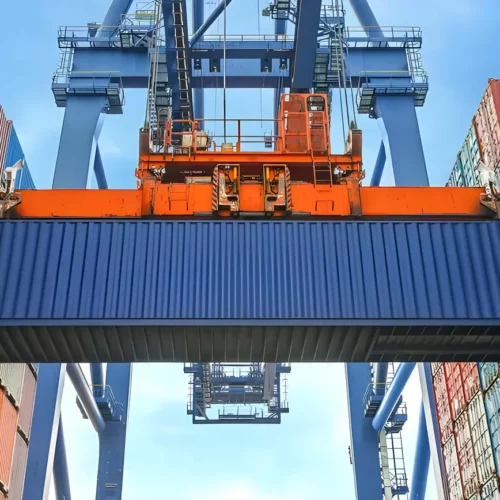

quayside container crane Safety Certifications

Quayside container cranes are essential for port operations but pose significant safety risks due to their size and complexity. Obtaining safety certifications is crucial to ensure both operational efficiency and the well-being of personnel. Here are the key safety certifications typically required:

1. ISO 45001: This certification is crucial for Occupational Health and Safety Management Systems. It helps organizations proactively improve injury prevention and reduce ill-health while ensuring compliance with safety laws and regulations.

2. CE Marking: In Europe, CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). It is crucial for cranes to be CE marked to confirm adherence to EU safety directives.

3. ANSI/ASME B30: In the United States, cranes often need to comply with the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) standards, particularly the B30 series which covers various crane-related safety and operational requirements.

4. IEC 61508/ISO 13849: Functional safety standards like IEC 61508 and ISO 13849 are often required. These standards focus on the reliability of control systems to ensure crane operations are fail-safe.

5. DNV GL Certification: Det Norske Veritas Germanischer Lloyd (DNV GL) provides guidelines and certification for the maritime industry, including the safe operation of cranes. This may cover everything from mechanical integrity to software safety systems.

6. OSHA Compliance: In the United States, compliance with Occupational Safety and Health Administration (OSHA) standards is compulsory. These regulations cover various aspects of crane operations, from maintenance to operator training and certification.

Following these certifications not only enhances safety but also boosts operational reliability and regulatory compliance, ensuring the quayside container cranes operate securely and efficiently.

List Reference Technical Parameters of “quayside container crane”

Quayside container cranes, also known as ship-to-shore (STS) cranes, are critical for efficient port operations. Here are some key technical parameters often referenced for quayside container cranes:

1. Lifting Capacity: This represents the maximum weight the crane can lift. It’s usually expressed in tonnes (e.g., 40, 50, or 65 tonnes).

2. Outreach: This is the horizontal distance the crane can extend over the water to reach the containers on the ship. It’s measured from the crane’s centerline to the farthest point it can reach, typically ranging from 40 to 60 meters.

3. Backreach: The horizontal distance the crane can extend inland from the quay. It is essential for accessing containers placed further back from the quayside.

4. Hoisting Height: The maximum vertical distance the lifting mechanism can move up or down. It generally has two components: above the rail (e.g., 40 meters) and below the rail (e.g., 15 meters).

5. Span: This measures the distance between the crane’s legs or rails that it operates on. It’s crucial for determining how much container yard space the crane can cover.

6. Lifting Speed: Indicates how fast the crane can raise or lower the containers, often measured in meters per minute. Speeds can vary, typically from 70 to 100 m/min for loaded lifts and 140 to 200 m/min for empty lifts.

7. Trolley Speed: This is the speed at which the trolley moves horizontally along the boom. Typical speeds range between 150 to 300 meters per minute.

8. Travel Speed: The speed the entire crane can move along the rail, generally 20-45 meters per minute.

9. Power Supply: Quayside cranes usually operate on electricity, requiring a substantial power source, often measured in kilovolts (kV).

10. Wind Speed Resistance: Operational wind limits indicate the maximum wind speed at which the crane can safely operate, typically around 20-25 meters per second, and survival wind speeds when the crane must be locked down, generally around 50-70 meters per second.

These parameters are critical for ensuring the crane’s compatibility with the port’s operational needs and the vessels it will service.

List Product features of “quayside container crane”

A quayside container crane, also known as a ship-to-shore crane (STS), is a crucial piece of equipment for modern ports and container terminals. Here are its key product features:

1. High Lifting Capacity: Designed to handle large containers, these cranes often have lifting capacities ranging from 40 to 80 tons, ensuring efficient port operations.

2. Extended Outreach: The crane’s horizontal reach is crucial for accessing containers on large vessels. Typical outreach extends from 30 meters to 65 meters to accommodate larger container ships.

3. Vertical Lift Height: With vertical lifting heights that can exceed 45 meters, these cranes can stack containers up to multiple tiers high both on the ship and onshore.

4. Trolley and Gantry Travel: Equipped with advanced trolley systems for precise movement and placement of containers. The gantry can travel along the quayside, providing flexibility to service ships at different berths.

5. Advanced Control Systems: Modern quayside cranes use computerized control systems for precise movements, load management, and increased safety during operations.

6. Automation and Remote Operation: Many come with semi-automated or fully automated options, reducing the need for manual handling and improving efficiency. Remote operation capabilities allow for control from a centralized location.

7. Energy Efficiency: Some models incorporate regenerative power systems and energy-efficient motors to reduce operational costs and environmental impact.

8. Durability and Weather Resistance: Built to withstand harsh maritime environments with materials and designs that resist corrosion, high winds, and other challenging conditions.

9. Safety Features: Equipped with various safety mechanisms, including anti-sway devices, overload protection, and emergency stop functions to ensure safe operations.

10. Customizability: Can be tailored to specific terminal requirements with customizable features like different cabin designs, spreader types, and additional attachments.

11. High-Speed Operations: Capable of fast loading and unloading cycles to maximize throughput and reduce ship turnaround time.

12. Maintenance Accessibility: Designed for ease of maintenance with accessible components and diagnostic systems to minimize downtime.

These features collectively ensure the efficiency, safety, and reliability of quayside container cranes in bustling port environments.

List Various Types of “quayside container crane”

Quayside container cranes, essential for loading and unloading cargo containers from ships at ports, come in various types. These cranes are generally categorized based on their design, reach, lifting capacity, and operational efficiency. Here are the main types:

1. Panamax Crane: Designed for ships that can pass through the Panama Canal, these cranes have a moderate reach, typically 12-13 containers wide. They are suited for smaller vessels and ports with limited space.

2. Post-Panamax Crane: As container ships grew in size, these cranes were developed to handle vessels too large for the Panama Canal, with a reach of 18 containers wide. They are more robust compared to Panamax cranes.

3. Super-Post-Panamax Crane: Built for the largest container ships, these cranes can handle up to 22-24 containers across. They feature elongated booms and enhanced lifting capacities, making them ideal for major, high-traffic ports.

4. Ultra-Large Container Vessel Crane (ULCV): These cranes cater to the new class of ultra-large container ships. They have an even longer reach (up to 26 containers wide) and usually incorporate the latest in automation and efficiency technologies.

5. Rubber-Tyred Gantry (RTG) Crane: While typically used for stacking containers in the yard rather than the quay, some variations are employed for quayside operations due to their mobility. RTGs are versatile and easier to maneuver in tight spaces.

6. Rail-Mounted Gantry (RMG) Crane: These fixed-position cranes move on rails and are often employed for both yard and dockside container handling. They offer high precision and are capable of handling heavy loads.

7. Automated Stacking Cranes (ASC): These are part of automated terminal operations and can be either rail-mounted or rubber-tyred. They enhance efficiency and reduce labor costs, often working in tandem with advanced port management systems.

Understanding the different types of quayside container cranes helps in choosing the right equipment for specific port requirements, enhancing productivity and operational efficiency.

List Application of “quayside container crane”

A quayside container crane, also known as a ship-to-shore (STS) crane, is an essential piece of equipment in modern port operations. These cranes are primarily used for loading and unloading container ships at port terminals. Below are several applications of quayside container cranes:

1. Loading and Unloading Containers: The primary application of quayside container cranes is to efficiently transfer containers between ships and the dock. They can lift and move heavy containers with precision and speed, optimizing the throughput of a port.

2. Container Stacking: These cranes help in stacking containers on the dock before they are transported to storage areas or loaded onto trucks and trains. Proper stacking is crucial for maximizing space utilization and efficient logistics.

3. Intermodal Operations: Quayside container cranes facilitate the seamless transfer of containers between marine transport and land-based transport systems, such as trains and trucks, thus supporting intermodal freight operations.

4. Customs and Inspection: The cranes assist in moving containers to and from inspection areas where customs and security personnel can perform necessary checks, ensuring compliance with international trade regulations.

5. Transshipment: In major hub ports, quayside cranes play a vital role in transshipment operations, where containers are transferred between vessels. This is common in ports that act as redistribution hubs on global shipping routes.

6. Supporting Automated Terminals: Advanced quayside cranes are integrated into automated port terminals, working in sync with automated guided vehicles (AGVs) and automated stacking cranes (ASCs) to enhance efficiency and reduce human intervention.

7. Project Cargo Handling: While primarily designed for containers, some quayside cranes are also used to handle oversized and project cargo, such as industrial machinery or large construction materials, thanks to their robust lifting capacity.

8. Emergency Operations: In case of incidents like oil spills or other maritime emergencies, quayside container cranes can be used to quickly offload or reposition containers, facilitating rapid response and mitigation efforts.

These applications underscore the importance of quayside container cranes in global trade, maritime logistics, and efficient port operations.

List Buyer Types of “quayside container crane”

When it comes to quayside container cranes, also known as ship-to-shore (STS) cranes, there are several types of buyers who typically invest in this highly specialized and essential port equipment:

1. Port Authorities: These are governmental or quasi-governmental organizations responsible for managing and overseeing ports. They make significant investments in quayside container cranes to improve port infrastructure, enhance operational efficiency, and attract more shipping lines to their facilities.

2. Terminal Operators: Companies or consortia that lease or manage ports and container terminals. These operators prioritize acquiring advanced and efficient cranes to maximize throughput, reduce vessel turnaround times, and stay competitive in the market.

3. Logistics Companies: Large logistics firms that own and operate their terminals might also invest in quayside container cranes to ensure they can offer comprehensive, end-to-end supply chain solutions. This vertical integration helps them maintain control over shipping operations and reduce dependency on third parties.

4. Shipping Lines: Some of the world’s largest shipping companies, like Maersk or MSC, own and operate their terminals in strategic locations worldwide. They may purchase quayside container cranes to ensure their ships can be loaded and unloaded quickly and efficiently.

5. Private Investors and Investment Funds: With the increasing privatization and concession agreements in port operations, private equity firms and investment funds often invest in port infrastructure, including quayside container cranes, as part of their asset portfolios.

6. Government Ministries and Agencies: In developing countries, national governments sometimes directly invest in port infrastructure to boost trade and economic growth. Such investments are often part of broader economic development programs.

7. Joint Ventures: These are partnerships between different maritime stakeholders, such as between a terminal operator and a shipping line. Joint ventures invest in quayside container cranes to realize shared benefits, including cost reductions and enhanced service capabilities.

By acquiring quayside container cranes, these various buyer types aim to improve operational efficiency, increase capacity, and ultimately gain a competitive edge in the increasingly globalized shipping and logistics industry.

List “quayside container crane” Project Types for Different Industries

Quayside container cranes, also known as ship-to-shore (STS) cranes, are vital in various industries for loading and unloading intermodal containers from container ships at ports and terminals. Here are different project types utilizing quayside container cranes across multiple industries:

1. Maritime Shipping:

– Container Terminals: Positioned at busy ports, quayside container cranes handle the loading and unloading of containers from large container ships.

– Transshipment Hubs: Facilities where containers are transferred between ships bound for different international destinations.

– Feeder Ports: Smaller ports catering to short-sea shipping routes.

2. Logistics and Warehousing:

– Distribution Centers: Large hubs where goods are transferred for further distribution.

– Intermodal Facilities: Transition points where containerized cargo is moved between ships, rail, and trucks.

3. Manufacturing and Industrial:

– Export-Import Facilities: Sites where raw materials and finished goods are either shipped out or received.

– Bulk Material Handling: Industries dealing in bulk goods such as metals or agriculture may use modified cranes to handle bulk containers.

4. Energy Sector:

– Offshore Oil and Gas: Some terminals support the shipping of equipment and supplies to offshore oil rigs.

– Renewable Energy: Ports aiding in the shipment of turbines, solar panel containers, etc.

5. Automotive Industry:

– Vehicle Manufacturing: Ports handling the import/export of vehicle parts and finished vehicles in containers.

6. Food and Beverage:

– Perishable Goods Terminals: Specialized to handle food containers which require careful and efficient handling.

7. Technology and Electronics:

– High-Value Goods Terminals: Ports equipped to ensure the secure and efficient handling of high-value electronic products.

Each industry deploys these cranes differently based on their logistical requirements, cargo types, and operational scales. The common thread remains the necessity for efficient, reliable, and high-capacity container handling to maintain smooth and cost-effective supply chains.

quayside container crane Accessories Upgrades and Custom Manufacturing Options

Quayside container cranes are vital for efficient cargo handling in seaports. To enhance their performance, several accessories, upgrades, and custom manufacturing options are available:

1. Automation Systems:

– Remote Control Operations: Enhances precision and safety by allowing operators to manage cranes from a distance.

– Advanced PLC Systems: Upgraded programmable logic controllers for better control and efficiency.

2. Safety Enhancements:

– Anti-Sway Systems: Minimizes container sway during lifting for increased safety and faster operations.

– Collision Avoidance Sensors: Uses advanced sensors to prevent accidental collisions, ensuring operation safety.

3. Energy Efficiency Upgrades:

– Regenerative Drives: Converts kinetic energy from crane movements back into electrical energy, reducing power consumption.

– LED Lighting: Replaces traditional lighting with energy-efficient LED systems.

4. Structural Enhancements:

– Boom Extensions: Custom boom extensions for reaching larger vessels and accommodating different port configurations.

– Reinforced Beams: Strengthening materials for increased load capacities and longer lifespan.

5. Weather Protection:

– Enhanced Corrosion Protection: Specialized coatings and materials to protect against harsh maritime environments.

– Improved Wind Resistance: Structural adjustments and weight distribution modifications to withstand high winds.

6. Operational Efficiency:

– Trolley Speed Upgrades: Faster trolleys for reduced cycle times.

– Advanced Spreader Systems: Customizable spreaders for different container types and sizes.

7. Maintenance and Monitoring:

– Condition Monitoring Systems: Real-time data analysis for predictive maintenance, reducing downtime.

– Lubrication Systems: Automated lubrication to ensure smooth operation and extend equipment life.

By integrating these accessories and custom options, ports can significantly enhance their crane operations, ensuring higher efficiency, safety, and longevity.

List Quality Control and The Manufacturing Process of “quayside container crane”

Quality Control of Quayside Container Crane:

1. Material Inspection: Raw materials such as steel undergo rigorous quality checks for strength, durability, and corrosion resistance.

2. Compliance: Ensure compliance with international standards (ISO, ASME) and industry regulations.

3. Non-Destructive Testing (NDT): Techniques like ultrasonic testing, radiographic testing, and magnetic particle testing are used to inspect welds and structural components without causing damage.

4. Load Testing: Crane structures and components are subjected to load tests to ensure they can safely handle maximum operational loads.

5. Dimensional Accuracy: Precise measurements of components are taken to ensure adherence to design specifications.

6. Functional Testing: Comprehensive tests are performed on electrical, hydraulic, and mechanical systems to ensure proper functionality.

7. Documentation and Traceability: Maintain detailed records of materials, inspections, and tests to ensure traceability and accountability.

8. Final Inspection: A thorough final inspection ensures the entire crane meets all quality and safety standards before delivery.

Manufacturing Process of Quayside Container Crane:

1. Design and Engineering: Detailed designs and engineering calculations are completed using CAD software to meet specific operational requirements and standards.

2. Material Procurement: High-quality materials such as steel plates, beams, and specialized components are sourced from reliable suppliers.

3. Cutting and Shaping: Materials are cut and shaped using CNC machines, laser cutters, and plasma torches for precision.

4. Welding and Fabrication: Components are welded and fabricated according to design specifications using advanced welding techniques.

5. Machining and Assembly: Machined parts are assembled, ensuring high precision in alignment and structural integrity.

6. Surface Treatment: Components undergo surface treatment like sandblasting and painting to prevent corrosion and enhance durability.

7. Electrical and Hydraulic Assembly: Installation of electrical systems, hydraulic circuits, and control panels.

8. Testing and Calibration: Functional tests, including load tests and system calibrations, are conducted to ensure operability.

9. Quality Assurance: Final inspections and quality assurance checks are carried out to verify compliance with design and operational standards.

10. Delivery and Installation: The crane is disassembled if necessary, transported to the installation site, and reassembled. Field tests are conducted to ensure seamless operation.

These steps ensure that quayside container cranes are manufactured to high standards of quality and reliability, ready for efficient and safe port operations.

How to use “quayside container crane”

A quayside container crane, also known as a ship-to-shore (STS) crane, is essential for loading and unloading containers between ships and the port. Here’s a step-by-step guide to using one:

1. Preparation:

– Safety Check: Ensure the crane is thoroughly inspected for mechanical integrity and potential hazards.

– Training: Only certified operators should handle the controls.

– Calibration: Confirm the crane is calibrated correctly.

2. Positioning:

– Align Crane: Position the crane over the intended container on the vessel for loading or over the container area on the quay for unloading.

– Spreaders: Adjust the spreader frame to match the size of the container (20-foot or 40-foot).

3. Operation:

– Engage Controls: Use the control panel to maneuver the crane.

– Lower Spreaders: Carefully lower the spreader onto the container.

– Lock Mechanism: Engage the twist locks to secure the container.

– Lift and Move: Hoist the container steadily and move it to the designated position on the vessel or quay.

4. Placement:

– Lower Container: Gently lower the container to avoid accidents or damaging goods.

– Release Locks: Disengage the twist locks once the container is in place.

– Retract Spreaders: Elevate the spreader frame and retract it to prepare for the next container.

5. Post-Operation:

– Shutdown Procedures: Power off the crane safely, securing all moving parts.

– Inspection: Conduct a post-operation check to ensure all is in order.

6. Documentation:

– Record Keeping: Document the operation details for tracking and future reference.

By following these steps, you can use a quayside container crane efficiently and safely to handle container logistics at a port.

“quayside container crane” Comparative Analysis

Quayside container cranes, essential for efficient port operations, come in various types, each with unique attributes. We will compare the commonly used Panamax, Post-Panamax, Super-Post-Panamax, and Megamax container cranes.

Panamax Cranes:

– Height: Approximately 35-45 meters.

– Outreach: Capable of handling vessels up to 12-13 containers wide.

– Tonnage: Typically lifts around 40-50 tons per lift.

– Usage: Preferred in older ports with restrictions due to canal (e.g., Panama Canal) dimensions.

– Pros: Cost-effective for smaller operations.

– Cons: Limited by modern, larger vessel sizes.

Post-Panamax Cranes:

– Height: About 40-50 meters.

– Outreach: Handles vessels up to 18 containers wide.

– Tonnage: Lifts between 40-60 tons.

– Usage: Suited for newer ports accommodating wider vessels.

– Pros: Versatile and can manage larger ships compared to Panamax.

– Cons: Cannot handle the largest, newest vessels.

Super-Post-Panamax Cranes:

– Height: Around 50-60 meters.

– Outreach: Manages vessels up to 23 containers wide.

– Tonnage: Capable of lifting 50-70 tons.

– Usage: Ideal for modern ports with extensive container throughput.

– Pros: Efficient for large-scale operations.

– Cons: Higher initial investment and operational costs.

Megamax Cranes:

– Height: Exceeding 60 meters.

– Outreach: Handles vessels over 23 containers wide.

– Tonnage: Lifts upwards of 70 tons per lift.

– Usage: Exclusively in the largest ports with the highest container volumes.

– Pros: Necessary for ultra-large vessels such as the Triple-E class.

– Cons: Significant capital expenditure and requires ample port infrastructure.

In summary, Panamax and Post-Panamax cranes are suited for smaller to medium-sized ports, focusing on cost efficiency and versatility. Super-Post-Panamax and Megamax cranes cater to extensive port facilities handling significant volumes and larger vessels, emphasizing capacity and reach. The choice of crane depends on port size, vessel dimensions, and throughput requirements.

“quayside container crane” Warranty and Support

Warranty and Support for Quayside Container Cranes

When investing in a quayside container crane, understanding the warranty and support options is critical to ensure operational efficiency and mitigate downtime. Manufacturers typically offer a comprehensive warranty that ranges from 1 to 5 years, covering essential components such as structural parts, electrical systems, and hydraulic assemblies. This period may vary based on the brand and specific model.

Standard warranties include coverage for manufacturing defects and workmanship errors. It’s essential to note the exceptions and exclusions, such as damage caused by improper use, overloading, or unauthorized modifications. Some manufacturers offer extended warranty plans, which can be purchased separately, to provide prolonged coverage for key components.

Support services are equally vital for maintaining crane performance. Leading manufacturers provide 24/7 customer support, often through global service networks. This includes remote diagnostics, technical assistance, and on-site repairs. Regular maintenance packages are also available, which can be tailored to your operational needs. These packages typically include periodic inspections, preventive maintenance, and software updates to ensure the crane operates at peak efficiency.

Training programs are another crucial support aspect. They equip your crew with the necessary skills to operate and maintain the crane safely. These programs can range from basic operational training to advanced courses on diagnostics and repairs.

In summary, a robust warranty and comprehensive support plan are essential when acquiring a quayside container crane. Ensure you thoroughly review the warranty terms and leverage available support services to maximize your investment and maintain uninterrupted port operations.

List “quayside container crane” FAQ

Quayside Container Crane FAQ

1. What is a quayside container crane?

Quayside container cranes, also known as ship-to-shore (STS) cranes, are large port cranes used for loading and unloading containers from ships at dockside.

2. How does a quayside container crane operate?

A quayside container crane moves containers between the ship and the dock using a trolley and spreader mechanism. The trolley moves along the boom, and the spreader attaches to and lifts the containers.

3. What are the key components of a quayside container crane?

– Boom: Extends over the ship for container handling.

– Trolley: Moves along the boom to carry the spreader.

– Spreader: Attaches to containers for lifting.

– Gantry: The structural frame that supports the boom and trolley.

4. What is the lifting capacity of a quayside container crane?

Lifting capacity varies but typically ranges from 40 to 70 tons, depending on the crane model and design.

5. How high can a quayside container crane lift?

These cranes can lift containers to heights sufficient to stack containers up to 20-40 meters high, depending on ship size and crane specifications.

6. What types of containers can these cranes handle?

Quayside cranes can handle standard ISO containers, which include 20-foot, 40-foot, and sometimes even 45-foot containers.

7. What safety features are included in quayside container cranes?

Safety features typically include anti-sway control, collision avoidance systems, overload protection, and emergency stop mechanisms.

8. How are quayside container cranes powered?

Most quayside cranes are electrically powered, often through a connection to the port’s electrical grid or via diesel generators.

9. What maintenance is required for quayside container cranes?

Regular maintenance includes inspections, lubrication, replacement of worn parts, electrical system checks, and software updates to ensure optimal performance and safety.

10. How long does a quayside container crane last?

The lifespan of a quayside container crane is generally 20-30 years, depending on usage, maintenance, and environmental conditions.

This concise FAQ provides an overview that covers the essential aspects of quayside container cranes.

Top 10 FAQ with answer about quayside container crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing quayside container cranes from China, along with concise answers:

1. What is a quayside container crane?

– A quayside container crane, also known as a ship-to-shore crane, is designed to load and unload shipping containers from vessels at ports and terminals.

2. Why source quayside container cranes from China?

– China is known for its advanced manufacturing capabilities, competitive pricing, and robust supply chain for heavy machinery, including quayside container cranes.

3. How do I ensure the quality of cranes from Chinese suppliers?

– Opt for well-known manufacturers with a proven track record. Request quality certifications such as ISO 9001, and consider third-party inspections or audits.

4. What are the payment terms typically offered?

– Common payment terms include a 30% deposit before production and 70% balance before shipment. Letters of credit (L/C) are also widely accepted.

5. What is the typical lead time for delivery?

– Lead times can vary but generally range from 6 to 12 months, depending on the complexity and customization required.

6. Can I get customized quayside container cranes?

– Yes, many Chinese manufacturers offer customization options to meet specific operational requirements and port configurations.

7. What about after-sales service and support?

– Ensure the supplier provides comprehensive after-sales support, including installation, training, maintenance, and a readily available supply of spare parts.

8. Are there any international standards or certifications required?

– Ensure the crane complies with international standards like ISO, IEC, and those required by local port authorities or regulatory bodies.

9. How are warranty terms structured?

– Warranties typically range from 1 to 2 years, covering major components. Clarify the scope and conditions of the warranty with the supplier.

10. What are the shipping and logistical considerations?

– Due to their size, cranes are shipped in sections and assembled on-site. Verify shipping logistics, including costs and responsibilities for offloading and assembly.

These answers provide a foundational understanding for buyers looking to source quayside container cranes from China while ensuring quality and reliability.