rotating jib crane Safety Certifications

Rotating jib cranes, widely used in various industries for material handling, require stringent safety certifications to ensure safe operation. Key certifications and safety standards often adhered to include:

1. OSHA Compliance: The Occupational Safety and Health Administration (OSHA) sets forth regulations such as 29 CFR 1910.179, governing the safety requirements for cranes and derricks. This includes the design, maintenance, and operation aspects.

2. ANSI/ASME B30: The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide a series of standards in the B30 series, specifically B30.11 for monorails and underhung cranes, covering rotating jib cranes. These standards include guidelines for construction, testing, and safe operation.

3. ISO Standards: The International Organization for Standardization (ISO) has several standards relevant to rotating jib cranes, such as ISO 4301 for classification of cranes and ISO 9927 for inspection, testing, and maintenance protocols.

4. EN Standards: European Norm (EN) standards like EN 14985 for cranes and EN 13001 for general design principles are crucial for ensuring safety in the European Union.

5. LOLER Compliance: In the UK, the Lifting Operations and Lifting Equipment Regulations (LOLER) mandates thorough examination and testing of lifting equipment, ensuring that jib cranes are kept in safe working order.

6. CE Marking: For cranes sold in the European Economic Area (EEA), CE marking is crucial. It signifies that the equipment meets the essential health and safety requirements set out in relevant EU directives.

7. CSA Standards: The Canadian Standards Association (CSA) outlines specific standards like CSA B167 for overhead cranes, which include jib cranes, ensuring safety compliance in Canada.

Regular inspections, routine maintenance, proper training, and adherence to these certifications and standards are essential in minimizing the risk of accidents and ensuring the safe operation of rotating jib cranes.

List Reference Technical Parameters of “rotating jib crane”

旋转臂架起重机技术参数

1. 起重量(Tons):

– 旋转臂架起重机可承载的最大重量。

2. 起升高度(m):

– 重物从地面起升的最大高度。

3. 工作半径(m):

– 臂架旋转工作范围内的最大半径。

4. 旋转角度(°):

– 臂架水平旋转的最大角度,通常为360°。

5. 起升速度(m/min):

– 起重机在空载和满载条件下的提升速度。

6. 旋转速度(r/min):

– 旋转臂架每分钟旋转的转数。

7. 运行速度(m/min):

– 起重机或运行小车沿轨道移动的速度。

8. 电机功率(kW):

– 不同部分的电机功率,包括提升电机、旋转电机等。

9. 电源参数:

– 常见电源类型为380V,50Hz。

10. 控制方式:

– 手动控制、遥控控制、自动化控制等。

11. 运行环境:

– 室内或室外使用,适应温度范围、防尘防水等级等。

12. 安全装置:

– 超载保护、限位器、紧急停止等。

13. 材料:

– 起重机主要部件所用材料,如高强度钢材。

14. 重量(kg):

– 起重机自身的总重量。

15. 尺寸(m):

– 起重机的主要外形尺寸,包括长度、宽度、高度。

List Product features of “rotating jib crane”

Here are the product features of a rotating jib crane:

1. Rotation Capability: The jib crane can rotate 180 degrees, 270 degrees, or even a full 360 degrees, providing extensive coverage and flexibility in material handling.

2. Load Capacity: Typically, rotating jib cranes can handle loads ranging from a few hundred kilograms to several tons, depending on the model and design.

3. Boom Length: The length of the boom can vary, allowing for different reach capabilities to suit various workspace requirements.

4. Mounting Options: These cranes can be floor-mounted, wall-mounted, or column-mounted, offering versatility in installation based on the workspace layout.

5. Height Adjustability: Some models offer adjustable height features to accommodate different lifting heights and improve operational efficiency.

6. Ease of Operation: Equipped with user-friendly controls, these cranes are designed for easy and precise operation, often including features like push-button controls or remote control options.

7. Durability: Constructed from high-quality materials such as steel, rotating jib cranes are built to withstand heavy use and harsh industrial environments.

8. Safety Features: Includes safety mechanisms such as overload protection, emergency stop buttons, and limit switches to ensure safe operation.

9. Customization: Many manufacturers offer customization options to tailor the crane to specific needs, including different boom lengths, load capacities, and mounting configurations.

10. Maintenance: Designed for easy maintenance with accessible components and straightforward servicing procedures to minimize downtime.

11. Versatility: Suitable for various applications, including manufacturing, warehousing, assembly lines, and maintenance tasks.

12. Cost-Effective: Provides an economical solution for lifting and moving heavy loads within a confined area, reducing the need for larger, more expensive lifting equipment.

These features make rotating jib cranes a valuable asset in many industrial and commercial settings, enhancing productivity and safety.

List Various Types of “rotating jib crane”

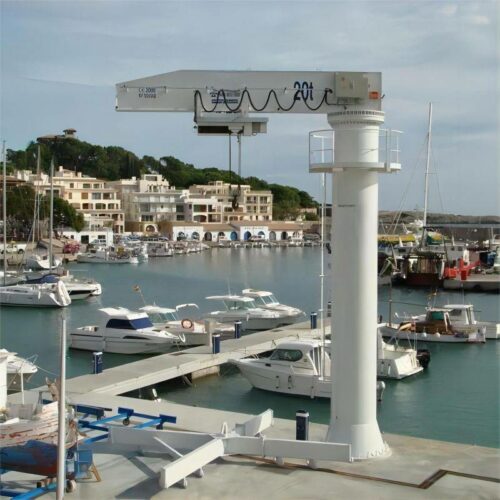

Rotating jib cranes are versatile lifting devices designed to handle materials within a specific radius, featuring a rotating arm (jib) that enables load movement. Common types of rotating jib cranes include:

1. Free-standing Jib Cranes:

– Characteristics: Self-supporting structure anchored to a concrete foundation.

– Applications: Warehousing, manufacturing, and outdoor storage yards.

2. Wall-mounted Jib Cranes:

– Characteristics: Mounted on existing building columns or structural walls, saving floor space.

– Applications: Factories and workshops with limited floor space.

3. Mast-style Jib Cranes:

– Characteristics: Combination of a floor-mounted and wall-mounted jib crane; less reliance on building structure.

– Applications: Facilities with structural limitations for wall mounting.

4. Articulating Jib Cranes:

– Characteristics: Two-piece jib arm for more complex load positioning and greater flexibility.

– Applications: Precision assembly, welding areas, and machinery servicing.

5. Mobile Jib Cranes:

– Characteristics: Mounted on a mobile base, typically with wheels, for easy relocation.

– Applications: Temporary workstations and environments where flexible positioning is needed.

6. Workstation Jib Cranes:

– Characteristics: Typically lighter-duty, designed for repetitive tasks, with ergonomic design.

– Applications: Assembly lines, packaging, and light manufacturing.

7. Foundationless Jib Cranes:

– Characteristics: Bolted to the existing concrete floor without the need for a foundation.

– Applications: Quick installation in existing facilities with adequate floor strength.

Each type of rotating jib crane offers unique advantages based on structural design, load requirements, and operational environments. When choosing the appropriate jib crane, factors such as load capacity, area coverage, and installation feasibility should be carefully considered.

List Application of “rotating jib crane”

Rotating jib cranes are versatile lifting devices used across various industries to handle heavy materials efficiently. Here are some key applications:

1. Manufacturing and Assembly Lines:

– *Component Handling*: Facilitate the movement of heavy parts and assemblies.

– *Tooling and Equipment Transport*: Transport tools and equipment within production zones.

2. Warehousing and Storage:

– *Loading and Unloading*: Assist in moving goods to and from pallets, racks, and shelves.

– *Inventory Management*: Aid in the organization and retrieval of bulk items.

3. Construction Sites:

– *Material Placement*: Position building materials like steel beams, concrete blocks, and panels.

– *Remote Handling*: Operate in confined spaces where larger cranes are impractical.

4. Dockyards and Shipyards:

– *Cargo Handling*: Move heavy cargo containers between ships and docks.

– *Maintenance and Repair*: Assist in lifting engines, propellers, and other heavy components.

5. Automotive Industry:

– *Engine and Transmission Installation*: Precisely place heavy components in vehicle assembly lines.

– *Vehicle Part Handling*: Manage heavy vehicle parts such as axles and large panels.

6. Maintenance and Repair:

– *Heavy Equipment Servicing*: Lift parts of heavy machinery for inspection and repair.

– *Facility Maintenance*: Lower or raise equipment and parts to heights where repair and maintenance are needed.

7. Mining and Quarrying:

– *Material Lifting*: Hoist mining equipment and extracted materials.

– *Operational Support*: Assist in the placement of heavy accessories and tools.

8. Energy Sector:

– *Wind Turbines*: Handle components during turbine assembly and maintenance.

– *Substation Construction*: Place transformers and other heavy electrical equipment.

These applications underscore the rotating jib crane’s role in improving operational efficiency and safety when handling heavy materials across diverse industries.

List Buyer Types of “rotating jib crane”

When it comes to purchasing a rotating jib crane, buyers can generally be categorized based on industry and application requirements. Here are some of the main buyer types:

1. Manufacturing Companies: These businesses often require rotating jib cranes to enhance production efficiency and streamline material handling within their factories. They use cranes to lift and move heavy components, assembly parts, or finished products.

2. Construction Firms: Companies involved in building infrastructure or constructing large facilities opt for rotating jib cranes to handle construction materials such as steel beams, concrete blocks, and other bulky construction items safely and efficiently.

3. Warehousing and Logistics Providers: These buyers seek rotating jib cranes to improve the movement of goods within a warehouse setting. By incorporating these cranes, they can significantly boost the speed and safety of loading and unloading operations.

4. Ports and Shipyards: Given the need to handle heavy and often unwieldy materials, ports and shipyards invest in rotating jib cranes to facilitate the loading and unloading of shipping containers, boats, or other heavy maritime equipment.

5. Automotive Industry: Car manufacturers and automotive repair shops use rotating jib cranes to move engines, car bodies, and other heavy automotive components. These cranes provide the precision and strength required for such tasks.

6. Aerospace Industry: The aerospace sector requires rotating jib cranes for the precise handling of aircraft parts, engines, and other critical components, ensuring both safety and efficiency during manufacturing and maintenance operations.

7. Heavy Equipment Maintenance: Companies offering maintenance services for heavy machinery, such as mining or agricultural equipment, often use rotating jib cranes to lift and transport large machine parts during repairs and servicing.

8. Renewable Energy Sector: This sector, particularly wind turbine and solar panel installation companies, utilizes rotating jib cranes to handle large, heavy equipment and components such as turbine blades and photovoltaic panels.

9. Retail and Wholesale Distributors: Equipment distributors and retailers specializing in material handling solutions also invest in rotating jib cranes to meet the diverse needs of their clients across various sectors.

By targeting these buyer types, suppliers of rotating jib cranes can effectively reach a broad range of industries, each with unique needs and applications.

List “rotating jib crane” Project Types for Different Industries

1. Construction Industry:

– High-Rise Buildings: Rotating jib cranes are essential for lifting heavy materials like steel beams, concrete slabs, and prefabricated sections to high elevations.

– Bridge Construction: Used for maneuvering large sections of bridges into place, enhancing precision and reducing manual labor.

2. Mining and Quarrying:

– Open-Pit Mining: Facilitates the lifting of drilling equipment, heavy machinery, and extracted minerals, streamlining the extraction process.

– Underground Mines: Compact models maneuver through narrow shafts to transport mined materials.

3. Oil and Gas Industry:

– Offshore Rigs: Deployed for lifting drilling equipment, pipes, and other heavy components, ensuring safe operations in adverse marine conditions.

– Refineries: Used for maintenance tasks, such as moving large machinery parts or components during shutdowns for repairs.

4. Manufacturing:

– Automobile Production: Utilized for the assembly line to handle heavy parts like engines and chassis components efficiently.

– Heavy Machinery Manufacturing: Aid in lifting large and cumbersome machine components during the production and assembly processes.

5. Shipping and Ports:

– Cargo Handling: Essential for loading and unloading heavy cargo from ships, enhancing the operational capacity of port facilities.

– Shipbuilding: Facilitate the assembly and repair of ships by moving large sections and components into place.

6. Aerospace:

– Aircraft Manufacturing: Employed for precise placement of heavy parts like engines, wings, and fuselage sections during the assembly process.

– Maintenance Hangars: Assist in the routine maintenance and assembling procedures of sizable aircraft components.

7. Renewable Energy Sector:

– Wind Turbine Installation: Facilitate the lifting and installation of heavy turbine parts, such as blades and nacelles, often in remote locations.

– Solar Power Plants: Aid in handling and positioning large solar panels and other infrastructural elements.

8. Automotive Repair and Maintenance:

– Garage Use: Smaller rotating jib cranes assist in lifting engines and other heavy automotive components for repair and maintenance tasks.

Each industry leverages the unique capabilities of rotating jib cranes to enhance efficiency, ensure safety, and streamline operations.

rotating jib crane Accessories Upgrades and Custom Manufacturing Options

Rotating jib cranes are vital for various industrial applications due to their versatility and reliability. To maximize their potential, numerous accessories, upgrades, and custom manufacturing options are available.

Accessories:

1. End Stops: Enhance safety by preventing the trolley from exceeding its travel limit.

2. Hoist Units: Choose between electric, pneumatic, or manual hoists depending on the application.

3. Control Options: Wired or wireless remote controls improve operational convenience and flexibility.

4. Load Indicators: Ensure accurate load measurements and prevent overloading.

5. Rotation Locks: Secure the crane in position when not rotating, adding an extra layer of safety.

Upgrades:

1. Motorized Rotation: Automate crane movement for increased efficiency and reduced manual effort.

2. Variable Speed Drives: Allow precise control over lifting and rotation speeds for enhanced precision and safety.

3. Anti-Collision Systems: Utilize sensors to prevent accidents by detecting obstacles and initiating automatic stops.

4. Weatherproofing: Protect components against harsh environmental conditions, ensuring longevity and reliable performance.

5. Ergonomic Enhancements: Adjustable handles and improved control layouts reduce operator fatigue and improve comfort.

Custom Manufacturing Options:

1. Capacity Adjustments: Tailor the crane’s lifting capacity to specific requirements, ensuring optimal performance.

2. Boom Length and Height Adjustments: Customize these dimensions to fit unique spatial constraints or operational needs.

3. Material Choices: Opt for stainless steel, aluminum, or other materials based on the working environment, especially for corrosive or hygienic conditions.

4. Base and Mounting Options: Select between wall-mounted, floor-mounted, or portable bases to suit facility layout and mobility requirements.

5. Specialty Attachments: Design unique hooks, clamps, or spreader bars to handle specialized loads or applications.

Combining these accessories, upgrades, and custom manufacturing options can significantly enhance the functionality, safety, and efficiency of rotating jib cranes, making them tailored solutions for diverse operational needs.

List Quality Control and The Manufacturing Process of “rotating jib crane”

Quality Control of Rotating Jib Crane

1. Material Inspection:

– Verify the quality and specifications of raw materials like steel, fasteners, and electrical components.

– Conduct non-destructive testing (NDT) such as ultrasonic or radiographic tests on critical parts.

2. Dimensional Accuracy:

– Use precision measuring tools to confirm that components meet design specifications.

– Ensure dimensional tolerances are within acceptable limits.

3. Welding Quality:

– Inspect welds visually and through NDT methods like magnetic particle inspection.

– Conduct tension and bend tests on welded joints for strength validation.

4. Load Testing:

– Perform static and dynamic load tests to ensure structural integrity under operational loads.

– Use calibrated weights to verify the crane’s lifting capacity and stability.

5. Electrical and Control Systems:

– Test electrical circuits for continuity, insulation resistance, and proper grounding.

– Validate the functionality of control systems, safety interlocks, and emergency stops.

6. Assembly Verification:

– Perform final checks for alignment and proper assembly.

– Evaluate the smoothness of rotation and jib arm extension/retraction.

7. Documentation and Traceability:

– Maintain detailed records of inspections, tests, and material certifications.

– Provide thorough manuals and safety documentation for end-users.

Manufacturing Process of Rotating Jib Crane

1. Design and Engineering:

– Create detailed 3D CAD models and engineering drawings.

– Conduct computational load analysis and structural integrity simulations.

2. Material Procurement:

– Source high-grade steel and other required materials from verified suppliers.

– Validate material quality through standardized inspections.

3. Cutting and Fabrication:

– Use CNC machines, plasma cutters, and other precision tools to cut steel components.

– Fabricate parts like the base plate, mast, and jib arm according to design specifications.

4. Welding and Assembly:

– Weld components together following stringent welding procedures.

– Assemble mechanical parts including bearings, gears, and rotating mechanisms.

5. Surface Treatment:

– Clean, paint, or galvanize components for rust prevention and aesthetic finish.

– Apply necessary coatings for corrosion resistance.

6. Electrical and Hydraulic Systems Installation:

– Install electrical wiring, control panels, and hydraulic systems.

– Ensure proper integration of motors, sensors, and safety devices.

7. Testing and Final Assembly:

– Conduct pre-assembly inspections and dimensional checks.

How to use “rotating jib crane”

A rotating jib crane is a versatile piece of equipment commonly used in various industries for lifting and moving heavy loads within a specific radius. Here’s a step-by-step guide to using a rotating jib crane:

1. Inspection: Before use, conduct a thorough inspection of the crane, including the jib, hoist, cables, and controls. Ensure that all parts are in good condition and functioning properly.

2. Safety Gear: Wear appropriate personal protective equipment (PPE), such as a hard hat, gloves, safety glasses, and steel-toed boots.

3. Clear Area: Ensure the area around the crane is clear of obstacles and personnel who are not involved in the operation.

4. Positioning: Position the jib crane such that the load is within the crane’s maximum radius and lifting capacity. Ensure the base is stable and secure.

5. Attach Load: Carefully attach the load to the hoist hook using appropriate slings or lifting gear. Double-check that the load is balanced and securely fastened.

6. Lift Load: Using the crane’s control panel, slowly lift the load a few inches off the ground to check balance and ensure all attachments are secure.

7. Rotate Jib: Once the load is stable, use the controls to rotate the jib arm to the desired position. Move slowly and steadily to avoid swinging the load.

8. Lower Load: Carefully lower the load to its destination. Make sure the area is clear and guide the load if necessary to ensure precise placement.

9. Detach Load: Once the load is stable and properly positioned, detach the lifting equipment.

10. Shutdown: After use, return the controls to the neutral position, lower the hoist hook, and secure the jib crane.

By following these steps, you can effectively and safely use a rotating jib crane for various lifting tasks. Always adhere to the manufacturer’s instructions and safety protocols.

“rotating jib crane” Comparative Analysis

Rotating jib cranes are versatile lifting devices used across various industries such as manufacturing, construction, and shipbuilding. Their compact design and ability to rotate provide significant advantages, making them a preferred choice for specific lifting tasks. This comparative analysis will outline the strengths and weaknesses of rotating jib cranes compared to other types of cranes, like overhead cranes and mobile cranes.

Advantages:

1. Flexibility and Reach:

– Rotating jib cranes offer a wide range of motion, typically up to 360 degrees or a limited rotation angle, depending on the model. This allows for greater versatility in small spaces and facilitates the precise positioning of loads.

2. Space Efficiency:

– These cranes are often mounted on floors, walls, or columns, saving valuable floor space. This makes them ideal for environments where space constraints are a significant consideration, such as workshops or production lines.

3. Ease of Installation:

– Their relatively simple installation process and lower initial cost compared to overhead or mobile cranes make them an accessible option for many businesses.

4. Operational Simplicity:

– Jib cranes are easy to operate, requiring less training, which can reduce operational downtime and improve productivity.

Disadvantages:

1. Limited Load Capacity:

– Rotating jib cranes generally have a lower load capacity compared to overhead and mobile cranes. This limits their use to lighter loads, typically up to several tons.

2. Restricted Coverage Area:

– While the rotation provides good coverage, the reach is usually limited to the length of the boom, which may not be sufficient for larger areas or sites.

3. Fixed Position:

– Unlike mobile cranes, jib cranes are stationary once installed, reducing their flexibility in terms of relocation and adaptability to different job sites.

Comparisons:

– Overhead Cranes:

– Better for heavy loads and wide-area coverage but require more complex installation and greater space.

– Mobile Cranes:

– Offer high mobility and capacity but are more expensive and require significant space for operation.

In summary, rotating jib cranes are a valuable solution for tasks requiring moderate lifting capacity and precision in confined spaces. Their installation ease and operational simplicity make them a pragmatic choice, although their fixed position and lower load capacity may be limitations for some applications.

“rotating jib crane” Warranty and Support

Warranty and Support for Rotating Jib Crane

Warranty:

Our rotating jib cranes are backed by a comprehensive warranty to ensure peace of mind and optimal performance. Generally, we offer a 2-year warranty from the date of purchase, covering any defects in materials and workmanship under normal use conditions. This warranty includes the repair or replacement of any defective parts at no extra cost. However, it does not cover issues arising from improper installation, unauthorized modifications, or misuse of the equipment. Clients are encouraged to read the warranty terms thoroughly and register their product within 30 days of purchase to activate the coverage.

Support:

Our commitment to customer satisfaction extends beyond the warranty period with our robust support services. We offer:

1. Technical Assistance: Our team of experienced technicians is available to help with installation, operation, and troubleshooting. You can reach out via phone, email, or our dedicated support portal.

2. Maintenance Plans: Regular maintenance is crucial for the longevity of your rotating jib crane. We offer customizable maintenance plans, including scheduled inspections and servicing to keep your equipment in top condition.

3. Training Programs: To ensure safe and efficient use, we provide comprehensive training programs for operators and maintenance personnel. These programs cover essential aspects of crane operation, safety protocols, and routine maintenance checks.

4. Spare Parts Supply: We maintain a wide inventory of genuine spare parts, ensuring timely availability and quick delivery to minimize downtime.

5. Online Resources: Our website features a wealth of resources, including user manuals, troubleshooting guides, and instructional videos to assist with any immediate questions or issues.

Our goal is to provide reliable, long-term support to maximize the productivity and safety of your rotating jib crane. For any further inquiries, please contact our customer support team.

List “rotating jib crane” FAQ

Rotating Jib Crane FAQ

1. What is a rotating jib crane?

A rotating jib crane is a type of crane featuring a horizontal arm (jib) that can rotate around a central pivot. This design enables it to lift and transport loads within a circular area.

2. Where are rotating jib cranes commonly used?

Rotating jib cranes are widely used in manufacturing plants, warehouses, assembly lines, and loading bays for applications like material handling, machine loading, and component assembly.

3. What are the key features of a rotating jib crane?

Key features include its rotational capability (typically up to 360 degrees), customizable jib length, and varying load capacities. Some models come with motorized rotation, while others rely on manual rotation.

4. How much weight can a rotating jib crane lift?

Lifting capacities vary widely, ranging from a few hundred kilograms to several tons, depending on the crane’s size, design, and manufacturer specifications.

5. How is a rotating jib crane mounted?

Rotating jib cranes can be floor-mounted, wall-mounted, or mounted on an existing structure. The mounting type depends on the specific application and workspace layout.

6. What are the power sources for a rotating jib crane?

These cranes can be powered electrically, pneumatically, or manually. Electric and pneumatic models provide more power and are suitable for heavier loads and more frequent use.

7. Is professional installation required?

Yes, professional installation is recommended to ensure safety, proper alignment, and compliance with regulations.

8. What maintenance is needed?

Regular inspections, lubrication of moving parts, and checking for structural integrity are essential for maintaining optimal performance and safety.

9. Can a rotating jib crane be customized?

Yes, manufacturers often provide customization options for jib length, height, rotation angle, and lifting capacity to meet specific needs.

10. How much does a rotating jib crane cost?

Costs vary based on specifications, size, and additional features. It’s advisable to get quotes from multiple suppliers to determine the best fit for your budget and needs.

Conclusion

Rotating jib cranes are versatile, reliable tools for various material handling tasks. Understanding their features, installation, and maintenance requirements is crucial for maximizing their utility and safety.

Top 10 FAQ with answer about rotating jib crane for Buyer Sourcing from China

Absolutely, sourcing a rotating jib crane from China requires careful consideration and understanding. Here are the top 10 frequently asked questions about it:

1. What is a rotating jib crane?

– A rotating jib crane is a type of crane with a horizontal member (jib or boom) that supports a movable hoist fixed to a wall or to a floor-mounted pillar. It can rotate to lift and move materials within a certain radius.

2. Why source a jib crane from China?

– China offers cost-effective manufacturing, advanced technology, and a wide range of suppliers. Their quality-control has significantly improved over the years, ensuring reliable products.

3. What are the key specifications to consider?

– Consider load capacity, jib length, rotation angle, lifting height, and type of hoist (electric/manual). These factors determine the crane’s compatibility with your operational needs.

4. How reliable are Chinese manufacturers?

– Many Chinese manufacturers adhere to international standards like ISO, CE, and ASME. Verify their certifications and read reviews or request client references to ensure reliability.

5. What is the typical lead time?

– Lead time varies by order size and customization. Standard models are usually ready in 4-6 weeks, while custom orders may take longer.

6. What are the shipping and logistics considerations?

– Shipping typically involves ocean freight, which takes 3-6 weeks. Factor in additional time for customs clearance and inland transportation.

7. How do I ensure quality control?

– Work with suppliers who offer pre-shipment inspections and third-party quality audits. Request detailed inspection reports and consider visiting the factory if possible.

8. What are the payment terms?

– Common terms are 30% deposit upon order and 70% balance before shipment. Letter of Credit (LC) is also a secure option for larger transactions.

9. Can I get customization options?

– Yes, many manufacturers offer customization based on your specific requirements. Discuss your needs upfront to ensure feasibility and cost implications.

10. What after-sales support is available?

– Verify the warranty terms (usually 1-2 years) and check if the supplier offers technical support, spare parts, and maintenance services as part of their after-sales support.

By considering these FAQs, you can make an informed decision when sourcing rotating jib cranes from China, ensuring both quality and efficient service.