semi gantry crane Safety Certifications

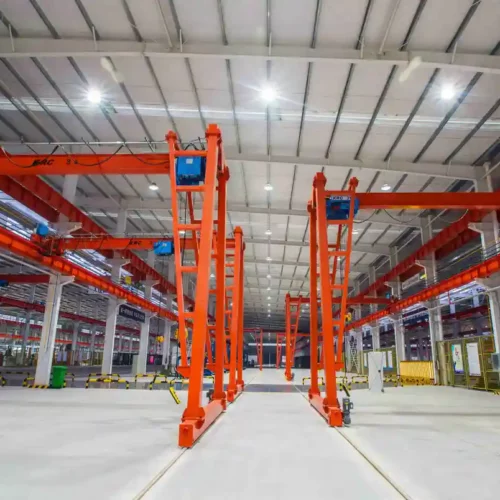

A semi-gantry crane is a hybrid lifting device featuring one end supported by an elevated track system, similar to traditional gantry cranes, and the other end supported by the factory floor. This crane type is commonly used in manufacturing, shipbuilding, and maintenance facilities. To ensure safety and compliance, semi-gantry cranes must adhere to various certifications and standards, typically governed by national and international safety organizations.

1. OSHA (Occupational Safety and Health Administration):

– OSHA regulations in the United States (29 CFR 1910.179) outline requirements for the safe operation, inspection, and maintenance of overhead and gantry cranes, including semi-gantry cranes.

2. ASME (American Society of Mechanical Engineers):

– ASME B30.2 addresses safety standards for overhead and gantry cranes. This standard is essential in ensuring that semi-gantry cranes are designed, inspected, tested, and maintained according to recommended guidelines.

3. ISO (International Organization for Standardization):

– ISO 9927-1:2013 covers the general requirements for the inspection, testing, and maintenance of cranes, including semi-gantry cranes. Compliance with ISO standards ensures global operational uniformity and safety.

4. CMAA (Crane Manufacturers Association of America):

– Specification No. 70 and 74 by CMAA provide guidelines for the construction, installation, and maintenance of overhead and gantry cranes, including those of the semi-gantry type. These specifications are industry benchmarks in North America.

5. CE Marking (European Union):

– In Europe, semi-gantry cranes must meet the Machinery Directive 2006/42/EC, ensuring they conform to essential health and safety requirements. CE marking indicates conformity with the directive.

6. LOLER (Lifting Operations and Lifting Equipment Regulations 1998):

– These UK regulations require that lifting equipment, including semi-gantry cranes, undergo thorough examinations by a competent person to ensure safety during operations.

Adhering to these certifications and standards is crucial for ensuring the safe and efficient operation of semi-gantry cranes, mitigating risks, and safeguarding personnel.

List Reference Technical Parameters of “semi gantry crane”

A semi-gantry crane is a type of overhead lifting device that combines characteristics of both gantry cranes and overhead (bridge) cranes. Here are key technical parameters:

1. Lifting Capacity: The maximum weight the crane can lift, typically measured in metric tons. Common capacities range from 1 ton to 50 tons, but custom configurations can support higher weights.

2. Span Length: The horizontal distance between the rails on which the crane operates. Span lengths typically range from 3 meters to 30 meters, depending on operational requirements.

3. Lifting Height: The maximum vertical distance a crane hook can travel from the ground to its highest point. Standard lifting heights vary from 6 meters to 30 meters.

4. Crane Speed: Comprises the hoisting speed (how quickly the load can be lifted or lowered), trolley speed (the horizontal travel speed of the lifting mechanism), and crane travel speed (how quickly the entire crane moves along the rails). Speed ranges depend on operational needs, such as precision or efficiency.

5. Travel Mechanism: Semi-gantry cranes typically have a top rail on one side and a floor-mounted rail on the other. The travel mechanism includes motorized drive systems that enable movement along these rails.

6. Control System: Can be manual, pendant-controlled, or radio remote-controlled, enhancing operational flexibility and safety.

7. Power Supply: Typically involves an electric power source, often 3-phase AC with standard voltages of 380V, 415V, or customized configurations based on regional standards.

8. Structural Material: Usually made of high-strength steel, providing durability and the ability to withstand heavy loads.

9. Duty Class: Denotes the operational workload capability, ranging from light duty (infrequent use) to heavy duty (continuous use), classified under standards like FEM (European Federation of Handling Equipment) or CMAA (Crane Manufacturers Association of America).

10. Safety Features: Includes overload protection, emergency stop functions, end stops, and limit switches for safe operation.

These parameters help in designing, selecting, and deploying semi-gantry cranes across various industrial applications, ensuring they meet specific needs for lifting and material handling within spaces like factories, warehouses, and shipyards.

List Product features of “semi gantry crane”

A semi gantry crane is a versatile and efficient lifting solution commonly used in various industrial applications. Here are some key product features:

1. Structure and Design:

– Steel Construction: Robust and durable steel framework ensures longevity and reliability.

– Single or Double Girder: Available in single or double girder configurations to meet different load capacities and span requirements.

– Adjustable Height: Can be tailored to accommodate varying heights of building ceilings and workspaces.

2. Mobility and Installation:

– Semi-Portal Design: One side runs on a runway attached to building columns, while the other side runs on ground rails, maximizing workspace efficiency.

– Easy Assembly: Modular design allows for straightforward installation and relocation if necessary.

– Minimal Ground Space: Efficient use of ground space with the semi-gantry configuration.

3. Lifting Mechanism:

– Electric Hoist: Equipped with a high-performance electric hoist for smooth and precise lifting operations.

– Variable Speeds: Adjustable lifting and traveling speeds for enhanced control and productivity.

4. Capacity and Range:

– Customizable Span and Capacity: Tailored to specific lifting requirements, available in various capacities and spans.

– Uniform Load Distribution: Even distribution of loads to minimize structural strain and enhance safety.

5. Safety and Compliance:

– Safety Features: Includes overload protection, emergency stop functions, and limit switches.

– Regulatory Compliance: Conforms to industry standards and safety regulations, ensuring safe operation.

6. Control Systems:

– Remote Control: Wireless remote control options for added convenience and safety.

– Manual Controls: Manual pendant controls for immediate and precise operational management.

7. Maintenance and Durability:

– Low Maintenance: Designed for minimal maintenance requirements, reducing downtime and operational costs.

– Corrosion Resistance: Coated with protective finishes to mitigate corrosion and wear in harsh environments.

8. Applications:

– Versatility: Ideal for various applications including warehouses, factories, construction sites, and shipyards.

These features make semi gantry cranes a reliable and efficient choice for material handling needs across multiple industries.

List Application of “semi gantry crane”

A semi gantry crane is a versatile lifting solution widely used in various industries due to its unique design, where one side of the crane runs on a raised runway and the other side runs on a floor-level rail. This distinct structure allows semi gantry cranes to operate efficiently in spaces where full gantry cranes might be impractical. Below are key applications of semi gantry cranes:

1. Manufacturing Facilities: Semi gantry cranes are commonly used in manufacturing settings for moving heavy machinery, tools, and materials within specific areas of the plant. Their ability to operate over existing equipment and floor obstacles makes them ideal for these environments.

2. Warehousing and Storage: These cranes facilitate the efficient loading and unloading of goods in storage facilities. They are particularly useful in warehouses with limited vertical space where full gantry or overhead cranes may not fit.

3. Shipbuilding: In shipyards, semi gantry cranes are used to handle large and heavy ship components. Their design allows for the efficient management of parts, equipment, and assemblies, essential in ship construction and repair processes.

4. Steel Industry: The semi gantry crane assists in the transportation of steel bars, coils, sheets, and other heavy products from production lines to storage areas or shipping zones. Their robust construction makes them suitable for heavy-duty applications in steel mills.

5. Construction Sites: On construction sites, semi gantry cranes are utilized for lifting and placing construction materials such as beams, girders, and prefabricated sections, enhancing efficiency and safety.

6. Railway Yards: These cranes aid in the maintenance, repair, and manufacturing of railway equipment by handling heavy components such as rails, bogies, and engines, supporting the efficient workflow in railway operations.

7. Automotive Industry: In car manufacturing plants, semi gantry cranes assist in the assembly process by moving heavy automotive parts along the production line, ensuring precise and safe handling.

By serving diverse industries, semi gantry cranes provide a blend of flexibility, efficiency, and cost-effectiveness, making them an invaluable asset in any heavy-duty material handling scenario.

List Various Types of “semi gantry crane”

Semi gantry cranes are industrial lifting devices combining features of both gantry and overhead cranes, used extensively in manufacturing, warehousing, and construction for material handling. They are distinctive for having one side mounted on a runway or track system, while the other side is supported by a leg running on the ground or a lower level. Here are various types of semi gantry cranes:

1. Single Girder Semi Gantry Crane:

– Description: Features a single horizontal girder supported by one leg on the ground and a wall-mounted runway.

– Use Cases: Light to medium-duty applications, smaller load capacities.

2. Double Girder Semi Gantry Crane:

– Description: Comprises two horizontal girders, offering greater strength and higher load capacities.

– Use Cases: Heavy-duty applications, large-scale lifting.

3. Adjustable Height Semi Gantry Crane:

– Description: Offers adjustable heights, allowing flexibility in operations for varying lifting requirements.

– Use Cases: Situations where different lifting heights are needed frequently.

4. Portable Semi Gantry Crane:

– Description: Features mobility and can be easily moved to different locations within the facility.

– Use Cases: Temporary worksites, maintenance tasks, or operations with varying locations.

5. Heavy Duty Semi Gantry Crane:

– Description: Designed for very heavy loads, often with reinforced structures.

– Use Cases: Heavy industry sectors, such as shipyards or steel yards.

6. Light Duty Semi Gantry Crane:

– Description: Designed for lighter loads and more frequent use.

– Use Cases: Small manufacturing units, warehouses, and assembly lines.

7. Custom-Built Semi Gantry Crane:

– Description: Tailored to meet specific user requirements, including unique dimensions, load capacities, and functionalities.

– Use Cases: Special projects or bespoke industrial needs.

By selecting the appropriate type of semi gantry crane, businesses can optimize their lifting operations, enhancing efficiency and safety in material handling tasks.

semi gantry crane Accessories Upgrades and Custom Manufacturing Options

A semi-gantry crane is a versatile lifting solution, often employed in various industrial applications such as manufacturing, warehousing, and construction. Enhancing its functionality through accessories, upgrades, and custom manufacturing options can significantly improve operational efficiency and safety.

Accessories:

1. Remote Controls: Wireless remote controls provide operators with a greater range of motion and improved safety by allowing them to operate the crane from a distance.

2. Anti-Collision Systems: These systems help prevent accidents by stopping or slowing the crane when an obstacle is detected.

3. Load Weighing Systems: Integrated load cells and digital displays can provide real-time load weights, ensuring safe lifting and transport.

4. Lighting Kits: LED lighting kits can be attached to the crane to enhance visibility in low-light conditions, improving safety and accuracy.

5. Cable Management Systems: Festoon systems and energy chains prevent cable tangling and damage, ensuring a clean and organized setup.

Upgrades:

1. Variable Frequency Drives (VFDs): VFDs offer smooth acceleration and deceleration, improving load control and reducing mechanical wear.

2. Advanced Hoisting Mechanisms: Upgrading to higher-capacity or faster hoists can optimize lifting operations for specific applications.

3. Safety Features: Additional safety features such as emergency stop buttons, overload protection, and limit switches enhance operational safety.

Custom Manufacturing Options:

1. Tailored Dimensions: Customizing the crane’s span, height, and overall dimensions to fit specific workspace requirements ensures optimal usage of available space.

2. Specialty Hook Attachments: Customized hooks or lifting devices can be designed to handle unique or awkward loads safely and efficiently.

3. Material and Finish: Depending on the application, cranes can be built with customized materials (e.g., stainless steel for corrosive environments) and finishes (e.g., specialized coatings for outdoor use).

4. Automated Systems: Incorporating automation and integration with existing systems (such as manufacturing execution systems) can streamline operations and enhance productivity.

Investing in these accessories, upgrades, and custom options can maximize the functionality, safety, and lifespan of a semi-gantry crane, tailored to meet specific operational demands.

List Quality Control and The Manufacturing Process of “semi gantry crane”

Quality Control of Semi Gantry Crane

1. Material Inspection

– Ensure all raw materials meet specified standards.

– Check for defects like rust or cracks.

2. Dimensional Accuracy

– Use precision instruments to verify dimensions.

– Confirm that all parts meet design specifications.

3. Welding Inspection

– Check quality and integrity of welds.

– Use non-destructive testing methods like ultrasonic testing.

4. Load Testing

– Test the crane with loads exceeding its rated capacity.

– Monitor for structural integrity and operational performance.

5. Electrical and Mechanical Systems Check

– Inspect electrical circuitry for safety and function.

– Verify mechanical components like motors and brakes.

6. Final Inspection

– Conduct a thorough audit of the assembled crane.

– Ensure compliance with international and safety standards.

7. Documentation

– Record all quality control tests and results.

– Maintain records for traceability and future reference.

Manufacturing Process of Semi Gantry Crane

1. Design and Engineering

– Develop detailed engineering drawings.

– Use computer-aided design (CAD) software.

2. Material Procurement

– Source high-quality materials such as steel.

– Ensure timely delivery to maintain production schedules.

3. Cutting and Machining

– Cut raw materials to required dimensions.

– Machine individual parts to precise tolerances.

4. Welding and Assembly

– Assemble components through high-quality welding.

– Use jigs and fixtures to maintain alignment.

5. Surface Treatment

– Apply anti-corrosive coatings.

– Paint for protection and aesthetic purposes.

6. Electrical Installation

– Install electrical wiring and components.

– Integrate control systems and test functionality.

7. Testing and Calibration

– Perform mechanical and electrical tests.

– Calibrate to ensure accurate operation.

8. Packaging and Shipping

– Pack for protection during transit.

– Arrange for shipping and delivery to the customer.

By adhering to strict quality control measures and a systematic manufacturing process, a reliable and efficient semi gantry crane can be produced, ensuring long-term operational safety and performance.

How to use “semi gantry crane”

A semi gantry crane is a type of crane where one end of the bridge is supported by a runway rail mounted on the ground, and the other end is supported by a runway rail mounted on an elevated structure such as a building column. It is particularly useful for applications where space constraints or specific operational needs make traditional cranes impractical.

Steps to Use a Semi Gantry Crane:

1. Pre-Operation Checks:

– Inspect the Crane: Check for any signs of wear or damage. Ensure all safety mechanisms are functioning.

– Control System: Verify that the control system is operational. Test the hoist, trolley, and bridge movements.

– Load Weight: Confirm that the load does not exceed the crane’s maximum lifting capacity.

2. Loading the Crane:

– Attach Load Safely: Use appropriate lifting gear such as slings, chains, or hooks. Ensure the load is securely fastened.

– Balancing: Position the load centrally underneath the hoist to maintain balance.

3. Operating the Crane:

– Lifting the Load: Gradually lift the load to avoid swinging. Use the hoist control to achieve the desired height.

– Movement: Move the trolley along the bridge and the bridge along the fixed path by using the control system. Make small, precise adjustments to avoid sudden movements.

– Lowering the Load: Once at the destination, slowly lower the load using the hoist controls.

4. Post-Operation:

– Secure the Crane: Ensure the crane is returned to its designated resting position.

– Inspection: Conduct a brief inspection to check for any anomalies or issues that occurred during operation.

– Shut Down: Turn off the control systems safely.

Safety Tips:

– Training: Operators should be adequately trained and certified.

– Clear Area: Ensure the pathway is free of obstructions and people during operation.

– Emergency Protocols: Be familiar with emergency shutdown procedures.

By following these guidelines, you can operate a semi gantry crane efficiently and safely.

“semi gantry crane” Comparative Analysis

A semi gantry crane is a versatile lifting solution widely used in industrial settings for material handling operations. It combines elements of both overhead and gantry cranes, providing unique benefits and catering to specific needs. Here’s a comparative analysis of a semi gantry crane, emphasizing its advantages over traditional gantry and overhead cranes:

1. Design and Structure:

– Semi Gantry Crane: Features one leg running on a ground rail and the other side supported by an elevated structure (usually a building wall).

– Gantry Crane: Entirely freestanding with two legs running on ground tracks.

– Overhead Crane: Fully supported by elevated structures, with no ground-level legs.

2. Space Utilization:

– Semi Gantry Crane: Ideal for facilities with limited floor space. The elevated side allows for unobstructed movement underneath, optimizing workspace.

– Gantry Crane: Requires significant ground space due to dual-leg support.

– Overhead Crane: Best for maximizing floor space, but necessitates strong structural support.

3. Installation and Infrastructure:

– Semi Gantry Crane: Simpler installation compared to overhead cranes, leveraging existing building structures.

– Gantry Crane: Installation is straightforward but requires dedicated tracks laid on the ground.

– Overhead Crane: Complex, needing robust structural modifications for support beams and rails.

4. Cost-Efficiency:

– Semi Gantry Crane: Affordable, balanced between gantry and overhead cranes. Economical in terms of installation and maintenance.

– Gantry Crane: Mid-range in cost, higher due to ground preparation and rail installation.

– Overhead Crane: Generally more expensive owing to structural reinforcements and complex setup.

5. Versatility and Application:

– Semi Gantry Crane: Suited for diverse environments, such as warehouses and workshops where partial ground obstruction is acceptable.

– Gantry Crane: Common in outdoor yards and open areas, handling heavy loads across long distances.

– Overhead Crane: Preferred in large manufacturing units, facilitating streamlined operations from above.

Conclusion:

Semi gantry cranes offer a middle ground solution, balancing spatial efficiency, installation simplicity, and cost-effectiveness. They are particularly advantageous in confined spaces where overhead cranes are impractical and ground space is at a premium.

“semi gantry crane” Warranty and Support

Warranty and Support for Semi Gantry Crane

When investing in a semi gantry crane, it’s essential to have robust warranty and support mechanisms in place to ensure optimal performance and longevity. Here is an overview of what you can expect:

#### Warranty

A typical warranty for a semi gantry crane covers:

1. Duration: Most manufacturers offer a 1 to 2-year warranty from the date of installation or purchase.

2. Coverage: This usually includes defects in materials and workmanship. Key components like the hoist, trolley, electrical systems, and structural components are often covered.

3. Exclusions: Wear and tear parts, damage due to improper use, unauthorized modifications, and routine maintenance items are usually not covered.

4. Claim Process: Warranty claims generally require proof of purchase, detailed descriptions of the issue, and sometimes, photographic evidence. Reputable providers aim to address claims promptly to minimize downtime.

#### Support

Support services accompanying your semi gantry crane are pivotal for smooth operation and may include:

1. Technical Assistance: Access to technical support via phone, email, or live chat, often available 24/7. Experienced technicians can help troubleshoot issues or provide guidance on operation and maintenance.

2. On-Site Support: For complex issues, manufacturers often offer on-site support. This can include diagnosis and repair services performed by qualified technicians.

3. Spare Parts Availability: Quick access to genuine spare parts is crucial. Many manufacturers maintain extensive inventories to ensure rapid delivery and minimize operational interruptions.

4. Training and Documentation: Comprehensive user manuals, maintenance guides, and training sessions for operators and maintenance staff ensure safe and efficient use of the crane.

5. Preventive Maintenance: Some manufacturers offer preventive maintenance programs, which include regular inspections and servicing to prevent breakdowns and extend the crane’s lifespan.

Investing in a semi gantry crane with strong warranty and support services ensures maximum uptime and longevity, delivering a reliable return on investment.

List “semi gantry crane” FAQ

Semi Gantry Crane FAQ

1. What is a semi gantry crane?

A semi gantry crane is a type of crane composed of a single overhead bridge supported on one side by a runway system, and on the other side by a leg running on a ground-level track. It combines the features of a gantry and overhead crane.

2. What are the typical applications?

Semi gantry cranes are commonly used in manufacturing, warehouses, and construction for lifting and transporting heavy materials, where space is limited or where overhead cranes are not feasible.

3. What are the load capacities?

Load capacities for semi gantry cranes can vary widely, typically ranging from 1 ton to 50 tons, depending on the design and manufacturer specifications.

4. How is a semi gantry crane different from a full gantry crane?

A full gantry crane has two legs running on ground tracks, whereas a semi gantry crane has only one leg, with the other side supported by an elevated runway system.

5. Can semi gantry cranes be customized?

Yes, semi gantry cranes can be customized per the specific requirements of the application, including size, load capacity, and additional features such as hoists or trolleys.

6. Are they suitable for outdoor use?

Semi gantry cranes can be used outdoors, but they must be designed and maintained to withstand environmental factors like weather and corrosion.

7. What maintenance is required?

Regular inspections and maintenance are essential, focusing on components such as the hoist, runway system, leg structure, and electrical systems to ensure safe and efficient operation.

8. What are the safety considerations?

Ensure that operators are trained, follow load limits, inspect the crane regularly, and have emergency procedures in place to handle any potential issues.

9. How is it installed?

Installation involves setting up the runway system, erecting the crane leg, and integrating electrical and control systems. Professional installation is recommended for safety and optimal performance.

10. What standards apply to semi gantry cranes?

Semi gantry cranes must comply with local, national, and international standards such as those set by OSHA, ANSI, and ISO to ensure safety and reliability.

Top 10 FAQ with answer about semi gantry crane for Buyer Sourcing from China

Top 10 FAQ about Sourcing Semi Gantry Crane from China

1. What is a Semi Gantry Crane?

– A semi gantry crane has one side supported by a rail system on the ground and the other side running on an elevated runway. It’s ideal for indoor and outdoor applications where part of the space is restricted.

2. What are the Key Features of Semi Gantry Cranes from China?

– Chinese semi gantry cranes offer features such as custom span and height, variable lifting capacities, advanced safety systems, and efficient motors. They can be tailored to meet specific operational needs.

3. What Industries Use Semi Gantry Cranes?

– They are widely used in manufacturing, construction, warehouses, shipyards, and logistics for handling materials, components, and heavy machinery.

4. How to Ensure Quality When Sourcing Semi Gantry Cranes from China?

– Choose reputable manufacturers with certifications like ISO 9001. Request quality inspection reports, customer testimonials, and actual performance data. Conduct factory audits if possible.

5. What is the Typical Lead Time for Delivery?

– The lead time can vary but typically ranges from 4 to 8 weeks, depending on customization requirements and manufacturing schedules.

6. How Can Shipping and Installation Be Managed?

– Manufacturers provide shipping support including packaging and logistics. For installation, many companies offer supervised installation services and comprehensive manuals.

7. What are the Payment Terms and Methods?

– Common terms include a combination of T/T (Telegraphic Transfer) and L/C (Letter of Credit), with a typical structure being 30% advance payment and 70% before shipment.

8. Are Spare Parts and After-Sale Services Available?

– Reputable suppliers offer spare parts, warranties, and after-sale services like maintenance and technical support to ensure uninterrupted operations.

9. How to Customize a Semi Gantry Crane to Fit Specific Needs?

– Provide detailed specifications like lifting capacity, span, height, working environment, and application specifics. Manufacturers can then design and produce cranes to meet these exact requirements.

10. What Safety Standards Do Chinese Semi Gantry Cranes Adhere to?

– They generally comply with international standards such as ISO, CE, and FEM. Ensure the crane meets local safety regulations specific to your country.

By addressing these FAQs, buyers can make well-informed decisions when sourcing semi gantry cranes from China.