semigantry crane Safety Certifications

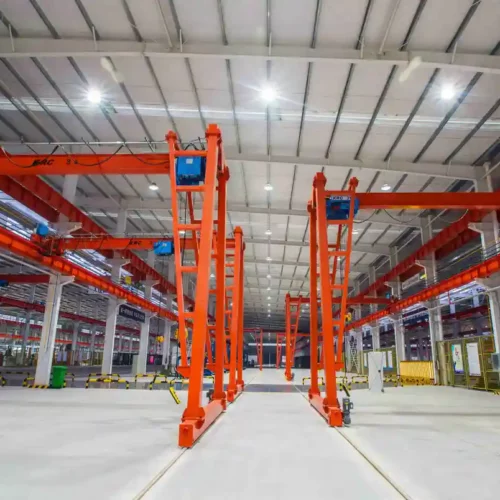

A semigantry crane is a type of crane system that typically combines elements of a gantry crane and an overhead crane. Ensuring the safety and reliability of these cranes involves adherence to various safety certifications and standards.

1. OSHA (Occupational Safety and Health Administration):

– OSHA sets standards in the U.S. for workplace safety, including for crane operation. Compliance with OSHA regulations is mandatory and includes meeting the safety requirements laid out in OSHA standard 29 CFR 1910.179 for overhead and gantry cranes.

2. ANSI (American National Standards Institute):

– ANSI B30.2: This standard specifically covers overhead and gantry cranes, including semigantry cranes. It provides guidelines for design, inspection, maintenance, and safety operations.

3. ASME (American Society of Mechanical Engineers):

– ASME B30.2: An extension of ANSI standards, this document further outlines safety requirements and operational guidelines aimed at minimizing risks during crane operations.

4. ISO (International Organization for Standardization):

– ISO 23853: Standard for performance and design criteria of overhead and gantry cranes. ISO certification ensures international compliance and is crucial for manufacturers and operators.

5. CE Marking (Conformité Européene):

– In Europe, CE Marking indicates compliance with EU safety, health, and environmental requirements. Machinery Directive 2006/42/EC outlines specific requirements for cranes, ensuring they meet stringent safety standards.

6. FEM (Fédération Européenne de la Manutention):

– FEM 1.001: The European standard for design and construction of cranes, providing guidelines for safe design, durability, and maintenance practices.

7. CSA (Canadian Standards Association):

– CSA B167: The Canadian standard specific to overhead traveling cranes, including semigantry cranes. It outlines comprehensive guidelines for safety and risk management in crane operations.

Adhering to these certifications and standards is crucial for ensuring the safe operation and maintenance of semigantry cranes, protecting both operators and equipment from potential hazards.

List Reference Technical Parameters of “semigantry crane”

A semigantry crane, also known as a semi-gantry crane, combines the features of a gantry crane and a bridge crane. It typically comprises one leg that runs on a rail at ground level and another end that runs on an elevated runway system. The design allows for efficient material handling, especially in spaces constrained by floor area or height limitations. Here are essential technical parameters to consider:

1. Load Capacity:

– The maximum weight the crane can lift, typically ranging from a few tons to hundreds of tons, depending on the application.

2. Span:

– The horizontal distance covered by the crane, measured from the centerline of one runway to the centerline of the other.

3. Lifting Height:

– The vertical distance the hoist can lift a load, crucial for operations requiring vertical movement.

4. Traveling Speed:

– Speed at which the crane or hoist moves along the runway or rail. This includes both the traverse and longitudinal speed.

5. Hoisting Speed:

– The rate at which the hoist lifts or lowers a load, often adjustable for precision operations.

6. Duty Cycle:

– Classification by ISO or other relevant standards indicating the operational usage and frequency.

7. Control System:

– Includes methods such as pendant control, remote control, or automated systems for crane operation.

8. Power Supply:

– Type of electrical feed used, whether it’s conductor bars, cable reels, or festoon systems.

9. Runway Rails:

– Specification and material of the ground-level rail on which one leg of the semigantry crane runs.

10. Safety Features:

– Essential safety measures such as overload protection, emergency stop buttons, anti-collision devices, and warning alarms.

11. Environmental Operating Conditions:

– The crane’s ability to operate under specific environmental conditions such as temperature range, humidity, and potential exposure to corrosive materials.

These parameters ensure that a semigantry crane is suitable for the intended application, aligns with safety standards, and integrates seamlessly into the work environment for efficient material handling.

List Product features of “semigantry crane”

Sure! Here are the product features of a semigantry crane, concisely highlighted:

1. Structural Design:

– Single and Double Girder Options: Available in both single and double girder configurations to suit different lifting needs.

– Space Optimization: Reduced floor space requirement, utilizing both the ground and overhead space efficiently.

2. Operation Modes:

– Manual and Automated Control: Can be operated manually or through automated systems for precision handling.

– Flexible Movement: Combines the features of both gantry and overhead cranes, offering flexibility in spatial movement and positioning.

3. Capacity and Range:

– Variable Load Capacities: Suitable for various lifting capacities ranging from a few tons to several tons, accommodating diverse industrial needs.

– Extended Span: Capable of covering extensive spans, providing a wide operational area.

4. Durability and Strength:

– Robust Construction: Made from high-quality steel and materials, ensuring durability and longevity.

– Weather Resistant: Designed for indoor and outdoor use, resistant to harsh environmental conditions.

5. Safety Features:

– Advanced Safety Mechanisms: Equipped with overload protection, emergency stop functions, and other safety mechanisms to ensure secure operation.

– Operator Safety: Features ergonomic controls and user-friendly interfaces for operator safety and ease of use.

6. Maintenance and Serviceability:

– Ease of Maintenance: Designed for easy maintenance with readily accessible components and straightforward service protocols.

– Minimal Downtime: Engineered to require minimal downtime, ensuring higher productivity rates.

7. Customization and Accessories:

– Customizable Configurations: Can be customized according to specific operational requirements, including adjustable heights and span lengths.

– Accessory Compatibility: Compatible with a wide range of lifting accessories and attachments like spreader beams, lifting magnets, and more.

8. Efficiency and Performance:

– High Precision Handling: Provides accurate load positioning and gentle handling of sensitive materials.

– Energy Efficient: Incorporates energy-efficient motors and systems to reduce operational costs.

These features collectively make the semigantry crane a versatile and reliable solution for various lifting and handling needs in industries such as manufacturing, warehousing, and construction.

List Application of “semigantry crane”

A semigantry crane, also known as a semi-gantry or partial gantry crane, is a versatile lifting device that is commonly used in a variety of industrial and logistical applications. Here are some key applications:

1. Warehousing and Logistics: Semigantry cranes are widely utilized in warehouses and distribution centers for the efficient handling and storage of goods. They facilitate the loading and unloading of trucks and trailers, and the movement of heavy pallets or containers within the facility.

2. Manufacturing Facilities: In manufacturing plants, semigantry cranes assist in moving raw materials, components, and finished products between different stages of production. They are especially useful in assembly lines, where precision and reliability are critical.

3. Construction Sites: These cranes are employed in construction projects for lifting and positioning building materials such as steel beams, concrete panels, and heavy machinery. Their adaptability allows them to operate in confined spaces typical of urban construction environments.

4. Shipyards and Ports: Semigantry cranes play a crucial role in shipbuilding and port operations. They facilitate the transfer of heavy and bulky cargo from ships to storage areas and vice versa, contributing to efficient port logistics.

5. Automotive Industry: In the automotive sector, these cranes are used for handling heavy components, such as engines and chassis, within production lines and maintenance areas. They enhance the safety and efficiency of material handling operations.

6. Maintenance and Repair Facilities: Semigantry cranes aid in the maintenance and repair of large equipment and machinery. They offer the flexibility to maneuver heavy parts within maintenance workshops.

7. Airports and Rail Yards: These cranes are critical in airports and rail yards for handling cargo and baggage. They streamline the processes of loading, unloading, and transferring goods, ensuring quick turnaround times.

In essence, semigantry cranes are invaluable in any setting that requires the efficient and safe handling of heavy loads, particularly in environments where space is limited and precise movements are essential. Their combination of robustness and flexibility makes them a preferred choice across numerous industries.

List Various Types of “semigantry crane”

Semigantry cranes are versatile lifting equipment that combine the features of gantry cranes and overhead cranes. They consist of one leg that runs on a rail at ground level and another end that rides on an elevated runway. Here are various types of semigantry cranes:

1. Single Girder Semigantry Crane: This crane has a single girder and is ideal for lighter lifting tasks. The design is simple, cost-effective, and requires less installation space.

2. Double Girder Semigantry Crane: Featuring two girders, this type is suited for heavier loads and offers greater stability. It’s often used in industries requiring high lifting capacities and more robust performance.

3. Full Cantilever Semigantry Crane: This crane has a fully extended arm on one side, providing more usable space under the cantilever. It’s beneficial in situations requiring extensive outreach over an obstacle.

4. Partial Cantilever Semigantry Crane: This type has a partially extended cantilever arm. It offers a balance between reach and support, suitable for congested areas or where partial outreach is needed.

5. Adjustable Height Semigantry Crane: This crane allows the height of the bridge to be adjusted. It’s particularly useful in settings with varied height requirements or where overhead obstructions must be avoided.

6. Folding Leg Semigantry Crane: Designed for easy transport and storage, the legs of this crane can be folded. It’s an ideal choice for temporary worksites or multipurpose facilities.

7. Motorized Semigantry Crane: Equipped with motors for horizontal movement along the rails, this type offers enhanced maneuverability and ease of operation, suited for tasks demanding frequent repositioning.

8. Manual Push Semigantry Crane: Relying on manual force for movement, this crane is economical and suited for lighter tasks and less frequent use.

9. Trackless Semigantry Crane: Operating without a ground rail, it relies on wheels and is useful for flexible positioning in varied environments.

Each type of semigantry crane addresses specific operational needs, enhancing efficiency across diverse industrial applications.

semigantry crane Accessories Upgrades and Custom Manufacturing Options

A semigantry crane is a versatile material handling solution ideal for spaces with limited overhead clearance or unique structural constraints. Enhancing the functionality and performance of semigantry cranes can be achieved through various accessories, upgrades, and custom manufacturing options.

Accessories:

1. Radio Remote Controls: Enhance safety and convenience by enabling wireless operation.

2. Anti-Collision Devices: Minimize accidents and damage by preventing crane collisions.

3. Variable Frequency Drives (VFDs): Improve motion control and reduce mechanical stress.

4. Load Indicators and Sensors: Provide real-time weight data to ensure safe lifting operations.

5. Lighting Systems: Improve visibility in low-light environments for safer operations.

6. Specialized End Effectors: Customize gripping and lifting tools for specific tasks.

Upgrades:

1. Capacity Enhancements: Reinforce structures and components to handle heavier loads.

2. Automation Integration: Incorporate automated systems for precision and efficiency.

3. Environmental Adaptations: Upgrade materials and finishes for specific environments, such as corrosion-resistant coatings for maritime or chemical industries.

4. Enhanced Control Systems: Install advanced PLCs and HMIs for better monitoring and control.

Custom Manufacturing Options:

1. Tailored Dimensions: Design cranes to fit specific spatial constraints or operational layouts.

2. Specialized Trolleys: Develop custom trolleys to suit unique load requirements or movement patterns.

3. Dual-Motion Configurations: Create cranes capable of both linear and rotational movements.

4. Integration with Existing Systems: Design cranes to seamlessly fit into pre-existing workflows or handling systems.

Investing in these accessories and customizations not only optimizes the crane’s performance but also extends its lifespan, enhances safety, and increases operational efficiency. Collaborating with manufacturers for bespoke solutions ensures that your semigantry crane is precisely tailored to meet the unique demands of your specific application.

List Quality Control and The Manufacturing Process of “semigantry crane”

Quality Control for Semigantry Crane

1. Material Inspection:

– Verify raw materials meet specifications (e.g., steel grades).

– Perform non-destructive tests to check for material flaws.

2. Machining Precision:

– Measure dimensions and tolerances of machined parts.

– Use precise tools like calipers and micrometers.

3. Welding Quality:

– Inspect welds visually and with tests like ultrasonic or X-ray.

– Conduct load testing on welded joints.

4. Component Testing:

– Load test individual components (motors, hoists).

– Check electrical systems for functionality and safety.

5. Assembly Inspection:

– Ensure all bolts and fastenings are secure and meet torque specifications.

– Conduct dry runs to verify mechanical movement.

6. Performance Testing:

– Load test the completed crane under various conditions.

– Measure performance against design specifications.

7. Final Inspection:

– Inspect paint, corrosion protection, and overall finish.

– Verify documentation and compliance with industry standards.

Manufacturing Process of Semigantry Crane

1. Design and Planning:

– Develop 3D models and blueprints.

– Plan manufacturing sequence and procure materials.

2. Material Preparation:

– Cut and machine steel profiles and plates.

– Prepare components according to design specifications.

3. Machining:

– Precision machine key components (e.g., gears, shafts).

– Drill and tap necessary holes for assembly.

4. Welding and Fabrication:

– Weld structural parts using certified procedures.

– Fabricate sub-assemblies like the bridge, supporting legs, and lifting mechanism.

5. Assembly:

– Assemble individual components into sub-assemblies.

– Install motors, control systems, and electrical wiring.

6. Quality Testing:

– Perform quality control checks (as described above).

7. Surface Treatment:

– Apply anti-corrosion treatments and paint.

– Ensure uniform coating according to specifications.

8. Final Assembly:

– Assemble the crane fully, integrating all components.

9. Final Testing and Commissioning:

– Conduct performance tests and safety tests.

– Verify operational efficiency and load-bearing capacity.

10. Packaging and Shipping:

– Disassemble into transportable sections if necessary.

– Package securely for shipping to the installation site.

How to use “semigantry crane”

A semigantry crane, also known as a semi-gantry or half-gantry crane, is a versatile lifting device used in various industrial settings such as warehouses, shipyards, and manufacturing plants. Its operation and proper usage can be summarized in a few key steps:

1. Inspection: Before using the semigantry crane, conduct a thorough inspection. Check for any visible damage to the crane components, including the runway, hoist, trolley, and electrical systems. Ensure all safety features are functional.

2. Load Placement: Position the load within the crane’s lifting capacity. Use appropriate slings, chains, or lifting straps. Ensure the load is balanced and secure to prevent slipping or tipping during movement.

3. Crane Positioning: Move the crane to the desired location. A semigantry crane typically has one leg running on the ground-level track, while the other side is supported by an elevated runway. Ensure both ends move smoothly and synchronously.

4. Control System: Use the control pendant or remote control to operate the crane. Familiarize yourself with the control buttons and emergency stop functions. Move the load vertically and horizontally with caution.

5. Lifting: Gradually lift the load to avoid sudden movements. Keep the load as low to the ground as possible while traveling to maintain stability.

6. Transporting Load: Move the load to its destination. Navigate carefully, avoiding obstructions. Ensure the path is clear and consider environmental factors such as wind indoors.

7. Lowering Load: Once the load is in position, slowly lower it into place. Ensure no personnel are underneath the load during this process.

8. Shut-down Procedure: After the operation, turn off the crane and perform any necessary checks to ensure it is left in a safe condition. Store the control pendant securely and address any issues noted during the operation.

By following these steps, you can safely and efficiently use a semigantry crane for various lifting tasks. Regular maintenance and adherence to safety protocols are essential to prolong the crane’s lifespan and ensure operational safety.

“semigantry crane” Comparative Analysis

A semigantry crane, also known as a semi-portal crane, combines features from both overhead bridge cranes and gantry cranes. This type of crane has one leg running on a rail or track at ground level, while the other end of the crane runs on an elevated rail. Here’s a comparative analysis of semigantry cranes versus other types of cranes:

Semigantry Crane vs. Overhead Bridge Crane

– Installation Flexibility: Semigantry cranes require less structural modification compared to overhead bridge cranes, which often need a large, dedicated support structure.

– Space Utilization: A semigantry crane is ideal for facilities with limited vertical space or those incorporating different levels, optimizing floor and overhead space.

– Operational Range: While overhead bridge cranes span the entire building, semigantry cranes operate in more confined areas, making them suitable for segmented workflows.

Semigantry Crane vs. Full Gantry Crane

– Cost-Effectiveness: Semigantry cranes generally have lower installation and maintenance costs compared to full gantry cranes, which require extensive rail systems on both sides.

– Foundation Requirements: Full gantry cranes necessitate more extensive ground preparations due to dual rail systems, whereas semigantry cranes need solid anchoring only for the single ground-rail side.

– Flexibility: A semigantry crane can be easily adapted to existing structures, making it more versatile in retrofitting situations without significant structural changes.

Semigantry Crane vs. Jib Crane

– Load Capacity: Semigantry cranes typically support heavier loads compared to jib cranes, which are more suited for lighter, localized lifting.

– Coverage Area: A semigantry crane provides a larger operational footprint, whereas jib cranes are limited by their arm’s reach.

– Movement Range: The semigantry crane can traverse a longer path along its rails, offering a longer operational range compared to the rotary motion restriction of jib cranes.

In summary, semigantry cranes offer a middle ground between overhead bridge and gantry cranes in terms of cost, installation, and operational flexibility, while providing enhanced coverage and load capacities compared to jib cranes. They are particularly beneficial in applications where space management and moderate lifting capacities are priorities.

“semigantry crane” Warranty and Support

Warranty and Support for Semigantry Crane

Our semigantry cranes come with a comprehensive warranty designed to safeguard your investment and ensure optimum performance. We offer a standard two-year warranty covering all mechanical and electrical components, ensuring that any manufacturer’s defects are promptly addressed. This warranty provides for the repair or replacement of defective parts at no additional cost to you.

Additionally, we offer extended warranty options to further protect your equipment beyond the standard period. To activate your warranty, simply register your crane upon installation by completing the provided warranty registration form.

To ensure your semigantry crane operates efficiently, we provide robust support services:

1. 24/7 Customer Service: Our dedicated support team is available around the clock to assist with any issues or queries you may have. You can reach us via phone, email, or our online support portal.

2. Technical Support: Our team of experienced engineers is on hand to help diagnose and resolve any technical problems. We offer remote assistance as well as on-site support when necessary.

3. Scheduled Maintenance: Regular maintenance is crucial for the longevity of your crane. We offer scheduled maintenance packages tailored to your operational needs, including inspections, lubrication, adjustments, and part replacements.

4. Spare Parts: Access to original spare parts is guaranteed, ensuring compatibility and optimal performance. We maintain an extensive inventory of parts for quick dispatch.

5. Training Programs: To maximize the efficiency and longevity of your crane, we offer training programs for your operational and maintenance personnel. These programs cover safe operation practices, routine inspection procedures, and troubleshooting techniques.

By choosing our semigantry cranes, you not only invest in high-quality equipment but also gain access to reliable warranty and support services, ensuring your operations run smoothly with minimal downtime.

List “semigantry crane” FAQ

Semigantry Crane FAQ

1. What is a semigantry crane?

A semigantry crane is a type of crane system that operates on a track, where one side runs on a runway (similar to a traditional overhead crane) and the other side runs on a rail at floor level.

2. What are the main components of a semigantry crane?

It consists of a bridge girder, hoist trolley, runway rail, floor rail, and supporting structure.

3. Where are semigantry cranes typically used?

They are often used in warehouses, manufacturing facilities, shipyards, and construction sites where space and operational constraints require flexible material handling solutions.

4. What are the advantages of a semigantry crane?

– Space efficiency: Utilizes both floor space and overhead space.

– Flexibility: Ideal for indoor and outdoor use.

– Cost-effectiveness: Requires fewer structures compared to a full gantry crane.

5. Are there different types of semigantry cranes?

Yes, they can be classified based on their design and load capacity, such as single-girder and double-girder semigantry cranes.

6. How is the capacity of a semigantry crane determined?

The capacity is determined by the crane’s design, materials used, and engineering standards. It can range from a few tons to several hundred tons, depending on the requirement.

7. What safety features are included in semigantry cranes?

They often include limit switches, overload protection, emergency stop buttons, and safety interlocks to ensure safe operation.

8. How often should semigantry cranes be maintained?

Regular maintenance should follow the manufacturer’s guidelines and typically includes inspections, lubrication, and replacements of worn-out parts to ensure longevity and safety.

9. Can semigantry cranes be customized?

Yes, they can be tailored to fit specific operational requirements, including size, load capacity, and additional features.

10. What is the installation process like for a semigantry crane?

Installation involves setting up the runway and floor rails, assembling the crane components, running electrical and control systems, and conducting thorough testing before full operation.

Keeping these FAQs in mind will help you understand the basic aspects and considerations related to semigantry cranes.

Top 10 FAQ with answer about semigantry crane for Buyer Sourcing from China

Here are the top 10 FAQs with concise answers about sourcing semigantry cranes from China:

1. What is a semigantry crane?

– A semigantry crane combines the features of a gantry crane and an overhead crane. It has one leg running on a floor-level rail and the other end supported by a wall or elevated track.

2. What should I consider when selecting a semigantry crane?

– Key factors include load capacity, span, lifting height, crane speed, duty cycle, and operating environment. Assessing these will ensure the crane meets your operational needs.

3. Is it cost-effective to buy a semigantry crane from China?

– Yes, Chinese manufacturers often offer competitive pricing due to lower labor costs. However, consider the total cost, including shipping, tariffs, and potential service or maintenance fees.

4. How do I verify the quality of a Chinese-made semigantry crane?

– Look for ISO certifications, check the manufacturer’s credentials, reviews, and past projects. Request third-party inspections and factory visits to ensure quality.

5. What is the typical lead time for semigantry crane orders from China?

– Lead times vary by manufacturer but generally range from 30 to 60 days, depending on the crane’s complexity and customization requirements.

6. Are there international standards that Chinese manufacturers follow?

– Yes, many reputable manufacturers adhere to international standards such as ISO, DIN, FEM, and CMAA, ensuring product quality and safety.

7. How is shipping and logistics handled?

– Chinese suppliers often provide CIF (Cost, Insurance, and Freight) or FOB (Free on Board) terms. Coordinate with logistics providers for smooth customs clearance and delivery.

8. What are the payment terms for purchasing from China?

– Common payment terms include a 30% deposit before production and 70% balance before shipment. Letters of credit are also accepted by some suppliers.

9. How can I ensure proper installation and maintenance support?

– Choose suppliers who offer installation services or detailed manuals. Some manufacturers provide remote or on-site support and maintenance training.

10. What warranty and after-sales services are available?

– Standard warranties range from 12 to 24 months. Ensure your supplier offers reliable after-sales support, spare parts availability, and responsive customer service.

By addressing these frequent questions, buyers can make informed decisions when sourcing semigantry cranes from China, ensuring a balance of cost, quality, and service.