ship to shore gantry crane Safety Certifications

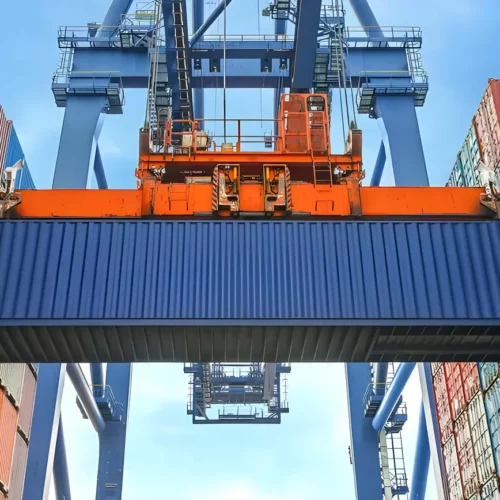

Ship-to-shore (STS) gantry cranes are integral components in modern ports, facilitating the efficient transfer of cargo between ships and shore facilities. Given their size, complexity, and operational environment, ensuring their safety is paramount. Here are the essential safety certifications and standards associated with STS gantry cranes:

1. ISO 9001 (Quality Management Systems): Ensures that organizations consistently provide products and services that meet customer and regulatory requirements. For STS cranes, this standard ensures the entire manufacturing and operational process adheres to high quality standards.

2. ISO 13849 (Safety of Machinery): Specifically deals with the safety-related parts of control systems. Compliance with this standard ensures that the electronic and software controls of the crane operate safely.

3. IEC 61508 (Functional Safety): Addresses the safety of electrical, electronic, and programmable electronic safety-related systems. It’s crucial for the automated functions of modern STS cranes.

4. ANSI/ASME B30.2 (Overhead and Gantry Cranes): Provides guidelines for the safe design, inspection, testing, maintenance, and operation of overhead and gantry cranes in the U.S. Compliance with these guidelines is essential for ensuring operational safety.

5. EUC Machinery Directive (2006/42/EC): Ensures that machinery meets essential health and safety requirements by establishing procedures to evaluate conformity before they can be marketed within the EU.

6. OSHA Standards (Occupational Safety and Health Administration): Applicable primarily in the U.S., these regulations aim to ensure a safe working environment through rigorous safety protocols and regular inspections.

7. FEM Standards (The European Materials Handling Federation): Provides guidelines for the design and maintenance of cranes, ensuring they’re fit for safe operational use.

Adherence to these certifications and standards is vital for ensuring the structural integrity, operational safety, and reliability of STS gantry cranes, thereby safeguarding the lives of workers and the surrounding environment.

List Reference Technical Parameters of “ship to shore gantry crane”

A Ship to Shore (STS) gantry crane is a critical piece of equipment in container terminal operations, facilitating the loading and unloading of containers from vessels. Here are the key technical parameters to consider:

1. Lifting Capacity: Typically ranges from 30 to 65 tons under the spreader, allowing the crane to handle a wide variety of container sizes and weights.

2. Outreach: The horizontal distance from the crane’s center to the farthest edge it can reach, usually between 38 to 70 meters, determining the number of container rows the crane can access on a ship.

3. Backreach: The horizontal distance the crane can reach behind its centerline, often around 15-25 meters, allowing for container handling over the quay.

4. Lifting Height: The vertical distance the spreader can be lifted, usually between 40 to 50 meters above the quay, ensuring clearance over the highest stacks of containers.

5. Span: The distance between the legs of the crane, typically around 15-35 meters, suitable for the terminal’s width requirements and accommodating one or more rows of trucks or rail tracks.

6. Hoisting Speed: The speed at which the crane can lift and lower the spreader, commonly 70-180 m/min under load and 150-210 m/min without load, impacting overall loading/unloading efficiency.

7. Trolley Speed: The lateral speed of the trolley traversing along the boom, usually between 150-270 m/min, critical for swift container positioning.

8. Gantry Speed: The movement speed of the entire crane along the quay, typically between 45-135 m/min, essential for repositioning the crane to match ship berthing positions.

9. Power Supply: Generally electric, with a voltage requirement of 6.6 – 11 kV, emphasizing energy efficiency and environmental considerations.

10. Automation and Control Systems: Modern STS cranes may include semi or fully automated control systems, ensuring precision and safety in operations.

These parameters define the operational capabilities and efficiency of a ship to shore gantry crane, influencing throughput and adaptability in a container terminal.

List Product features of “ship to shore gantry crane”

Sure! Here are the product features of a “Ship to Shore Gantry Crane” concisely presented:

1. High Lifting Capacity: Designed to handle heavy loads, often ranging from 40 to 80 tons, to accommodate different shipping containers and cargo types.

2. Extended Outreach: Long horizontal reach, typically between 40 to 60 meters, allowing the crane to service large container ships with multiple rows of containers.

3. Quick Lifting Speed: Efficient lifting speeds to ensure fast loading and unloading of containers, enhancing port throughput and reducing vessel turnaround time.

4. Anti-Sway Technology: Advanced control systems to minimize swaying of the load, ensuring precision, safety, and smooth operation during lifting and placing of containers.

5. Automation and Remote Control: Options for semi-automated or fully automated operations, including remote control capabilities for improved safety and operational efficiency.

6. Durability: Constructed from robust, weather-resistant materials to withstand harsh maritime environments and ensure longevity.

7. Energy Efficiency: Equipped with energy-efficient motors and regenerative power systems to reduce operational costs and environmental impact.

8. Advanced Safety Features: Comprehensive safety systems including overload protection, emergency stop functions, and collision avoidance systems to protect both the operators and cargo.

9. Smart Diagnostics and Maintenance: Integrated monitoring systems for real-time diagnostics and predictive maintenance, minimizing downtime and optimizing crane performance.

10. Ergonomic Operator Cabins: Comfortable and ergonomically designed cabins with advanced control interfaces for enhanced operator efficiency and reduced fatigue.

11. Adjustable Hoisting Mechanisms: Flexible hoisting capabilities to accommodate various container sizes and non-standard cargo.

12. Compliance with International Standards: Meets global standards for port crane operations, ensuring operational compatibility and safety compliance.

By focusing on these features, a Ship to Shore Gantry Crane enhances the efficiency of port operations, reduces operational costs, and promotes safety and sustainability.

List Various Types of “ship to shore gantry crane”

Ship-to-shore (STS) gantry cranes are pivotal in container ports for loading and unloading cargo from ships. They come in various types tailored to specific requirements and operational needs. Below are the primary types of STS gantry cranes:

1. Panamax

– Description: Designed to handle ships that can pass through the original Panama Canal.

– Specifications: Typically handle vessels with a capacity of up to 5,000 TEUs (Twenty-foot Equivalent Units).

– Reach: Around 12-13 containers wide.

2. Post-Panamax

– Description: Suited for vessels too large for the original Panama Canal but smaller than the larger Post-Panamax Plus category.

– Specifications: Accommodates ships up to 6,000-8,000 TEUs.

– Reach: 15-16 containers wide.

3. Super Post-Panamax

– Description: Used for larger vessels that have gained prominence with the expansion of global trade.

– Specifications: Works with ships up to 10,000-13,000 TEUs.

– Reach: 18 containers wide or more.

4. Ultra Large Container Vessel (ULCV) Cranes

– Description: Designed for the largest vessels currently in operation.

– Specifications: Can handle ships with capacities exceeding 18,000 TEUs.

– Reach: Up to 24 containers wide.

5. High Outreach

– Description: Equipped with extended jib booms to reach across wider vessels.

– Specifications: Useful for ships with enhanced beam widths.

– Reach: Optimized for versatility with varying container sizes.

6. Twin-Lift Cranes

– Description: Allows for handling two 20-foot containers simultaneously.

– Specifications: Increases throughput efficiency.

– Reach: Can vary, but mechanisms are designed for quick, simultaneous moves.

7. Automated Cranes

– Description: Incorporates automation for improved precision and reduced manual intervention.

– Specifications: Integrated with advanced software for optimized operations.

– Reach: Compatible with various vessel sizes.

Each type of STS gantry crane is engineered for specific operational contexts, optimizing port efficiency, accommodating various ship sizes, and adapting to technological advances in maritime logistics.

List Application of “ship to shore gantry crane”

Ship-to-shore gantry cranes are crucial pieces of equipment in modern ports and maritime logistics. Their primary function is to efficiently transfer cargo between ships and the shore, optimizing the loading and unloading process. Below are some key applications of ship-to-shore gantry cranes:

1. Container Handling: These cranes are predominantly used to lift and move shipping containers from container ships to trailers or railcars on land and vice versa. They are essential for ports involved in international trade.

2. Bulk Cargo Management: In addition to containers, ship-to-shore gantry cranes also handle bulk cargo such as coal, grain, and ore, facilitating the swift transfer of these materials for storage or further transportation.

3. Automotive Shipping: The cranes are employed to load and unload vehicles directly from ships, playing a vital role in the import and export of automobiles.

4. Heavy Machinery and Equipment: These cranes can handle oversize and heavy machinery, making them indispensable for industries that require the shipment of large equipment.

5. Project Cargo: For specialized construction or large-scale projects, ship-to-shore gantry cranes manage the transportation of materials and components that are not easily containerized.

6. Military and Defense Operations: They support the logistical needs of military operations by efficiently moving equipment and supplies, ensuring rapid deployment and restocking.

7. Offshore Industry Support: In the offshore oil and gas sectors, these cranes facilitate the transportation of essential supplies and equipment to and from offshore platforms.

8. Cranes for Cruise Ships: Some ports use ship-to-shore cranes to handle luggage and supplies for cruise ships, expediting the embarkation and disembarkation process.

By performing these varied roles effectively, ship-to-shore gantry cranes are integral to maintaining the efficiency and flow of maritime commerce, supporting economic and industrial activities across the globe.

List Buyer Types of “ship to shore gantry crane”

Ship-to-shore gantry cranes (STS cranes) are pivotal in maritime logistics, and their buyers typically include:

1. Ports and Terminals:

– Container Terminals: These facilities handle large volumes of containerized cargo, requiring robust and efficient STS cranes to maintain high productivity and turnaround times.

– Multipurpose Terminals: Handling diverse cargo types, they need versatile cranes capable of various lifting configurations.

2. Shipping Companies:

– Some large shipping lines invest in their own cranes for dedicated terminals to ensure consistent handling rates and reduce dependency on port-owned equipment.

3. Logistics Companies:

– Integrated logistics providers might invest in port assets, including STS cranes, to streamline their supply chain operations and improve service reliability.

4. Terminal Operating Companies (TOCs):

– Independent firms specializing in terminal operations often procure STS cranes to equip and upgrade the facilities they manage, optimizing operational efficiency.

5. Government and Public Authorities:

– National or regional port authorities may purchase cranes to modernize or expand public ports, enhancing infrastructure to boost trade and economic growth.

6. Private Investors:

– Investment firms and private equity groups sometimes invest in port infrastructure, including STS cranes, as part of broader portfolios in transport and logistics sectors.

7. Industrial Companies:

– Large industrial firms involved in manufacturing or resource extraction may acquire STS cranes for private ports or dedicated berths to streamline their logistics.

8. Supply Chain Consortiums:

– Groups formed by alliances of companies in the shipping and logistics industries may jointly buy STS cranes for shared use to distribute costs and maximize utilization.

Understanding these buyer types helps stakeholders tailor their offerings to meet the specific needs and preferences of each purchaser group.

List “ship to shore gantry crane” Project Types for Different Industries

Ship-to-shore (STS) gantry cranes are crucial for various industries that rely on maritime logistics and cargo handling. Here are some key project types for different industries:

1. Container Terminals:

– Container Handling Projects: Utilize STS cranes for efficient loading and unloading of shipping containers, ensuring rapid turnaround times for container vessels.

2. Bulk Material Handling:

– Mineral Resources: Projects involving ore, coal, and other bulk materials. STS cranes are used to transfer these from ships to storage areas or transportation systems.

– Agricultural Products: Grain terminals leverage STS cranes to handle bulk cereals and grains, facilitating export and import activities.

3. Automotive Industry:

– Vehicle Shipping: For moving both partially and fully assembled vehicles, STS cranes provide efficient, secure, and organized loading and unloading directly from ship decks to the dockside.

4. General Cargo:

– Mixed Cargo Ports: Projects that handle a diverse range of goods including palletized items, steel products, and machinery parts. STS cranes offer versatility for diverse cargo types.

5. Energy Sector:

– Offshore Energy Projects: Equipment and supplies for offshore oil and gas platforms, as well as wind farms, are often transferred using STS cranes due to the size and weight of the cargo.

6. Logistics and Supply Chain:

– Intermodal Terminals: Projects that integrate sea, rail, and road transport systems. STS cranes play a key role in transferring containers efficiently between modes of transport.

7. Construction:

– Heavy Equipment Shipping: Construction machinery, prefabricated building sections, and other heavy materials are handled using STS cranes for both domestic and international construction projects.

8. Breakbulk Terminals:

– Breakbulk Handling: For non-containerized cargo like timber, project cargo, and oversized equipment, STS cranes provide the necessary lifting capacity and range.

By employing ship-to-shore gantry cranes, these industries enhance their operational efficiency, improve handling speeds, and ensure safer transport of goods across various maritime and port-related projects.

ship to shore gantry crane Accessories Upgrades and Custom Manufacturing Options

Ship-to-shore (STS) gantry cranes are essential components in modern port operations, facilitating the efficient loading and unloading of cargo vessels. To enhance their performance, various accessories, upgrades, and custom manufacturing options are available:

Accessories

1. Spreaders: Customizable spreaders can handle different container sizes and weights, ensuring versatility.

2. Anti-Sway Systems: These systems minimize load sway, enhancing safety and operational speed.

3. Cameras and Sensors: Advanced camera systems and sensors provide real-time monitoring and precision.

4. Automated Systems: Integration with automated guided vehicles (AGVs) and terminal operating systems (TOS) for seamless operation.

Upgrades

1. Energy Efficiency: Upgrading to regenerative drives and LED lighting can significantly reduce energy consumption.

2. Remote Control: Implementing remote control technology allows operators to manage cranes from a distance, improving safety and efficiency.

3. Structural Reinforcements: Upgrading the structural components to handle higher loads and endure harsher conditions.

4. Software Updates: Enhanced software for better diagnostics, predictive maintenance, and smoother operations.

Custom Manufacturing Options

1. Tailored Design: Cranes can be designed to meet specific port requirements, including height, reach, and lifting capacity.

2. Material Choices: High-strength materials can be used for components to improve durability and reduce maintenance needs.

3. Customization for Different Cargo Types: Modifications to handle not just containers but bulk, breakbulk, or other specialized cargo.

4. Climate Adaptation: Designing cranes to withstand extreme weather conditions, from saltwater corrosion protection to temperature-resistant components.

Enhancing STS gantry cranes with these accessories, upgrades, and custom manufacturing options can lead to improved efficiency, safety, and overall port productivity. When selecting options, it’s essential to consider the specific operational needs and future scalability to ensure long-term value and performance.

List Quality Control and The Manufacturing Process of “ship to shore gantry crane”

Quality Control in Manufacturing Ship-to-Shore Gantry Cranes

1. Raw Material Inspection: Ensure high-grade steel and other materials meet stringent quality standards for durability and strength.

2. Component Testing: Conduct rigorous tests on motors, winches, and control systems to verify performance and reliability.

3. Weld Inspection: Use non-destructive testing (NDT) techniques like ultrasonic testing to check weld integrity and detect flaws.

4. Dimensional Accuracy: Employ computer-aided design (CAD) and manufacturing (CAM) to maintain precise dimensions and tolerances.

5. Load Testing: Perform real-world load tests to ensure the crane can handle maximum weight capacity without deformation or failure.

6. Safety Compliance: Ensure adherence to international safety standards such as ISO, OSHA, and other relevant regulations.

Manufacturing Process of Ship-to-Shore Gantry Cranes

1. Design and Planning: Begin with detailed CAD designs and simulations to optimize crane geometry and functionality. Engineers create blueprints and set project timelines.

2. Material Procurement: Source high-quality materials, including specialized steel alloys, electronic components, and hydraulic systems. Perform initial quality checks upon receipt.

3. Fabrication: Cut and shape steel components using CNC machines and other precision equipment. Welders join the components using high-precision techniques to ensure structural integrity.

4. Assembly: Assemble major subcomponents such as the mainframe, trolley, and boom. Install motors, winches, and hydraulic systems. Integrate control systems and software.

5. Welding and Inspection: Conduct extensive welding to join structures, followed by NDT inspections to ensure no internal flaws.

6. Painting and Corrosion Protection: Apply anti-corrosion coatings and paint to protect against harsh marine environments.

7. Installation of Electrical Systems: Set up power distribution, control circuitry, and software configuration. Test all electrical components for functionality.

8. Testing and Commissioning: Perform comprehensive load testing, functional testing of all systems, and safety checks. Resolve any issues identified during testing.

9. Final Inspection and Certification: Conduct a thorough final inspection, align with international standards, and obtain necessary certifications.

10. Delivery and Installation: Transport the crane to the port and oversee the assembly and installation on-site, ensuring that it is fully operational and meets customer expectations.

This structured approach ensures high quality, safety, and reliability for ship-to-shore gantry cranes.

How to use “ship to shore gantry crane”

A Ship to Shore (STS) gantry crane is an essential piece of equipment used in ports and container terminals to load and unload containers from ships to the dock and vice versa. Here is a concise guide on how to operate an STS gantry crane:

1. Pre-Operational Checks:

– Inspect the crane for any visible damage or wear.

– Ensure all safety systems, such as alarms and emergency stop buttons, are functional.

– Verify that the crane controls are working properly.

– Confirm that the crane’s travel path is clear of obstructions.

2. Positioning:

– Move the crane along its rail track to align it over the ship’s hold or the dock area where containers need to be transferred.

– Utilize the control cabin, usually positioned at a height for a clear view, or use remote control operations.

3. Operation:

– Lower the spreader using the hoist mechanism to attach to the container’s locking points.

– Once securely locked, lift the container and move the trolley horizontally along the gantry.

– Ensure smooth and controlled movements to prevent swinging of the container.

4. Transferring:

– Position the container over the designated spot on the dock (for unloading) or over the ship’s hold (for loading).

– Lower the container slowly and release it by unlocking the spreader.

– Repeat the process for each container.

5. Safety:

– Follow all safety protocols to ensure the safety of personnel and equipment.

– Communicate effectively with the ground crew to synchronize operations.

6. After Operations:

– Conduct a post-operation inspection of the crane.

– Record any anomalies or maintenance requirements.

Effective training and adherence to safety regulations are crucial for the efficient and safe use of an STS gantry crane.

“ship to shore gantry crane” Comparative Analysis

Ship-to-shore (STS) gantry cranes are pivotal assets in maritime logistics, primarily used for loading and unloading containers from ships. These cranes are essential for enhancing port efficiency, ensuring quick turnaround times, and supporting high-volume operations. A comparative analysis of STS gantry cranes involves evaluating several key factors: design, performance, efficiency, technology integration, and cost.

Design:

Modern STS cranes come in various designs, including single-lift, twin-lift, and tandem-lift configurations. Single-lift cranes handle one container at a time, while twin-lift and tandem-lift cranes can manage two or more containers simultaneously, significantly increasing throughput.

Performance and Efficiency:

Performance metrics include lifting capacity, speed, and reach. The lifting capacity of STS cranes ranges from about 40 to 100 tons. Larger cranes designed for ultra-large container ships (ULCS) have greater reaches (across up to 24 rows of containers) and higher lift heights, allowing for efficient handling of larger vessels. Faster operational speeds enhance port efficiency, with modern cranes capable of making upwards of 30 moves per hour.

Technology Integration:

Advanced STS cranes leverage automation and remote control technologies. Automated STS cranes can operate with minimal human intervention, reducing labor costs and increasing safety. Features like anti-sway systems, optical character recognition (OCR), and real-time data analytics improve precision and visibility, fostering proactive decision-making.

Cost:

Investment and operational costs vary significantly. High-capacity, technologically advanced STS cranes entail greater upfront investments but promise long-term efficiency and lower operational costs. On the contrary, traditional manual cranes have lower initial costs but might incur higher labor and maintenance expenses over time.

Conclusion:

The choice of an STS gantry crane should align with a port’s specific needs and future growth projections. Ports handling high volumes and larger vessels benefit from advanced, high-capacity, and automated cranes, ensuring sustained operational efficiency and competitiveness. Conversely, smaller ports with lower container traffic might prioritize cost-effective, simpler models to balance performance and investment.

“ship to shore gantry crane” Warranty and Support

Warranty and Support for Ship-to-Shore Gantry Crane

We proudly offer comprehensive warranty and support services for our ship-to-shore gantry cranes, ensuring optimal performance and peace of mind for your operations. Our standard warranty covers a period of 24 months from the date of installation or 30 months from the date of shipment, whichever comes first. This warranty includes coverage for defects in materials and workmanship under normal operating conditions.

In addition to our robust warranty, we provide extensive support services designed to maintain and enhance the functionality of your crane. Our support infrastructure includes:

1. 24/7 Technical Assistance: Our experienced technicians are available around the clock to address any operational issues or queries, minimizing downtime and maintaining efficiency.

2. Scheduled Maintenance Programs: We offer tailored maintenance packages aimed at preventing issues before they arise. These programs include regular inspections, lubrication, adjustments, and the replacement of wear parts to keep your crane in top condition.

3. Spare Parts Availability: We maintain a comprehensive inventory of critical spare parts, ensuring swift replacement and minimal operational disruption. These parts are readily available through our global network of distribution centers.

4. Training Programs: We provide specialized training for your operational and maintenance staff, ensuring they have the knowledge and skills required to operate the crane safely and effectively.

5. Remote Monitoring and Diagnostics: Our advanced remote monitoring system allows for real-time diagnostics, providing predictive maintenance alerts and detailed performance reports to optimize operational efficiency.

By choosing our ship-to-shore gantry crane, you not only invest in a top-tier product but also in a partnership committed to long-term operational excellence and support.

List “ship to shore gantry crane” FAQ

Sure, here’s a concise list of frequently asked questions (FAQ) about ship-to-shore gantry cranes:

1. What is a Ship-to-Shore Gantry Crane?

– A ship-to-shore gantry crane is a large, port-based crane used to load and unload container ships. It bridges the gap between vessel and dock, facilitating efficient cargo transfer.

2. How Does a Ship-to-Shore Gantry Crane Work?

– These cranes move parallel to the quay along rails or tracks, and their booms extend over the ship to lift containers using a hoist mechanism. They can precisely control the position of the containers for loading and unloading.

3. What are the Key Components of This Crane?

– Key components include the boom, trolley, spreader, hoist, and gantry structure. Other essential elements are the control cabin, power supply system, and safety features.

4. What are the Different Types of Ship-to-Shore Cranes?

– Types include high-profile cranes with an A-frame structure and low-profile cranes suitable for areas with height restrictions.

5. How is Crane Capacity Measured?

– Capacity is measured in terms of lifting weight (typically in tons), and reach, which is the horizontal distance the boom can extend.

6. What Safety Features are Included?

– Safety features often include anti-collision systems, overload sensors, wind limit devices, and emergency stop functions.

7. What is the Average Lifespan of a Ship-to-Shore Gantry Crane?

– With proper maintenance, these cranes can last between 20 to 30 years.

8. How is Maintenance Conducted?

– Regular inspections, lubrication, and part replacements are essential. Specialized technicians often carry out these tasks to ensure safety and efficiency.

9. What Power Sources Do These Cranes Use?

– They are usually powered by electricity, often supplied through a cable reel or busbar system.

10. What are Common Upgrades for These Cranes?

– Upgrades can include automation systems, remote operation capabilities, and energy-efficient technologies.

This FAQ provides a quick overview of the essential aspects of ship-to-shore gantry cranes. For detailed information, consulting technical manuals and manufacturer guidelines is recommended.

Top 10 FAQ with answer about ship to shore gantry crane for Buyer Sourcing from China

Top 10 FAQs About Ship to Shore Gantry Cranes for Buyer Sourcing from China

1. What is a Ship to Shore (STS) Gantry Crane?

An STS Gantry Crane is a type of large crane used in ports to load and unload containers from ships. They are critical for efficient port operations.

2. Why Source STS Gantry Cranes from China?

China is renowned for its manufacturing capabilities, cost-effective production, and reliable quality. Leading manufacturers offer competitive prices and innovative technology.

3. What Should I Consider When Choosing a Supplier?

Look for a supplier with a solid track record, quality certifications, advanced technology, after-sales support, and positive customer feedback.

4. What Certifications Should the Crane Have?

Ensure the crane meets international standards such as ISO, CE, and other relevant safety and quality certifications.

5. How are Cranes Transported from China?

STS Gantry Cranes are typically disassembled for transport and shipped via cargo vessels. Ensure the supplier has experience in shipping and reassembling large cranes.

6. What is the Estimated Lead Time?

The lead time can vary, typically ranging from 6 to 12 months depending on the complexity and customization of the crane. Early planning is crucial.

7. Are Spare Parts and Maintenance Services Available?

Most reputable suppliers provide spare parts and maintenance contracts. Confirm the availability of these services to ensure long-term operational efficiency.

8. What Payment Terms are Common?

Standard terms often involve a down payment (30-40%) upon contract signing, with the balance paid before shipment or upon delivery and installation completion.

9. Can I Customize the Crane as per My Requirements?

Yes, leading manufacturers usually offer customization to fit specific needs such as lifting capacity, span, height, and technological features.

10. What After-Sales Support Should I Expect?

Good suppliers offer extensive after-sales support, including installation supervision, training, technical support, and a warranty period (usually 1-2 years).

Carefully evaluating these aspects will help ensure a smooth and successful procurement process for your port operations.