sts crane Safety Certifications

Ship-to-Shore (STS) cranes are pivotal in modern port operations, necessitating stringent safety measures and certifications to ensure safe and efficient functioning. Here’s a concise overview of essential safety certifications required for STS cranes.

1. ISO 9001: This standard specifies requirements for a quality management system (QMS). Organizations use it to demonstrate their ability to consistently provide products and services that meet customer and regulatory requirements.

2. ISO 14001: Focuses on environmental management systems (EMS), aiding organizations in enhancing their environmental performance. It ensures that STS crane operations have a minimal ecological impact.

3. ISO 45001: This international standard for occupational health and safety (OH&S) management systems reduces workplace risks and enhances employee safety, a critical aspect for operating STS cranes.

4. CE Marking: This European certification indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

5. EC Declaration of Conformity: Ensures that cranes meet the essential health and safety requirements of the Machinery Directive (2006/42/EC) before they can be marketed in Europe.

6. ASME B30.2: A standard under the American Society of Mechanical Engineers (ASME) B30 series, provides safety guidelines for cranes and related rigging equipment.

7. FEM Standards: The European Federation of Material Handling (FEM) issues guidelines and standards pertinent to the safety and operation of cranes, widely recognized in the industry.

8. DNV-GL Certification: Det Norske Veritas and Germanischer Lloyd (DNV-GL) offer certification services that ensure STS cranes meet stringent safety, reliability, and performance criteria.

9. Loler (Lifting Operations and Lifting Equipment Regulations): In the UK, these regulations specify that lifting equipment must be strong and stable enough for its proposed use, marked to indicate safe working loads, and regularly inspected.

Acquiring and maintaining these certifications involve rigorous inspections, audits, and adherence to safety practices, ensuring the cranes’ optimal and safe performance in port operations.

List Reference Technical Parameters of “sts crane”

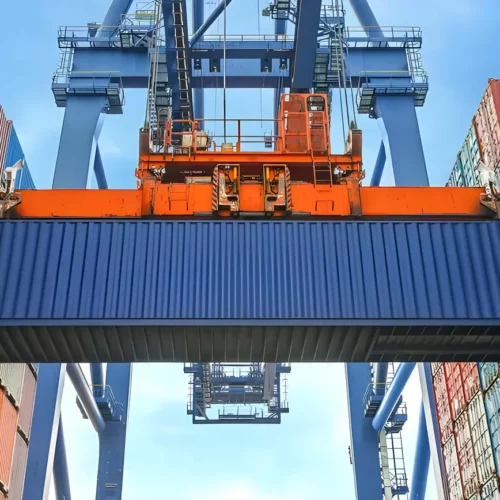

Ship-to-Shore (STS) cranes, also known as container cranes, are crucial for port operations, enabling the efficient loading and unloading of cargo containers from ships. Here are some key technical parameters:

1. Lifting Capacity: Ranges from 40 to 100 tons, typically including the spreader (lifting device).

2. Outreach: Distance from the waterside rail track to the far side of the ship. Common ranges are from 30 to over 60 meters to accommodate large container ships.

3. Backreach: Distance from the landside rail track toward the terminal yard. Typically ranges from 10 to 20 meters.

4. Lift Height: Measured from the rail track to the height the spreader can lift, ranging from 30 to 50+ meters to stack containers up to 8 or more high on the ship.

5. Span: Distance between the crane’s supporting legs, often between 18 to 35 meters, based on the number of rail tracks and traffic lanes it spans.

6. Hoist Speed: Vertical lifting speed of the container, ranging from 30 to 60 meters per minute when loaded and faster when empty.

7. Trolley Speed: Horizontal movement speed along the boom, typically from 150 to 250 meters per minute.

8. Gantry Speed: Movement speed of the entire crane along the quay, ranging from 20 to 45 meters per minute.

9. Power Supply: Primarily powered via an electrical connection, often with a power rating between 2 to 5 MW depending on the size and capability of the crane.

10. Automation: Level of automation varies from manual to semi-automated, or fully automated systems, incorporating advanced control and safety features like anti-sway systems and automated positioning.

These parameters are essential for selecting the appropriate STS crane to match the operational needs and the specific dimensions of container ships they will service.

List Product features of “sts crane”

Sure, here are some of the key product features of an STS (Ship-to-Shore) crane:

1. High Handling Capacity: STS cranes are designed to handle large volumes of cargo efficiently, often featuring multiple lifting capabilities, including tandem and twin-lift functions.

2. Advanced Automation: Modern STS cranes integrate state-of-the-art automation technologies, including semi-automatic or fully automatic operation modes, which enhance precision and speed.

3. Robust Structure: These cranes are built with high-strength materials to endure harsh marine environments and heavy usage, ensuring longevity and reliability.

4. Wide Span and Outreach: They are equipped with extensive outreach capabilities to handle large container ships, including Panamax and Post-Panamax vessels.

5. Fast Hoisting Speed: STS cranes feature rapid hoisting and lowering speeds, significantly reducing load and unload times and increasing overall terminal productivity.

6. Energy Efficiency: Many STS cranes are designed with energy-efficient technologies such as regenerative drives and LED lighting systems to reduce operational costs and environmental impact.

7. User-Friendly Controls: Ergonomic and intuitive control cabins, often equipped with advanced human-machine interface (HMI) systems, provide operators with enhanced comfort and ease of use.

8. Safety Features: Safety is paramount, with features including anti-collision systems, load moment indicators, and emergency stop mechanisms to ensure safe operation.

9. Dynamic Load Management: Smart load monitoring systems that adjust crane operations dynamically to prevent overloading and ensure optimal performance.

10. Versatility: Capable of handling a variety of cargo types including containers, bulk materials, and break-bulk items, making them versatile tools for different shipping needs.

11. Minimal Downtime: These cranes are engineered for rapid maintenance and minimal downtime, often featuring modular components that can be quickly replaced or serviced.

12. Environmental Compliance: Modern STS cranes adhere to stringent environmental regulations and standards, minimizing emissions and noise pollution.

These features make STS cranes indispensable assets in modern port operations, aiming to maximize efficiency, safety, and sustainability.

List Various Types of “sts crane”

Sure, below are various types of Ship-to-Shore (STS) cranes, which are used for loading and unloading containers from ships at port terminals:

1. Panamax STS Cranes:

– Designed to handle Panamax-sized vessels, which can pass through the original Panama Canal locks.

– Typically have an outreach of around 13-16 containers.

2. Post-Panamax STS Cranes:

– Built for ships wider than the Panama Canal’s original locks but narrower than the post-expansion dimensions.

– Outreach is about 18-20 containers.

3. Super Post-Panamax STS Cranes:

– Used for even larger vessels that exceed the Panama Canal’s expanded capacity.

– Outreach ranges from 22-24 containers or more.

4. Ultra-Large Container Vessel (ULVC) Cranes:

– Designed for ultra-large ships, often referred to as “mega ships.”

– Outreach can be 25 containers or greater.

5. High-Lift STS Cranes:

– Equipped with extended hoisting height to handle containers stacked high on large vessels.

– Useful for ships with more than 10 tiers of containers on deck.

6. Light-Duty STS Cranes:

– Primarily used for smaller vessels or regional port operations.

– Usually have less outreach and lower lifting capacities.

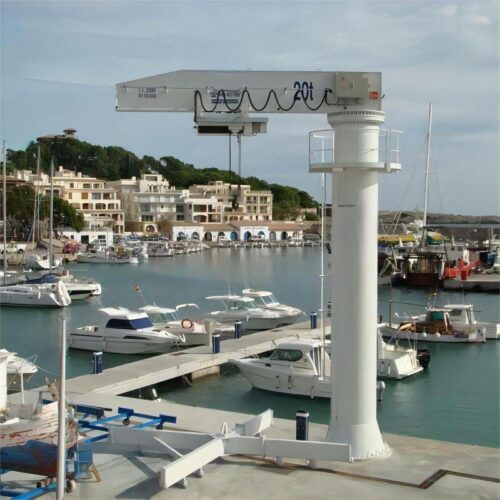

7. Mobile Harbor Cranes:

– Although not true STS cranes, they can perform similar functions with increased flexibility.

– Suitable for ports needing versatility and quick deployment.

8. Tandem Lifting STS Cranes:

– Designed to lift two 20-foot containers or one 40-foot container simultaneously, improving operational efficiency.

9. Automated STS Cranes:

– Integrated with advanced automation systems for remote control or autonomous operations.

– Enhances precision and reduces labor costs.

Each type is engineered to cater to specific vessel sizes and operational requirements, enabling ports to handle various shipping demands effectively.

List Application of “sts crane”

A Ship-to-Shore (STS) crane is an essential piece of equipment in modern port operations designed primarily to facilitate the rapid loading and unloading of container ships. Here are key applications of STS cranes:

1. Cargo Handling: The primary application is the loading and unloading of containers from ships. Efficient cargo handling reduces turnaround time for ships, optimizing port operations and increasing throughput.

2. Intermodal Transport: STS cranes are pivotal in intermodal transport, where goods are transferred between different modes of transportation, such as from ships to trucks or trains, ensuring a continuous flow in the logistics chain.

3. Bulk Cargo Operations: Specialized STS cranes can handle bulk cargo such as grain, coal, and ores. Adaptable grippers or grabs may be used to suit the type of bulk material being loaded or unloaded.

4. Container Stacking: High stacking capabilities allow for the efficient use of port storage space. STS cranes can stack containers several layers deep and high, making full use of available yard space.

5. Oversized Cargo Handling: Some STS cranes are designed to handle non-standard and oversized cargo like machinery, vehicles, and heavy equipment, requiring highly specialized lifting equipment and protocols.

6. Ship Maintenance and Repair: STS cranes equipped with the necessary apparatus can assist in the maintenance and repair of ships, facilitating the movement of heavy parts and equipment during dry dock operations.

7. Cross-Docking Operations: In cross-docking, goods are directly transferred from inbound to outbound transport without prolonged storage. STS cranes help quickly shift containers for immediate onward transport to minimize storage time and costs.

8. Supporting Offshore Operations: STS cranes are occasionally used in offshore logistics, transferring supplies and equipment to and from offshore platforms and vessels, crucial for the energy sector.

In summary, STS cranes are versatile and robust tools in the shipping and logistics industry, crucial for improving operational efficiency, reducing costs, and supporting a variety of cargo handling needs.

List Buyer Types of “sts crane”

Buyers of STS (Ship-to-Shore) cranes are typically entities involved in maritime operations and logistics. The major buyer types include:

1. Container Terminals and Ports: These are primary buyers of STS cranes. They use these cranes for loading and unloading shipping containers from vessels to the dock and vice versa. Examples include large ports like the Port of Los Angeles, Port of Rotterdam, and Port of Shanghai.

2. Shipping Companies: Major shipping companies operating their own private terminals often purchase STS cranes to enhance efficiency in container handling. Companies such as Maersk, MSC, and CMA CGM may invest in these cranes.

3. Logistics and Freight Forwarding Companies: Firms involved in comprehensive logistics services may invest in STS cranes as part of their infrastructure to ensure seamless cargo transfer operations. Examples include DHL Global Forwarding and Kuehne + Nagel.

4. Port Authorities and Government Bodies: Government entities that manage and develop ports may procure STS cranes to improve port infrastructure and operational capabilities. Examples include the Port Authority of New York and New Jersey.

5. Terminal Operating Companies: Independent operators managing port and terminal operations for multiple clients often invest in state-of-the-art STS cranes. Examples include Hutchison Ports, DP World, and PSA International.

6. Industrial Corporations: Large manufacturers and companies with significant import-export operations, such as automotive manufacturers or mining companies, may invest in STS cranes to streamline their supply chain operations.

7. Private Equity and Investment Firms: Investors involved in infrastructure projects may purchase STS cranes for ports to enhance asset value and operational efficiency. These are often long-term investments aimed at increasing port throughput capabilities.

Each buyer has unique requirements and specifications for STS cranes based on the scale of their operations, types of cargo handled, and technological preferences, thereby driving advances and customizations in crane technology.

List “sts crane” Project Types for Different Industries

Ship-to-Shore (STS) cranes are crucial pieces of equipment used primarily in port and terminal operations to load and unload container ships efficiently. However, their applications extend across several industries, each necessitating distinct project types tailored to specific operational demands. Here are various “STS crane” project types for different industries:

Maritime Industry

1. Container Terminals:

– High-Capacity STS Cranes: Designed for mega-ships with high stacking and outreach capabilities.

– Automated STS Cranes: Incorporates advanced automation for enhanced efficiency and reduced labor costs.

2. Bulk Handling Ports:

– Heavy-Duty STS Cranes: Built for the lifting and transferring of bulk goods like coal, ore, and grains.

Oil & Gas Industry

1. Offshore Platforms:

– Specialized STS Cranes: Custom-designed for heavy lifting and precise operations in offshore drilling sites.

– STS Maintenance Cranes: Focus on maintenance and service crane operations on offshore rigs.

Logistics & Transportation

1. Intermodal Transport Yards:

– Intermodal STS Cranes: Facilitate the transfer of containers between trucks, trains, and ships efficiently.

Construction Industry

1. Pre-fabricated Structures:

– Heavy Lift STS Cranes: Used to lift and position large pre-fabricated sections during maritime construction projects like bridges and piers.

Renewable Energy

1. Wind Farm Installation:

– STS Cranes for Wind Turbines: Tailored for the transport and installation of wind turbine components.

Military & Defense

1. Naval Ports:

– Versatile STS Cranes: Equipped for military cargo handling, including vehicles, equipment, and supplies.

Aerospace Industry

1. Spaceport Operations:

– Precision STS Cranes: Employed for the careful lifting and handling of sensitive aerospace components and spacecraft.

In summary, STS crane project types vary across industries but share a common emphasis on customization and strategic functionality to meet specific operational needs.

sts crane Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing your Ship-to-Shore (STS) crane can significantly enhance its performance, safety, and longevity. Below are some accessory upgrades and custom manufacturing options available:

1. Spreader Beams: Modern spreader beams can handle various container types and weights, improving load management and reducing operational downtime.

2. Automation Systems: Implementing semi-automated or fully automated systems can increase precision, reduce human error, and enhance operational efficiency. This includes automated guided vehicles (AGVs) for container transport.

3. Cameras and Sensors: Installing high-resolution cameras and advanced sensor systems helps in monitoring crane operations, thereby enhancing safety and operational efficiency. These systems assist in obstacle detection, load positioning, and collision avoidance.

4. Control Systems: Upgrading to advanced control systems with user-friendly interfaces and remote operation capabilities can simplify crane management.

5. Anti-Sway Technology: Implementing anti-sway systems can stabilize loads, minimizing the risk of accidents and improving operational safety.

6. Energy-Efficient Drives: Upgrading to energy-efficient motors and drives can reduce power consumption, operational costs, and environmental impacts. Regenerative drives can further enhance energy savings by converting kinetic energy back into electrical power.

7. Custom Fabrication: Tailoring the crane to specific operational needs through custom fabrications, such as extended boom lengths or reinforced structural components, can address unique port requirements.

8. Weatherproofing: Enhancing the crane’s durability with weather-resistant materials and coatings can protect it from harsh environmental conditions, extending its service life.

9. Load Monitoring Systems: Advanced load monitoring systems provide real-time data on weight and distribution, ensuring safe and efficient handling.

10. LED Lighting: Upgrading to LED lighting improves visibility and reduces energy consumption, facilitating night operations and enhancing overall safety.

These upgrades and custom options can transform your STS crane into a more efficient, safe, and cost-effective asset, tailored to meet the specific demands of modern port operations.

List Quality Control and The Manufacturing Process of “sts crane”

Quality Control for STS Crane

1. Material Inspection: All raw materials (steel, electrical components, etc.) are inspected for compliance with engineering standards.

2. Design Verification: Detailed scrutiny of design specifications to ensure compliance with operational and safety protocols.

3. Weld Quality Testing: Non-destructive testing methods such as ultrasonic or radiographic testing are used to verify the integrity of welds.

4. Component Testing: Each component (motors, cables, hydraulic systems) undergoes rigorous stress and performance testing.

5. Dimensional Checks: Measurements are checked against design specifications to ensure precise construction.

6. Load Testing: Cranes undergo load tests to ensure they can handle specified weights safely.

7. Functional Testing: Operational tests are performed to verify that the crane operates smoothly under different conditions.

8. Safety Inspections: Safety features are checked and tested to ensure compliance with safety standards.

9. Documentation and Review: Detailed records of all inspections and tests are maintained and reviewed.

10. Final Approval: Only cranes that pass all quality checks are approved for shipment and installation.

Manufacturing Process of STS Crane

1. Design and Engineering: Engineers create detailed blueprints and 3D models to specify all design parameters and construction guidelines.

2. Material Procurement: High-quality materials such as structural steel, motors, and electrical components are sourced.

3. Cutting and Shaping: Raw materials are cut and shaped to required dimensions using CNC machines, plasma cutters, and other tools.

4. Fabrication: Components like jibs, girders, and frameworks are welded and assembled. Precision is key to ensure structural integrity.

5. Machining: Precision machining processes are applied to create custom fittings, gearboxes, and other mechanical components.

6. Surface Treatment: Completed structures undergo surface treatments like sandblasting, priming, and painting to prevent corrosion.

7. Assembly: All components including mechanical, hydraulic, and electrical systems are assembled into the crane framework.

8. Testing: The assembled crane undergoes various mechanical, electrical, and load tests to ensure functionality and safety.

9. Inspection: A final inspection ensures the crane meets all design and quality standards.

10. Delivery and Installation: The crane is disassembled if required, transported to the site, reassembled, and installed. Post-installation tests are conducted to ensure operational readiness.

How to use “sts crane”

Using a Ship-to-Shore (STS) crane involves several steps and requires careful coordination and adherence to safety protocols. Here’s a simplified guide:

1. Pre-Operation Checks:

– Inspection: Conduct a thorough inspection of the crane, looking for any visible damage or wear.

– Safety Gear: Ensure all operators wear appropriate safety gear, such as helmets, gloves, and reflective vests.

2. Crane Setup:

– Positioning: Align the crane with the vessel, making sure it’s positioned correctly over the cargo hold.

– Configuration: Set up the crane’s control panel, calibrate instruments, and confirm that communication lines with the vessel’s crew are open.

3. Operating the Crane:

– Lift Preparation: Attach the appropriate lifting equipment (spreader, hooks) to the crane.

– Lifting Cargo: Start lifting the cargo slowly and steadily. Ensure that the load is balanced and fully secured.

– Movement: Use the crane’s controls to move the cargo from the ship to the designated area on the dock. Avoid sudden movements to minimize the risk of swinging or dropping the load.

4. Unload/Release Cargo:

– Position Cargo: Gently lower the cargo to the dock or storage area.

– Disconnect: Safely disconnect the lifting equipment from the cargo once it’s in place.

5. Post-Operation Procedures:

– Shutdown: Turn off the crane and secure the control panel.

– Inspection: Conduct a post-operation inspection for any potential issues and log the operation details.

6. Communication:

– Maintain clear and constant communication with the team on the vessel and dock throughout the operation.

*Safety Considerations*: Always follow standard operating procedures (SOPs) and international maritime regulations to ensure safety and efficiency. Proper training and certification for crane operation are mandatory.

By strictly adhering to these steps and maintaining diligent communication and safety standards, the operation of an STS crane can be efficient and incident-free.

“sts crane” Comparative Analysis

Ship-to-shore (STS) cranes are pivotal in port operations, facilitating the transfer of goods between ships and the dock. When analyzing these cranes, it’s essential to compare their key attributes, including lifting capacity, reach, speed, automation, and energy efficiency.

Lifting Capacity: STS cranes come in various capacities, typically ranging from 40 to over 100 tons. Larger cranes can handle heavier and larger containers, benefiting major ports with high cargo volumes. For example, super post-Panamax cranes can lift up to 100 tons and serve the largest container ships.

Reach: The reach of an STS crane, often measured by the number of rows of containers it can span across a vessel, influences its adaptability to different ship sizes. Modern cranes boast reaches upwards of 70 meters, suitable for the latest, widest vessels.

Speed: Operational speeds, including hoist speed (vertical movement) and trolley speed (horizontal movement), are critical for efficiency. Advanced STS cranes achieve hoist speeds of 70-100 meters per minute, significantly enhancing throughput. Faster cranes reduce vessel turnaround time, a vital factor for high-traffic ports.

Automation: Automation levels vary. Basic models rely heavily on human operators, while state-of-the-art cranes feature remote operation, diagnostics, and even full automation. Automated STS cranes reduce human error, improve safety, and can operate 24/7, enhancing overall port efficiency. However, they require substantial initial investment and maintenance.

Energy Efficiency: Energy consumption is a growing concern. Modern cranes integrate regenerative power systems, LED lighting, and energy-efficient motors to reduce operational costs and environmental impact. Hybrid and electric STS cranes are increasingly common, reflecting the industry’s push towards sustainability.

In conclusion, the choice of STS crane depends on port-specific needs, balancing lifting capacity, reach, speed, automation, and energy efficiency. Ports with high cargo throughput might prioritize high-capacity, automated cranes, while smaller ports may opt for less advanced but cost-effective models. The trend towards automation and energy efficiency is evident, driven by the demand for higher productivity and ecological considerations.

“sts crane” Warranty and Support

STS cranes are integral to port operations, and ensuring their continuous operation is crucial. Here’s a brief overview of warranty and support for STS cranes:

Warranty

Manufacturers typically offer a warranty period spanning from 12 to 24 months from the date of commissioning. The warranty usually covers:

– Defects in material and workmanship: Any flaws noticed during the warranty period are rectified or replaced at no extra charge.

– OEM parts replacement: Genuine parts are provided to ensure seamless operation.

– Service visits: Onsite inspections and repairs by certified technicians if any issues arise.

Support

Robust support systems are in place to ensure minimal downtime:

– 24/7 Helpline: Many manufacturers have a round-the-clock helpline to address urgent issues.

– Remote Monitoring: Advanced diagnostic systems enable remote monitoring and troubleshooting, allowing for quick responses to any anomalies.

– Preventive Maintenance: Regularly scheduled maintenance checks and servicing to prevent potential issues, thereby enhancing crane longevity.

– Training: Training programs for operators and maintenance personnel to ensure proper handling and upkeep.

– Spare Parts Availability: Quick access to essential spare parts based on predictive maintenance analytics, minimizing downtime.

– Onsite Support: On-demand dispatch of technicians to address critical failures or perform routine maintenance.

Extended Warranty and Support Plans

Some manufacturers offer extended warranty options and comprehensive support plans, which include:

– Extended coverage beyond the initial warranty period.

– Regular update and retrofit services to keep the crane up-to-date with the latest technology.

– Enhanced preventive maintenance packages for continuous, reliable operations.

This robust warranty and support framework ensures that your STS crane remains operational, safe, and efficient, minimizing disruptions to your port activities.

List “sts crane” FAQ

STS Crane FAQ

What is an STS Crane?

STS (Ship-to-Shore) Cranes are large, powerful cranes designed to load and unload containers from vessels at ports. They play a critical role in container shipping logistics.

How does an STS Crane operate?

STS Cranes use a trolley mechanism that moves along a boom, extending from the dock over the vessel to lift containers. The crane operator or an automated system controls the loading and unloading process.

What are the main components of an STS Crane?

Key components include the gantry, boom, trolley, spreader, hoist, lifting gear, and operator cabin. These elements work together to ensure efficient and safe container handling.

What is the typical lifting capacity?

Lifting capacities vary, but modern STS Cranes can typically handle weights between 40 to 100 tons, depending on the model and configuration.

What are the different types of STS Cranes?

STS Cranes can be classified by size (Panamax, Post-Panamax, and Super-Post-Panamax) and by automation level (manual, semi-automated, and fully automated).

How tall is an STS Crane?

Height can vary, but they generally range between 50 to 150 meters, depending on the specific requirements and the size of vessels they service.

What is the outreach of an STS Crane?

Outreach, which refers to the horizontal reach of the boom, can extend up to 70 meters or more, allowing the crane to access containers across wide vessels.

What kind of maintenance is required?

Regular maintenance is crucial and typically includes inspections, lubrication, parts replacement, and system checks. This ensures operational safety and longevity.

Are STS Cranes environmentally friendly?

Modern STS Cranes often incorporate electric drives and regenerative power systems to minimize environmental impact. However, traditional models using diesel engines may have higher emissions.

What are the safety measures?

Safety measures include load limiters, anti-collision systems, emergency stop mechanisms, and rigorous operator training.

How long is the lifecycle of an STS Crane?

With proper maintenance, an STS Crane can have an operational lifespan of approximately 25 to 30 years.

Armed with this information, ports can better understand the capabilities and requirements of STS Cranes to ensure efficient and safe container handling.

Top 10 FAQ with answer about sts crane for Buyer Sourcing from China

Sure, here are the top 10 FAQs with answers about sourcing STS (Ship-to-Shore) cranes from China:

1. What is an STS Crane?

An STS crane is a large dockside crane used for loading and unloading containers from ships. It plays a crucial role in port operations.

2. Why source STS cranes from China?

China is known for its advanced manufacturing capabilities, cost-effective production, and extensive experience in heavy machinery, making it a popular choice for sourcing.

3. Which Chinese companies are reputable suppliers of STS cranes?

Reputable suppliers include ZPMC (Shanghai Zhenhua Heavy Industries Co., Ltd.), SANY, and DHHI (Dalian Huarui Heavy Industry Group Co., Ltd.).

4. What should I look for in a supplier?

Look for ISO certification, a strong track record, references, and the ability to provide comprehensive after-sales support and warranties.

5. What are the average lead times for delivery?

Depending on the complexity and customization, lead times can range from 6 to 12 months from the order date.

6. What are the key specifications to consider?

Consider lifting capacity, outreach, back reach, hoisting speed, and the crane’s ability to handle different ship sizes.

7. Are there any standards and certifications required?

Ensure the crane complies with international standards like ISO, FEM (Federation Europeenne de la Manutention), and IEC (International Electrotechnical Commission).

8. What is the cost range for an STS crane?

Costs can vary widely based on specifications and capacity but typically range from $5 million to $15 million.

9. What are the shipping and installation considerations?

Due to their size, STS cranes are transported in parts and assembled on-site. The supplier usually provides skilled technicians for installation.

10. How can I ensure quality and reliability?

Conduct factory audits, ask for third-party inspection reports, and verify the supplier’s experience with similar projects.

By addressing these common questions, buyers can make informed decisions when sourcing STS cranes from China.