truss gantry crane Safety Certifications

Truss gantry cranes are vital in various industrial applications, including manufacturing, construction, and shipping. Ensuring their safe operation is paramount, which is why they must comply with several safety certifications and standards. Here are the key certifications and guidelines:

1. OSHA (Occupational Safety and Health Administration): OSHA sets forth regulations under 29 CFR Part 1910 for general industry, providing guidelines to ensure safe crane operation.

2. ASME B30.2: The American Society of Mechanical Engineers (ASME) offers guidelines specifically for overhead and gantry cranes, focusing on safety in design, construction, inspection, testing, maintenance, and operation.

3. CMAA (Crane Manufacturers Association of America): CMAA Spec No. 70 and 74 provide detailed criteria for the design and manufacturing of overhead and gantry cranes, ensuring they meet stringent safety and performance requirements.

4. ANSI (American National Standards Institute): ANSI B30.2 pertains to overhead and gantry cranes and works in conjunction with ASME standards to ensure comprehensive safety protocols.

5. LOLER (Lifting Operations and Lifting Equipment Regulations): In the UK, LOLER mandates that lifting equipment must be strong, stable, and used safely. Regular inspections and thorough examinations are required to maintain compliance.

6. ISO 9001: While not specific to cranes, ISO 9001 certification ensures that an organization has a quality management system in place, which can impact the safety and reliability of crane operations.

7. IEC (International Electrotechnical Commission) Standards: IEC 60204-32, for example, deals with the safety of electrical equipment in cranes and helps in mitigating electrical hazards.

8. CSA (Canadian Standards Association): CSA C22.2 covers electrical safety for industrial cranes used in Canada, ensuring alignment with both Canadian and global safety practices.

9. FEM (Fédération Européenne de la Manutention): FEM 1.001 guidelines provide standardized norms for the design and construction of cranes within the European framework, ensuring high safety standards.

Adherence to these standards reduces risks, assures compliance with local regulatory requirements, and enhances the overall safety and efficiency of truss gantry crane operations.

List Reference Technical Parameters of “truss gantry crane”

Reference Technical Parameters of Truss Gantry Crane

1. Loading Capacity:

– Variants ranging from 5 tons to over 200 tons.

– Custom configurations available upon request.

2. Span Length:

– Standard spans from 5 meters to 35 meters.

– Custom spans available.

3. Lifting Height:

– Typically ranges between 3 meters to 30 meters.

– Adaptable to specific operational requirements.

4. Operating Temperature:

– Suitable for environments between -20°C to +40°C.

– Options available for extreme conditions with specialized equipment.

5. Crane Speed:

– Hoisting speed: 3 to 15 m/min (variable frequency drive for precise control).

– Trolley traversing speed: 2 to 30 m/min.

– Crane traveling speed: 5 to 50 m/min.

6. Power Supply:

– Standard: 3-phase, 380V/50Hz.

– Variants: Based on regional specifications, e.g., 415V/60Hz or 440V/60Hz.

7. Control System:

– Options include pendant control, remote control, or cabin control.

– Provisions for semi-automatic or fully automated systems.

8. Structural Specifications:

– Composed of high-strength steel with either a single or double girder design.

– Enhanced stability via triangular truss framework.

9. Safety Mechanisms:

– Overload protection, end limit switches, emergency brakes.

– Anti-sway devices and wind-resistant features for outdoor operations.

10. Installation and Maintenance:

– Modular design for ease of assembly and disassembly.

– Regular maintenance protocols recommended to ensure optimal performance.

11. Application Areas:

– Widely used in construction sites, shipyards, warehouses, and outdoor manufacturing facilities where heavy lifting and transport are required.

These parameters ensure that truss gantry cranes are versatile, reliable, and suitable for a wide range of industrial applications.

List Product features of “truss gantry crane”

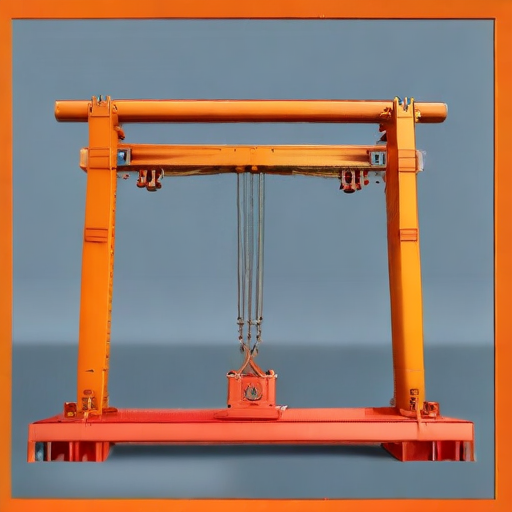

A truss gantry crane is a specialized lifting device designed for a variety of material handling applications. Below are key features of truss gantry cranes:

1. Robust Construction: Truss gantry cranes are built using high-strength materials, often featuring trussed structures that provide excellent load-bearing capacity without significantly increasing weight.

2. High Load Capacity: These cranes are designed to handle heavy loads, with capacities ranging from a few tons to several hundred tons, depending on the specific configuration.

3. Long Span Capability: Truss gantry cranes can cover large spans, making them ideal for applications where wide areas need to be serviced.

4. Height Flexibility: They offer variable height configurations, allowing for customization based on the height requirements of the working area.

5. Outdoor Suitability: The open truss design is particularly resistant to weather conditions, making these cranes suitable for outdoor use.

6. Ease of Assembly and Disassembly: Truss gantry cranes can be assembled and disassembled relatively easily, facilitating transportation and relocation.

7. Cross-section Stability: The truss design ensures minimal deflection under load, offering greater stability and precision during operations.

8. Versatile Applications: These cranes are widely used in construction, shipyards, manufacturing, and heavy engineering sectors where robust and reliable material handling is essential.

9. Manual and Motorized Options: Truss gantry cranes can come in both manual and motorized versions, catering to different operational needs and budgets.

10. Customization Availability: They can be tailored to specific needs, including the integration of various lifting devices like hoists and trolleys.

11. Safety Features: Many models include safety features such as limit switches, emergency stop functions, and overload protection systems.

12. Cost-effective: Truss gantry cranes provide a cost-effective solution for lifting needs, particularly as they reduce the necessity for permanent structures.

These features make truss gantry cranes a versatile and essential tool for many industrial and construction applications.

List Various Types of “truss gantry crane”

A truss gantry crane is a type of overhead crane featuring a truss structure that makes it both strong and lightweight. These cranes are extensively used for outdoor applications and environments with heavy wind loads or harsh weather. Below are various types of truss gantry cranes:

1. Single Girder Truss Gantry Crane: This type features a single truss girder and is suitable for light to moderate lifting tasks. It offers economical advantages and is easier to install.

2. Double Girder Truss Gantry Crane: With two parallel truss girders, this crane type provides greater lifting capacity and stability. It is ideal for heavy-duty tasks.

3. Semi-Gantry Truss Crane: This crane has one side supported by a track on the ground and the other side supported by a runway system attached to a building or structure. It optimizes space utilization.

4. Rail-Mounted Truss Gantry Crane: Equipped with rails, this type can move along a predefined path, making it useful for long-range movement and repetitive tasks.

5. Rubber-Tired Truss Gantry Crane: Featuring rubber tires, this crane type is highly mobile and can be used in various locations within a facility without permanent rail tracks.

6. Portable Truss Gantry Crane: This lightweight and mobile crane can be easily disassembled and moved, making it ideal for temporary lifting tasks on different sites.

7. Adjustable Truss Gantry Crane: Designed with adjustable height and span, this type offers versatility to handle different load requirements and operational constraints.

8. Heavy-Duty Truss Gantry Crane: Built for handling extremely heavy and large loads, this crane type features robust construction and advanced lifting mechanisms.

9. Cantilever Truss Gantry Crane: Equipped with a projecting jib or arm, these cranes are effective for lifting material beyond the span of the crane, adding flexibility in operation.

Truss gantry cranes, with their distinctive designs and functionality, are critical for various industrial applications, providing customized solutions for diverse lifting needs.

List Application of “truss gantry crane”

Applications of Truss Gantry Crane:

1. Construction Sites:

– Truss gantry cranes are extensively used in construction for lifting heavy materials like steel beams, concrete blocks, and other bulky construction materials.

– They enable efficient movement of elements vertically and horizontally across the site, enhancing productivity and safety.

2. Shipyards:

– In shipbuilding and repair, these cranes are pivotal for handling large ship components such as hull sections and engines.

– Truss gantry cranes facilitate the precise placement of massive parts, ensuring structural integrity and expedited assembly processes.

3. Railway Yards:

– Utilized for lifting and positioning railroad tracks, carriages, and maintenance equipment.

– They help in streamlining logistic operations and accelerate the maintenance and construction of railway infrastructure.

4. Manufacturing Plants:

– Truss gantry cranes aid in the production processes by handling large machinery and heavy components.

– Their use enhances workflow efficiency by minimizing material handling time and reducing labor costs.

5. Outdoor Storage Yards:

– These cranes are ideal for outdoor storage areas where heavy goods like pipelines, containers, and oversized industrial equipment are kept.

– They are designed to withstand various weather conditions and provide reliable service for lifting and organizing heavy inventories.

6. Hydroelectric Plants:

– Essential for the installation and maintenance of heavy generators, turbines, and other electrical equipment.

– Their robust structure and lifting capacity ensure efficient handling of enormous hydroelectric infrastructure components.

7. Steel Mills:

– Used for transporting heavy steel materials including large coils, slabs, and bars within the mill.

– They contribute to the seamless operation of steel production, enhancing material flow and handling safety.

8. Wind Turbine Installation:

– Truss gantry cranes play a critical role in the assembly and maintenance of wind turbines.

– They facilitate the lifting of turbine components such as nacelles, blades, and towers, ensuring safe and efficient setup.

In summary, truss gantry cranes are indispensable across various industries requiring the lift and move of heavy, large-scale objects efficiently and safely. Their structural integrity and versatility make them equally adaptable to both indoor and outdoor applications.

List Buyer Types of “truss gantry crane”

1. Construction Companies

* Application: Heavy lifting of construction materials such as steel beams, concrete sections, bridge parts, etc.

* Features: High load capacity, robustness, mobility on construction sites.

2. Manufacturing Plants

* Application: Moving heavy components and machinery in fabrication, assembly lines, and maintenance.

* Features: Precision in lifting, repeatable and reliable operations, integration with other plant equipment.

3. Shipping Ports and Terminals

* Application: Loading and unloading of containers, cargo, and shipbuilding materials.

* Features: High lifting height, long span, efficient operation in outdoor environments.

4. Warehouses and Distribution Centers

* Application: Handling of large goods, pallets, and equipment.

* Features: Better space optimization, flexibility in operations, integration with logistics systems.

5. Railway Yards

* Application: Lifting of heavy rail components like tracks, carriages, and maintenance equipment.

* Features: Ability to operate over large areas, strong lifting capacity.

6. Heavy Equipment Repair Shops

* Application: Movement and positioning of heavy machinery and parts for repair and maintenance.

* Features: Precise lifting, ability to handle large and heavy components.

7. Mining Industries

* Application: Transporting large mining equipment and minerals.

* Features: Durability in harsh environmental conditions, substantial lifting capacity.

8. Wind Turbine Manufacturing and Maintenance

* Application: Lifting and positioning of heavy turbine components such as nacelles and blades.

* Features: Customizable height, strong and stable lifting mechanism.

Understanding the specific requirements of these buyer types allows for providing tailored solutions that meet operational needs efficiently.

List “truss gantry crane” Project Types for Different Industries

Truss gantry cranes are versatile lifting solutions widely used across various industries due to their robust and adaptable structures. Here are some project types across different industries where truss gantry cranes are frequently employed:

1. Construction Industry:

– High-Rise Building Construction: For lifting heavy steel beams and concrete elements.

– Bridge Construction: Movement and placement of sections during assembly.

– Infrastructure Projects: Transporting large pipes, culverts, and other heavy materials.

2. Manufacturing Industry:

– Assembly Line Support: Handling and assembling large machinery parts.

– Heavy Equipment Manufacturing: Moving substantial and heavy machine parts during production.

– Steel Plants: In processes involving large steel components that require precise positioning.

3. Shipbuilding Industry:

– Dry Dock Operations: Lifting and placing large ship modules and components.

– Loading and Unloading: Moving heavy subassemblies and materials around shipyards.

4. Aerospace Industry:

– Aircraft Assembly: Transporting and assembling large aircraft sections.

– Rocket Assembly: Moving and positioning rocket stages and components.

5. Logistics and Freight Handling:

– Container Handling: Loading and unloading containers at ports and rail terminals.

– Warehouse Operations: Handling oversized and heavy goods within large warehouses.

6. Power Generation:

– Hydroelectric Projects: Placing large turbine components and other heavy equipment.

– Wind Farms: Erecting wind turbine components and blades.

7. Mining Industry:

– Material Handling: Moving large quantities of raw materials like coal, ores, and stones.

– Equipment Assembly: Assembling and repairing large mining equipment.

8. Automotive Industry:

– Vehicle Assembly: Transporting heavy automotive parts and assemblies.

– Tool and Die Handling: Lifting large dies and molds during manufacturing.

In all these industries, truss gantry cranes enhance operational efficiency, safety, and productivity by allowing for precise and reliable handling of heavy loads.

truss gantry crane Accessories Upgrades and Custom Manufacturing Options

Truss gantry cranes are integral for various industries due to their robust design and high load capacity. To maximize their functionality, several accessories, upgrades, and custom manufacturing options are available:

1. Wireless Remote Controls: Enhances safety and ease of operation by allowing operators to control the crane from a distance.

2. Anti-Sway Systems: Reduces load swing, which improves precision and safety during lifting and moving operations.

3. Variable Frequency Drives (VFDs): Enable smooth acceleration and deceleration, enhancing control and reducing mechanical stress on the crane components.

4. Customized Lifting Attachments: Including magnets, grabs, and spreader beams, tailored to specific material handling needs, ensuring versatile usage.

5. Automation Systems: Incorporating PLCs and IoT solutions for advanced monitoring, diagnostics, and automation, improving efficiency.

6. Height and Span Adjustments: Custom alterations to the crane’s height and span to suit unique operational environments.

7. Weatherproofing Solutions: Galvanization, painting, and special coatings to protect the crane from harsh conditions and extend its lifespan.

8. Enhanced Safety Features: Limit switches, overload protection, and emergency stop systems to enhance operational safety.

9. Lighting and Warning Systems: Integrated lighting and audible/visual alarms to improve safety and operational awareness.

10. Maintenance Platforms: Additional platforms and access points for easier, safer maintenance operations.

Custom manufacturing options allow for specific design alterations to fit unique spatial and load requirements, ensuring the crane meets precise operational demands. Collaborating with manufacturers to tailor these features can significantly enhance the efficiency, safety, and versatility of truss gantry cranes in any industrial setting.

List Quality Control and The Manufacturing Process of “truss gantry crane”

Quality Control of Truss Gantry Crane:

1. Material Inspection: Ensure that materials such as steel meet required standards and specifications.

2. Welding Quality: Perform non-destructive testing (NDT) methods like ultrasonic testing or radiographic testing to check weld integrity.

3. Dimensional Accuracy: Use precise measurement tools to ensure components conform to design specifications.

4. Load Testing: Conduct load tests to verify the crane’s ability to handle its maximum rated capacity without failure.

5. Surface Treatment: Ensure proper application of anti-corrosion coatings and paint to enhance durability.

6. Electrical System Verification: Test electrical components, control systems, and safety mechanisms.

7. Documentation: Maintain thorough records of all tests, inspections, and compliance checks.

8. Final Inspection: Conduct a comprehensive final inspection to ensure the complete system functions correctly and meets all safety standards.

Manufacturing Process of Truss Gantry Crane:

1. Design & Engineering:

– Initial conceptual designs and 3D modeling.

– Structural analysis and stress simulation using CAD software.

– Generating detailed fabrication drawings and specifications.

2. Material Preparation:

– Procurement of high-quality materials.

– Cutting and shaping of steel beams and components using CNC machinery.

3. Fabrication:

– Assembling the main truss structure using welding techniques.

– Fabricating and machining components like end carriages, hoist frames, and trolley mechanisms.

4. Machining:

– Precision machining of components to exact tolerances.

– Drilling, milling, and turning operations to prepare for assembly.

5. Assembly:

– Assembling the truss structure with end carriages, trolley, hoist, and electrical systems.

– Installation of motors, gears, and safety devices.

6. Welding:

– Skilled welders perform welding according to the stringent welding procedure specifications (WPS).

– Welds inspected through NDT methods.

7. Surface Treatment:

– Sandblasting or shot blasting of the structure.

– Application of anti-corrosive coatings and paint.

8. Testing:

– Conduct factory acceptance testing (FAT), including load testing, functional testing, and stress tests.

– Electrical and control system validations.

9. Documentation & Compliance:

– Compiling inspection reports and certificates.

– Ensuring compliance with industry standards and regulations.

10. Installation & Commissioning:

– Transporting the crane to the site.

How to use “truss gantry crane”

A truss gantry crane is a type of overhead crane with a structural frame formed by trusses. It is typically used in outdoor environments for heavy lifting and material handling. Here’s a basic guide on how to use one:

1. Pre-Operation Checks:

– Inspect the Crane: Inspect the crane structure, lifting mechanism, and trolley for any visible damage or wear.

– Safety Gear: Ensure operators wear appropriate personal protective equipment (PPE) such as helmets, gloves, and safety boots.

2. Power Up:

– Connect Power: Ensure the crane is properly connected to its power source.

– Test Controls: Verify that all control buttons and levers are functioning correctly.

3. Load Preparation:

– Check Load: Confirm the weight and dimensions of the load to ensure it does not exceed the crane’s capacity.

– Secure Load: Use appropriate slings, hooks, or other lifting devices to secure the load.

4. Lifting the Load:

– Position Crane: Move the crane so that the hoist is directly above the load.

– Attach Load: Securely attach the load to the hook or lifting device.

– Lift Load: Use the hoist control to lift the load slowly, ensuring it is balanced and stable.

5. Transporting the Load:

– Horizontal Movement: Use the trolley to move the load along the gantry arm.

– Crane Travel: Move the entire crane along its track if necessary, using the proper travel controls.

6. Lowering the Load:

– Position Over Drop Area: Move the load to the designated drop area.

– Lower Gently: Slowly lower the load to the ground or platform, ensuring it lands safely and securely.

7. Shut Down:

– Disengage Load: Remove slings or hooks from the load.

– Turn Off Power: Cut off the power supply to the crane.

– Conduct Post-Operation Checks: Inspect the crane for any potential issues that need addressing.

8. Maintenance:

– Regular Checks: Conduct regular maintenance and inspections as per manufacturer guidelines.

Following these steps ensures safe and efficient operation of a truss gantry crane. Safety should always be the priority.

“truss gantry crane” Comparative Analysis

A truss gantry crane is a specialized type of crane that uses a truss structure for the main beam and legs, providing enhanced strength and stability with reduced weight. When assessing truss gantry cranes, it’s essential to consider key factors such as design, application, performance, and cost.

Design

The truss structure, with its triangular units, offers high strength-to-weight ratio. Unlike box gantry cranes, truss gantry cranes are less susceptible to wind forces due to their open framework, making them ideal for outdoor applications. The design also provides greater span lengths, extending the crane’s coverage area.

Application

Truss gantry cranes are versatile and used in various industries such as construction, shipyards, and container terminals. They are particularly suitable for environments with high wind speeds or where long spans are required. Conversely, solid web gantry cranes are preferred for indoor environments or areas with limited space, owing to their compact design.

Performance

In terms of load capacity, both truss and solid web gantry cranes can handle similar weights. However, the truss gantry crane’s lighter structure allows for easier and cost-effective transportation and installation. Their design also contributes to reduced sway and vibration, ensuring precise load handling and increased safety, especially in heavy lifting and large-scale construction projects.

Cost

While the initial cost of truss gantry cranes can be higher due to their more complex fabrication, the investment can be offset by their longer spans and reduced material usage. Over time, operations in high wind areas will see a return on investment due to lower maintenance costs associated with the truss design’s inherent wind resistance.

conclusion

In conclusion, truss gantry cranes are an excellent choice for outdoor, high-wind environments, and applications requiring long spans. Although they may involve higher initial costs, their structural benefits and operational efficiency often justify the investment, particularly in infrastructure and heavy-duty projects.

“truss gantry crane” Warranty and Support

When investing in a truss gantry crane, it’s crucial to understand the warranty and support options available to ensure long-term reliability and efficiency. Typically, manufacturers offer a standard warranty that covers defects in materials and workmanship. The duration of these warranties can vary, but they generally range from one to five years. Be sure to read the fine print to understand what is and isn’t covered, such as parts, labor, and any limitations on usage.

In addition to the standard warranty, some manufacturers may offer extended warranty options for an additional fee. These extended warranties can provide peace of mind, especially if the crane will be used in demanding environments.

Support is another critical aspect of owning a truss gantry crane. Most reputable manufacturers provide comprehensive support services that include installation, routine maintenance, and emergency repairs. Many offer 24/7 customer service hotlines to address urgent issues, minimizing downtime. Technical support often includes troubleshooting assistance and remote diagnostics, which can be invaluable for resolving minor issues quickly.

Regular maintenance is usually a requirement to keep the warranty valid. Some companies offer scheduled maintenance plans where certified technicians perform essential upkeep tasks. This not only extends the lifespan of the crane but also ensures it operates safely and efficiently.

Training for operators is another support service that can enhance the effective use of the truss gantry crane. Proper training programs help users understand the operational capacities and safety protocols, thereby minimizing the risk of accidents and equipment misuse.

In summary, when evaluating a truss gantry crane, thoroughly review the warranty and support options. Standard and extended warranties, comprehensive support services, and proper training programs are essential elements to consider for optimal performance and longevity of the crane.

List “truss gantry crane” FAQ

Truss Gantry Crane FAQ

#### What is a Truss Gantry Crane?

A truss gantry crane is a type of overhead crane designed with a trussed beam for better strength and reduced wind resistance, ideal for outdoor operations in construction, shipping yards, and manufacturing units.

#### What are the key components?

Key components typically include the trussed beam (girder), A-frame legs, trolley, lifting mechanism (hoist), control systems, and wheels for mobility.

#### What are the advantages?

1. Strength & Durability: The trussed design offers high strength and stability.

2. Wind Resistance: Reduced wind load makes it suitable for outdoor use.

3. Versatility: Can handle various load types and sizes.

#### What capacities are available?

Truss gantry cranes come in various capacities, from a few tons to several hundred tons, depending on the application requirements.

#### Are they customizable?

Yes, these cranes can be tailored to meet specific operational needs, including size, lifting capacity, span, height, and control options.

#### How is a truss gantry different from a box gantry crane?

The main difference lies in the design of the main beam. Truss gantries have a trussed (triangular or lattice) design, offering better wind resistance and generally lighter weight, while box gantries use a thicker, rectangular boxed beam.

#### What maintenance is required?

Regular inspection of structural components, lubrication of moving parts, checking electrical systems, and ensuring all safety devices are in working order are critical for maintaining safety and functionality.

#### What safety features are included?

Safety features often include limit switches, warning alarms, overload protection, emergency stop buttons, and proper signage.

#### How do you operate a truss gantry crane?

Operation typically involves a remote control or a cab with manual controls, manipulated by a trained and certified operator following all safety guidelines and operational protocols.

#### Can they be used indoors?

While primarily designed for outdoor use, truss gantry cranes can also be utilized indoors, provided there is sufficient space and necessary configurations.

By understanding these aspects, you can determine if a truss gantry crane meets your operational requirements. Always consult with a professional supplier or manufacturer to get the most suitable and safe crane for your specific needs.

Top 10 FAQ with answer about truss gantry crane for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about sourcing truss gantry cranes from China, with concise answers:

1. What is a Truss Gantry Crane?

– A truss gantry crane is a type of overhead crane supported by a truss structure, designed for lifting and moving heavy loads in various environments, including construction sites and warehouses.

2. Why Choose a Truss Gantry Crane Over Other Types?

– Truss gantry cranes are preferred for their lightweight, high strength-to-weight ratio, and excellent wind resistance. They are ideal for outdoor applications with large spans.

3. How to Verify the Quality of a Truss Gantry Crane from China?

– Request for certifications like ISO, CE, and conduct an on-site inspection or hire a third-party inspection service. Also, read reviews and ask for customer references.

4. What are the Common Load Capacities and Span Lengths?

– Load capacities generally range from 5 tons to over 100 tons, and spans can vary widely, commonly up to 40 meters or more, depending on specific requirements.

5. What Factors Affect the Price of Truss Gantry Cranes?

– The price is influenced by load capacity, span length, lifting height, materials used, customization requirements, and additional features like remote control or automation.

6. How Long Does It Take to Manufacture and Deliver a Truss Gantry Crane?

– Typically, manufacturing can take 4-12 weeks based on complexity and load capacity, with additional 2-6 weeks for shipping, depending on location and shipping method.

7. What are the Key Terms in a Supply Contract?

– Ensure the contract includes terms on delivery schedules, payment conditions, warranty, after-sales service, installation and testing, and penalties for delays or defects.

8. Is On-Site Installation and Training Provided?

– Many Chinese manufacturers offer on-site installation and training services either directly or through local partners. Confirm this service and associated costs beforehand.

9. What Maintenance and After-Sales Services are Available?

– Most reputable manufacturers provide maintenance guidelines, spare parts supply, and after-sales support. Verify the duration and terms of these services in the contract.

10. Are There Any Import Restrictions or Licensing Requirements?

– Import restrictions vary by country. It’s essential to check local import regulations and whether special licenses or certifications are required for importing truss gantry cranes.