wall mounted jib crane Safety Certifications

Wall-mounted jib cranes are essential tools in various industries, providing a seamless way to move heavy loads within a workspace. Ensuring their safety is paramount, and several certifications and standards help guarantee this:

1. OSHA (Occupational Safety and Health Administration):

– Adheres to OSHA standards for safe crane operation, specifically OSHA 1910.179, which addresses overhead and gantry cranes. Compliance ensures safe design, installation, maintenance, and operation.

2. ASME (American Society of Mechanical Engineers):

– ASME B30.11: Covers safety standards for monorails and underhung cranes, impactful for wall-mounted jib cranes.

– ASME B30.2: Overhead and gantry cranes including jib attachments, emphasizing the importance of manufacturing standards and safe use.

3. ANSI (American National Standards Institute):

– ANSI/ASSP A10.18: Focuses on safety requirements for crane operation, including jib cranes. It offers guidelines on operational safety and effective load handling.

4. CMAA (Crane Manufacturers Association of America):

– CMAA Specification No. 74: Pertains to jib cranes, detailing design specifications, performance requirements, and safety standards.

5. ISO (International Organization for Standardization):

– ISO 9001: Ensures a comprehensive quality management system, crucial for manufacturers. It assures consistent product quality and safety standards.

– ISO 14001: Environmental management standards, highlighting the importance of safety and environmental considerations during crane manufacturing and operation.

6. NEMA (National Electrical Manufacturers Association):

– For cranes with electrical components, NEMA ensures that the electrical parts meet stringent safety criteria.

Incorporating these certifications and standards in the design, installation, and maintenance of wall-mounted jib cranes helps mitigate risks, ensuring they operate safely and efficiently in various environments. Regular training, inspections, and adherence to these guidelines are crucial for maintaining a high safety standard.

List Reference Technical Parameters of “wall mounted jib crane”

Certainly! Here are the key reference technical parameters for a wall-mounted jib crane:

1. Capacity:

– Range: Typically from 100 kg to 10,000 kg (0.1 to 10 metric tonnes).

2. Span (Jib Length):

– Range: Usually between 2 to 10 meters.

3. Slew Range:

– Degrees of rotation: Generally up to 180°.

4. Height Under Boom:

– Distance from the floor to the underside of the jib arm, usually between 2 to 6 meters depending on installation specifics and user needs.

5. Mounting Height:

– Distance from the floor to the mounting point on the wall, tailored to application requirements.

6. Construction Material:

– Typically made of high-strength steel to ensure durability under load.

7. Power Supply:

– Electrical Requirements: Usually available in various configurations such as 220V/380V, single-phase or three-phase, 50Hz or 60Hz depending on the operational environment.

8. Motor Specifications:

– Motor types: Standard or explosion-proof.

– Power ratings: Typically range from 0.5 kW to 5 kW.

9. Control System:

– Options: Manual (via push-pull trolley) or electric (with a motorized trolley).

– Types: Pendant control, radio remote control.

10. Lifting Speed:

– Range: Often from 0.8 m/min to 8 m/min, adjustable based on the hoist specification.

11. Jib Arm Type:

– Variants: Standard or articulated, depending on the required maneuverability.

12. Safety Features:

– Includes overload limiters, emergency stop buttons, and limit switches for hoist travel and boom rotation.

13. Installation Requirements:

– Wall or column must have sufficient structural integrity to support the jib crane and its loads.

These parameters provide an essential guideline for selecting and installing a wall-mounted jib crane that suits specific application needs.

List Product features of “wall mounted jib crane”

Certainly! Here are the product features of a wall-mounted jib crane:

1. Space Efficiency: Wall-mounted jib cranes save valuable floor space, making them ideal for congested environments.

2. Versatile Positioning: They can be mounted on various wall heights, providing flexible lifting and positioning capabilities.

3. Robust Construction: Typically made from high-strength steel to handle substantial weights securely and safely.

4. High Capacity: Can support substantial load capacities, generally ranging from a few hundred pounds to several tons, depending on the model.

5. Swivel Range: Offers a wide degree of rotation, often up to 180 degrees, providing a large operational area.

6. Ease of Installation: Designed for straightforward mounting to existing walls or columns, simplifying setup processes.

7. Customizable Options: Available with different arm lengths, mounting heights, and configurations to suit specific needs.

8. Electric or Manual Operation: Options for both electric hoists for ease of use or manual operations for simplicity and cost-effectiveness.

9. Adjustable Heights: Some models offer adjustable boom heights to accommodate different lifting requirements.

10. Durability and Longevity: Built to withstand rigorous industrial environments with minimal maintenance.

11. Safety Features: Often equipped with safety locks, overload protection, and ergonomic designs to ensure operator safety.

12. Smooth Operation: Designed for easy and precise load control with smooth rotation and lifting mechanisms.

13. Compliance: Meets industry standards and regulations for safety and performance in lifting equipment.

14. Corrosion Resistance: Coated with anti-corrosive materials, making them suitable for outdoor or harsh environments.

15. Minimal Swing: Engineered to reduce unwanted swing, ensuring precise load placement.

16. Cost-Effective: A budget-friendly solution for lifting needs compared to floor-mounted cranes or gantry systems.

17. Ergonomic: Enhances workplace ergonomics by reducing the need for manual lifting and positioning of heavy loads, thereby reducing the risk of injury.

These features make wall-mounted jib cranes a valuable tool in various industrial and commercial settings, promoting efficiency, safety, and productivity.

List Application of “wall mounted jib crane”

Applications of Wall Mounted Jib Crane

Wall mounted jib cranes are versatile material handling devices used across various industries due to their space-saving design and high efficiency. Here are some common applications:

1. Manufacturing Facilities: Used for tasks such as moving heavy components along assembly lines, loading and unloading machinery, and handling raw materials or finished products.

2. Warehouses: Ideal for lifting and moving bulky items from storage racks to pallet trucks or conveyors, thereby optimizing space and improving workflow.

3. Workshops and Maintenance Areas: Assist in maintaining and repairing equipment, such as engines or heavy machinery, by providing localized lifting capabilities.

4. Automotive Industry: Facilitate the handling of heavy car parts, such as engines and transmissions, within assembly lines, repair bays, or storage areas, ensuring efficiency and safety.

5. Marine and Ports: Employed to load and unload heavy goods, such as containers or bundled materials, onto ships or dockside trucks, enhancing operational efficiency.

6. Construction Sites: Used for lifting construction materials such as steel beams, tools, and equipment, enabling safer and more streamlined operations.

7. Aerospace Sector: Supports handling of aircraft components like engines, wings, and other large parts during manufacturing or maintenance processes.

8. Pharmaceutical and Chemical Plants: Assist in moving large drums, reactors, or containers filled with chemicals, ensuring safe handling and preventing contamination.

9. Food Processing Units: Aid in transporting large quantities of raw ingredients or packaged goods, ensuring hygienic and efficient material handling.

10. Mining Operations: Utilized for lifting heavy mining tools, machinery, and extracted minerals, facilitating operations in confined spaces.

By leveraging wall mounted jib cranes, industries can enhance operational efficiency, safety, and productivity, making them an invaluable asset in various material handling applications.

List Various Types of “wall mounted jib crane”

Wall-mounted jib cranes are invaluable in environments where floor space is limited or where material handling needs are specific. Here are various types of wall-mounted jib cranes:

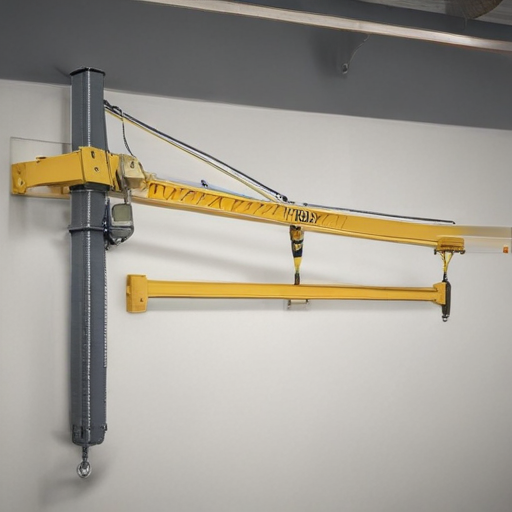

1. Cantilever Wall-Mounted Jib Crane:

– Description: Features a beam that extends out from the wall or column, with a full 180-degree rotation.

– Advantages: Maximizes floor space and provides a clear span for lifting and moving materials.

– Applications: Ideal for warehouse loading zones and workstations adjacent to walls.

2. Wall-Bracket Jib Crane:

– Description: Uses a bracket attached to the wall or a vertical support combined with a horizontal arm extending outward.

– Advantages: Simplified design and cost-effective. Suitable for lighter loads.

– Applications: Suitable for use above workbenches or for mounting close to ceilings.

3. Articulating Wall-Mounted Jib Crane:

– Description: Features multiple pivot points on the boom, allowing for more complex movement patterns.

– Advantages: Provides increased flexibility and precision. Can reach around obstacles.

– Applications: Perfect for tasks requiring maneuverability and for working around corners or machinery.

4. Mast Type Wall-Mounted Jib Crane:

– Description: Uses a vertical mast mounted to the wall and a horizontal arm that can rotate around the mast.

– Advantages: Offers a stable and robust lifting solution with significant height and outreach.

– Applications: Suitable for heavy-duty applications, such as foundries and heavy manufacturing.

5. Workbench Jib Crane:

– Description: A compact jib crane mounted on or near a workbench with limited outreach.

– Advantages: Compact, easy to install, and great for precision work.

– Applications: Ideal for small parts assembly, repair work, and light fabrication.

6. I-Beam Jib Crane:

– Description: Utilizes an I-beam for the jib arm, providing substantial lifting capacity.

– Advantages: Durable and capable of handling heavier loads.

– Applications: Frequently used in industrial settings, such as steel fabrication shops and heavy equipment maintenance areas.

Each type offers unique advantages depending on the application, space constraints, and load requirements, making wall-mounted jib cranes versatile solutions for material handling challenges.

wall mounted jib crane Accessories Upgrades and Custom Manufacturing Options

Wall-mounted jib cranes are versatile tools widely used in industrial settings to lift and move heavy loads with precision. To enhance their functionality and tailor them to specific requirements, several accessories, upgrades, and custom manufacturing options are available:

Accessories

1. Electric Hoists: Adding an electric hoist can automate lifting, making operations quicker and more efficient.

2. Festoon Systems: These systems neatly manage electrical cables and air hoses, reducing wear and tear and enhancing safety.

3. Hooks and Lifting Attachments: Swivel hooks, C-hooks, magnets, and vacuum lifters can be attached to accommodate various types of loads.

4. Trolley Options: Manual or motorized trolleys can be added for smoother and more precise load positioning along the jib arm.

5. Control Systems: Remote control systems and pendant stations allow for safer and more convenient operation from a distance.

Upgrades

1. Capacity Enhancement: Strengthening the crane’s structure or upgrading components can increase its weight capacity.

2. Extended Reach: Customizing the length of the jib arm can extend its operational reach to suit large work areas.

3. 360-degree Rotation: Upgrading to a full-circle rotation allows for greater flexibility and coverage.

4. Anti-Slip Surface Treatments: Adding these can improve safety by reducing the risk of accidents.

Custom Manufacturing Options

1. Material and Finish: Cranes can be manufactured using stainless steel or coated with special finishes for enhanced durability and corrosion resistance.

2. Mounting Configurations: Custom mounting brackets can be designed to fit unique structural conditions or constraints.

3. Ergonomic Design: Tailor the height and control interfaces for better operator comfort and efficiency.

4. Environmental Adaptations: Cranes can be customized to withstand harsh environments such as extreme temperatures, high humidity, or exposure to chemicals.

By leveraging these accessories, upgrades, and custom options, wall-mounted jib cranes can be effectively tailored to meet specific operational demands, enhancing productivity, safety, and versatility in any industrial setting.

List Quality Control and The Manufacturing Process of “wall mounted jib crane”

Quality Control in Wall Mounted Jib Crane Manufacturing

1. Material Inspection: Verify raw materials’ compliance with quality standards. Check for defects and ensure they meet specifications for strength and durability.

2. Dimensional Inspection: Measure components to ensure they align with design tolerances. Tools like calipers, micrometers, and gauges are used.

3. Welding Quality: Conduct non-destructive testing (NDT) such as ultrasonic or magnetic particle inspections to ensure welds are solid and defect-free.

4. Load Testing: Perform static and dynamic load tests to verify the crane can handle its rated capacity without deformation or failure.

5. Surface Treatment: Inspect surface coatings for uniformity, thickness, and adherence to prevent corrosion and ensure longevity.

6. Electrical System Inspection: For cranes with motorized features, verify electrical systems and controls are functioning as designed.

7. Assembly Verification: Ensure all parts fit together precisely during assembly. Confirm bolt torques and component alignments.

8. Documentation: Maintain detailed records of inspections, tests, and quality assurance measures. This ensures traceability and accountability.

Manufacturing Process of Wall Mounted Jib Crane

1. Design: Create CAD models and engineering drawings, incorporating customer specifications and safety standards.

2. Material Procurement: Source high-quality steel and other necessary materials based on design requirements.

3. Cutting and Shaping: Use CNC machines, plasma cutters, or saws to cut steel components to the required dimensions. Bend and shape parts as needed.

4. Welding: Weld the main components, such as the arm, mounting bracket, and support structure, using certified welding techniques.

5. Machining: Machine parts for precision, such as bearing housings and mounting holes, to ensure proper fits.

6. Surface Treatment: Apply surface treatments like galvanizing or painting to protect against corrosion and enhance appearance.

7. Assembly: Assemble the crane components, including the arm, mounting bracket, bearings, and if necessary, motorized systems.

8. Testing and Inspection: Conduct rigorous quality control checks, including load testing, dimensional verification, and NDT of welds.

9. Packaging and Shipping: Safely package the crane and include all necessary documentation before shipping to the customer.

By integrating stringent quality control measures throughout the manufacturing process, the reliability and safety of wall mounted jib cranes are assured.

How to use “wall mounted jib crane”

A wall-mounted jib crane is a versatile material handling device commonly used in workshops, warehouses, and manufacturing environments. Follow these steps to use it safely and efficiently:

1. Inspection:

– Before operating, inspect the crane for any visible damage or wear.

– Ensure the mounting and hardware are secure.

– Check that the hoist, trolley, and electrical system (if applicable) are functioning correctly.

2. Preparation:

– Clear the area of any obstacles that may interfere with crane operation.

– Verify the load weight does not exceed the crane’s rated capacity.

3. Operation:

– Attach the load to the hoist using appropriate lifting slings or other approved attachments.

– Double-check that the load is secure and balanced.

– Use the control system (manual or remote) to lift the load slowly off the ground.

4. Movement:

– Gently push or use the control mechanism to move the jib arm horizontally, positioning the load where needed.

– For precise movements, use both the rotation of the jib arm and the trolley system.

– Move slowly to prevent swinging or abrupt movements.

5. Lowering the Load:

– Position the load above the desired location.

– Gradually lower the load, ensuring it is stable and secure as it touches down.

– Once settled, detach the load from the hoist.

6. Post-Operation:

– Safely park the crane arm in its designated position.

– Conduct a brief inspection to ensure the crane has not been damaged during operation.

– Report any issues to maintenance personnel for repairs.

Safety Tips:

– Always wear appropriate personal protective equipment (PPE).

– Never exceed the crane’s load capacity.

– Keep hands and feet clear of moving parts.

– Do not stand under a suspended load.

By following these steps, you can operate a wall-mounted jib crane effectively while maintaining a safe working environment.

“wall mounted jib crane” Comparative Analysis

Comparative Analysis of Wall-Mounted Jib Cranes

Wall-mounted jib cranes are pivotal in material handling, providing versatile lifting solutions across industries. The focus here is a comparative analysis of two key types: wall-mounted cantilever jib cranes and wall-mounted tie-rod jib cranes.

#### Wall-Mounted Cantilever Jib Cranes

Design & Structure: These cranes feature a horizontal boom attached to a wall or vertical support structure. The cantilever design allows the boom to support loads independently.

Capacity: Typically supports lighter loads, up to 5 tons.

Outreach: Known for a longer outreach, ranging from 10 to 20 feet.

Installation: Requires sturdy wall or column structures to ensure stability, and generally easier to install compared to tie-rod types.

Flexibility: Offers considerable horizontal motion and rotation, up to 200 degrees.

Best For: Ideal for areas with limited floor space, such as workshops and production lines.

#### Wall-Mounted Tie-Rod Jib Cranes

Design & Structure: Includes a horizontal boom supported at one end by a vertical mast and at the other by a tie-rod connected to the wall.

Capacity: Can handle heavier loads, typically up to 10 tons.

Outreach: Shorter outreach compared to cantilever types, generally about 5 to 15 feet.

Installation: More complex due to tie-rod attachment; requires precise alignment and strong anchorage points both on the wall and ceiling.

Flexibility: Provides an extensive range of motion with the potential for 180-degree rotation but limited vertical flexibility due to the tie-rod.

Best For: Best suited for environments where additional weight support is necessary, such as warehouses and manufacturing plants.

Conclusion

Wall-mounted cantilever jib cranes are preferable for lighter loads and simpler installations with extended reach, offering flexibility in restricted spaces. Conversely, wall-mounted tie-rod jib cranes excel in handling heavier loads with robust stability, albeit with a shorter outreach and more demanding installation. Choosing the appropriate crane type hinges on load requirements, workspace constraints, and installation feasibility.

“wall mounted jib crane” Warranty and Support

Wall Mounted Jib Crane Warranty and Support

Warranty Coverage:

Our wall mounted jib cranes come with a comprehensive one-year warranty from the date of purchase. This warranty covers any defects in materials or workmanship under normal use and conditions. During this period, we will repair or replace, at our discretion, any part found to be defective. The warranty does not cover damage due to misuse, neglect, unauthorized modifications, or improper installation.

Support Services:

We provide a range of support services to ensure you get the most out of your wall mounted jib crane:

1. Installation Assistance: Our team can guide you through the installation process to guarantee the crane is set up correctly and safely.

2. Technical Support: Reach out to our dedicated support team via phone, email, or our online portal for any technical assistance or troubleshooting needs. Our experts are available to help diagnose and resolve any issues promptly.

3. Maintenance Guidelines: We offer detailed maintenance schedules and guidelines to help keep your crane in optimal condition. Regular maintenance can significantly extend the lifespan of your equipment.

4. Training Resources: Access our online training modules and user manuals to educate yourself and your team on proper usage and safety protocols.

Extended Warranty Options:

For added peace of mind, extended warranty packages are available. These packages extend coverage beyond the standard one-year term and include additional benefits such as annual inspections and preventive maintenance services.

Contact Information:

For any warranty claims or support inquiries, please contact our customer service department at [[email protected]](mailto:[email protected]) or call us at 1-800-123-4567. Our team is committed to providing swift and effective solutions to minimize any downtime and keep your operations running smoothly.

With our robust warranty and dedicated support, you can have confidence in the reliability and longevity of our wall mounted jib cranes.

List “wall mounted jib crane” FAQ

Wall Mounted Jib Crane FAQ

1. What is a wall mounted jib crane?

A wall mounted jib crane is a type of lifting device that is installed on a wall or pillar. It consists of a horizontal jib arm that extends from the mounting point and can rotate to lift and move loads within a designated area.

2. What are the typical applications?

Common applications include workshops, manufacturing plants, and warehouses where lifting and moving heavy materials is necessary. They are used for tasks such as loading and unloading, assembly operations, and positioning workpieces.

3. What are the weight capacities?

The weight capacities of wall mounted jib cranes vary depending on the model and manufacturer, typically ranging from 500 lbs to 5 tons. Always consult the manufacturer’s specifications to determine the appropriate crane for your needs.

4. How far can the jib arm extend?

The extension of the jib arm, or boom, can range from a few feet to over 20 feet. The exact reach depends on the model and the installation environment.

5. What is the rotation angle?

Most wall mounted jib cranes offer a rotation angle of 180 degrees, although some models may provide up to 200 degrees or more. The rotation capability allows for greater flexibility in handling loads.

6. How is the crane mounted?

The crane is typically bolted to a wall or column using mounting brackets. Proper installation is crucial for ensuring stability and safety. It’s often advisable to have the installation performed by a professional.

7. What kind of maintenance is required?

Regular inspection and maintenance are essential for the crane’s longevity and safety. This includes checking for wear and tear, lubricating moving parts, and ensuring that bolts and connections are secure.

8. Is it suitable for outdoor use?

While some wall mounted jib cranes are designed for outdoor use with weather-resistant materials, most are intended for indoor applications. Always verify with the manufacturer if the crane is suitable for outdoor environments.

9. Can the crane be customized?

Many manufacturers offer customization options, such as specific jib arm lengths, weight capacities, and rotation capabilities to meet unique requirements.

10. What safety features are included?

Typical safety features include overload protection, safety stops, and durable construction. Regular operator training and adherence to safety guidelines are also critical for safe operation.

Top 10 FAQ with answer about wall mounted jib crane for Buyer Sourcing from China

1. What is a wall-mounted jib crane?

A wall-mounted jib crane is a type of crane that is attached directly to a building’s wall or structural column. It provides a flexible lifting solution within a specific area and can rotate typically up to 180 degrees.

2. What are the advantages of a wall-mounted jib crane?

Wall-mounted jib cranes save floor space, are cost-effective, and provide easy installation. They also improve workflow efficiency by allowing quick and flexible material handling.

3. What is the lifting capacity of wall-mounted jib cranes?

Lifting capacities can vary, but common models range from 250 kg to 5 tons. It’s essential to check specific manufacturer specifications for exact capacities.

4. How do I ensure the crane’s compatibility with my workspace?

Measure the area where the crane will be installed, considering both the wall structure and the rotational angle required. Provide these details to the supplier to ensure the crane fits your workspace.

5. What information should I provide to suppliers for accurate quotations?

Offer details on lifting capacity, length of the jib arm, height of the lift, rotation type, and any specific customization needs like motorization or attachment types.

6. How long is the typical lead time for sourcing from China?

Lead times can vary based on the manufacturing process and customization, but standard models usually have a lead time of 4-8 weeks.

7. What certifications should I look for when sourcing from China?

Ensure the crane complies with international standards such as ISO, CE, or other relevant certifications to guarantee quality and safety.

8. What are the shipping options and costs?

Options often include sea freight, air freight, or rail, with costs depending on the weight, volume, and urgency. Discuss this with the supplier to get accurate estimates.

9. What are the common maintenance needs for a wall-mounted jib crane?

Regular inspections for wear and tear, lubrication of moving parts, and checking for structural integrity are essential. Follow the manufacturer’s maintenance schedule for the best performance.

10. Can the supplier provide after-sales service and technical support?

Yes, many reputable suppliers offer after-sales services, including installation guidance, technical support, and spare parts availability. Confirm these services before purchasing to ensure reliable assistance.