workstation overhead crane Safety Certifications

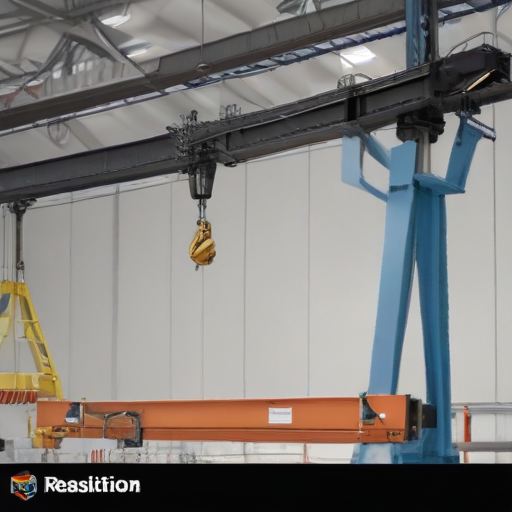

Workstation overhead cranes are pivotal in enhancing productivity and safety in industrial settings, but they must meet stringent safety certifications to ensure operational safety and reliability. Key certifications and standards for these cranes include:

1. OSHA (Occupational Safety and Health Administration): OSHA sets general industry standards to ensure the health and safety of employees using overhead cranes. Compliance with OSHA guidelines is mandatory in the U.S. and involves rigorous inspection and maintenance programs.

2. ASME B30.2: The American Society of Mechanical Engineers (ASME) sets standards for overhead and gantry cranes, including safety requirements for the design, maintenance, training, and operation. ASME B30.2 is widely recognized and respected within the industry.

3. FEM (Fédération Européenne de la Manutention): In Europe, certification according to FEM standards ensures that workstation cranes comply with the latest safety and performance guidelines. FEM 1.001 outlines principles for the design and classification of cranes.

4. ISO 9001: This international standard specifies requirements for quality management systems and ensures that organizations consistently provide products that meet customer and regulatory demands. Adherence to ISO 9001 by crane manufacturers indicates a commitment to quality and safety.

5. CE Marking: For cranes operating within the European Economic Area (EEA), the CE mark indicates compliance with EU safety, health, and environmental protection requirements. The Machinery Directive 2006/42/EC is particularly relevant for workstation overhead cranes.

6. CMAA (Crane Manufacturers Association of America): CMAA guidelines provide detailed recommendations for the construction, installation, use, and maintenance of overhead traveling cranes. CMAA Crane Duty Classifications (Classes A-F) help determine the appropriate crane based on application and usage frequency.

Ensuring that workstation overhead cranes are certified under these standards guarantees not only regulatory compliance but also enhances safety, performance, and longevity, thereby protecting workers and minimizing operational risks.

List Reference Technical Parameters of “workstation overhead crane”

A workstation overhead crane is a versatile lifting device commonly used in manufacturing units, warehouses, and assembly areas for material handling. Here are key technical parameters to consider:

1. Load Capacity: Defines the maximum weight the crane can safely lift, typically ranging from a few hundred kilograms to several tons.

2. Span Length: The horizontal distance covered by the crane, usually between 2 meters to over 10 meters, depending on the specific application needs.

3. Lift Height: The maximum vertical distance the hoist can move the load upwards, often varying from 2 to 10 meters or more.

4. Crane Type:

– Bridge Cranes: Feature a movable bridge connected to runways.

– Gantry Cranes: Consist of a bridge supported by freestanding legs.

5. Hoist Type: Various hoist mechanisms can be used, including:

– Electric Hoists: Provide faster and more efficient lifting.

– Manual Hoists: Suitable for lighter loads and limited budgets.

– Air-Powered Hoists: Ideal for explosive or hazardous environments.

6. Rail Type:

– Top-running: Positioned on top of a runway.

– Under-running: Suspended from a runway beam, allowing more workspace.

7. Power Supply: Specification of voltage and phase requirements, with common options being 220V/380V, single-phase or three-phase.

8. Speed:

– Lifting Speed: Rate at which the hoist can raise or lower a load.

– Travel Speed: Speed at which the crane moves along the runway or bridge.

9. Control Options:

– Pendant Controls: Handheld device connected to the crane.

– Wireless Remote: Enables operation from a distance.

– Cabin Controls: For larger cranes, allowing an operator to sit and control.

10. Duty Cycle: Usage frequency and duration, influencing motor and component selection.

11. Safety Features:

– Overload Protection: Prevents lifting beyond the rated capacity.

– Emergency Stop: Instant halting in case of trouble.

– Limit Switches: Prevents movement beyond predetermined points.

By considering these technical parameters, you can select the appropriate workstation overhead crane tailored to your operational requirements and ensure efficient, safe, and reliable material handling.

List Product features of “workstation overhead crane”

A workstation overhead crane is an essential piece of equipment in various industrial and manufacturing settings. These cranes enhance efficiency, safety, and workflow within work environments. Below are some key features of a workstation overhead crane:

1. Ergonomic Design: Built to minimize physical strain on workers, these cranes often feature user-friendly controls and are easy to operate.

2. High Load Capacity: Capable of handling heavy loads, typically ranging from a few hundred pounds to several tons, depending on the model and configuration.

3. Modular Construction: Designed with modularity in mind, allowing for easy installation, expansion, and reconfiguration to suit different workspace requirements.

4. Flexible Configurations: Available in various configurations, such as single-girder or double-girder designs, and can be customized for specific applications.

5. Smooth and Precise Movement: Equipped with advanced trolley systems and hoists for smooth, precise, and controlled lifting and positioning of loads.

6. Durable Materials: Constructed from high-strength steel and other durable materials to withstand rigorous industrial use.

7. Safety Features: Incorporates advanced safety mechanisms, including emergency stop buttons, overload protection, anti-sway technology, and secure lifting mechanisms.

8. Easy Maintenance: Designed for low maintenance with accessible components that allow for straightforward service and inspection.

9. Automation Compatibility: Can be integrated with automated systems for improved efficiency and reduced human intervention.

10. Versatile Application: Suitable for a variety of industries, including manufacturing, assembly, warehousing, and automotive sectors.

11. Efficient Space Utilization: Overhead design maximizes floor space, allowing for more workspace and better organization within the facility.

12. Energy Efficiency: Often built with energy-efficient motors and systems to reduce operational costs and environmental impact.

13. Noise Reduction: Incorporates design elements that minimize operational noise, contributing to a quieter and more pleasant work environment.

In summary, workstation overhead cranes are versatile, efficient, and essential tools for modern industrial operations, offering advanced features that improve productivity, safety, and ergonomics.

List Various Types of “workstation overhead crane”

Sure! Workstation overhead cranes are vital for material handling in various industrial settings. They enhance efficiency, safety, and productivity. Here are some types:

1. Freestanding Workstation Cranes:

– Description: These cranes are independent structures that do not rely on the building for support.

– Applications: Ideal for spaces where overhead support structures are unavailable or insufficient.

2. Ceiling-Mounted Workstation Cranes:

– Description: These are suspended from the ceiling, maximizing floor space.

– Applications: Suitable for facilities with robust roof support, allowing free movement underneath.

3. Monorail Systems:

– Description: Utilizes a single rail for hoist movement, following a fixed path.

– Applications: Perfect for assembly lines, where materials need to be transported along a predefined route.

4. Bridge Cranes:

– Description: These feature a bridge that travels on fixed runways along the length of the crane.

– Applications: Versatile in covering large rectangular areas, common in manufacturing and warehousing.

5. Jib Cranes:

– Description: Consists of a horizontal arm (jib) that supports a hoist, which can move in a circular area.

– Applications: Used in workstations needing localized lifting, like tooling or assembly areas.

6. Gantry Cranes:

– Description: Portable cranes supported by freestanding legs that can move along fixed paths.

– Applications: Useful when lifting tasks need to be performed across different workstations.

7. Articulating Arm Cranes:

– Description: Features an arm with multiple joints, allowing greater flexibility and reach.

– Applications: Ideal for precise positioning, common in small parts assembly or robotic servicing.

Each type offers distinct advantages based on structural capabilities and application needs, catering to various industrial processes.

List Application of “workstation overhead crane”

A workstation overhead crane is a versatile lifting solution commonly used in various industries to facilitate efficient material handling and improve workplace safety and productivity. Here are some key applications:

1. Manufacturing: Essential for moving heavy components or assemblies along production lines. Used in automotive, aerospace, and electronics industries to position parts precisely and efficiently.

2. Warehousing and Distribution: Facilitates the unloading and loading of heavy goods, reducing manual handling and speeding up inventory management processes.

3. Maintenance and Repair: Used in workshops and service centers for lifting engines, machinery, and other heavy equipment during repairs, reconditioning, or routine maintenance.

4. Metalworking and Fabrication: Assists in handling heavy metal sheets, pipes, and fabricated components. Frequently used for loading and unloading CNC machines, welding stations, and cutting tables.

5. Construction: Helps in pre-building facilities where large components, like concrete slabs or steel beams, need to be moved and positioned accurately.

6. Chemical and Pharmaceutical: Assists in handling heavy containers, drums, and equipment. Ensures safe and efficient movement of hazardous materials and delicate chemicals without manual interference.

7. Food and Beverage: Used for moving large raw material containers, heavy machinery parts, and packaging units within the production plant.

8. Automotive Service Centers: Used for lifting vehicle parts, engines, and gearboxes, ensuring safer and efficient service and repair operations.

9. Assembly Lines: Facilitates the movement of products between different stations, enhancing workflow efficiency and reducing bottlenecks.

10. Renewable Energy: Employed in the assembly and maintenance of wind turbines and solar panels, where precise and safe handling of large components is crucial.

Incorporating workstation overhead cranes significantly reduces worker fatigue and injury risks while improving operational efficiency and productivity across diverse industry applications.

List Buyer Types of “workstation overhead crane”

Buyers of workstation overhead cranes typically belong to various industries and sectors, each with specific needs for material handling and workflow efficiency. Here’s a list of common buyer types for these cranes:

1. Manufacturing Plants: These buyers need cranes for lifting and moving heavy materials, machinery, and components during production processes.

2. Warehouses and Distribution Centers: Cranes are essential for handling large shipments, loading and unloading goods, and organizing inventory efficiently.

3. Automotive Industry: In this sector, workstation cranes aid in assembling vehicles, moving engines, and handling other heavy automotive parts.

4. Aerospace Industry: Precision and safety are crucial, necessitating cranes for handling large but delicate components such as aircraft fuselages and engines.

5. Metalworking Shops: Cranes are used for lifting and positioning heavy metal sheets, bars, and fabrication parts to ensure precision in machining and welding tasks.

6. Energy Sector: Oil & gas companies, renewable energy firms, and power plants use cranes to handle large infrastructure components such as turbines, transformers, and drilling equipment.

7. Construction Companies: Workstation cranes assist in lifting building materials, equipment, and temporary structures on construction sites.

8. Food and Beverage Processing: Facilities use cranes to manage heavy processing equipment, transport large batches of raw materials, and streamline production lines.

9. Pharmaceutical Industry: Cranes help in handling and moving heavy containers, large batches of drugs, and equipment safely and cleanly.

10. Shipping and Logistics: Ports and shipping yards employ cranes for loading and unloading cargo efficiently, improving turnaround times.

These diverse buyers invest in workstation overhead cranes to enhance productivity, ensure safety, and optimize their material handling processes.

List “workstation overhead crane” Project Types for Different Industries

A workstation overhead crane is a versatile lifting solution utilized across various industries to improve efficiency, safety, and productivity. Here are some common project types where workstation overhead cranes are employed:

1. Manufacturing:

– Assembly Lines: Facilitates the movement of heavy components in automotive, aerospace, or electronics manufacturing.

– Machining Centers: Assists in handling raw materials and finished products between machines.

2. Warehousing and Distribution:

– Inventory Management: Simplifies the stacking, storing, and retrieving of heavy items.

– Loading and Unloading: Improves the speed and safety of moving goods to and from delivery trucks.

3. Metalworking:

– Fabrication Shops: Used to lift and move heavy sheets, plates, and metal structures.

– Foundries: Assists in handling molten metal and finished cast products.

4. Construction:

– Precast Concrete Yards: Handles large concrete pieces such as beams and columns.

– Modular Building Assembly: Lifts and positions pre-fabricated building sections.

5. Energy Sector:

– Wind Turbine Manufacturing: Moves large components such as blades and nacelles.

– Oil & Gas: Assists in assembling and maintaining heavy drilling equipment.

6. Automotive:

– Engine Assembly: Facilitates the precise placement of engines and other heavy components.

– Body Shops: Helps in the movement of vehicle frames and parts during manufacturing or repair.

7. Pharmaceuticals and Chemicals:

– Laboratory Equipment Handling: Ensures safe and precise movement of delicate equipment.

– Chemical Processing: Handles heavy containers and tanks of raw materials and finished products.

8. Food and Beverage:

– Processing Lines: Moves heavy mixing bowls, containers, and packaging materials.

– Maintenance Areas: Assists in handling heavy machinery and equipment for cleaning and repairs.

By catering to the specific needs of different industries, workstation overhead cranes significantly enhance operational efficiency and safety, making them an indispensable asset for various industrial applications.

workstation overhead crane Accessories Upgrades and Custom Manufacturing Options

Upgrading a workstation overhead crane with the right accessories and custom manufacturing options can significantly enhance productivity, safety, and versatility. Here are some key upgrades to consider:

1. Runway Systems: Upgrading the crane’s runway systems can provide smoother and more reliable operation. Options include enclosed track systems for reduced rolling resistance and freestanding runway structures for flexibility in various environments.

2. End Trucks and Trolleys: High-quality end trucks and trolleys with advanced features like variable speed controls and ergonomic designs can improve material handling efficiency and reduce operator fatigue.

3. Workstation Bridge Cranes: Custom bridge cranes can be tailored to specific workspace dimensions and load requirements, ensuring optimal performance and maximum coverage.

4. Hoists: Electric, pneumatic, or manual hoists can be customized with additional features like dual-speed operation, precise positioning controls, and increased lifting capacities.

5. Powered Rotating Cranes: Adding powered rotation capabilities can enhance maneuverability and make it easier to position loads accurately.

6. Safety Accessories: Safety enhancements such as anti-collision systems, load limiters, and emergency stop functions are vital for preventing accidents and ensuring compliance with safety standards.

7. Ergonomic Controls: Upgrading to ergonomic controls, including wireless remote controls or pendant stations with intuitive interfaces, can improve operational efficiency and reduce strain on operators.

8. Custom Fabrication: Tailor-made components like custom-sized beams, columns, or brackets can adhere precisely to your operational needs. This ensures the workstation fits seamlessly into your workflow.

9. Environmental Preparation: Options like weatherproofing and corrosion-resistant materials extend the crane’s lifespan in harsh environments such as outdoor or corrosive industrial settings.

Investing in these accessories and custom manufacturing options ensures your workstation overhead crane is not only more efficient and easier to use but also safer and better suited to your specific operational demands.

List Quality Control and The Manufacturing Process of “workstation overhead crane”

Manufacturing Process of Workstation Overhead Crane

1. Design and Engineering:

– Initial design based on customer requirements and standards (e.g., ANSI, OSHA).

– Detailed engineering blueprints created using CAD software.

– Load calculations and material selection (steel gradation, welding specifications).

2. Material Procurement:

– High-quality raw materials sourced from certified suppliers.

– Incoming material inspection for defects and compliance with specifications.

3. Cutting and Machining:

– CNC machines and laser cutters used for precision cutting and machining.

– Components shaped to exact dimensions as per design specifications.

4. Welding and Assembly:

– Certified welders perform welding according to industry standards.

– Components assembled including girders, trolleys, hoists, and end trucks.

5. Surface Treatment:

– Sandblasting to remove impurities.

– Applying anti-corrosive coatings and paint for durability and longevity.

6. Electrification:

– Electrical components like motors, wiring, and control systems installed.

– Compliance with electrical safety standards ensured.

7. Inspection and Testing:

– Static and dynamic load testing to verify strength and functionality.

– Electrical systems tested for reliability and safety.

8. Packaging and Delivery:

– Final components packaged securely.

– Transportation arranged to deliver crane to customer site.

Quality Control Measures

1. Design Validation:

– Prototypes tested and validated against initial design specifications.

2. Material Testing:

– Use of spectrometers and ultrasonic testing to verify material quality.

– Inspect raw materials for compliance with mechanical and chemical properties.

3. In-Process Inspections:

– Regular audits during cutting, welding, and assembly processes.

– Dimensional checks using calipers and gauges to ensure precision.

4. Welding Quality Control:

– Non-destructive testing methods (NDT) like X-ray and ultrasonic tests on weld joints.

– Visual inspection to catch defects like cracks or undercut.

5. Load Testing:

– Overload and cycle tests to assess crane’s performance under maximum load.

– Checking operational fluidity and response times.

6. Final Inspection:

– Comprehensive inspection checklist covering all aspects of the crane.

– Functional testing of all electrical and mechanical systems.

7. Customer Feedback and Continuous Improvement:

– Collect customer feedback and incorporate insights into the continuous improvement process.

– Regular training and updates for staff on new quality control techniques.

How to use “workstation overhead crane”

A workstation overhead crane is typically used to lift and move heavy materials safely and efficiently within a designated work area. Here’s a step-by-step guide on how to use one:

1. Initial Setup and Inspection:

– Safety Gear: Wear appropriate safety gear, including a hard hat, gloves, and safety shoes.

– Inspection: Check the crane for any visible damages, frayed cables, or signs of wear. Ensure that all parts are in proper working condition, including the hoist, trolley, and controls.

2. Preparation:

– Area Clearance: Make sure the area beneath and around the crane is clear of obstructions and unauthorized personnel.

– Load Assessment: Determine the weight of the load. Ensure it does not exceed the crane’s maximum capacity.

3. Operation:

– Hoist Positioning: Position the hoist directly above the load to avoid swinging.

– Attachment: Securely attach slings, hooks or other lifting devices to the load. Ensure the load is balanced.

– Lifting: Use the control pendant to slowly lift the load. Initially lift it a few inches to check stability.

– Movement: With the load secure, use the trolley control to move the load horizontally along the workstation. Move slowly and steadily to prevent swaying.

– Lowering: Move the load to the designated area and slowly lower it to the ground, ensuring it is stable before detaching.

4. Post-Operation:

– Detachment: Carefully detach the lifting devices from the load.

– Shutdown: Return the hoist to a safe position, usually away from work areas, and turn off the controls.

– Inspection: Perform a quick post-operation inspection to ensure the crane is in good condition for the next use.

5. Maintenance:

– Regular Checks: Follow a regular maintenance schedule. Report and fix any issues immediately.

Always follow the manufacturer’s instructions and workplace safety protocols to ensure safe and efficient operation.

“workstation overhead crane” Comparative Analysis

A workstation overhead crane, or bridge crane, is a crucial piece of material handling equipment used in various industries for lifting and moving heavy loads within a limited work area. When comparing workstation overhead cranes, several critical factors need consideration: capacity, structural design, ease of use, flexibility, and cost.

Capacity and Structural Design: Workstation overhead cranes typically range from a few hundred pounds to several tons in lifting capacity. Comparing models, the capacity directly affects the crane’s engineering requirements, such as beam strength and trolley durability. Heavier loads necessitate robust materials and precise engineering, usually driving up costs. Conversely, lighter capacity cranes can be more cost-effective and sufficient for certain applications.

Ease of Use and Operation: Modern workstation cranes are equipped with advanced control systems, including wireless remote controls and automated operations. Ease of use can impact productivity dramatically. Cranes with intuitive, user-friendly interfaces and smooth operation can enhance worker efficiency and safety. Comparison should also include the type of power drive—manual, electric, or pneumatic—as it influences operational ease and speed.

Flexibility and Modularity: A key comparative aspect is the crane’s adaptability to different tasks and spaces. Some models allow for modular expansions, such as additional tracks or upgraded hoists, providing greater flexibility. Systems that can be easily reconfigured or extended offer significant long-term value, especially in dynamic work environments.

Cost and Maintenance: Initial investment, alongside long-term maintenance costs, are pivotal in comparative analysis. High-end cranes might have steep upfront costs but could offer better durability, lower maintenance, and reduced downtime. Evaluating the total cost of ownership, including energy consumption and spare part availability, is essential for an informed decision.

Conclusion: When conducting a comparative analysis of workstation overhead cranes, consider the balance between required capacity, structural integrity, operational ease, flexibility, and overall cost. The optimal crane will vary based on specific use cases, budget constraints, and future scalability needs.

“workstation overhead crane” Warranty and Support

Warranty and Support for Workstation Overhead Cranes

Our workstation overhead cranes come with a comprehensive warranty to ensure your investment is protected. The standard warranty period covers defects in materials and workmanship for up to 2 years from the date of installation. During this period, any malfunction or failure resulting from normal use will be repaired or replaced at no additional cost to you. This warranty excludes regular wear and tear, misuse, modifications, and any damages caused by improper maintenance or installation.

Our commitment to support extends beyond the warranty period. We offer a robust support program that includes:

1. Technical Assistance: Our team of experienced technicians is available to provide prompt and knowledgeable support for any operational questions or issues you may encounter.

2. Preventive Maintenance: To extend the lifespan of your crane, we offer customizable preventive maintenance packages. These services help identify potential issues before they become costly problems, ensuring optimal performance and safety.

3. Spare Parts Availability: We maintain a comprehensive inventory of spare parts to minimize downtime. Fast and reliable parts replacement ensures your operations can continue with minimal interruption.

4. Training: Proper training is crucial for the safe and efficient use of your overhead crane. We provide on-site and virtual training sessions for your operators and maintenance staff. Our training covers essential topics such as safe operation, routine inspections, and basic troubleshooting.

5. Extended Support Contracts: For peace of mind, we offer extended support contracts that include regular maintenance checks, priority service scheduling, and discounted rates on parts and labor.

Our goal is to provide you with a seamless ownership experience, underpinned by reliable products and exceptional support services. Contact our support team anytime for assistance, and rest assured that your workstation overhead crane is backed by a leading industry warranty and support program.

List “workstation overhead crane” FAQ

Workstation Overhead Crane FAQ

1. What is a workstation overhead crane?

– A workstation overhead crane is a type of crane designed for lifting and transporting loads in a smaller, defined area such as a workstation or lower-capacity lifting environment.

2. What are the benefits of using a workstation overhead crane?

– These cranes enhance productivity, improve worker ergonomics, reduce the risk of injury, and allow for the efficient movement of materials within a specific area.

3. What types of workstation cranes are available?

– The main types include bridge cranes, jib cranes, and gantry cranes. Each type serves different lifting and material handling needs based on the layout and requirements of the workspace.

4. What is the typical load capacity for a workstation overhead crane?

– Load capacities typically range from 150 pounds to 2 tons, but they can vary based on the design and manufacturer’s specifications.

5. Can workstation overhead cranes be customized?

– Yes, many manufacturers offer customizable options to meet specific workspace dimensions, load requirements, and operational needs.

6. What are the installation requirements for a workstation overhead crane?

– Installation requirements include sufficient ceiling height, proper structural support, and adequate space. Some setups may require professional installation to ensure stability and safety.

7. Are workstation cranes easy to operate?

– Most workstation cranes are designed with user-friendly controls and are relatively easy to operate with minimal training required.

8. What maintenance is required for workstation overhead cranes?

– Regular inspections, lubrication of moving parts, and checking for wear and tear are essential. Adhering to the manufacturer’s maintenance schedule helps ensure longevity and safety.

9. How much do workstation overhead cranes cost?

– The cost varies widely based on the type, capacity, and customization requirements. Basic models might start around $3,000, with more complex systems costing significantly more.

10. Are there safety features included in workstation overhead cranes?

– Yes, many come with features like overload protection, emergency stop buttons, and anti-sway technology to enhance safety during operations.

Top 10 FAQ with answer about workstation overhead crane for Buyer Sourcing from China

Absolutely! Here are the top 10 FAQs with answers for buyers sourcing workstation overhead cranes from China:

1. What is a workstation overhead crane?

– A workstation overhead crane is a type of lifting equipment designed for efficient material handling in workstations or smaller areas. They are ideal for tasks that require high precision and repetitive movements.

2. Why source workstation overhead cranes from China?

– China offers a wide range of high-quality, affordable workstation overhead cranes. The country’s advanced manufacturing capabilities and competitive labor costs provide value for money.

3. How do I verify the quality of a crane from a Chinese supplier?

– Ensure the supplier is ISO certified and check for compliance with international standards. Request detailed specifications, third-party inspection reports, and client testimonials.

4. What are the standard capacities and spans available?

– Workstation overhead cranes typically have capacities ranging from 250 kg to 2,000 kg, and spans can vary from 2 meters to over 10 meters, depending on the specific application.

5. What is the lead time for delivery?

– Lead times can vary, but generally, it takes about 4-8 weeks from order confirmation to shipment. Custom orders may require additional time.

6. Can I customize the crane according to my needs?

– Yes, most manufacturers offer customization options including capacity, span, lifting height, and specialized features to suit your specific requirements.

7. What are the payment terms?

– Common payment terms include a 30% deposit with the balance paid before shipment, often via T/T (Telegraphic Transfer). Other terms can be negotiated.

8. What about warranty and after-sales service?

– Reputable Chinese manufacturers typically offer a 1-2 year warranty. They also provide comprehensive after-sales service, including installation assistance, spare parts, and technical support.

9. How can I ensure safe and reliable installation?

– Choose manufacturers that offer professional installation services or provide detailed installation manuals. Hiring a local expert can also ensure proper setup.

10. Are there any import duties or regulations I should be aware of?

– Import duties and regulations vary by country. Consult with a customs broker to understand the specific requirements and ensure compliance with local laws.

By keeping these FAQs in mind, you’ll be better equipped to source a reliable and effective workstation overhead crane from China.