wrecking ball crane Safety Certifications

Safety certifications are crucial for operating a wrecking ball crane to ensure the safety of the operators, nearby workers, and the general public. Here are some key certifications and requirements:

1. OSHA Compliance: In the United States, the Occupational Safety and Health Administration (OSHA) sets forth specific regulations for cranes and derricks in construction (29 CFR 1926 Subpart CC). Compliance with these regulations is mandatory and includes operator certification and equipment inspection.

2. ANSI/ASME Standards: The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide safety standards, such as ASME B30.5 for mobile and locomotive cranes. Adherence to these standards helps ensure safe operations.

3. NCCCO Certification: The National Commission for the Certification of Crane Operators (NCCCO) offers certification programs for crane operators, riggers, and signal persons. NCCCO certification is widely recognized and often required for crane operators.

4. State Regulations: Some states have additional requirements or certifications for crane operators. For instance, New York City requires a specific hoisting machine operator license.

5. Manufacturer Training: Crane manufacturers often provide specialized training and certification for their equipment. This ensures operators are familiar with the specific nuances and safety features of their machines.

6. Regular Equipment Inspections: Regular inspections by certified personnel are necessary to identify and rectify potential safety issues. This includes daily checks by operators and more detailed periodic inspections by qualified professionals.

7. Continuing Education: Operators should engage in continuing education and re-certification to stay up-to-date with the latest safety protocols and technological advancements.

By meeting these certifications and requirements, operators and companies can help mitigate risks associated with wrecking ball crane operations.

List Reference Technical Parameters of “wrecking ball crane”

A wrecking ball crane, also known as a demolition crane, is a heavy-duty machine primarily used in the demolition of large structures. Here are the reference technical parameters:

1. Boom Length: Typically ranges from 30 to 100 feet, adjustable to suit the height and reach requirements of the demolition task.

2. Lifting Capacity: Often between 10 to 20 tons, depending on the model and manufacturer. This capacity includes the weight of the wrecking ball itself.

3. Wrecking Ball Weight: Usually ranges from 1 to 10 tons. The ball’s weight is selected based on the type and toughness of the material being demolished.

4. Crane Type: Generally, lattice boom cranes or crawler cranes are used due to their stability and ability to support heavy loads.

5. Swing Radius: This is the arc within which the wrecking ball can be swung. Typically, a swing radius can extend up to 70-90 feet, allowing for effective demolition range.

6. Travel Speed: The speed at which the crane can be moved varies. Crawler cranes may move at speeds around 1 to 2 mph, ensuring safe repositioning during demolition.

7. Operating Weight: The total weight of the crane, including the wrecking ball and other attachments, can range from 50 to 200 tons.

8. Power Source: Most wrecking ball cranes are diesel-powered, offering robust performance and reliability in heavy-duty operations.

9. Hydraulic Systems: Advanced models include hydraulic systems that provide smoother operation and enhanced control, crucial for precision in demolition tasks.

10. Safety Features: Includes load moment indicators, anti-two block systems, and reinforced operator cabs to protect against debris.

11. Control Systems: Modern cranes often feature both manual and computerized controls, allowing for precision and ease of operation.

12. Tracks or Wheels: Crawler cranes are typically used, offering better stability and mobility on uneven or rough terrain compared to wheeled variants.

Understanding these parameters ensures the selection of a suitable wrecking ball crane for specific demolition needs, optimizing efficiency and safety.

List Product features of “wrecking ball crane”

A wrecking ball crane, an essential piece of heavy machinery in demolition, offers numerous features designed for efficient and safe building demolition. Here’s a concise overview of its key features:

1. Heavy-Duty Construction: Engineered with rugged materials to withstand intense demolition operations.

2. Powerful Wrecking Ball: Suspended from a robust boom, the heavy steel ball delivers powerful blows to structures, facilitating their collapse.

3. High-Reach Boom: Equipped with a long, extendable arm to reach higher building sections, enhancing operational versatility.

4. Rotating Platform: Features a 360-degree rotating base, providing flexibility and strategic control over the demolition area.

5. Hydraulic Systems: Advanced hydraulics offer precise control over the boom’s movement, ensuring safety and effectiveness.

6. Stabilization Mechanisms: Outriggers and counterweights ensure the crane remains stable during operation, preventing tipping.

7. Operator Cab: Ergonomically designed with extensive visibility and comfort features, the cab often includes reinforced glass for safety.

8. Control Systems: User-friendly controls, often enhanced with electronic assistance, facilitate precise maneuvering and operation.

9. Safety Features: Includes emergency stop buttons, alarms, and failsafe mechanisms to protect operators and bystanders.

10. Durability: Components are designed to endure harsh demolition environments, reducing maintenance needs and increasing machine longevity.

11. Transportability: Although large, these cranes often feature disassembly options for easier transport between sites.

12. Attachments Compatibility: Capable of fitting various attachments, allowing for versatility beyond just using a wrecking ball.

These features make the wrecking ball crane an indispensable tool in commercial demolition, blending power with precision to safely and efficiently tear down large structures.

List Various Types of “wrecking ball crane”

Wrecking ball cranes, primarily used for demolition, come in several types differentiated by their design, mobility, and the specific tasks they are suited for. Here are the main types:

1. Crawler Cranes:

– Description: Equipped with tracks instead of wheels, these cranes offer superior stability and mobility on uneven terrain.

– Use: Ideal for large-scale demolition projects where mobility over rough surfaces is required.

2. Truck-Mounted Cranes:

– Description: Mounted on a truck chassis, they are mobile and can be driven on public roads.

– Use: Suitable for urban demolition tasks where transportation between sites is frequent.

3. All-Terrain Cranes:

– Description: Capable of operating on both paved roads and rough terrains, combining features of truck-mounted and rough-terrain cranes.

– Use: Versatile for both urban and off-road demolition projects.

4. Rough-Terrain Cranes:

– Description: Designed with large tires for stability and off-road mobility.

– Use: Excellent for demolition sites without paved roads, offering good maneuverability in rugged conditions.

5. Telescopic Cranes:

– Description: Feature extendable/telescoping booms, offering variable reach.

– Use: Useful for demolition projects requiring reaching different heights without relocating the crane.

6. Lattice Boom Cranes:

– Description: Utilize a lattice structure for the boom, which provides high strength-to-weight ratio.

– Use: Best for heavy-duty demolition tasks requiring robust lifting capabilities.

Each type of crane has its unique advantages and is chosen based on the specific requirements of the demolition project, such as terrain, reach, and mobility needs.

List Application of “wrecking ball crane”

A wrecking ball crane is a specialized heavy-duty demolition machine primarily designed to demolish large structures. Its primary applications include:

1. Building Demolition

– High-Rise Structures: Used to bring down multi-story buildings, especially those made of brick, concrete, or steel.

– Residential and Commercial Buildings: Effective for demolishing old or unsafe residential homes and commercial properties.

2. Industrial Facility Decommissioning

– Factories and Plants: Used in the dismantling of old factories, manufacturing plants, or other industrial facilities.

– Warehouses: Efficient in tearing down outdated or damaged large storage buildings.

3. Bridge and Overpass Removal

– Ideal for demolishing old or structurally unsound bridges and overpasses to make way for new construction.

4. Urban Renewal Projects

– Clearing Out Dated Infrastructure: Employed in city renewal plans where old buildings need to be cleared to make way for modern infrastructure.

– Brownfield Redevelopment: Cleaning contaminated industrial sites by demolishing existing structures.

5. Disaster Response

– Collapsed Structures: Clearing debris and unsafe buildings after natural disasters like earthquakes or floods.

– Emergency Demolition: Prompt demolition of hazardous buildings to prevent potential accidents or further damage.

6. Historical Preservation Efforts

– Controlled demolition of deteriorated parts of historical sites, enabling safe restoration and preservation.

7. Public Safety

– Unsafe Buildings: Demolishing structures that pose immediate risk to public safety due to damage or decay.

– Code Violations: Removal of buildings failing to meet safety or building codes.

Wrecking ball cranes are indispensable in controlled demolitions, offering a balance of power and precision to ensure the safe and efficient removal of large and old structures. This equipment contributes significantly to modern urban development, disaster management, and infrastructure renewal initiatives.

List Buyer Types of “wrecking ball crane”

1. Construction Companies: These are the primary buyers of wrecking ball cranes, utilized for the demolition of buildings and other structures. Construction firms, especially those specializing in demolition, rely on these cranes for their efficiency in bringing down large structures in a controlled manner.

2. Demolition Contractors: Specialized demolition companies, focusing exclusively on tearing down buildings, bridges, and other structures, invest in wrecking ball cranes to streamline their operations. These cranes are indispensable for breaking down large and sturdy constructions.

3. Scrap and Recycling Companies: Firms engaged in scrap metal and recycling may use wrecking ball cranes to dismantle large metal structures like old factories or shipyards. The cranes help reduce these structures into manageable pieces for recycling purposes.

4. Municipalities and Government Agencies: Local governments and municipal bodies sometimes purchase or lease wrecking ball cranes for public works projects. This includes clearing unsafe buildings, old infrastructure, and preparing land for redevelopment.

5. Industrial Plants: Facilities like power plants, refineries, or factories facing decommissioning may purchase wrecking ball cranes to expedite the demolition and cleanup process. These cranes assist in safely dismantling large, hazardous structures.

6. Real Estate Developers: Developers often need to clear existing structures to make way for new projects. Investing in wrecking ball cranes can help them speed up the process of site preparation, reducing the turnaround time for new construction projects.

7. Rental Companies: Equipment rental businesses often purchase wrecking ball cranes to lease to other companies that require them for short-term projects. This facilitates access to specialized demolition equipment without a significant upfront investment for temporary needs.

In summary, wrecking ball cranes play a critical role in the demolition sector, attracting buyers ranging from construction companies to government agencies and equipment rental firms. Their capability to efficiently demolish large structures makes them a valuable asset for various industries.

List “wrecking ball crane” Project Types for Different Industries

Wrecking Ball Crane Project Types for Different Industries

1. Construction:

– Building Demolition: Used extensively for demolishing old or unsafe buildings to make way for new constructions.

– Site Clearing: Removing residual structures or large debris to prepare land for new projects.

2. Industrial:

– Factory Decommissioning: Demolishing obsolete or defunct factory buildings for land re-utilization.

– Heavy Equipment Removal: Tear down large bases or supports where heavy machinery once operated.

3. Infrastructure:

– Bridge Demolition: Breaking down old or unsafe bridges to be replaced with modern structures.

– Road Overhaul Projects: Removing old overpasses or ancillary structures to facilitate road expansion or modification.

4. Commercial:

– Shopping Center Renovation: Demolishing old sections of a mall or shopping center during a major overhaul.

– Warehouse Demolition: Clearing old commercial storage facilities for new business opportunities.

5. Residential:

– Housing Development: Knocking down old housing units to build new residential areas or complexes.

– Urban Renewal: Demolishing decayed or condemned buildings to rejuvenate city neighborhoods.

6. Utilities:

– Power Plant Decommissioning: Demolishing outdated power plant structures, especially in transitioning to sustainable energy.

– Water Treatment Facilities: Removing defunct storage tanks or treatment buildings for upgrades or new installations.

7. Environmental:

– Contaminated Site Remediation: Knocking down structures on polluted land to clean up environmental hazards.

– Disaster Response: Removing hazardous structures after natural disasters to ensure public safety.

8. Entertainment:

– Movie Sets: Creating dramatic destruction scenes for films or TV shows.

– Theme Parks: Demolishing old attractions to make way for new developments.

Wrecking ball cranes remain a versatile and powerful tool across various sectors, enhancing efficiency in demolition projects for future advancements.

wrecking ball crane Accessories Upgrades and Custom Manufacturing Options

When optimizing a wrecking ball crane, various accessories and upgrades can enhance performance, safety, and efficiency. Here’s a breakdown of key options:

Accessories

1. Specialized Wrecking Balls: Different weights and materials can optimize impact force and durability.

2. Ball Swivels and Shackles: Ensures smooth rotation and secure attachment of the wrecking ball to the crane hook.

3. Anti-Sway Systems: Reduces unexpected crane movements, improving precision and safety.

4. Crane Jibs: Extend reach for better maneuverability in tight or high spaces.

Upgrades

1. Hydraulic Systems: Improve control and precision for delicate demolition tasks.

2. Cabin Enhancements: Ergonomic seats, better visibility, and climate control make long operations more comfortable for operators.

3. Telematics: Real-time data collection for monitoring crane performance and maintenance needs.

4. Advanced Control Systems: Incorporate touchscreens and joystick controls for intuitive operation.

5. Enhanced Safety Features: Proximity sensors, cameras, and alarms for an extra layer of precaution.

Custom Manufacturing Options

1. Tailored Boom Lengths: Custom-designed booms to meet specific project requirements.

2. Heavy-Duty Chassis and Frames: Reinforced structures for heavy demolition tasks.

3. Power Options: Diesel, electric, or hybrid power setups tailored to operational needs and environmental considerations.

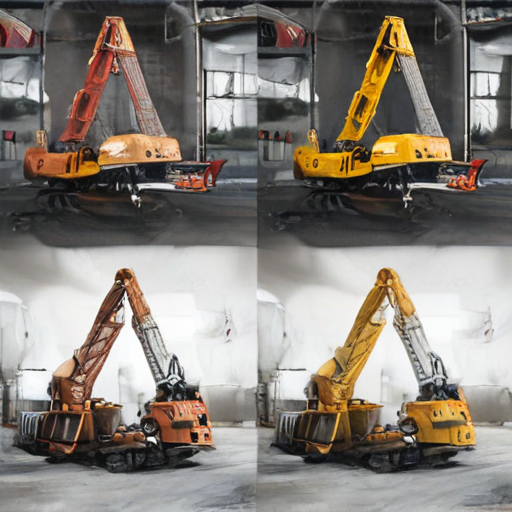

4. Custom Paint and Branding: Unique color schemes and decals to match company branding or for easy identification on the job site.

5. Modular Attachments: Custom attachments that can be switched out to adapt the crane for varied demolition tasks.

By leveraging these customization and upgrade options, operators can greatly improve their wrecking ball crane’s versatility, safety, and efficiency, ensuring it meets the demands of specific demolition projects.

List Quality Control and The Manufacturing Process of “wrecking ball crane”

Quality Control in Wrecking Ball Crane Manufacturing

1. Material Inspection:

– Steel Quality: Verified for strength, toughness, and durability.

– Components Check: Fasteners, bearings, and hydraulic parts inspected against specifications.

2. Dimensional Verification:

– Precision Measuring: Structural components checked for exact dimensions.

– Tolerance Adherence: Ensures parts fit together seamlessly.

3. Welding Integrity:

– Ultrasonic Testing: Detects internal flaws.

– X-Ray Examination: Ensures weld quality and soundness.

4. Load Testing:

– Simulated Load Conditions: Crane subjected to maximum load capacity.

– Operational Testing: Verifies maneuverability and stability under stress.

5. Safety Compliance:

– Regulatory Standards: Ensures adherence to industry safety norms like OSHA.

– Failure Mode Analysis: Evaluates potential weak points through hypothetical scenarios.

6. Final Inspection:

– Functionality Check: Comprehensive testing of all systems.

– Visual Inspection: Ensures no defects or cosmetic damages.

Manufacturing Process of Wrecking Ball Cranes

1. Design and Prototyping:

– CAD Modeling: Detailed design using computer-aided drafting software.

– Simulation Testing: Prototype tested virtually for stress and load distribution.

2. Material Selection:

– Sourcing High-Quality Materials: Procurement of premium steel and essential components.

– Supplier Verification: Ensuring reliability and quality of suppliers.

3. Fabrication:

– Cutting and Shaping: Steel beams cut to size and shaped using CNC machines.

– Welding: High-strength welding techniques employed for assembling structural elements.

4. Assembly:

– Component Integration: Installation of hydraulic systems, motors, and essential controls.

– Structural Assembly: Mainframe and auxiliary parts bolted and welded together.

5. Painting and Coating:

– Corrosion Resistant Coating: Application of anti-rust treatment.

– Final Paint Job: Ensures aesthetic quality and additional protection.

6. Electrical and Hydraulic Systems:

– Wiring and Hoses: Installation of electrical circuits and hydraulic lines.

– Systems Testing: Ensures all moving parts and controls are functional.

7. Quality Assurance & Delivery:

How to use “wrecking ball crane”

Using a wrecking ball crane involves several key steps to ensure safety and efficiency. Here’s a concise guide:

Preparation:

1. Site Assessment: Conduct a thorough survey of the demolition site to identify potential hazards and plan the operation.

2. Permits and Regulations: Obtain necessary permits and ensure compliance with local demolition regulations.

3. Equipment Check: Inspect the crane and wrecking ball for any damage or defects. Ensure all parts are functioning correctly.

Setup:

1. Positioning: Place the crane in a stable location with a clear swing path for the wrecking ball. Ensure the ground can support the crane’s weight.

2. Safety Zone: Establish a safety perimeter to keep personnel and unauthorized parties away from the demolition area.

3. Stabilizing the Crane: Extend outriggers and stabilize the crane to prevent tipping during operations.

Operation:

1. Lift the Ball: Use crane controls to lift the wrecking ball to the desired height, typically slightly above the structure to be demolished.

2. Swinging: Begin with gentle swings to control the force and direction. Increase intensity as needed to break through structural components.

3. Precision: Aim for structural weak points to maximize efficiency and minimize debris scatter.

4. Monitoring: Continuously observe the structure’s response and adjust swings accordingly. Stop if instability or unexpected hazards arise.

Safety Protocols:

1. Communication: Maintain clear communication with the team using radios or hand signals.

2. Personal Protective Equipment (PPE): Ensure all personnel are wearing appropriate PPE, including helmets, gloves, and eye protection.

3. Emergency Procedures: Have a plan in place for emergencies, including how to quickly halt operations and evacuate if necessary.

Post-Demolition:

1. Inspection: Inspect the site for remaining hazards and assess if additional demolition work is needed.

2. Equipment Storage: Lower the wrecking ball and secure the crane. Perform any necessary maintenance.

By following these steps, a wrecking ball crane can be operated safely and effectively for demolition projects.

“wrecking ball crane” Comparative Analysis

Comparative Analysis: Wrecking Ball Crane

#### Definition and Purpose

A wrecking ball crane is a specialized type of crane used primarily for demolition purposes. Unlike other cranes designed for construction, lifting, or material handling, the wrecking ball crane employs a massive, heavy steel ball suspended from its boom to smash through structures.

#### Types of Cranes

1. Wrecking Ball Crane:

– Role: Demolition

– Mechanism: Utilizes a heavy steel ball to physically break down structures.

– Advantages: Simple mechanism, highly effective for certain demolition tasks, adaptable to different terrains due to various crane configurations.

– Limitations: Less precise, limited to structures where debris control is not critical, generates significant dust and noise.

2. Standard Construction Crane:

– Role: Construction, lifting

– Mechanism: Uses a hook or lifting device to hoist materials.

– Advantages: Versatile, precise, capable of lifting a wide range of weights, can be used for both light and heavy construction tasks.

– Limitations: More complex setup, higher operational costs, requires skilled operators.

3. Excavators with Hydraulic Breakers:

– Role: Demolition and excavation

– Mechanism: Uses hydraulic pressure to power tools like breakers and shears.

– Advantages: Precision, ability to handle different materials, integrated dust control options.

– Limitations: Higher operational costs, more maintenance, limited by reach and access.

#### Technological Evolution

Modern construction and demolition are increasingly incorporating technology for safety and precision. While traditional wrecking ball cranes remain a cost-effective solution for certain projects, newer methods like robotic demolition are gaining popularity for their precision and reduced environmental impact.

#### Conclusion

Wrecking ball cranes serve a specific niche in demolition. They are robust, cost-effective, but less precise compared to modern alternatives like hydraulic breakers. The choice between these and other cranes depends on the project’s specific needs, weighing factors like cost, precision, and environmental impact.

“wrecking ball crane” Warranty and Support

At [Your Company Name], we stand behind the quality and durability of our Wrecking Ball Cranes. Each crane comes with a comprehensive warranty and robust support services to ensure your peace of mind and seamless operation.

Warranty Coverage:

1. Duration: Our standard warranty covers 24 months or 2000 operational hours, whichever comes first, starting from the date of delivery.

2. Parts and Labor: Coverage includes all necessary repairs and replacements of defective parts due to manufacturing faults and workmanship errors. Labor costs for repairs conducted by our authorized service centers are also covered.

3. Exclusions: Routine maintenance, normal wear and tear, misuse, modifications, and damage due to unauthorized repairs are excluded from the warranty.

Support Services:

1. 24/7 Customer Support: Our dedicated support team is available around the clock to assist with any operational issues, queries, or concerns.

2. On-site Service: For critical issues, we offer on-site repair services. Our network of trained technicians ensures prompt and efficient resolution of problems.

3. Preventive Maintenance: Optional preventive maintenance plans are available to help you keep your crane in optimal condition, reducing downtime and extending its lifespan.

4. Training Programs: We provide comprehensive training for your operators and maintenance personnel to ensure safe and efficient use of the crane.

5. Spare Parts Availability: Our extensive inventory of genuine spare parts ensures that any required replacements are readily available, minimizing downtime.

How to Initiate a Claim:

1. Contact: Reach our customer support at

or [email address].2. Documentation: Provide the equipment serial number, purchase details, and a detailed description of the issue.

3. Assessment: A technician will assess the situation and guide you through the repair or replacement process.

By choosing our Wrecking Ball Crane, you benefit from reliable performance backed by exceptional warranty and support services.

List “wrecking ball crane” FAQ

Certainly! Here are some frequently asked questions (FAQ) about wrecking ball cranes:

Wrecking Ball Crane FAQ

1. What is a wrecking ball crane?

A wrecking ball crane is a type of crane specifically designed for demolition. It features a heavy steel ball attached to a cable and boom, which is used to demolish structures by swinging the ball into the target.

2. How does a wrecking ball crane operate?

The crane operator maneuvers the boom and releases the ball to swing. Gravity pulls the ball, generating kinetic energy that is used to break apart structures. The ball can be swung in different directions for targeted demolition.

3. What types of buildings are demolished using a wrecking ball crane?

Wrecking ball cranes are typically used for demolishing concrete and brick structures, such as old factories, warehouses, and multi-story buildings.

4. Is the wrecking ball method still commonly used?

While effective, wrecking ball demolition has declined in popularity due to advancements in more precise and safer demolition technologies, such as high-reach excavators and controlled implosions.

5. What safety precautions are necessary?

Safety precautions include securing the demolition site, ensuring no unauthorized personnel are nearby, and using barriers to prevent debris from flying into surrounding areas. Operators must be highly trained and vigilant.

6. How heavy is a typical wrecking ball?

Wrecking balls can vary in weight, typically ranging from 1,000 to 12,000 pounds (450 kg to 5,500 kg), depending on the needs of the demolition project.

7. Are there environmental considerations?

Yes, using a wrecking ball generates significant dust and debris. Proper dust suppression methods, such as water spraying, should be in place to protect air quality. Recycling and proper disposal of demolition materials are also important.

8. How cost-effective is wrecking ball demolition?

Costs can vary, but wrecking ball demolition is generally less expensive than other methods. However, it might not be the best option for sites requiring precision or having tight space constraints.

By addressing these key questions, you can gain a fundamental understanding of wrecking ball cranes and their role in the demolition industry.

Top 10 FAQ with answer about wrecking ball crane for Buyer Sourcing from China

Sure, here are the top 10 frequently asked questions (FAQ) about sourcing a wrecking ball crane from China, along with brief and informative answers:

1. What types of wrecking ball cranes are available from China?

– Chinese manufacturers offer various types of wrecking ball cranes, including mobile cranes, crawler cranes, and tower cranes equipped with wrecking balls. Customizations are often available based on specific project needs.

2. How can I verify the quality of a wrecking ball crane from a Chinese supplier?

– Ask for international certifications (like ISO, CE), request a factory audit, ask for product testing reports, and check customer reviews or references from previous buyers.

3. What is the average lead time for ordering a wrecking ball crane from China?

– The lead time typically ranges from 4 to 12 weeks, depending on the manufacturer’s production schedule, customization requirements, and shipping logistics.

4. Are there any specific import regulations for wrecking ball cranes?

– Yes, you need to comply with your country’s import regulations, including safety and customs requirements. Check for any specific documentation or clearance needed.

5. What are the shipping options and costs for transporting a wrecking ball crane from China?

– Options include sea freight (most common for heavy machinery), air freight, and rail transport. Costs vary based on size, weight, shipping method, and destination.

6. Can Chinese suppliers offer after-sales support and service?

– Many reputable suppliers provide after-sales services, including installation support, maintenance training, and spare parts. Ensure to clarify this aspect in your contract.

7. What are the payment terms typically required by Chinese manufacturers?

– Common payment terms include a 30-50% deposit upfront, with the balance paid before shipment or through a letter of credit (L/C). Negotiations can sometimes modify these terms.

8. How can I handle warranty claims for a wrecking ball crane bought from China?

– Ensure the purchase contract clearly outlines the warranty terms, including the duration, coverage, and procedure for claims. Many suppliers offer a one-year warranty.

9. Is it possible to customize the wrecking ball crane according to specific requirements?

– Yes, most Chinese manufacturers offer customization options to meet specific operational requirements. Discuss your needs in detail with the supplier to get a tailored product.

10. What are some recommended tips for selecting the right supplier in China?