yacht davit crane Safety Certifications

Yacht davit cranes are essential for safely deploying and retrieving tenders, jet skis, and other equipment on board. Ensuring these cranes meet safety standards is paramount to prevent accidents and injuries. Several safety certifications and standards apply to yacht davit cranes:

1. CE Marking (European Conformity): Required in the European Economic Area, CE marking ensures that the equipment complies with EU safety, health, and environmental protection standards. It signifies adherence to directives such as the Machinery Directive (2006/42/EC).

2. ISO Standards: The International Organization for Standardization (ISO) provides specific standards for lifting devices and marine equipment. ISO 10535 outlines requirements for hoists and lifting devices for disabled persons, which can also be applicable to smaller davit systems.

3. American Bureau of Shipping (ABS) Certification: ABS offers certification for marine equipment, ensuring compliance with rigorous safety and reliability standards. This certification is widely recognized in the maritime industry.

4. DNV-GL (Det Norske Veritas–Germanischer Lloyd): This certification ensures that marine equipment meets safety and quality standards. DNV-GL evaluates everything from material properties to operational safety.

5. Lloyd’s Register (LR) Certification: This globally recognized certification focuses on safety and environmental standards. Lloyd’s Register verifies that the yacht davit crane meets strict regulatory and operational criteria.

6. Classification Society Approvals: Various international classification societies such as Bureau Veritas (BV) and Registro Italiano Navale (RINA) provide certifications tailored to marine equipment, ensuring adherence to national and international regulations.

7. Occupational Safety and Health Administration (OSHA): Although more commonly associated with workplace safety in the United States, adherence to OSHA standards can also indicate a commitment to operational safety.

Regular inspections, maintenance, and adherence to these certifications help ensure that yacht davit cranes operate safely and effectively, thereby protecting both personnel and property.

List Reference Technical Parameters of “yacht davit crane”

A yacht davit crane is an essential piece of equipment used to launch and retrieve tenders, lifeboats, and other small equipment on a yacht. The following are the primary technical parameters to consider for a yacht davit crane:

1. Load Capacity:

– Rated Load: The maximum weight the crane can safely lift, typically measured in kilograms or pounds.

– Safe Working Load (SWL): Often slightly less than the rated load to ensure safety margins.

2. Reach:

– Maximum Outreach: The horizontal distance the arm can extend from the mounting point.

– Minimum Outreach: The shortest distance the arm can retract to.

3. Lifting Height:

– Maximum Height: The vertical distance the hook or lifting mechanism can raise a load.

– Boom Lift Angle: The range of angles that the boom can be lifted or lowered.

4. Power Source:

– Hydraulic: Uses hydraulic power for lifting and positioning.

– Electric: Powered by electric motors, often preferred for their convenience and efficiency.

– Manual: Operated by hand, suitable for smaller, lighter loads.

5. Operational Speed:

– Lifting speed: The rate at which the crane can raise or lower loads.

– Slewing Speed: The rotation speed of the crane around its axis.

6. Control System:

– Manual Control: Lever or pulley systems requiring human effort.

– Remote Control: Operated via wireless remote for precision and convenience.

– Automated: Fully automated systems requiring minimal human intervention.

7. Mounting Type:

– Deck-Mounted: Fixed directly to the yacht’s deck.

– Bulkhead-Mounted: Attached to vertical surfaces such as the ship’s bulkheads.

– Base-Mounted: Installed on a dedicated base or pedestal.

8. Material:

– Construction materials like marine-grade aluminum or stainless steel to resist corrosion and enhance durability.

9. Safety Features:

– Overload protection: Systems to prevent lifting above the crane’s capacity.

– Emergency Stop: Immediate halting capabilities in case of malfunction.

10. Dimensions and Weight:

– Overall size and weight of the davit crane affecting installation and load-bearing structures on the yacht.

These parameters help in selecting an appropriate yacht davit crane that meets specific operational needs and ensures safety and efficiency.

List Product features of “yacht davit crane”

Certainly! Here are the key product features of a yacht davit crane:

1. Durability and Corrosion Resistance: Constructed from high-quality materials like stainless steel or marine-grade aluminum, ensuring longevity and resistance to harsh marine environments.

2. Load Capacity: Capable of lifting a range of weights, typically varying from a few hundred pounds to several thousand, catering to small inflatables to heavy tenders and equipment.

3. Ease of Operation: Designed for user-friendly operation with options for manual, electric, or hydraulic mechanisms, allowing easy deployment and retrieval of loads.

4. Compact Design: Space-efficient design that integrates smoothly into the yacht structure without taking up excessive deck or storage space, often foldable or removable when not in use.

5. Safety Features: Equipped with essential safety mechanisms like automatic brakes, overload protection, and emergency stop functions to ensure secure and reliable operation.

6. Rotational Capability: Offers 360-degree rotation for flexible and precise positioning of the tender or other equipment, making loading and unloading tasks efficient.

7. Adjustable Arm Length: Telescoping or adjustable length arms to extend reach and accommodate various vessel sizes and loading configurations.

8. Customizable Options: Available in various styles and finishes to match yacht aesthetics and specific requirements, including color and material choices.

9. Wireless Remote Control: Optional wireless remote control feature for added convenience, allowing single-person operation from a safe distance.

10. Minimal Maintenance: Engineered to require low maintenance with easily accessible components and straightforward servicing protocols, ensuring hassle-free upkeep.

11. Versatile Applications: Suitable for lifting a variety of loads beyond tenders, such as jet skis, lifesaving equipment, and heavy cargo.

12. Certification and Compliance: Meets industry standards and regulations, often certified by marine safety authorities to ensure dependable performance.

These features combine to make yacht davit cranes an essential accessory for enhancing the functionality and safety of modern yachts.

List Various Types of “yacht davit crane”

Sure, here’s a concise description of various types of yacht davit cranes:

1. Pivoting Davits

– Manual Pivoting Davits: These are manually operated and suitable for smaller yachts. They use mechanical leverage to tilt the davit arm and deploy or retrieve tenders.

– Electric/Hydraulic Pivoting Davits: Powered by electric motors or hydraulic systems, these are ideal for larger yachts. They offer ease of operation and can handle heavier loads.

2. Rotating Davits

– Manual Rotating Davits: These allow for the 360-degree rotation of the davit arm, making it easier to position the tender for launch or retrieval. Manual effort is required.

– Electric/Hydraulic Rotating Davits: These provide motorized rotation, offering enhanced control and less physical effort. Suitable for various yacht sizes.

3. Telescoping Davits

– Manual Telescoping Davits: These davits offer extendable arms that can be manually adjusted to different lengths. Useful for positioning tenders at variable distances.

– Electric/Hydraulic Telescoping Davits: Motorized versions that allow easy adjustment of arm length, making the deployment process more flexible and efficient.

4. Folding Davits

– Compact Folding Davits: Designed to save space, these davits can fold down when not in use. They are popular on yachts with limited storage space.

5. Freestanding Davits

– These are independent units that can be placed at different locations on the yacht. They offer flexibility but may require more storage space when not in use.

6. Deck-Mounted Davits

– Permanently mounted on the deck, these davits are robust and can handle larger tender sizes. They offer stability but require a dedicated installation space.

7. Rail-Mounted Davits

– Fitted onto the yacht’s railings, these are less intrusive and can often be detached when not in use. They are typically used for lighter tenders and equipment.

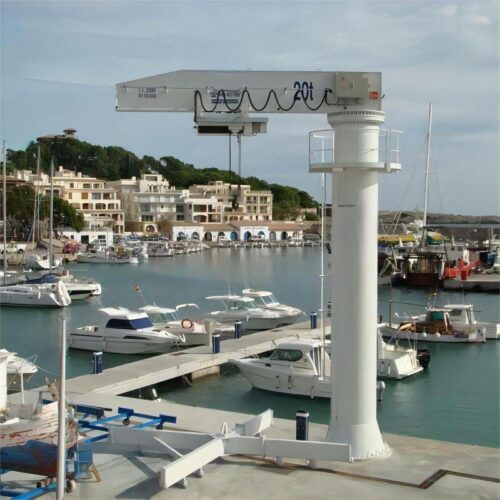

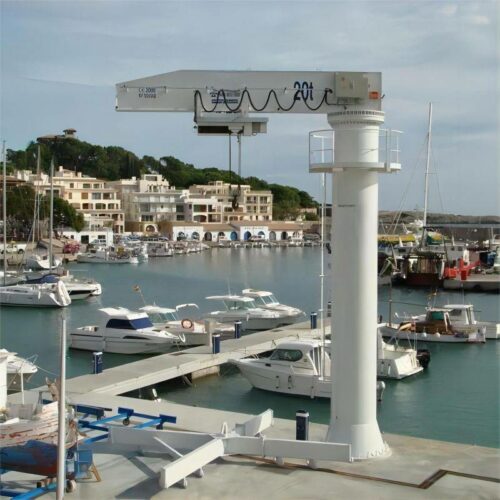

8. Overhead Crane Davits

– Installed on the top deck, these cranes can lift heavy loads vertically, making them suitable for larger tenders or water toys. They offer significant lifting capacity but require substantial space and structural support.

These various types of yacht davit cranes cater to different yacht sizes, tender weights, and operational preferences, ensuring there’s an option to meet most needs.

List Application of “yacht davit crane”

A yacht davit crane is a pivotal piece of equipment in the maritime industry, primarily used on yachts and other vessels to enhance versatility, safety, and functionality. Here are several notable applications:

1. Tender Deployment and Retrieval:

Yacht davit cranes are often used for launching and retrieving tenders or smaller boats. They allow for the easy transfer of these auxiliary vessels from the deck to the water and back, facilitating excursions and ensuring rapid deployment in emergencies.

2. Watersport Equipment Handling:

These cranes are instrumental in managing watersport gear such as jet skis, kayaks, and paddleboards. They simplify the loading and unloading process, ensuring that heavy or cumbersome items can be moved safely.

3. Cargo Handling:

Davit cranes are used to load and unload supplies and equipment. From food provisions to spare parts, they help manage the logistical demands of long voyages by streamlining the transfer process between the yacht and dock or another vessel.

4. Safety Operations:

In emergency situations, yacht davit cranes play a crucial role in deploying life rafts and other emergency equipment quickly and efficiently. This ensures adherence to safety protocols and enhances overall onboard safety.

5. Maintenance and Repairs:

These cranes assist in the handling of parts and equipment needed for maintenance activities. For instance, deploying heavy engines, winches, or other critical components for repairs is made easier, reducing the risk of injury and equipment damage.

6. Diving Operations:

For yachts equipped for diving expeditions, davit cranes facilitate the lowering and raising of diving equipment, including heavy diving rigs and underwater vehicles, promoting efficient and safe access to underwater activities.

In summary, yacht davit cranes are essential tools that extend a vessel’s functionality by efficiently managing various heavy or cumbersome loads, ensuring safety, and improving the overall operational efficiency of maritime activities.

List Buyer Types of “yacht davit crane”

When considering buyers for yacht davit cranes, it’s important to recognize the diverse range of users and their specific needs. The types of buyers typically include:

1. Private Yacht Owners:

– These individuals seek enhanced convenience and luxury. They prioritize high-quality, aesthetically pleasing, and easy-to-operate davit cranes to handle tenders, jet skis, and other water toys.

2. Yacht Builders and Manufacturers:

– These buyers require davit cranes as standard or optional equipment on new yachts. They emphasize reliability, integration, and compliance with marine standards to appeal to potential yacht buyers.

3. Yacht Charter Companies:

– Focused on durability and ease of maintenance, charter companies need davit cranes that can withstand frequent use and variable operating conditions. They generally prioritize cost-effectiveness without compromising on functionality.

4. Commercial Marine Operators:

– This group includes organizations like transport services, offshore service vessels, and marine research entities. They demand robust, heavy-duty cranes capable of handling various equipment and operational needs.

5. Yacht Refurbishment and Retrofit Companies:

– Specializing in upgrading older yachts, these buyers look for versatile davit cranes that can be seamlessly integrated into existing structures. They focus on modern features and compliance with newer safety standards.

6. Luxury Resorts and Marinas:

– Resorts with private marinas might invest in high-end davit cranes for guest services. They need equipment that aligns with the luxury standards of their facilities and can handle multiple types of small watercrafts.

7. Government and Patrol Vessels:

– These entities require reliable and durable cranes for general operations, rescue missions, and maintenance tasks. They often look for equipment that meets regulatory standards and ensures operational efficiency in challenging conditions.

Each buyer type values specific features like load capacity, material quality, ease of installation and use, and compliance with marine and safety standards. The wide variety of users indicates a flexible market for davit crane manufacturers, allowing them to cater to both luxury and practical needs across different sectors.

List “yacht davit crane” Project Types for Different Industries

A yacht davit crane is a small crane mounted on a vessel, used primarily for lifting and lowering tenders, jet skis, or other small watercraft from the yacht to the water and vice versa. These cranes have several applications across different industries:

1. Marine and Yachting Industry:

– Luxury Yachts: Installation for launching and retrieving tenders or water toys.

– Commercial Ships: Used for handling lifeboats or smaller operational boats.

– Marinas and Yacht Clubs: Equipped for maintenance and services for members’ boats.

2. Tourism and Recreation:

– Tours and Charters: Yachts used for charter services often have davit cranes to manage watercraft for guest activities.

– Resorts: Coastal or island resorts use these cranes to operate small boats for guest excursions and watersports.

3. Research and Exploration:

– Oceanographic Vessels: Employed for deploying research submarines, drones, or remote-operated vehicles (ROVs).

– Environmental Monitoring: Used to handle small boats or equipment for water sampling and environmental studies.

4. Defense and Coast Guard:

– Naval Ships: For rapid deployment of small patrol boats or rescue crafts.

– Coast Guard Vessels: For launching rescue missions or patrolling activities using smaller boats.

5. Oil and Gas Industry:

– Offshore Platforms: Used to handle crew transfer vessels or inspection crafts for rig maintenance.

– Support Vessels: Integral for transferring equipment and personnel to and from offshore locations.

6. Emergency and Rescue:

– Fire and Rescue Boats: Equipped to launch swift-water rescue boats or other emergency equipment.

– Disaster Response: Deployed on emergency vessels for quick action in disaster-stricken areas.

Conclusion:

Yacht davit cranes are versatile and crucial equipment across various sectors, notably enhancing operational efficiency in marine, tourism, research, defense, oil and gas, and emergency services. Their capability in handling multiple forms of watercraft paves the way for diverse applications tailored to specific industry needs.

yacht davit crane Accessories Upgrades and Custom Manufacturing Options

Upgrading and customizing yacht davit cranes can significantly enhance their functionality, safety, and aesthetics. Here are key accessories and custom manufacturing options to consider:

1. Remote Control Systems: Integrate wireless remote control systems for convenient and safer operations. Advanced models may include touchscreens and pre-programmed lifting sequences.

2. Hydraulic Upgrades: Opt for powerful hydraulic systems for smoother, quieter, and more efficient lifting and lowering functions. Consider dual-speed pumps for better control.

3. Load Monitoring Systems: Enhance safety with digital load monitoring systems that provide real-time weight data, preventing overloading and potential damage.

4. Stainless Steel Components: For increased durability and corrosion resistance, upgrade to stainless steel parts, including bolts, shackles, and winches.

5. LED Lighting: Incorporate LED lighting on the crane arm for improved visibility during night operations and to enhance the yacht’s aesthetics.

6. Custom Paint and Finishes: Choose custom colors and finishes to match the yacht’s design. Options may include powder coating, anodizing, or marine-grade paint.

7. Telescopic Boom: For added versatility, consider a telescopic boom that extends reach without compromising strength or stability.

8. Noise Reduction Kits: Minimize operational noise with dampening materials and specialized winches designed for quieter performance.

9. Smartphone Integration: Future-proof your davit crane with smartphone apps that allow for monitoring and control directly from mobile devices.

10. Modular Design: Custom modular designs allow for easy upgrades and replacements of components as technology advances or needs change.

11. Folding Mechanisms: Foldable cranes save space when not in use and offer quick deployment, making them ideal for yachts with limited deck space.

12. Custom Load Attachments: Tailor load attachments to specific needs such as jet skis, dinghies, or diving equipment for more versatile use.

By focusing on these upgrades and custom options, yacht owners can ensure their davit cranes meet specific needs, improve operational efficiency, and enhance overall enjoyment and safety on the water.

List Quality Control and The Manufacturing Process of “yacht davit crane”

Quality Control of Yacht Davit Crane

1. Material Inspection: Verify raw materials (steel, aluminum) for compliance with strength and corrosion resistance specifications.

2. Welding Quality: Ultrasonic or X-ray testing ensures weld integrity.

3. Dimensional Accuracy: CNC machinery guarantees precise dimensions.

4. Load Testing: Simulate operational loads to check structural performance.

5. Corrosion Resistance: Salt spray tests evaluate surface coating durability.

6. Operational Testing: Functional tests to ensure smooth movement and lifting.

7. Certification: Compliance with maritime standards like ABS, DNV-GL, or Lloyd’s Register.

Manufacturing Process of Yacht Davit Crane

1. Design & Engineering:

– *Concept Development*: Define specifications based on yacht size and lifting needs.

– *3D Modeling*: Use CAD software to create detailed designs.

– *Prototyping*: Develop a small-scale model for initial testing.

2. Material Procurement:

– *Sourcing*: High-grade metals, hydraulic systems, and electrical components.

– *Inspection*: Quality check to ensure raw materials meet required standards.

3. Fabrication:

– *Cutting*: CNC machines cut materials to precise dimensions.

– *Welding*: Assemble components using both manual and robotic welders.

– *Machining*: Fabricate intricate parts and ensure a perfect fit.

4. Surface Treatment:

– *Cleaning*: Remove impurities using sandblasting.

– *Coating*: Apply anti-corrosive coatings through galvanization or painting.

5. Assembly:

– *Structural Assembly*: Join all major components.

– *Hydraulic/Electrical Integration*: Install and test hydraulic systems and electronic controls.

6. Testing & Validation:

– *Load Testing*: Test cranes under maximum load conditions.

– *Operational Tests*: Ensure smooth operation of all moving parts.

– *Final Inspection*: Thorough final check for any defects or issues.

7. Packaging & Shipping:

– *Packaging*: Securely pack to prevent damage during transit.

– *Logistics*: Arrange transport to client or shipyard.

This procedure ensures a reliable and durable yacht davit crane, meeting stringent maritime standards.

How to use “yacht davit crane”

A yacht davit crane is a device used to lift and lower equipment such as dinghies, jet skis, and other heavy objects to and from the deck of a yacht. Here are the basic steps to use one safely:

1. Preparation:

– Read the manufacturer’s manual to understand the specific model and safety guidelines.

– Inspect the crane for any damage or wear before each use.

– Ensure the lifting area is clear of obstacles and that the yacht is stable.

2. Positioning:

– Rotate the davit crane arm to align with the object to be lifted.

– Make sure the crane base is securely anchored or bolted to the deck.

3. Attaching the Load:

– Attach the lifting harness or slings to the object securely.

– Connect the harness or slings to the hook on the crane’s lifting cable.

– Ensure all connections are tight and secure.

4. Lifting:

– Operate the crane’s lifting mechanism (manual, electric, or hydraulic) to slowly raise the object.

– If manually operated, use the provided handle or crank. For electric/hydraulic systems, use the control panel or remote.

– Lift the object just enough to clear any obstacles and stabilize it.

5. Swinging the Load:

– Once the object is raised, carefully pivot the crane arm to move the load over the desired drop zone.

– Move slowly to avoid swinging or swaying of the load.

6. Lowering:

– Gradually lower the object into position by reversing the lifting mechanism.

– Ensure it is steady and secure before detaching the harness or slings.

7. Securing the Crane:

– Once the task is completed, retract the crane arm to its storage position.

– Perform any necessary maintenance and inspections to keep the davit crane in good condition.

Always follow safety protocols to avoid accidents and ensure smooth operation.

“yacht davit crane” Comparative Analysis

A yacht davit crane is an essential piece of equipment used for lowering and lifting lighter vessels, such as tenders or personal watercraft, from a yacht. In comparing different types of yacht davit cranes, it’s important to consider a few crucial factors: capacity, ease of use, durability, and cost.

Capacity: Yacht davit cranes vary in their load capacities, typically ranging from a few hundred kilograms to several tons. For larger yachts that carry substantial tenders, a heavier capacity crane is necessary. Hydraulic davits generally offer higher load capacities compared to manual systems, making them suitable for lifting heavier equipment.

Ease of Use: Manual davit cranes require physical effort to operate, which can be labor-intensive and less convenient. Hydraulic and electric davit systems, however, provide automated operations, allowing users to lift and lower tenders with minimal effort. These automated systems often come with remote controls, making them more user-friendly.

Durability: The marine environment is harsh, with exposure to saltwater, UV rays, and constant movement. Materials like stainless steel and marine-grade aluminum are commonly used due to their resistance to corrosion. Hydraulic systems, although more robust, involve more complex components that might require regular maintenance. Simpler manual davits are less prone to technical failures but might wear out faster from heavy use.

Cost: Manual davit cranes are generally the most cost-effective. They are simpler, with fewer mechanical parts, translating to lower purchase and maintenance costs. Hydraulic and electric systems are more costly upfront due to their complex mechanics and advanced features. The long-term maintenance costs of hydraulic systems should also be factored in.

In conclusion, while manual davit cranes are cost-effective and simpler, hydraulic and electric davits provide greater load capacity and ease of use. Yacht owners should weigh these factors based on their specific needs, frequency of use, and budget to make an informed decision.

“yacht davit crane” Warranty and Support

When purchasing a yacht davit crane, it’s essential to understand the warranty and support services provided to ensure long-term reliability and peace of mind.

Warranty:

Most yacht davit cranes come with a manufacturer’s warranty that typically covers defects in materials and workmanship. The warranty duration may vary but often ranges from 1 to 3 years. Key components such as the winch, motors, hydraulics, and structural parts are usually included. However, regular wear and tear, misuse, and improper installation are generally excluded. Always read the specific terms and conditions provided by the manufacturer to understand the coverage and limitations fully.

Support:

A reputable yacht davit crane manufacturer or supplier should offer robust support services. This includes:

1. Technical Assistance: Access to knowledgeable technical support for troubleshooting and repair guidance through phone, email, or online resources.

2. Installation Services: Professional installation services to ensure the crane is mounted correctly and functions as intended.

3. Maintenance Programs: Comprehensive maintenance and inspection routines to keep the crane in optimal working condition and extend its lifespan.

4. Replacement Parts: Availability of genuine replacement parts to maintain the crane’s performance and safety standards.

5. User Manuals and Documentation: Detailed user manuals, installation guides, and maintenance schedules to assist in proper usage and upkeep.

In conclusion, understanding the warranty and support services for a yacht davit crane can significantly impact your investment. Opt for manufacturers and suppliers who provide extensive coverage and reliable support to ensure your crane remains in optimal condition for years to come.

List “yacht davit crane” FAQ

Yacht Davit Crane FAQ

#### 1. What is a yacht davit crane?

A yacht davit crane is a mechanical device installed on yachts and boats, designed to lift and lower dinghies, jet skis, and other small vessels. It consists of a hoisting mechanism and a boom arm that extends out over the water.

#### 2. How does a yacht davit crane operate?

Most yacht davit cranes operate using a combination of electric or hydraulic power systems. The operator controls the crane via a wired or wireless remote, allowing for precise lifting and lowering of attached vessels.

#### 3. Are there different types of yacht davit cranes?

Yes, there are several types, including manual, electric, and hydraulic davit cranes. The choice depends on the yacht size, weight capacity required, and user preference.

#### 4. What weight can a yacht davit crane lift?

Yacht davit cranes come with varying weight capacities, typically ranging from 200 to 2,000 pounds. It’s crucial to select a crane that matches the weight of the items you intend to lift.

#### 5. How do I maintain a yacht davit crane?

Regular maintenance involves cleaning to remove salt and debris, lubricating moving parts, and conducting periodic inspections for any signs of wear or damage. It’s advisable to follow the manufacturer’s maintenance guidelines.

#### 6. Can I install a yacht davit crane myself?

While it’s possible, professional installation is recommended to ensure safety and proper functioning. Improper installation can lead to malfunctions and potential accidents.

#### 7. How much does a yacht davit crane cost?

The cost varies widely based on type, material, and weight capacity. Prices typically range from $1,000 to over $10,000. Custom or high-capacity models may cost more.

#### 8. What materials are yacht davit cranes made from?

Most cranes are made from stainless steel or marine-grade aluminum to withstand harsh marine environments and prevent corrosion.

#### 9. Are yacht davit cranes easy to use?

Yes, modern yacht davit cranes are designed to be user-friendly, often featuring remote controls and safety mechanisms for effortless operation.

#### 10. Is a yacht davit crane a necessary addition to my yacht?

If you frequently use or transport smaller vessels, a yacht davit crane is an invaluable asset, offering convenience and ease of handling.

These FAQs offer a basic understanding of yacht davit cranes, helping you make informed decisions about their use and maintenance.

Top 10 FAQ with answer about yacht davit crane for Buyer Sourcing from China

Here are the top 10 frequently asked questions (FAQ) with answers about sourcing a yacht davit crane from China:

1. What is a yacht davit crane?

– A yacht davit crane is a mechanical device used to lift and lower tenders, jet skis, or other equipment onto and off a yacht.

2. Why should I source a yacht davit crane from China?

– China is known for its competitive pricing, diverse manufacturers, and cutting-edge manufacturing technology, making it a cost-effective option for high-quality davit cranes.

3. How can I ensure the quality of a yacht davit crane from China?

– Look for manufacturers with ISO certification, positive reviews, references from other international buyers, and request product samples or third-party inspections.

4. What are the main features to look for in a davit crane?

– Key features include load capacity, material (usually stainless steel or aluminum for corrosion resistance), ease of installation, and compatibility with your yacht’s specifications.

5. What is the typical lead time for delivery?

– Lead times can vary, but generally, it takes about 20-45 days from placing an order to receive the shipment, depending on the manufacturer and your location.

6. Can I customize the davit crane according to my needs?

– Yes, many manufacturers in China offer customization options based on load capacity, design, size, and additional features like remote control operation.

7. What certifications should I look for in a yacht davit crane?

– Look for certifications such as CE, RoHS, and ISO, which indicate compliance with international safety and quality standards.

8. How do I handle shipping and customs duties?

– Most suppliers offer shipping options and can assist with documentation. Customs duties depend on your local regulations; working with a freight forwarder can simplify the process.

9. What is the price range for yacht davit cranes from China?

– Prices can range significantly based on specifications and features, but generally fall between USD 1,000 to USD 5,000. Bulk orders may offer additional discounts.

10. How do I maintain and service the davit crane?

– Follow the manufacturer’s maintenance recommendations, which often include regular inspections, lubrication of moving parts, and checking for signs of wear or corrosion. Many suppliers offer after-sales support and service guides.

These FAQs should help buyers make informed decisions when sourcing yacht davit cranes from China.