Sure, here are some frequently asked questions (FAQ) about manufacturing “Production Crane quality work from SourcifyChina factory”, with each question in bold:

1. What is the production capacity of SourcifyChina factory for cranes?

SourcifyChina factory can produce up to 500 cranes per month, depending on the complexity and customization required for each project.

2. How long does it generally take to complete an order?

The typical lead time for production is 6-8 weeks from the date of order confirmation. This can vary based on order size and any special requirements.

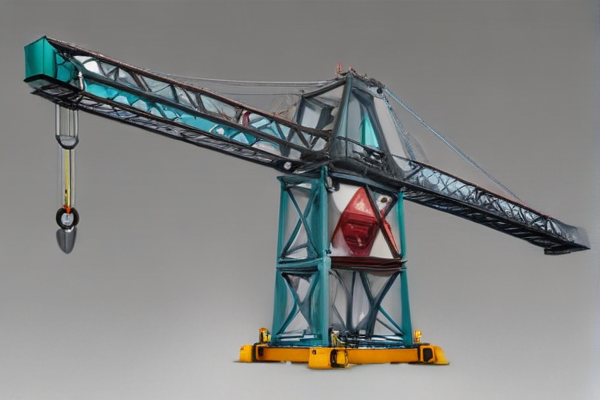

3. What types of production cranes are available?

We offer a wide range of production cranes including overhead cranes, gantry cranes, jib cranes, and monorail cranes. Customization options are also available to meet specific needs.

4. What quality control measures are in place?

SourcifyChina factory follows strict quality control protocols including ISO 9001 standards, regular inspections, and testing of raw materials through to finished products to ensure top-notch quality.

5. Can your factory handle custom design requests?

Yes, we have an in-house engineering team dedicated to custom design projects. We work closely with clients to ensure their specific requirements are met.

6. What materials are used in the cranes?

We use high-grade steel and other durable materials to ensure the cranes are robust and reliable. Components such as motors and control systems are sourced from reputable suppliers.

7. Is there a warranty on the cranes?

Yes, all cranes manufactured by SourcifyChina come with a 12-month warranty covering any manufacturing defects.

8. Do you offer installation services?

We do offer installation services across various locations. Our skilled technicians ensure that the cranes are installed correctly and safely.

9. How do you handle after-sales service?

We provide comprehensive after-sales support including routine inspections, maintenance services, and spare parts supply to ensure your crane remains in optimal working condition.

10. Are there any certifications for your production cranes?

Yes, our production cranes are certified under CE, ISO 9001, and other relevant international standards, ensuring compliance with global safety and quality norms.