FAQs

for Manufacturing “Shipbuilding Crane Quality Work from SourcifyChina Factory”:

1. What types of shipbuilding cranes do you manufacture?

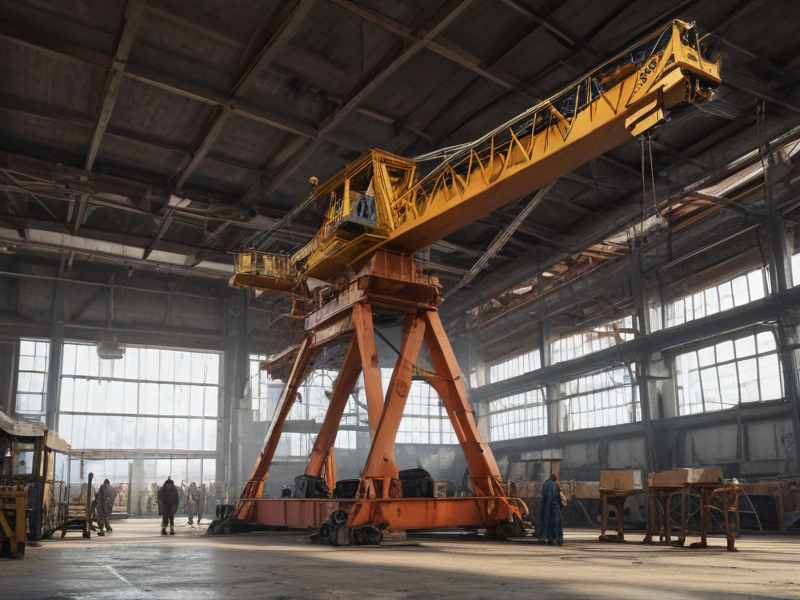

We produce a range of shipbuilding cranes including gantry cranes, overhead cranes, jib cranes, and container handling cranes tailored for various shipyard applications.

2. What standards do you follow to ensure quality in your cranes?

We adhere to international standards such as ISO, CE, and ASME to ensure utmost quality and reliability in every crane we manufacture.

3. Can I customize the crane specifications according to my shipyard needs?

Yes, we offer custom design services to tailor crane specifications like load capacity, span, and lift height to meet the unique requirements of your shipyard.

4. What materials are used in the construction of your cranes?

We use high-grade materials such as Q345B alloy steel and other robust construction materials known for their durability and strength.

5. How do you ensure the safety of your cranes?

Our cranes incorporate advanced safety features including overload protection, emergency stop systems, and fail-safe brake mechanisms to ensure operator and equipment safety.

6. What is the typical lead time for manufacturing a shipbuilding crane?

The average lead time varies depending on the complexity of the crane design, but it generally ranges from 8 to 12 weeks.

7. Can you provide installation and after-sales services?

Yes, we provide comprehensive services including crane installation, commissioning, and after-sales support such as maintenance, spare parts, and technical training.

8. Do you offer warranties on your cranes?

Yes, we offer a standard one-year warranty on all our cranes, with extended warranty options available.

9. What is your factory’s production capacity?

Our factory is equipped with state-of-the-art manufacturing facilities capable of producing up to 100 shipbuilding cranes annually.

10. How can I get a quote for a shipbuilding crane?

To get a quote, please contact our sales team through our website or email us directly with your specific requirements for a tailored quotation.

By keeping these answers concise, we have focused on delivering essential information clearly and effectively.