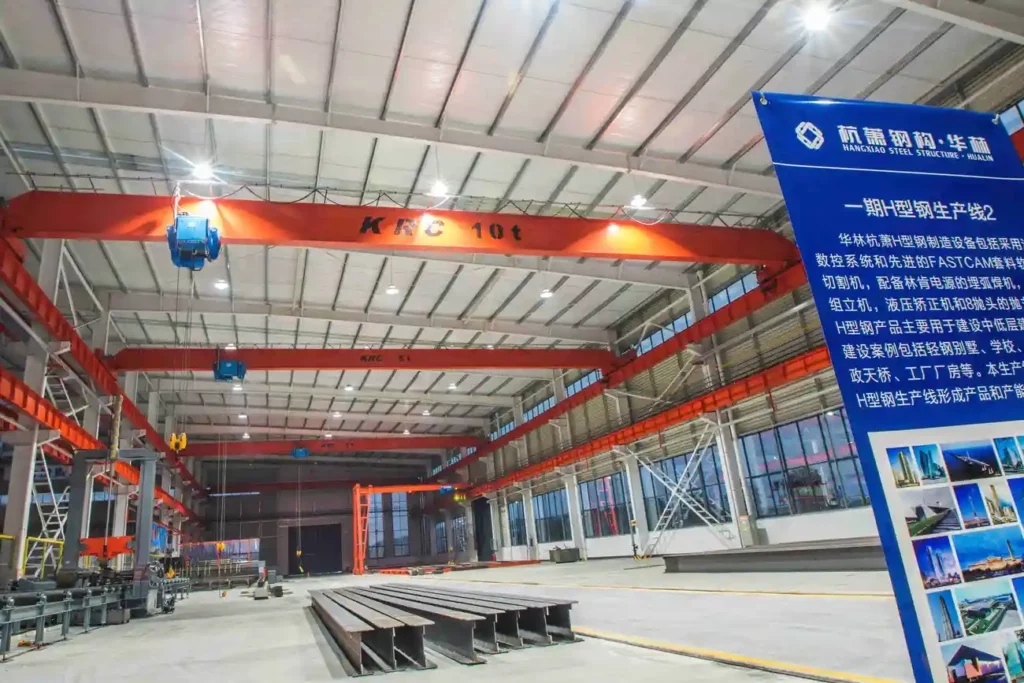

The KRC European Single Girder Overhead Crane is engineered with German technology, featuring optimized box-type main girders for enhanced structural integrity. This design offers superior strength and stiffness compared to traditional LD cranes, ensuring efficient performance and longevity.

The crane is specially designed to support smooth and stable operations, with a wear-resistant hoist running track surface that minimizes wear and extends its lifespan. During operations, the hoist maintains stability with minimal shaking, even as the trolley travels, providing safe and reliable lifting.

Single girder EOT (Electric Overhead Traveling) cranes are versatile and commonly used in a variety of industries due to their efficiency and cost-effectiveness. Here are some typical applications across different sectors:

Manufacturing: In smaller manufacturing facilities where space may be limited, single girder cranes are ideal for handling lighter loads, such as machine parts and raw materials, with precision and ease.

Automotive: These cranes are used in automotive assembly lines to transport components like engines, chassis, and other smaller assemblies throughout the facility, facilitating smooth production flow.

Warehousing and Logistics: Single girder cranes are excellent for stacking and moving goods in warehouses, especially in narrow aisles where space optimization is crucial.

Workshops: For mechanical and repair workshops, these cranes are essential for lifting and positioning heavy machinery and equipment safely and efficiently.

Aerospace: Used for handling lighter aerospace components and tools, single girder cranes contribute to the meticulous assembly processes in the aerospace industry.