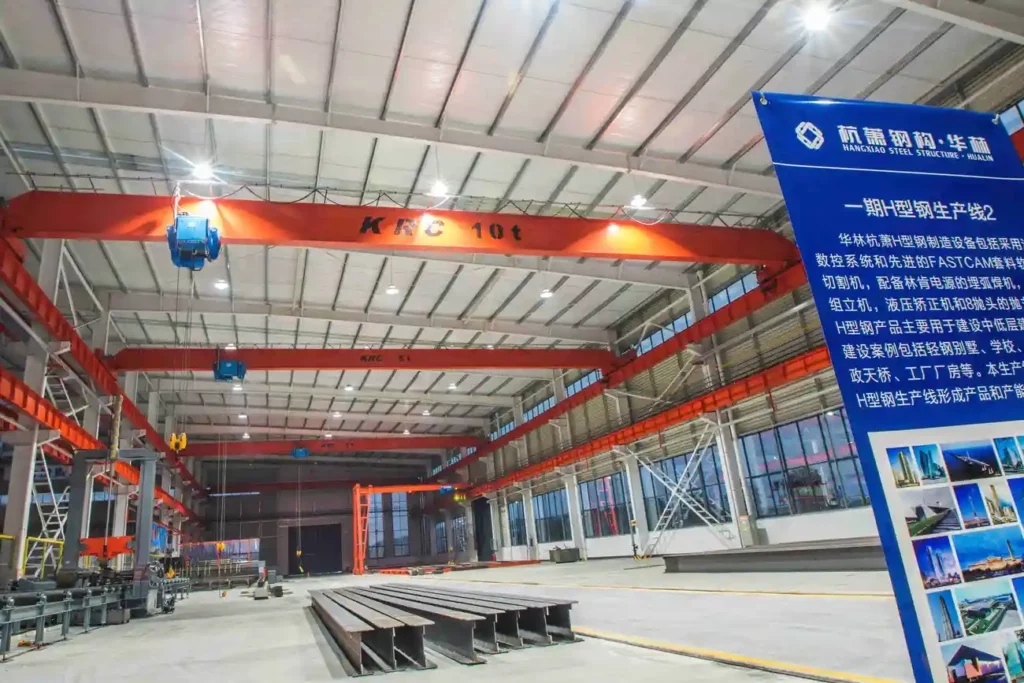

1. Manufacturing Plants Single girder overhead cranes are extensively used in manufacturing plants for handling raw materials, components, and finished products. They enhance productivity by facilitating efficient material handling and reducing downtime.

2. Warehouses In warehouses, these cranes are essential for loading and unloading goods, organizing inventory, and optimizing storage space. Their ability to move heavy loads quickly and safely makes them indispensable in logistics operations.

3. Assembly Lines Single girder overhead cranes are crucial in assembly lines, where they help in the precise positioning of parts and components. This ensures smooth and efficient assembly processes, particularly in the automotive and electronics industries.

4. Maintenance and Repair Shops These cranes are used in maintenance and repair shops for lifting and moving heavy machinery and equipment. They provide the necessary support for disassembling and reassembling components, ensuring safe and efficient repair operations.

5. Metalworking and Fabrication In metalworking and fabrication shops, single girder overhead cranes handle large and heavy metal sheets, plates, and structures. They facilitate cutting, welding, and assembly processes, contributing to efficient production workflows.

6. Power Plants Power plants utilize these cranes for maintenance and operation tasks, including lifting and moving heavy turbines, generators, and other equipment. Their precision and reliability are vital for maintaining uninterrupted power generation.

7. Construction Sites On construction sites, single girder overhead cranes assist in lifting and positioning construction materials such as steel beams, concrete panels, and prefabricated components. They improve safety and efficiency in material handling.

8. Chemical and Petrochemical Industries In the chemical and petrochemical industries, these cranes are used for handling heavy containers, reactors, and equipment. Their robust design and precise control make them suitable for hazardous and demanding environments.

9. Food and Beverage Industry The food and beverage industry employs single girder overhead cranes for handling heavy processing equipment, containers, and packaging materials. They help maintain hygiene standards and ensure smooth production processes.

10. Paper and Pulp Industry In the paper and pulp industry, these cranes are used for moving heavy rolls of paper, pulp, and machinery. They enhance operational efficiency and ensure the smooth flow of materials through various stages of production.

Single girder overhead cranes are versatile and reliable, making them suitable for a wide range of industrial applications where efficient material handling, precision, and safety are paramount.