Sure, here are some frequently asked questions (FAQ) about sourcing structural cranes from SourcifyChina factory:

Q1. What types of structural cranes does SourcifyChina offer?

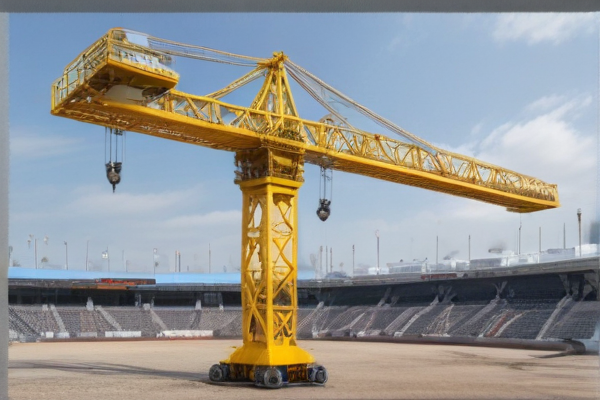

A1. SourcifyChina offers a variety of structural cranes, including overhead cranes, gantry cranes, jib cranes, and tower cranes. Each type is available in different sizes and capacities to meet specific project needs.

Q2. How can I request a quote for a structural crane?

A2. To request a quote, you can visit the SourcifyChina website, navigate to the “Request a Quote” section, and fill out the form with your project details and specifications. Alternatively, you can contact their customer service directly.

Q3. What information do I need to provide for an accurate quote?

A3. For an accurate quote, provide details such as the type of crane, lifting capacity, span length, height, application, and any additional features you require. Providing comprehensive information ensures a more accurate and tailored quote.

Q4. What is the lead time for manufacturing and delivery?

A4. The lead time varies depending on the complexity and specifications of the crane. Typically, it ranges from 4 to 12 weeks. The customer service team at SourcifyChina can provide an estimated delivery time based on your specific order.

Q5. Does SourcifyChina provide installation and maintenance services?

A5. Yes, SourcifyChina offers installation and maintenance services. They have a team of experienced professionals who can assist with the setup, commissioning, and maintenance of the cranes to ensure optimal performance.

Q6. What certifications do the cranes from SourcifyChina comply with?

A6. Cranes from SourcifyChina comply with international standards such as ISO, CE, and other relevant industry-specific certifications. These ensure the cranes meet safety and quality benchmarks.

Q7. How does SourcifyChina support after-sales service?

A7. SourcifyChina provides robust after-sales support, including warranty services, spare parts supply, and technical assistance. Their customer support team is available to address any issues or queries you may have post-purchase.

Q8. Are financing options available for purchasing cranes?

A8. Yes, SourcifyChina offers various financing options to accommodate your budget. They work with financial institutions to provide flexible payment plans. Contact their sales team to discuss available options.